1/6ページ

Download(3.9Mb)

Sanding and Polishing Robots - Finishing Automation Systems

Product Catalog

By automating the sanding and polishing process, we can help you to reduce your labour shortage, save manpower and improve workplace.

More Details

https://www.yamahafinetech.co.jp/en/fa_products/robots/

Document Information

| Document Title | Sanding and Polishing Robots - Finishing Automation Systems |

|---|---|

| Document Type | Product Catalog |

| File size | 3.9Mb |

| Category | |

| Company | YAMAHA FINE TECHNOLOGIES CO., LTD. (Documents List) |

Documents related to this company

Document Contents

Page1

THE FINISHING ROBOT SYSTEM

Product catalog

FA Division

283, Aoya-cho, Minami-ku, Hamamatsu, 435-8568, Japan

TEL +81-53-467-3601 FAX +81-53-467-3613

Website Inquiry

URL https://www.yamahafinetech.co.jp/en/ The contents of this catalog are subject to change without notice.

Page2

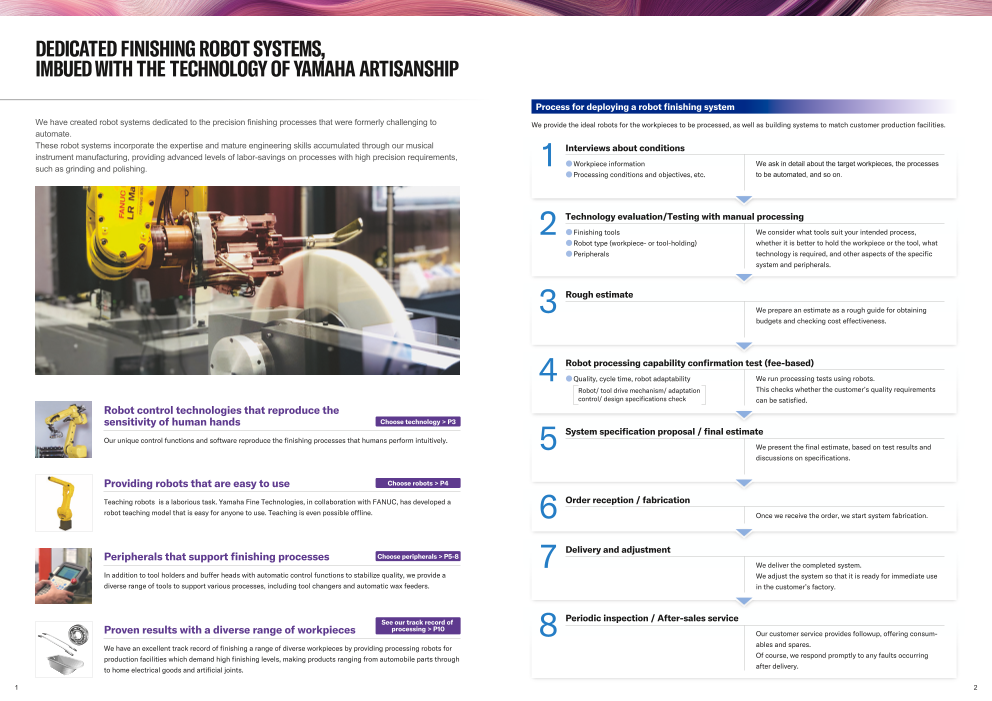

DEDICATED FINISHING ROBOT SYSTEMS,

IMBUED WITH THE TECHNOLOGY OF YAMAHA ARTISANSHIP

Process for deploying a robot finishing system

We have created robot systems dedicated to the precision finishing processes that were formerly challenging to We provide the ideal robots for the workpieces to be processed, as well as building systems to match customer production facilities.

automate.

These robot systems incorporate the expertise and mature engineering skills accumulated through our musical 1 Interviews about conditionsinstrument manufacturing, providing advanced levels of labor-savings on processes with high precision requirements, Workpiece information We ask in detail about the target workpieces, the processes such as grinding and polishing.

