1/16ページ

Download(5.6Mb)

Ultra High-Accuracy Laser Displacement Sensor : CDX series

Product Catalog

A fusion of ultra high-accuracy

We have accumulated decades of know-how since our first laser

displacement sensor was introduced to market,

all which have been utilized to achieve the World is No. 1

measurement accuracy.

We arrived at a simple configuration by examining various

user needs and are able to provide operability by way of

a built-in Web server, a new concept for displacement sensors.

Featuring a fusion of ultra high-accuracy and ease-of-use,

these laser displacement sensors feature an extremely

high level of perfection.

Movie

Document Information

| Document Title | Ultra High-Accuracy Laser Displacement Sensor : CDX series |

|---|---|

| Document Type | Product Catalog |

| File size | 5.6Mb |

| Category | |

| Company | OPTEX FA CO., LTD. (Documents List) |

Document Contents

Page1

Ultra High-Accuracy Laser Displacement Sensor

CDX series

New models added

Attention: Not to be Used for Personnel Protection.

Never use these products as sensing devices for personnel protection. Doing so could lead to serious injury or death.

These sensors do not include the self-checking redundant circuitry necessary to allow their use in personnel safety applications.

A sensor failure or malfunction can cause either an energized or de-energized sensor output condition.

Please consult our distributors about safety products which meet OSHA, ANSI and IEC standards for personnel protection.

● Specifications are subject to change without prior notice.

● Specifications and technical information not mentioned here are written in Instruction Manual. Or visit our website for details.

● All the warnings and cautions to know prior to use are given in Instruction Manual.

World’s No. 1 Linearity

91 Chudoji-Awata-cho Shimogyo-ku Kyoto 600-8815 JAPAN

TEL. +81-75-325-1314 FAX. +81-75-325-2936

http://www.optex-fa.com

Catalog content accurate as of January 2018. 78021-01-008-1801 OPTEX FA CO., LTD.

Page2

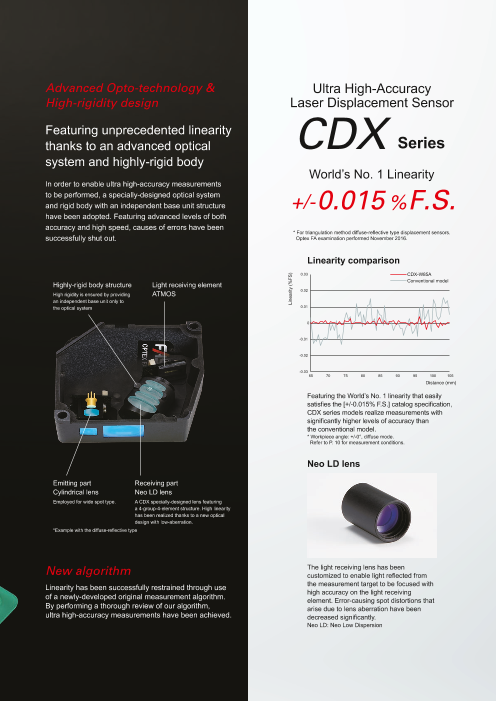

A fusion of ultra high-accuracy Advanced Opto-technology & Ultra High-AccuracyHigh-rigidity design Laser Displacement Sensor

and ease-of-use Featuring unprecedented linearity

We have accumulated decades of know-how since our first laser thanks to an advanced optical CDX Series

displacement sensor was introduced to market, system and highly-rigid body

all which have been utilized to achieve the World’s No. 1 World’s No. 1 Linearity

measurement accuracy. In order to enable ultra high-accuracy measurements

We arrived at a simple configuration by examining various to be performed, a specially-designed optical system

user needs and are able to provide operability by way of and rigid body with an independent base unit structure +/-0.015 %F.S.

a built-in Web server, a new concept for displacement sensors. have been adopted. Featuring advanced levels of both

Featuring a fusion of ultra high-accuracy and ease-of-use, accuracy and high speed, causes of errors have been * For triangulation method diffuse-reflective type displacement sensors.

these laser displacement sensors feature an extremely successfully shut out. Optex FA examination performed November 2016.

high level of perfection.

Linearity comparison

0.03 CDX-W85A

Conventional model

Highly-rigid body structure Light receiving element

0.02

High rigidity is ensured by providing ATMOS

an independent base unit only to

the optical system 0.01

0

-0.01

-0.02

-0.03

65 70 75 80 85 90 95 100 105

Distance (mm)

Featuring the World’s No. 1 linearity that easily

satisfies the [+/-0.015% F.S.] catalog specification,

CDX series models realize measurements with

significantly higher levels of accuracy than

the conventional model.

* Workpiece angle: +/-0°, diffuse mode.

Refer to P. 10 for measurement conditions.

Neo LD lens

Emitting part Receiving part

Cylindrical lens Neo LD lens

Employed for wide spot type. A CDX specially-designed lens featuring

a 4-group-4-element structure. High linearity

has been realized thanks to a new optical

design with low-aberration.

*Example with the diffuse-reflective type

New algorithm The light receiving lens has been customized to enable light reflected from

Linearity has been successfully restrained through use the measurement target to be focused with

of a newly-developed original measurement algorithm. high accuracy on the light receiving element. Error-causing spot distortions that

By performing a thorough review of our algorithm, arise due to lens aberration have been

ultra high-accuracy measurements have been achieved. decreased significantly.

