0.175mm Pitch, 0.65mm Height, Bottom Contact, Double-sided Lead, Back Flip/Front Axis™, FPC Connector

TF20 Series

Compact Size and Easy Mounting

Product:TF20-15S-0.175SHW

4.3 Closed Actuator1mm Mounted Depth : 3.0mm

0.65mm Depth : 2.85mm

Mounted Pitch : 0.35mm

Double-sided Lead Design

A-Row : Blue

B-Row : Red Staggered contact leads

on both sides of the connector

Pitch : 0.175mm

Fig.1

■ Features

1. Narrow Pitch, Low Height and

Space-saving FPC Side Catch Design

Two Protrusions of Actuator and Housing Secure FPC

Compact size with 0.175mm pitch, 0.65mm height, and 3.0mm Tab from Upper and Lower Sides

mounted depth contribute to high density mounting.

Meanwhile, double-sided lead design provides a 0.35mm <FPC Side Catch Design>

mounted pitch and ensures easier mounting. (Fig. 1)

2. High FPC Retention Force & Reliability

Actuator Protrusion

FPC side catch design secures connection and enhances Housing Protrusion

reliability. (Fig. 2)

FPC

3. A chieve Both Space Reduction and

High Durability

Enhances FPC Retention Force and

Metal shell with retention tabs covers the mating face and Prevents Incomplete Mating Fig.2

achieve high durability against external forces. (Fig. 3)

4. Back Flip / Front Axis™

High Durability Against External Forces

Secures a constant contact gap regardless of actuator

operation. The actuator can be closed before FPC is inserted. Metal Shell Integrated with Retention Tabs Covers Mating Face

Furthermore, since the actuator can be delivered and

mounted in a closed state, workability during inspection and

storage after mounting is enhanced. Case 1 Case 2

5. Pick & Place Mounting FPC hits the left and right FPC is pulled out verticallysides of connector ⇨ Risk of damage to upper

Offered in tape and reel packaging that is compatible with ⇨ Risk of damage to both side of mating face

automatic machine mounting. sides of mating face

Metal Shell

(Retention Tab)

6. Halogen-Free

All materials and substances used to produce this product

comply with Halogen-Free standards.

* As defined by IEC 61249-2-21 Safe Safe

Br : 900ppm max., Cl : 900ppm max.,

Br+Cl : 1,500ppm max.

Enhanced Breaking Strength

Due to Metal Shell (Retention Tabs) Fig.3

In cases where the application will demand a high level of reliability, such as automotive,

please contact a company representative for further information. 2021.06 ① 1

Jul.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

TF20 Series●0.175mm Pitch, 0.65mm Height, Bottom Contact, Double-sided Lead, Back Flip/Front AxisTM, FPC Connector

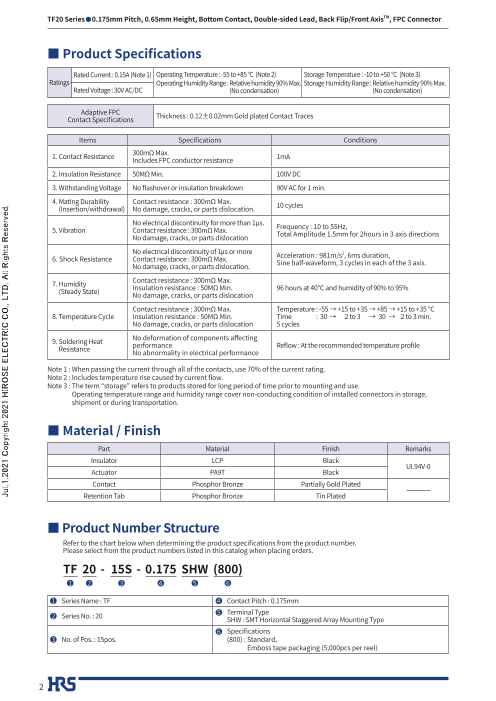

■ Product Specifications

Rated Current : 0.15A (Note 1) Operating Temperature : -55 to +85 °C (Note 2) Storage Temperature : -10 to +50 °C (Note 3)

Ratings Operating Humidity Range : Relative humidity 90% Max. Storage Humidity Range : Relative humidity 90% Max.