Processing conditions and objectives, etc. to be automated, and so on.

2 Technology evaluation/Testing with manual processingFinishing tools We consider what tools suit your intended process,

Robot type (workpiece- or tool-holding) whether it is better to hold the workpiece or the tool, what

Peripherals technology is required, and other aspects of the specific

system and peripherals.

3 Rough estimate We prepare an estimate as a rough guide for obtaining

budgets and checking cost effectiveness.

4 Robot processing capability confirmation test (fee-based)Quality, cycle time, robot adaptability We run processing tests using robots.

Robot/ tool drive mechanism/ adaptation This checks whether the customer’s quality requirements

control/ design specifications check can be satisfied.

Robot control technologies that reproduce the

sensitivity of human hands Choose technology > P3

System specification proposal / final estimate

Our unique control functions and software reproduce the finishing processes that humans perform intuitively. 5 We present the final estimate, based on test results and

discussions on specifications.

Providing robots that are easy to use Choose robots > P4

Teaching robots is a laborious task. Yamaha Fine Technologies, in collaboration with FANUC, has developed a Order reception / fabrication

robot teaching model that is easy for anyone to use. Teaching is even possible offline. 6 Once we receive the order, we start system fabrication.

Delivery and adjustment

Peripherals that support finishing processes Choose peripherals > P5-8 7 We deliver the completed system.

In addition to tool holders and buffer heads with automatic control functions to stabilize quality, we provide a We adjust the system so that it is ready for immediate use

diverse range of tools to support various processes, including tool changers and automatic wax feeders. in the customer’s factory.

See our track record of 8 Periodic inspection / After-sales serviceProven results with a diverse range of workpieces processing > P10 Our customer service provides followup, offering consum-

We have an excellent track record of finishing a range of diverse workpieces by providing processing robots for ables and spares.

production facilities which demand high finishing levels, making products ranging from automobile parts through Of course, we respond promptly to any faults occurring

to home electrical goods and artificial joints. after delivery.

1 2

Page3

Choose technology Choose technology Choose robots We deliver robots that are easy to use

Adaptation control Yamaha started to team up with FANUC, a world-reputed

We convert tool wear and artisans’ sensitivity to numerical data, and teach the robot skills so it can deliver ideal processing of the company, in 2002. The technologies of both companies have

workpiece, every time. We can provide ongoing stable processing quality. been put together, aiming to not only ensure stable quality but

also provide robots anyone can handle. The robot dedicated to

finishing, “the FINISHING MODEL”, was jointly developed.

Load feedback control Used for tools which vary in diameter due to the wear acting on buffers and brushes etc. Comprehensive System technology

robot technology

Finishing robot

Artisan Robot processing

Visual check Load monitoring technology

Process with visual checking Monitors the load when the workpiece

and adjustment of force touches the tool, and corrects the robot’s

application level, to fix position data as the load drops.

declines in processing force Key points of adaptation control

due to buffer wear. Visual check = Load monitoring Teaching support

Force application level = Position data correction

Finishing depends on human senses in many parts. Load put on

teaching is a headache to many people. To reduce such load, the

robot jointly developed by FANUC and us, “the FINISHING MODEL”

This is used with tools such as belt sanders, which are affected by declining processing force,

Offset speed control due to grit offset, speed control, and wear is introduced here. Offline teaching can also be executed.

Artisan Robot

Processing time Automatic speed correction

adjustment Corrects robot position data and sander head

We adjust force application motor speed to match declining processing force.

level and processing time, etc., Key points of adaptation control

to fix declines in processing Teaching support software Offline teachingForce application level = Position data correction

force due to belt wear. Processing time = Speed UP This software is “an operability improving package dedicated Offline teaching, which loads 3D data and automatically

to finishing robots” developed based on long years of experi- creates a machining path, can be proposed. Without stopping

ence. It radically reduces time for work whose load is heavy the robot, data can be created; it becomes possible to maintain

such as teaching work and data editing high accuracy efficiently.