Neo LD: Neo Low Dispersion

Linearity (%FS)

Page3

A fusion of ultra high-accuracy Advanced Opto-technology & Ultra High-AccuracyHigh-rigidity design Laser Displacement Sensor

and ease-of-use Featuring unprecedented linearity

We have accumulated decades of know-how since our first laser thanks to an advanced optical CDX Series

displacement sensor was introduced to market, system and highly-rigid body

all which have been utilized to achieve the World’s No. 1 World’s No. 1 Linearity

measurement accuracy. In order to enable ultra high-accuracy measurements

We arrived at a simple configuration by examining various to be performed, a specially-designed optical system

user needs and are able to provide operability by way of and rigid body with an independent base unit structure +/-0.015 %F.S.

a built-in Web server, a new concept for displacement sensors. have been adopted. Featuring advanced levels of both

Featuring a fusion of ultra high-accuracy and ease-of-use, accuracy and high speed, causes of errors have been * For triangulation method diffuse-reflective type displacement sensors.

these laser displacement sensors feature an extremely successfully shut out. Optex FA examination performed November 2016.

high level of perfection.

Linearity comparison

0.03 CDX-W85A

Conventional model

Highly-rigid body structure Light receiving element

0.02

High rigidity is ensured by providing ATMOS

an independent base unit only to

the optical system 0.01

0

-0.01

-0.02

-0.03

65 70 75 80 85 90 95 100 105

Distance (mm)

Featuring the World’s No. 1 linearity that easily

satisfies the [+/-0.015% F.S.] catalog specification,

CDX series models realize measurements with

significantly higher levels of accuracy than

the conventional model.

* Workpiece angle: +/-0°, diffuse mode.

Refer to P. 10 for measurement conditions.

Neo LD lens

Emitting part Receiving part

Cylindrical lens Neo LD lens

Employed for wide spot type. A CDX specially-designed lens featuring

a 4-group-4-element structure. High linearity

has been realized thanks to a new optical

design with low-aberration.

*Example with the diffuse-reflective type

New algorithm The light receiving lens has been customized to enable light reflected from

Linearity has been successfully restrained through use the measurement target to be focused with

of a newly-developed original measurement algorithm. high accuracy on the light receiving element. Error-causing spot distortions that

By performing a thorough review of our algorithm, arise due to lens aberration have been

ultra high-accuracy measurements have been achieved. decreased significantly.

Neo LD: Neo Low Dispersion

Linearity (%FS)

Page4

Newly Developed Image Sensor for Highly Accurate, Applications

High-speed, and Stable Measurements Shape measurement of cam shafts

NEW Newly developed image sensor: ATMOS

In order to achieve the World’s No. 1 Linearity, ATMOS image sensors

were newly developed with a light receiving element featuring

a CDX specialized design. By applying the latest technology,

accuracy has been increased by 3.3 times* that of the conventional model.

ATMOS: Auto Tuning cMOS

*Comparison between the CDX-W85 and conventional equivalent model

Industry

first Feedback-free high-speed shutter When receiving light level changes suddenly Workpiece

With conventional image sensors, feedback control to height difference

the shutter could not keep up with sudden changes in Shape measurement of tires Deflection measurement of large diameter drills

receiving light levels caused by changes in workpiece Conventional Response

feedback type delaycolors, momentary inabilities to perform measurements

would be caused, resulting in response delays. With

newly developed ATMOS image sensors, Real-time

measurements can be performed without the need for ATMOS measurement

feedback control thanks to an industry-first algorithm. ¢ Receiving light level

Because momentary inabilities to perform Black Appropriate Metal Saturated Metal Appropriate Automatic shutter

measurements and response delays have been release (light Saturation Saturation Saturation

level level level reception ends)

eliminated, real-time measurements are now possible. when receiving light

level saturation

occurs means no

Appropriate receiving light level after one sampling period feedback time

Stable measurements even with Class 1 lasers

With ATMOS image sensors, stable measurements are possible even Flatness measurement of transmission parts Height inspection of smartphone frames (specular reflection type)

with a Class 1 laser thanks to their high level of sensitivity.

Even when measuring black workpieces such as tires, highly accurate

measurements can be performed without using a high output laser.

Stable measurement of black workpieces is possible while ensuring

the safety of worker’s eyes.

Laser class 1:

LASER RADIATION

AVOID DIRECT EYE EXPOSURE Designed to be inherently safe.

CLASS 3R LASER PRODUCT Class

MAXIMUM OUTPUT : 5mW

PULSE DURATION : 6.4ms max. 1 Light is collected optically, ensuring WAVE LENGTH : 658nmMEDIUM : SEMICONDUCTOR LASERLASER APERTURE a safe level even when the laser is CLASS 3R LASER PRODUCTAVOID EXPOSURE (IEC 60825-1:2001)

Laser radiation is emitted to the human body

emitted from this aperture.

(eyes and skin).

High-speed measurement: Max. sampling period of 12.5 μs (Measuring frequency: 80 kHz) Warpage measurement of glass substrates (specular reflection type)

With highly sensitive ATMOS image sensors, ultra high-speed shutter speeds are possible as the required exposure

time is minimized. Because sampling periods have been reduced to 12.5 μs, 1/8th of the conventional model, these

sensors can be utilized for application that require ultra high-speed measurements.

Large glass height measurement

100 μs

100 μs Sampling period 1

8

10 μs

12.5 μs

Conventional model CDX

*With a sampling period of 12.5 μs, the measurement range will be limited. For details, refer to P. 10.