Rated Voltage : 30V AC/DC (No condensation) (No condensation)

Adaptive FPC

Contact Specifications Thickness : 0.12±0.02mm Gold plated Contact Traces

Items Specifications Conditions

1. Contact Resistance 300mΩ Max.Includes FPC conductor resistance 1mA

2. Insulation Resistance 50MΩ Min. 100V DC

3. Withstanding Voltage No flashover or insulation breakdown 90V AC for 1 min.

4. M ating Durability Contact resistance : 300mΩ Max.

(Insertion/withdrawal) No damage, cracks, or parts dislocation. 10 cycles

No electrical discontinuity for more than 1μs.

5. Vibration Contact resistance : 300mΩ Max. Frequency : 10 to 55Hz,

No damage, cracks, or parts dislocation Total Amplitude 1.5mm for 2hours in 3 axis directions

No electrical discontinuity of 1㎲ or more 2

6. Shock Resistance Contact resistance : 300mΩ Max. Acceleration : 981m/s , 6ms duration,

No damage, cracks, or parts dislocation. Sine half-waveform, 3 cycles in each of the 3 axis.

7. H umidity Contact resistance : 300mΩ Max.

(Steady State) Insulation resistance : 50MΩ Min. 96 hours at 40℃ and humidity of 90% to 95%No damage, cracks, or parts dislocation

Contact resistance : 300mΩ Max. Temperature : -55 → +15 to +35 → +85 → +15 to +35 ℃

8. Temperature Cycle Insulation resistance : 50MΩ Min. Time : 30 → 2 to 3 → 30 → 2 to 3 min.

No damage, cracks, or parts dislocation 5 cycles

9. Soldering Heat No deformation of components affecting

Resistance performance Reflow : At the recommended temperature profile No abnormality in electrical performance

Note 1 : When passing the current through all of the contacts, use 70% of the current rating.

Note 2 : Includes temperature rise caused by current flow.

Note 3 : The term “storage” refers to products stored for long period of time prior to mounting and use.

Operating temperature range and humidity range cover non-conducting condition of installed connectors in storage,

shipment or during transportation.

■ Material / Finish

Part Material Finish Remarks

Insulator LCP Black

UL94V-0

Actuator PA9T Black

Contact Phosphor Bronze Partially Gold Plated

Retention Tab Phosphor Bronze Tin Plated

■ Product Number Structure

Refer to the chart below when determining the product specifications from the product number.

Please select from the product numbers listed in this catalog when placing orders.

TF 20 - 15S - 0.175 SHW (800)

1 2 3 4 5 6

1 Series Name : TF 4 Contact Pitch : 0.175mm

2 Series No. : 20 5 Terminal TypeSHW : SMT Horizontal Staggered Array Mounting Type

6 Specifications

3 No. of Pos. : 15pos. (800) : S tandard,

Emboss tape packaging (5,000pcs per reel)

2

Jul.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

TF20 Series●0.175mm Pitch, 0.65mm Height, Bottom Contact, Double-sided Lead, Back Flip/Front AxisTM, FPC Connector

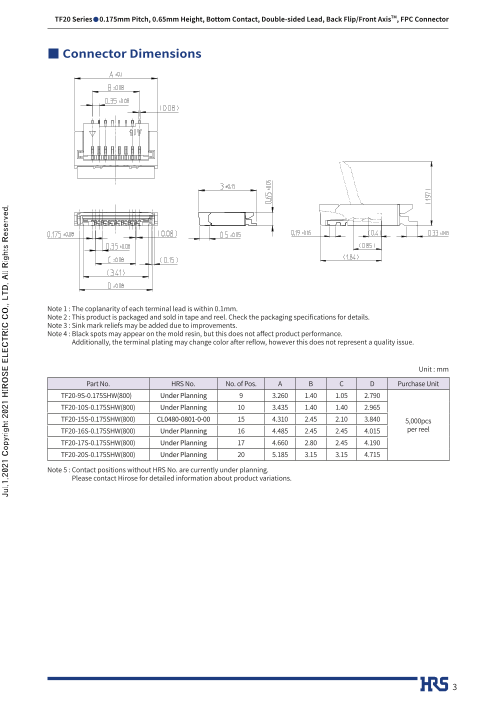

■ Connector Dimensions

Note 1 : The coplanarity of each terminal lead is within 0.1mm.