Pressing force control Use when pressing force adjustment is desired work. This software is provided to the

FINISHING MODEL as standard.

Artisan Robot

Force application level Pressing force control

adjustment The robot applies the set pressing force,

Adjust force application level regardless of the position it operates in.

intuitively. Key points of adaptation control

Force application level = Pressing force control

FINISHING MODEL customized by Yamaha

This is a model to which our unique expertise was added, while leaving FANUC's proven standard functions as-is.

Teaching support software Users currently using FANUC products can also use it without any concern.

LR Mate 200iD M-20iB M-710iC R-2000iC

Conventional Teaching support software Small robot with a maximum wrist Medium robot with a maximum wrist Medium robot with a maximum wrist Large robot with a maximum wrist

Revise one point at a time Reduce the workload loading capacity (mass) of 7 kg loading capacity (mass) of 35 kg loading capacity (mass) of 70 kg loading capacity (mass) of 210 kg

Teaching points created Teaching imposes a high workload, including finish

will never be perfect quality checking, as well as data entry and revision.

immediately. We provide proprietary software to reduce the

It is necessary to check the process, and correct workload.

missing or excess points individually. You can use this software to make batch revisions to

It is difficult to make teaching points perfect the points and speeds etc., that you want to revise.

with a single revision, so it is necessary to work Keyboard shortcuts allow revisions with fewer keystrokes.

iteratively through revision and checking.

3 4

Page4

Choose peripherals Peripherals supporting finishing Workpiece handling specifications

Two handling methods Sander heads

Choose whether the robot holds the workpiece or the tool, according to the finishing method and the type of workpiece. This head rotates a sanding belt and performs grinding.

As a standard feature, it is provided with a mechanism that swings a contact wheel to absorb workpiece variations.

Workpiece handling Comparison parameters Workpiece grasping Tool grasping

The robot holds a workpiece. △ Vertical sander head Horizontal sander headTarget Weight Constraints due to the mass the robot can carry ◎ No restrictions

workpiece

Size △ Constraints due to the mass the robot can carry △ Robot movement, workpiece movement

Type (multiple types are supported) △ Hand changing is required (AHC) ○ Change of tools, etc.

Tool Tool type ◎ Within robot’s movable range (multiple) △ Restricted / Supports ATC, AHC

Tool head output ◎ High output, because installed on floor △ Restricted by weight the robot can carry

Processing capacity ◎ Capable of many types of high-power processing ○ Restricted by tool power

Systematization Workpiece fixing method △ The robot’s holding hand must be engineered ○ Simple with a fixing jig

Tool handling

Workpiece supply method ○ Pallet and stocker types △ Supply feeder to the jig

The robot holds a tool.

Inlining ◎ Dedicated for handling ○ Loader, etc.

Features Space-saving design, highly efficient dust collection, Features Teaching usability, swing mechanism

Others Cycle time ○ Actual processing + setting workpieces aside ○ Actual processing (+ tool change)

swing mechanism Contact wheel Standard: φ300 (Shape and material can be customized)

Robot teaching ○ Workpiece holding operation is similar to human work ○ Hand tool operation is similar to human work Contact wheel Standard: φ300 (Shape and material can be customized) Sanding belt Standard: 2100 circumference (up to 75 wide)

Dust collection efficiency ○ One-direction hood type △ Dust scattering in all directions, overall dust collection Sanding belt Standard: 2100 circumference (up to 75 wide) Customization Automatic duct opening / closing unit /

Summary Switch to process cells Switch to general-purpose processing units Customization Automatic duct opening / closing unit / support Controllable contact wheel swing force

support Controllable contact wheel swing force

Combination with peripherals

Buffing head

Robots can be selected in isolation, or in combination with standard peripherals to suit workpieces.

We then su

est other peripherals to suit the system. A tool for performing polishing by rotating a wheel tool such as buff and a brush.