4 5

Page5

Newly Developed Image Sensor for Highly Accurate, Applications

High-speed, and Stable Measurements Shape measurement of cam shafts

NEW Newly developed image sensor: ATMOS

In order to achieve the World’s No. 1 Linearity, ATMOS image sensors

were newly developed with a light receiving element featuring

a CDX specialized design. By applying the latest technology,

accuracy has been increased by 3.3 times* that of the conventional model.

ATMOS: Auto Tuning cMOS

*Comparison between the CDX-W85 and conventional equivalent model

Industry

first Feedback-free high-speed shutter When receiving light level changes suddenly Workpiece

With conventional image sensors, feedback control to height difference

the shutter could not keep up with sudden changes in Shape measurement of tires Deflection measurement of large diameter drills

receiving light levels caused by changes in workpiece Conventional Response

feedback type delaycolors, momentary inabilities to perform measurements

would be caused, resulting in response delays. With

newly developed ATMOS image sensors, Real-time

measurements can be performed without the need for ATMOS measurement

feedback control thanks to an industry-first algorithm. ¢ Receiving light level

Because momentary inabilities to perform Black Appropriate Metal Saturated Metal Appropriate Automatic shutter

measurements and response delays have been release (light Saturation Saturation Saturation

level level level reception ends)

eliminated, real-time measurements are now possible. when receiving light

level saturation

occurs means no

Appropriate receiving light level after one sampling period feedback time

Stable measurements even with Class 1 lasers

With ATMOS image sensors, stable measurements are possible even Flatness measurement of transmission parts Height inspection of smartphone frames (specular reflection type)

with a Class 1 laser thanks to their high level of sensitivity.

Even when measuring black workpieces such as tires, highly accurate

measurements can be performed without using a high output laser.

Stable measurement of black workpieces is possible while ensuring

the safety of worker’s eyes.

Laser class 1:

LASER RADIATION

AVOID DIRECT EYE EXPOSURE Designed to be inherently safe.

CLASS 3R LASER PRODUCT Class

MAXIMUM OUTPUT : 5mW

PULSE DURATION : 6.4ms max. 1 Light is collected optically, ensuring WAVE LENGTH : 658nmMEDIUM : SEMICONDUCTOR LASERLASER APERTURE a safe level even when the laser is CLASS 3R LASER PRODUCTAVOID EXPOSURE (IEC 60825-1:2001)

Laser radiation is emitted to the human body

emitted from this aperture.

(eyes and skin).

High-speed measurement: Max. sampling period of 12.5 μs (Measuring frequency: 80 kHz) Warpage measurement of glass substrates (specular reflection type)

With highly sensitive ATMOS image sensors, ultra high-speed shutter speeds are possible as the required exposure

time is minimized. Because sampling periods have been reduced to 12.5 μs, 1/8th of the conventional model, these

sensors can be utilized for application that require ultra high-speed measurements.

Large glass height measurement

100 μs

100 μs Sampling period 1

8

10 μs

12.5 μs

Conventional model CDX

*With a sampling period of 12.5 μs, the measurement range will be limited. For details, refer to P. 10.

4 5

Page6

Direct Network Connections are Possible without Equipped with a Web Server

Use of a Controller

NEW Setup software is unnecessary

NEW Direct Ethernet connection The CDX series features a new Web server. Using a web browser on the computer

Because an Ethernet serial interface is built-in to the sensor head, connected to the same network, browsing and controlling measured values and setup

connection to a network is possible without use of a controller. contents are possible. Use is possible without need for a dedicated computer software. Internet Explorer® Google Chrome™

Not only can the cost of a controller be eliminated, but any worries Supported browsers Internet Explorer Ver.11 and above, Google Chrome 49 and above

about securing space for controller installation can also be forgotten.

¢ No controller required. Simply add new sensors to the hub.

Hub Network

Branch connector

Power supply

¢ Operation is possible by connecting directly to ¢ Of course, connection to a PLC Ethernet port

a PC LAN port is also possible

Branch connector Branch connector

Power supply Power supply

When Analog/Control Output is Necessary Main functions

Displacement sensor amplifier unit CDA-M ¢ Distance monitor ¢ Storage ¢ Light distribution

Simultaneous display for 4 CHs No data logger required Masking of unnecessary areas

The CDA-M amplifier unit is equipped with an organic EL display

on which both Japanese characters and English lettering can be Mask area: Blue

viewed with clarity. Control can be performed Ambient

using either analog or control outputs, while light

thickness and height difference measurements

can be performed using two sensor heads. Thickness Height

difference

Model CDA-M

Sensor head No. of connectable units Max. 2 units

(CDX series) Connection type Amplifier side: M8, 4-pin connector

Supply voltage 12 to 24 VDC +/-10%, including 10% ripple (p-p)

Rating

Current consumption 100 mA or less (at 12 V)

Dot matrix display Organic EL panel 128 × 96 pixels

Display

Indicators Power display: Red/Green, Output 1 to 3 display: Orange (Only output 1 display available) With the CDX series, judgment settings can be Measured values for up to 100,000 points By monitoring receiving light waveforms,

Analog current output 4 to 20 mA/F.S. Load impedance 300 Ω or less configured for channels 1 to 4. The measured can be stored. By operating using a browser, receiving light levels and mounting angle

NPN/PNP open collector (selectable by setting) 3 outputs (Only output 1 available) values for each channel can be displayed at once data can be viewed and CSV files can be can be confirmed. Thanks to a newly Control output max. 100 mA / 30 VDC, Residual voltage: 1.8 V or less on a graph, allowing for simple comparison of downloaded. developed mask function, even if there are

External input 2 inputs (Only 1 input available) measurement data. Moreover, monitoring of speed unnecessary objects or ambient light in the

and thickness of transparent objects in addition to measurement range, those can be masked

Connection type Cable type: Cable length: 2 m (ø5.8 mm) displacement is possible simultaneously. to enable measurements to be performed

Ambient temperature/humidity -20 to +50°C / 35 to 85% RH (no freezing or condensation) free of influence.