Note 2 : This product is packaged and sold in tape and reel. Check the packaging specifications for details.

Note 3 : Sink mark reliefs may be added due to improvements.

Note 4 : Black spots may appear on the mold resin, but this does not affect product performance.

Additionally, the terminal plating may change color after reflow, however this does not represent a quality issue.

Unit : mm

Part No. HRS No. No. of Pos. A B C D Purchase Unit

TF20-9S-0.175SHW(800) Under Planning 9 3.260 1.40 1.05 2.790

TF20-10S-0.175SHW(800) Under Planning 10 3.435 1.40 1.40 2.965

TF20-15S-0.175SHW(800) CL0480-0801-0-00 15 4.310 2.45 2.10 3.840 5,000pcs

TF20-16S-0.175SHW(800) Under Planning 16 4.485 2.45 2.45 4.015 per reel

TF20-17S-0.175SHW(800) Under Planning 17 4.660 2.80 2.45 4.190

TF20-20S-0.175SHW(800) Under Planning 20 5.185 3.15 3.15 4.715

Note 5 : Contact positions without HRS No. are currently under planning.

Please contact Hirose for detailed information about product variations.

3

Jul.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

TF20 Series●0.175mm Pitch, 0.65mm Height, Bottom Contact, Double-sided Lead, Back Flip/Front AxisTM, FPC Connector

Recommended Land / Metal Mask Dimensions

Recommended Metal Mask Thickness:0.1mm

Unit : mm

Part No. HRS No. No. of Pos. A B

TF20-9S-0.175SHW(800) Under Planning 9 5.0 4.0

TF20-10S-0.175SHW(800) Under Planning 10 5.0 5.0

TF20-15S-0.175SHW(800) CL0480-0801-0-00 15 8.0 7.0

TF20-16S-0.175SHW(800) Under Planning 16 8.0 8.0

TF20-17S-0.175SHW(800) Under Planning 17 9.0 8.0

TF20-20S-0.175SHW(800) Under Planning 20 10.0 10.0

Note 1 : Contact positions without HRS No. are currently under planning.

Please contact Hirose for detailed information about product variations.

4

Jul.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

TF20 Series●0.175mm Pitch, 0.65mm Height, Bottom Contact, Double-sided Lead, Back Flip/Front AxisTM, FPC Connector

Recommended FPC Dimensions

Unit : mm

Part No. HRS No. No. of Pos. A B C D

TF20-9S-0.175SHW(800) Under Planning 9 2.350 1.400 4 5

TF20-10S-0.175SHW(800) Under Planning 10 2.525 1.575 5 5

TF20-15S-0.175SHW(800) CL0480-0801-0-00 15 3.400 2.450 7 8

TF20-16S-0.175SHW(800) Under Planning 16 3.575 2.625 8 8

TF20-17S-0.175SHW(800) Under Planning 17 3.750 2.800 8 9

TF20-20S-0.175SHW(800) Under Planning 20 4.275 3.325 10 10

Note 1 : Contact positions without HRS No. are currently under planning.

Please contact Hirose for detailed information about product variations.

5

Jul.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

TF20 Series●0.175mm Pitch, 0.65mm Height, Bottom Contact, Double-sided Lead, Back Flip/Front AxisTM, FPC Connector

FPC Construction (Recommended Specifications)

● F PC : Flexible Printed Circuit

Material Name Material Thickness(㎛)

Covering layer film Polyimide 1mil (12.5)

Cover adhesive (25)

Surface treatment Nickel 1 to 5㎛ + 4

Gold plating

Copper foil CU 1/2 oz 18

Base adhesive Thermoset adhesive

Base film Polyimide 1mil 25

Reinforcement Thermoset adhesive 30

material adhesive

Stiffener Polyimide 5mil 50

Total 127

NOTE 1 : The material composition of FPC is for reference. Please make the thickness of the FPC mating section 0.12±0.02mm

in reference to the above FPC construction.