Let us know the Vertical swing buffing head Horizontal buffing head

target workpieces

We offer proposals for System operation panel

specifications that meet Safety fence

customer needs Robot System control device

We design and build systems FANUC Robot A

customized b

y YAMAH

to suit the intended workpieces tool holder

Standard specification

tool

Application

Features Space-saving design, highly efficient dust collection, Features Teaching usability

buffing swing mechanism Buffing Standard: φ300 (Shape and material can be customized)

Buffing Standard: φ300 (Shape and material can be customized) Customization Automatic duct opening / closing unit /

Customization Automatic duct opening / closing unit / support Automatic solid waxing unit

support Automatic solid waxing unit

Robot control device

Workpiece feeder Workpiece fixing jig Teaching pendant

Tool heads

Select from the standard lineup Select from delivered examples

Tool heads are arranged around the robot to suit the machining usage.

●Robot ●Overall base

●Tool drive mechanism (tool head / tool holder) ●Safety fence (safety and environmental measures: dust and noise prevention) Thrust tool head (1) Thrust tool head (2) Radial tool head Oscillating rasp head

●Workpiece feeder ●Dust collection-related (hood, pipes, dust collector)

●Peripherals, tool changers, etc. ●System control devices (control panel, operation panel, indicator lights)

We accept special orders to suit the intended workpieces

●Workpiece fastener (robot hand / fixing jig)

5 6

Page5

Choose peripherals Peripherals supporting finishing Buffing tool holder Wax supplier

Tool handling specifications This holder is suitable for polishing the surface of large A wax supplier applied to buffing tool holders. Automatic wax supply

workpiece. increases work efficiency and contributes to manpower saving.

Thrust floating

Solid wax supplier

The use of a linked structure for linear sliding both improves rigidity and enables smooth floating. By profiling the irregularities in the Buffing tool holder

workpiece surface and applying tools at a given level of force, it is possible to machine in a variety of directions from flat surfaces to

curved surfaces, while absorbing variances in workpiece dimensions and clamps. The robot applies thrust control that presses a tool at

a given level of force without being affected by the tool angle.

Wheel tool holder Disk tool holder

Motor specifications (options) AC servomotor Liquid wax supplier

Customization support Tool diameter compensation control Buffing tool holder

Applicable peripherals Tool dresser / Tool changer / Waxer

Motor specifications (options) Spindle motor / AC servomotor Motor specifications (options) Spindle motor / AC servomotor /

Customization support Tool diameter compensation control / High frequency motor

Floating amount output / ATC collet Rotating mechanisms (options) Single / Gear action / Double action Tool holder based tool changer

Applicable peripherals Tool dresser / Tool changer / Wax supplier Customization support Localized dust collection / Disk pad shape

Applicable peripherals Automatic changer for sandpaper disks For each tool holder, a tool changer for automatically changing tools is available. This increases work efficiency and contributes to

manpower saving.

Belt sander tool holder

Tool changer Sandpaper disks changer

Wheel tool holder Disk tool holder

Provided with ATC functionality and

applicable to spindle motors

Sandpaper disk Choose between φ100 and 125

Motor specifications AC servomotor Belt sander changer specifications (with magic tape)

φ Sandpaper disk 100 disks per stockContact wheel Standard: 80 x 65 (Shape and material can be customized) Belt sander tool holder

stock capacity (varies depending on the thickness of disks)

Sanding belt Standard: 70 mm wide by 620 mm circumference (Shape and material can be customized)

Customization support The number of paper supply components

Customization support Contact wheel

can be increased.

Applicable peripherals Belt sander changer

Radial tool holder

An escape mechanism in the radial direction (360°) is provided to make it easy to deal with burr irregularities. The floating power

(centripetal force) can be configured as desired in the program. This holder is suitable for removing tiny burrs using a rotary bar. Added NC axis

Motor specifications (options) Electric spindle motor / Air motor A standard turntable using a robot's optional axis. This table rotates in synchronization with

Customization support ATC collet the robot and is effective at machining a cylinder type workpiece as a workpiece rotation

Applicable peripherals Tool changer positioning unit.