Storage temperature/humidity -20 to +60°C / 35 to 85% RH (no freezing or condensation)

Environmental Vibration resistance 10 to 55 Hz; double amplitude 1.5 mm; 2 hours in each of the X, Y, and Z directions Other functions

resistance Shock resistance Approx. 50 G (500 m/s2), 3 times in each of the X, Y, and Z directions ¢ Measurement setting ¢ I/O setting ¢ Device setting ¢ Communication setting ¢ Product information etc.

Protection circuit Reverse connection protection

Degree of protection IEC standard, IP50

Material Polycarbonate • Internet Explorer and the Internet Explorer logo are trademarks or registered trademarks of Microsoft Corporation in the United States and other countries.

Weight 170 g • Google Chrome and the Google Chrome logo are trademarks or registered trademarks of Google Inc. in the United States and other countries.

If using an amplifier unit, some settings for the CDX series cannot be confirmed or changed. For details, see the CDX series user's manual.

On the CDX series, CH1 is the only output that can be set and used with an amplifier unit.

The CDX series does not support CC-Link communication.

The resolution of the analog outputs (shown below) will be lower than that when using Ethernet communication.

CDX-L15A/-LW15A: 1 μm, CDX-30A/-W30A: 1 μm, CDX-85A/-W85A: 10 μm, CDX-150A/-W150A: 10 μm

6 7

Page7

Direct Network Connections are Possible without Equipped with a Web Server

Use of a Controller

NEW Setup software is unnecessary

NEW Direct Ethernet connection The CDX series features a new Web server. Using a web browser on the computer

Because an Ethernet serial interface is built-in to the sensor head, connected to the same network, browsing and controlling measured values and setup

connection to a network is possible without use of a controller. contents are possible. Use is possible without need for a dedicated computer software. Internet Explorer® Google Chrome™

Not only can the cost of a controller be eliminated, but any worries Supported browsers Internet Explorer Ver.11 and above, Google Chrome 49 and above

about securing space for controller installation can also be forgotten.

¢ No controller required. Simply add new sensors to the hub.

Hub Network

Branch connector

Power supply

¢ Operation is possible by connecting directly to ¢ Of course, connection to a PLC Ethernet port

a PC LAN port is also possible

Branch connector Branch connector

Power supply Power supply

When Analog/Control Output is Necessary Main functions

Displacement sensor amplifier unit CDA-M ¢ Distance monitor ¢ Storage ¢ Light distribution

Simultaneous display for 4 CHs No data logger required Masking of unnecessary areas

The CDA-M amplifier unit is equipped with an organic EL display

on which both Japanese characters and English lettering can be Mask area: Blue

viewed with clarity. Control can be performed Ambient

using either analog or control outputs, while light

thickness and height difference measurements

can be performed using two sensor heads. Thickness Height

difference

Model CDA-M

Sensor head No. of connectable units Max. 2 units

(CDX series) Connection type Amplifier side: M8, 4-pin connector

Supply voltage 12 to 24 VDC +/-10%, including 10% ripple (p-p)

Rating

Current consumption 100 mA or less (at 12 V)

Dot matrix display Organic EL panel 128 × 96 pixels

Display

Indicators Power display: Red/Green, Output 1 to 3 display: Orange (Only output 1 display available) With the CDX series, judgment settings can be Measured values for up to 100,000 points By monitoring receiving light waveforms,

Analog current output 4 to 20 mA/F.S. Load impedance 300 Ω or less configured for channels 1 to 4. The measured can be stored. By operating using a browser, receiving light levels and mounting angle

NPN/PNP open collector (selectable by setting) 3 outputs (Only output 1 available) values for each channel can be displayed at once data can be viewed and CSV files can be can be confirmed. Thanks to a newly Control output max. 100 mA / 30 VDC, Residual voltage: 1.8 V or less on a graph, allowing for simple comparison of downloaded. developed mask function, even if there are

External input 2 inputs (Only 1 input available) measurement data. Moreover, monitoring of speed unnecessary objects or ambient light in the

and thickness of transparent objects in addition to measurement range, those can be masked

Connection type Cable type: Cable length: 2 m (ø5.8 mm) displacement is possible simultaneously. to enable measurements to be performed

Ambient temperature/humidity -20 to +50°C / 35 to 85% RH (no freezing or condensation) free of influence.

Storage temperature/humidity -20 to +60°C / 35 to 85% RH (no freezing or condensation)

Environmental Vibration resistance 10 to 55 Hz; double amplitude 1.5 mm; 2 hours in each of the X, Y, and Z directions Other functions

resistance Shock resistance Approx. 50 G (500 m/s2), 3 times in each of the X, Y, and Z directions ¢ Measurement setting ¢ I/O setting ¢ Device setting ¢ Communication setting ¢ Product information etc.

Protection circuit Reverse connection protection

Degree of protection IEC standard, IP50

Material Polycarbonate • Internet Explorer and the Internet Explorer logo are trademarks or registered trademarks of Microsoft Corporation in the United States and other countries.