NOTE 2 : For details about component configuration, please contact a FPC manufacturer.

6

Jul.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

TF20 Series●0.175mm Pitch, 0.65mm Height, Bottom Contact, Double-sided Lead, Back Flip/Front AxisTM, FPC Connector

Packaging Specifications

● Embossed Carrier Tape Dimensions

● Reel Dimensions

Note 1 : 5,000pcs / Reel (Outer diameter of Reel ø330mm)

Note 2 : Material

1) Emboss tape : PS (Antistatic Treatment)

2) Cover tape : PET (Antistatic Treatment)

Unit : mm

Part No. HRS No. No. of Pos. A B C

TF20-9S-0.175SHW(800) Under Planning 9 7.5 16.0 16.5

TF20-10S-0.175SHW(800) Under Planning 10 7.5 16.0 16.5

TF20-15S-0.175SHW(800) CL0480-0801-0-00 15 7.5 16.0 16.5

TF20-16S-0.175SHW(800) Under Planning 16 7.5 16.0 16.5

TF20-17S-0.175SHW(800) Under Planning 17 7.5 16.0 16.5

TF20-20S-0.175SHW(800) Under Planning 20 7.5 16.0 16.5

Note 3 : Contact positions without HRS No. are currently under planning.

Please contact Hirose for detailed information about product variations.

7

Jul.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

TF20 Series●0.175mm Pitch, 0.65mm Height, Bottom Contact, Double-sided Lead, Back Flip/Front AxisTM, FPC Connector

Recommended Temperature Profile

HRS Test Conditions

Reflow Method : Reflow, IR/hot air

Reflow Environment : Room air

Solder Composition : Paste, 96.5%Sn/3%Ag/0.5%Cu

(M705-221CM5-32-10.5 from Senju Metal Industry Co., Ltd.)

Test Board : Glass epoxy 50mm×25mm×1mm thick

Land Dimensions : Check the recommended land

dimensions for details.

Metal Mask : Check the recommended metal mask

dimensions for details.

The temperature profile is based on the above conditions.

Please check the mounting conditions before use,

conditions such as solder paste types, manufacturer,

PCB size and any other soldering materials may alter the

performance of such materials.

8

Jul.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

TF20 Series●0.175mm Pitch, 0.65mm Height, Bottom Contact, Double-sided Lead, Back Flip/Front AxisTM, FPC Connector

Connector Operation and Precautions

Board Mounting Precautions FPC Insertion and Mating Precautions

● Board Warpage ● Actuator Operation

Be sure to minimize the board warpage as much as 1. D o not apply excessive force when releasing the actuator

possible. The lead co-planarity is 0.1mm or less. from the initial position (without FPC inserted).

Too much board warpage may result in soldering failures Inserting a nail or finger as shown in the below picture may

or co-planarity issues. result in terminal deformation.

● Connector Load

Do not apply a force of 0.5N or more to the connector

before mounting it on the board in order to prevent

connector damage.

Do not insert the FPC or operate the connector before

mounting.

● Board Load

• Splitting a large board into several pieces

• S crewing the board

Avoid the handling described above so that no 2. The actuator rotates around the rotational axis as

excessive force is exerted on the board during the shown below. Please rotate the actuator.

assembly process.

Otherwise, the connector may become defective.

● Acceptable Amount of Board Warpage

A 100mm wide board has an acceptable warp range of

0.5mm or less. (Below)

Excessive amounts of warping will place stress on the

connector which may result in damage and malfunction.

3. Please do not push the actuator downwards with

a force of 0.3N force or more as shown below.

Otherwise, the actuator may fall off or be damaged.

9

Jul.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

TF20 Series●0.175mm Pitch, 0.65mm Height, Bottom Contact, Double-sided Lead, Back Flip/Front AxisTM, FPC Connector

FPC Insertion and Mating Precautions FPC Insertion and Mating Precautions

4. T he actuator is not designed to open more than 105°. ● Inserting the FPC

Do not apply any force to open it beyond this point.