7 8

Page6

See our track record of processing Solution case See our track record of processing Proven with a range of workpieces

Deburring system for small parts Automobiles Automobiles / Bicycles

Ideal for deburring small Application examples Multiple workpieces can be set from the worker side Aluminum wheels Door handle Brake lever Crank

during operation.

・ Material: Aluminum Material: Aluminum Material: Aluminum Material: Aluminumparts. Holding the Cellphones Processing method: Processing method: Processing method: Processing method: Grinding

workpiece makes it ・Computer parts Grinding and deburring Grinding and polishing Grinding and polishing

・Binocular frames

possible to perform highly ・Camshafts Consider dust countermeasures. Systems can be

efficient deburring, even customized to suit the customer’s environment. Dust

with multiple tools. Takt collectors can be installed as options.

losses due to tool

Control of all devices, including the control panel, Door mirror holder Door frame Brake parts Motorcycle fuel tankschanges are eliminated,

pneumatic devices, and teaching pendant, as well as Material: Aluminum and plastic Material: Aluminum and steel Material: Aluminum Material: Steel

which assists automation. tool changes can be performed from the front of the Processing method: Deburring Processing method: Grinding Processing method: Grinding Processing method: Grinding

system.

Grinding and polishing systems for small parts Run the sanding belt to polish. Functions to absorb variations between workpieces are included as

standard.

Grinding and polishing processes can be Application examples Wood panel Roof rails Helmets

automated by mounting sander or buffer ・Cranks Material: Wood Material: Aluminum Material: FRP

・Brake levers Multiple workpieces can be set from the worker side Processing method: Polishing Processing method: Polishing Processing method: Grinding heads.

・Door handles during operation.

Consider dust countermeasures. Systems can be

customized to suit the customer’s environment. Dust

collectors can be installed as options.

Tools and blades Housing devices

Control of all devices, including the control panel,

pneumatic devices, and teaching pendant, as well as Hammer Cutting pliers Sanitary fitting Chair parts

tool changes can be performed from the front of the Material: Steel Material: Steel Material: Copper alloy Material: Plastic

system. Processing method: Grinding Processing method: Grinding Processing method: Processing method: Deburring

Grinding and polishing

Deburring system for aluminum wheels

Burring from mechani- Application examples We mount a tool holder, developed specifically for

chamfering in the decorative holes of aluminum

cal processing of ・Aluminum wheels, onto a small robot. Box wrenches Kitchen knives Door handle Bathtubs

aluminum wheels can automobile wheels Material: Steel Material: Wood and steel Material: Aluminum / Stainless steel Material: FRP

Processing method: Grinding Processing method: Processing method: Processing method: Grinding

be removed. NC indexers rotate the workpieces to compensate for Grinding and polishing Grinding and polishing

Cylindrical workpieces the robot’s range of motion, saving space.

other than aluminum

wheels can also be

handled. Specialized sensors automatically grind to form

vertices. Positioning work at the setup stage is

simple. Other

Aircraft frames Golf club head Artificial joint Trumpet parts

Material: CFRP Material: Titanium / Stainless / Aluminum Material: Stainless steel Material: Brass

Grinding and polishing systems for medium parts Processing method: Processing method: Processing method: Processing method:

Grinding and polishing Grinding and polishing Grinding and polishing Grinding and polishing

These systems handle workpieces which Application examples Wheel tool-supporting

cannot be held by small robots, and handle ・Cranks ・Wheel tool holder

・Tool changer

workpieces for which there is an inadequate ・Case covers

・Transmission cases

range of motion. We select other peripherals Disk tool-supporting Ko-dai (incense holder) Turbine blade Bearings

to suit the customer’s wishes. ・Disk tool holder Material: Brass Material: Superalloy and ceramic Material: Steel

・Disk paper changer Processing method: Processing method: Processing method: Polishing

Grinding and polishing Grinding and polishing

Belt sander tool-supporting

・Belt sander tool holder

・Belt sander changer

9 10