Weight 170 g • Google Chrome and the Google Chrome logo are trademarks or registered trademarks of Google Inc. in the United States and other countries.

If using an amplifier unit, some settings for the CDX series cannot be confirmed or changed. For details, see the CDX series user's manual.

On the CDX series, CH1 is the only output that can be set and used with an amplifier unit.

The CDX series does not support CC-Link communication.

The resolution of the analog outputs (shown below) will be lower than that when using Ethernet communication.

CDX-L15A/-LW15A: 1 μm, CDX-30A/-W30A: 1 μm, CDX-85A/-W85A: 10 μm, CDX-150A/-W150A: 10 μm

6 7

Page8

Lineup Options/Accessories

¢ Sensor heads ¢ Connectors/Connector Cables

Linearity

Type Measurement range Spot size Resolution Model Type Specifications Cable length Model

Diffuse mode Specular mode Dedicated cable for extension between the sensor head and branch connector. 2 m DSC-1208-G02MA

Sensor head Up to two extention cables can be connected and extended.

extension cable Robot cable specifications. 5 m DSC-1208-G05MA• Sensor side: M12, 8-pin socket

Spot 15 +/-1 mm ø30 μm CDX-L15A • Branch connector side: M12, 8-pin plug 10 m DSC-1208-G10MA

NEW Dedicated cable for connecting from the branch connectors to the Ethernet port. 2 m SSL-2J04-G02ME-R

Specular — +/-0.05% of F.S. (+/-1 μm) Ethernet cable Robot cable specifications.

reflection • Branch connector side: M12, 4-pin socket 5 m

SSL-2J04-G05ME-R

• Host side: RJ45 plug 10 m SSL-2J04-G10ME-R

Wide 30 × 1000 μm CDX-LW15A

Power supply/ Power supply/external input cable for connecting to branch connector.

2 m DOL-1204-G02M

• Branch connector side: M12, 4-pin socket

external input cable • Power supply/external device side: discrete wire 5 m DOL-1204-G05M

Spot 30 +/-5 mm 25.5 +/-3.0 mm ø30 μm +/-0.03% of F.S. (+/-3 μm) CDX-30A

Branch connector for connecting sensor heads and various cables.

NEW Branch connector Included with sensor head. - SYL-1208-G0M

Short +/-0.04% of F.S. (+/-2.4 μm)

range

Diffuse installation Specular installation

Wide 30 × 1000 μm +/-0.015% of F.S. (+/-1.5 μm) CDX-W30A

0.25 μm ¢ Amplifier unit, connector cables for amplifier unit

Meas. range 65 to 85 mm:

Spot ø70 μm +/-0.018% of F.S.(+/-7.2 μm) CDX-85A Type Specifications Cable length Model

85 +/-20 mm 81.5 +/-10 mm Meas. range 85 to 105 mm:

+/-0.03% of F.S.(+/-12.0 μm)

Middle An amplifier unit to which up to two sensor heads can be connected.

range +/-0.03% of F.S. (+/-6.0 μm) Amplifier unit Control can be performed using either analog or control outputs, while thickness and height difference measurements can be performed 2 m CDA-M

using two sensor heads.

Wide Diffuse installation Specular installation 70 × 2000 μm +/-0.015% of F.S. (+/-6.0 μm) CDX-W85A

Connector cable for connecting branch connectors and amplifier units.

Sensor/amplifier Robot cable specifications.

connection cable • Branch connector side: M12, 5-pin socket 2 m DSL-1204-G02M

Meas. range 110 to 150 mm: • Amplifier unit side: M8, 4-pin plug

Spot ø120 μm +/-0.03% of F.S.(+/-24 μm)

150 +/-40 mm Meas. range 150 to 190 mm:

CDX-150A Extension cable for connection to DSL-1204-G02M. 2 m DSL-0804-G02M

+/-0.04% of F.S.(+/-32 μm) Sensor-to-amplifier Robot cable specifications.

Long extension cable • Sensor/amplifier connection cable side: M8, 4-pin socket

range — • Amplifier unit side: M8, 4-pin plug 5 m DSL-0804-G05M

Please ensure that the overall cable length when an amplifier unit is used is within 10 m (sensor head extension cable + sensor/amplifier connection cable + sensor-to-amplifier extension cable).

Wide 120 × 4000 μm +/-0.015% of F.S. (+/-12 μm) CDX-W150A If using an amplifier unit, some settings for the CDX series cannot be confirmed or changed. For details, see the CDX series user's manual.

On the CDX series, CH1 is the only output that can be set and used with an amplifier unit.

The CDX series does not support CC-Link communication.

The resolution of the analog outputs (shown below) will be lower than that when using Ethernet communication.

CDX-L15A/-LW15A: 1 μm, CDX-30A/-W30A: 1 μm, CDX-85A/-W85A: 10 μm, CDX-150A/-W150A: 10 μm

Regarding applicability of Export Trade Control Order enacted by Japanese government for

the CDX series

CDX series sensor heads are products that are subject to “Export Trade Control Order Appended Table 1 2-(12) Measurement

Caution devices (including machine tools with a measurement function)”. Please inquire for details.

Measurement Resolution Additional informationModel

mode Sensor head only With amplifier unit There is no differentiation for the applicability of CDA series

CDX-L15 amplifier units and the resolution outputted from amplifiers

Specular mode 0.01 μm

CDX-LW15 connected to sensor heads is regulated as shown in the table to

Diffuse mode the left even if the average number of cycles is increased.