Doing so may result in actuator damage or breakage. 1. I nsert the FPC horizontally along the surface and at right angle to the connector.

Insert it completely to the end.

If the FPC is incorrectly inserted at a diagonal the

conductors may short-circuit due to pitch shift misalign-

ment or the edge of the FPC may catch in the terminals

resulting in deformation of the terminal deformation.

This connector has a ZIF structure and its effective mating

length is 1.87mm.

(when the recommended FPC nominal is used)

Use the actuator carefully to prevent the FPC from shifting

after insertion.

5. Operate the actuator towards the center.

It may break if operated on one side of the actuator 2. D o not insert the FPC diagonally from above.

with FPC inserted. If the FPC is incorrectly inserted at a diagonal as shown

in the above FPC insertion process, the FPC may be bent,

resulting in pattern breakage or insufficient FPC insertion

6. Do not pull or pick the actuator to lift it as shown below. which may cause conduction failure.

Failure to do so may result in connector breakage.

(Do not carry out any operation other than rotating

the actuator as shown in 2 on the previous page.)

• Secure sufficient FPC insertion space during layout

design to prevent incorrect FPC insertion.

Additionally, if the FPC is too short it will make insertion

difficult so please design an appropriate component

layout.

● Contact Orientation

This connector utilizes bottom contacts. Insert the • M ake adjustments with the FPC manufacturer for

FPC with the exposed conductors face down. bending performance and breakage resistance.

● Ensuring a Completed Connection

After completing the locking operation, check that the

actuator is horizontal to the board surface.

Do not apply excessive force when the actuator reaches 0°,

doing so may damage the terminals.

(Allowable force: 1N Max.)

10

Jul.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

TF20 Series●0.175mm Pitch, 0.65mm Height, Bottom Contact, Double-sided Lead, Back Flip/Front AxisTM, FPC Connector

Instructions on FPC Layout after Mating Other Precautions

● Load to FPC ● Manual Soldering

Do not apply direct force to the connector during FPC Follow the instructions listed below when soldering the

routing. Contact failure, disconnection or breakage may connector manually during repair work, etc.

occur when using a FPC bent near the connector.

In general the FPC should not be bent sharply near the 1. Do not perform reflow soldering or manual soldering

insertion opening. Secure the FPC when applying a with the FPC inserted into the connector.

continuous load.

2. D o not overheat the connector. Do not allow the

soldering iron to contact any part other than the

intended connector leads.

Otherwise, the connector may be deformed or melted.

3. D o not use excessive solder (or flux).

If excessive solder (or flux) is used on the terminals,

solder or flux may adhere to the contacts or the rotating

parts of the actuator, resulting in poor contact or a

rotation failure of the actuator.

FPC Removal Precautions

Release the actuator at approximately the center.

The actuator may break if operated at one side with the

FPC inserted.

Remove the FPC with the actuator released.

11

Jul.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

TF20 Series●0.175mm Pitch, 0.65mm Height, Bottom Contact, Double-sided Lead, Back Flip/Front AxisTM, FPC Connector

While Taking into Consideration

Specifications mentioned in this catalog are reference values.

When considering to order or use this product, please confirm the Drawing and Product Specifications sheets.

Use an appropriate cable when using the connector in combination with cables.

If considering usage of a non-specified cable, please contact your sales representative.

If assembly process is done by jigs & tools which are not identified by Hirose, assurance will not be given.

If considering usage for below mentioned applications, please contact your sales representative.

In cases where the application will demand a high level of reliability, such as automotive, medical instruments, public infrastructure,

aerospace/ defense etc. Hirose must review before assurance of reliability can be given.

2-6-3,Nakagawa Chuoh,Tsuzuki-Ku,Yokohama-Shi 224-8540,JAPAN

https://www.hirose.com/

12 The contents of this catalog are current as of date of 06/2021. Contents are subject to change without notice for the purpose of improvements.

Jul.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.