CDX-30 0.05 μm 1 μm

Specular mode

Diffuse mode

CDX-W30 0.05 μm

Specular mode

Diffuse mode

CDX-85 0.1 μm

Specular mode

Diffuse mode

CDX-W85 0.1 μm 10 μm

Specular mode

CDX-150

Diffuse mode 0.2 μm

CDX-W150

8 9

Page9

Lineup Options/Accessories

¢ Sensor heads ¢ Connectors/Connector Cables

Linearity

Type Measurement range Spot size Resolution Model Type Specifications Cable length Model

Diffuse mode Specular mode Dedicated cable for extension between the sensor head and branch connector. 2 m DSC-1208-G02MA

Sensor head Up to two extention cables can be connected and extended.

extension cable Robot cable specifications. 5 m DSC-1208-G05MA• Sensor side: M12, 8-pin socket

Spot 15 +/-1 mm ø30 μm CDX-L15A • Branch connector side: M12, 8-pin plug 10 m DSC-1208-G10MA

NEW Dedicated cable for connecting from the branch connectors to the Ethernet port. 2 m SSL-2J04-G02ME-R

Specular — +/-0.05% of F.S. (+/-1 μm) Ethernet cable Robot cable specifications.

reflection • Branch connector side: M12, 4-pin socket 5 m

SSL-2J04-G05ME-R

• Host side: RJ45 plug 10 m SSL-2J04-G10ME-R

Wide 30 × 1000 μm CDX-LW15A

Power supply/ Power supply/external input cable for connecting to branch connector.

2 m DOL-1204-G02M

• Branch connector side: M12, 4-pin socket

external input cable • Power supply/external device side: discrete wire 5 m DOL-1204-G05M

Spot 30 +/-5 mm 25.5 +/-3.0 mm ø30 μm +/-0.03% of F.S. (+/-3 μm) CDX-30A

Branch connector for connecting sensor heads and various cables.

NEW Branch connector Included with sensor head. - SYL-1208-G0M

Short +/-0.04% of F.S. (+/-2.4 μm)

range

Diffuse installation Specular installation

Wide 30 × 1000 μm +/-0.015% of F.S. (+/-1.5 μm) CDX-W30A

0.25 μm ¢ Amplifier unit, connector cables for amplifier unit

Meas. range 65 to 85 mm:

Spot ø70 μm +/-0.018% of F.S.(+/-7.2 μm) CDX-85A Type Specifications Cable length Model

85 +/-20 mm 81.5 +/-10 mm Meas. range 85 to 105 mm:

+/-0.03% of F.S.(+/-12.0 μm)

Middle An amplifier unit to which up to two sensor heads can be connected.

range +/-0.03% of F.S. (+/-6.0 μm) Amplifier unit Control can be performed using either analog or control outputs, while thickness and height difference measurements can be performed 2 m CDA-M

using two sensor heads.

Wide Diffuse installation Specular installation 70 × 2000 μm +/-0.015% of F.S. (+/-6.0 μm) CDX-W85A

Connector cable for connecting branch connectors and amplifier units.

Sensor/amplifier Robot cable specifications.

connection cable • Branch connector side: M12, 5-pin socket 2 m DSL-1204-G02M

Meas. range 110 to 150 mm: • Amplifier unit side: M8, 4-pin plug

Spot ø120 μm +/-0.03% of F.S.(+/-24 μm)

150 +/-40 mm Meas. range 150 to 190 mm:

CDX-150A Extension cable for connection to DSL-1204-G02M. 2 m DSL-0804-G02M

+/-0.04% of F.S.(+/-32 μm) Sensor-to-amplifier Robot cable specifications.

Long extension cable • Sensor/amplifier connection cable side: M8, 4-pin socket

range — • Amplifier unit side: M8, 4-pin plug 5 m DSL-0804-G05M

Please ensure that the overall cable length when an amplifier unit is used is within 10 m (sensor head extension cable + sensor/amplifier connection cable + sensor-to-amplifier extension cable).

Wide 120 × 4000 μm +/-0.015% of F.S. (+/-12 μm) CDX-W150A If using an amplifier unit, some settings for the CDX series cannot be confirmed or changed. For details, see the CDX series user's manual.

On the CDX series, CH1 is the only output that can be set and used with an amplifier unit.

The CDX series does not support CC-Link communication.

The resolution of the analog outputs (shown below) will be lower than that when using Ethernet communication.

CDX-L15A/-LW15A: 1 μm, CDX-30A/-W30A: 1 μm, CDX-85A/-W85A: 10 μm, CDX-150A/-W150A: 10 μm

Regarding applicability of Export Trade Control Order enacted by Japanese government for

the CDX series

CDX series sensor heads are products that are subject to “Export Trade Control Order Appended Table 1 2-(12) Measurement

Caution devices (including machine tools with a measurement function)”. Please inquire for details.

Measurement Resolution Additional informationModel

mode Sensor head only With amplifier unit There is no differentiation for the applicability of CDA series

CDX-L15 amplifier units and the resolution outputted from amplifiers

Specular mode 0.01 μm

CDX-LW15 connected to sensor heads is regulated as shown in the table to

Diffuse mode the left even if the average number of cycles is increased.

CDX-30 0.05 μm 1 μm

Specular mode

Diffuse mode

CDX-W30 0.05 μm

Specular mode

Diffuse mode

CDX-85 0.1 μm

Specular mode

Diffuse mode

CDX-W85 0.1 μm 10 μm

Specular mode

CDX-150

Diffuse mode 0.2 μm

CDX-W150

8 9

Page10

Specifications

¢ Sensor head (model based specifications) ¢ Sensor head (common specifications)

Model CDX-L15A CDX-LW15A CDX-30A CDX-W30A Supply voltage 12 to 24 VDC (+/-10%, including ripple)

Optical method Specular reflection Diffuse installation Specular installation Diffuse installation Specular installation Current consumption 340 mA (at 12 VDC), 180 mA (at 24 VDC)

Measurement range*1 15 +/-1 mm 30 +/-5 mm 25.5 +/-3.0 mm 30 +/-5 mm 25.5 +/-3.0 mm Communication interface Ethernet (100BASE-TX) / Corresponding to IEEE1588

Medium Red semiconductor laser External input Selectable from laser OFF, hold/reset, start storage, and offset

Light source Wavelength 655 nm Indicators Link indicator (green) / power indicator (orange/green/blue/red)

Maximum output 0.39 mW Degree of protection IP67 (including connector part)

JIS/IEC CLASS 1 Ambient temperature/humidity -10 to +50°C / 35 to 85% RH (no condensation or freezing)

Laser class

FDA*2 CLASS 1 Storage temperature/humidity -20 to +60°C / 35 to 85% RH (no condensation or freezing)

Spot size*3 ø30 μm 30 × 1000 μm ø30 μm 30 × 1000 μm Ambient illuminance Incandescent lamp: 3,000 lx or less, fluorescent lamp: 10,000 lx or less

Linearity +/-0.05% of F.S. +/-0.03% of F.S. +/-0.04% of F.S. +/-0.015% of F.S. +/-0.04% of F.S. Vibration resistance 10 to 55 Hz; double amplitude 1.5 mm; 2 hours in each of the X, Y, and Z directions(+/-1 μm) (+/-3 μm) (+/-2.4 μm) (+/-1.5 μm) (+/-2.4 μm) Shock resistance 50 G (500 m/s2), 3 times in each of the X, Y, and Z directions

Resolution*4 0.25 μm EMC EMC directive (2014/30/EU)

Repeat accuracy*5 0.25 μm Applicable regulations Environment RoHS directive (2011/65/EU), Battery directive (2006/66/EC), China RoHS (Directive No. 32)

Sampling period 12.5 μs / 25 μs / 50 μs / 100 μs / 200 μs / 500 μs / 1 ms / Auto Safety FDA regulations (21 CFR 1040.10 and 1040.11)*6

Temperature -10 to +40°C +/-0.02% F.S./°C +/-0.03% F.S./°C +/-0.01% F.S./°C +/-0.02% F.S./°C Applicable standards EN 60947-5-2:2007 / A1:2012, IEC 60825-1:2007 and 2014

drift +40 to +50°C +/-0.03% F.S./°C +/-0.1% F.S./°C +/-0.03% F.S./°C +/-0.04% F.S./°C Warm-up time Approx. 30 minutes

Weight Approx. 300 g (including 500 mm connector cable) Approx. 280 g (including 500 mm connector cable) Approx. 280 g (including 500 mm connector cable) Material Housing: Aluminum die-cast, Optical window: Glass

*6. Excluding differences per Laser Notice No. 50.

Model CDX-85A CDX-W85A CDX-150A CDX-W150A

Optical method Diffuse installation Specular installation Diffuse installation Specular installation Diffuse installation

Measurement range*1 85 +/-20 mm 81.5 +/-10.0 mm 85 +/-20 mm 81.5 +/-10.0 mm 150 +/-40 mm

Medium Red semiconductor laser

Light source Wavelength 655 nm I/O Circuit Diagram

Maximum output 0.39 mW

JIS/IEC Class 1 ¢ Connection and Circuit Diagram of Power Supply/External Input Cable DOL-1204-G0xM

Laser class

FDA*2 Class 1

Spot size*3 ø70 μm 70 × 2000 μm ø120 μm 120 × 4000 μm Blue: 0V

Meas. range 65 to 85 mm: Meas. range 110 to 150 mm:

+/-0.018% of F.S. +/-0.03% of F.S.

Linearity (+/-7.2 μm) +/-0.03% of F.S. +/-0.015% of F.S. +/-0.03% of F.S. (+/-24 μm) +/-0.015% of F.S. 5R5VMeas. range 85 to 105 mm: (+/-6.0 μm) (+/-6.0 μm) (+/-6.0 μm) Meas. range 150 to 190 mm: (±12 μm)

+/-0.03% of F.S. +/-0.04% of F.S.

(+/-12.0 μm) (+/-32 μm) White: External input (NPN)

Resolution*4 0.3 μm

Repeat accuracy*5 0.3 μm 3R3V

Sampling period 12.5 μs / 25 μs / 50 μs / 100 μs / 200 μs / 500 μs / 1 ms / Auto

Temperature -10 to +40°C +/-0.01% F.S./°C

drift Black: External input (PNP)+40 to +50°C +/-0.03% F.S./°C

Weight Approx. 280 g (including 500 mm connector cable)

The CDX series sensor heads mentioned above are products to which limits on resolution have been added to enable their non-applicability to “Export Trade Control Order Appended Table 1 2-(12)

Measurement devices.” For applicable products with no limited resolution, refer to P.8.

The measurement conditions are as follows unless otherwise designated: Brown: 24V DC

Measurement Ambient temperature: 25°C (normal temperature), Supply voltage: 24 VDC, Sampling period: 50 μs, Moving average performed: 256, Median filter: 31, Center of measurement range,

conditions Measurement target ([specular reflection: glass] for the 15 mm/30 mm type, [specular reflection: aluminum vapor deposition mirror] and [diffuse reflection: visible light shielding

ceramic] for the 85 mm type) Furthermore, the sensor head is fixed in place with an aluminum jig when measurements are performed.

*1. The measurement range will become narrower when the sampling period is set to the maximum speed of 12.5 μs. Please use by selecting from Near/Center/Far below.

Measurement range

Model ¢ Connection and Circuit Diagram of Amplifier Unit CDA-M

Near Center Far

CDX-L15A/-LW15A 14.0 to 14.6 mm 14.4 to 15.4 mm 15.3 to 16.0 mm With the NPN setting With the PNP setting

Diffuse installation 25.0 to 28.1 mm 27.8 to 31.9 mm 31.1 to 35.0 mm

CDX-30A/-W30A

Specular installation 22.5 to 24.0 mm 22.8 to 27.9 mm 26.7 to 28.5 mm Brown: 12 to 24V DC Brown: 12 to 24V DC

Diffuse installation 65.0 to 77.7 mm 73.5 to 90.8 mm 84.8 to 105.0 mm

CDX-85A/-W85A

Specular installation 71.5 to 74.3 mm 70.6 to 86.9 mm 81.0 to 91.5 mm LoadBlack: Output

CDX-150A/-W150A 110.0 to 134.4 mm 124.8 to 166.3 mm 150.2 to 190.0 mm Black: Output

Yellow: NC

*2. In accordance with the FDA provisions of Laser Notice No. 50, the laser is classified as Class 1 per the IEC 60825-1:2007 standard. Yellow: NC

*3. Defined with center strength 1/e2 (13.5%) at the center of measurement range. There may be leak light other than the specified spot size. Purple: NC

The sensor may be affected when there is a highly reflective object close to the detection area.

*4. The minimum step that can be identified when the distance between the sensor and target changes one step at a time (when performing moving average 65,536 times) Purple: NC

*5. Peak-to-peak value of measured value when measuring in stationary state (when performing moving average 65,536 times) 3.3 V Gray: External input Gray: External input

Pink: NC Pink: NC Load

White: Analog output White: Analog output

Analog output Analog output

evaluation evaluation

equipment equipment

Blue: 0V/Analog GND Blue: 0V/Analog GND

10 11

Internal circuit Main circuit

Internal circuit

Page11

Specifications

¢ Sensor head (model based specifications) ¢ Sensor head (common specifications)

Model CDX-L15A CDX-LW15A CDX-30A CDX-W30A Supply voltage 12 to 24 VDC (+/-10%, including ripple)

Optical method Specular reflection Diffuse installation Specular installation Diffuse installation Specular installation Current consumption 340 mA (at 12 VDC), 180 mA (at 24 VDC)

Measurement range*1 15 +/-1 mm 30 +/-5 mm 25.5 +/-3.0 mm 30 +/-5 mm 25.5 +/-3.0 mm Communication interface Ethernet (100BASE-TX) / Corresponding to IEEE1588

Medium Red semiconductor laser External input Selectable from laser OFF, hold/reset, start storage, and offset

Light source Wavelength 655 nm Indicators Link indicator (green) / power indicator (orange/green/blue/red)

Maximum output 0.39 mW Degree of protection IP67 (including connector part)

JIS/IEC CLASS 1 Ambient temperature/humidity -10 to +50°C / 35 to 85% RH (no condensation or freezing)

Laser class

FDA*2 CLASS 1 Storage temperature/humidity -20 to +60°C / 35 to 85% RH (no condensation or freezing)

Spot size*3 ø30 μm 30 × 1000 μm ø30 μm 30 × 1000 μm Ambient illuminance Incandescent lamp: 3,000 lx or less, fluorescent lamp: 10,000 lx or less

Linearity +/-0.05% of F.S. +/-0.03% of F.S. +/-0.04% of F.S. +/-0.015% of F.S. +/-0.04% of F.S. Vibration resistance 10 to 55 Hz; double amplitude 1.5 mm; 2 hours in each of the X, Y, and Z directions(+/-1 μm) (+/-3 μm) (+/-2.4 μm) (+/-1.5 μm) (+/-2.4 μm) Shock resistance 50 G (500 m/s2), 3 times in each of the X, Y, and Z directions

Resolution*4 0.25 μm EMC EMC directive (2014/30/EU)

Repeat accuracy*5 0.25 μm Applicable regulations Environment RoHS directive (2011/65/EU), Battery directive (2006/66/EC), China RoHS (Directive No. 32)

Sampling period 12.5 μs / 25 μs / 50 μs / 100 μs / 200 μs / 500 μs / 1 ms / Auto Safety FDA regulations (21 CFR 1040.10 and 1040.11)*6

Temperature -10 to +40°C +/-0.02% F.S./°C +/-0.03% F.S./°C +/-0.01% F.S./°C +/-0.02% F.S./°C Applicable standards EN 60947-5-2:2007 / A1:2012, IEC 60825-1:2007 and 2014

drift +40 to +50°C +/-0.03% F.S./°C +/-0.1% F.S./°C +/-0.03% F.S./°C +/-0.04% F.S./°C Warm-up time Approx. 30 minutes

Weight Approx. 300 g (including 500 mm connector cable) Approx. 280 g (including 500 mm connector cable) Approx. 280 g (including 500 mm connector cable) Material Housing: Aluminum die-cast, Optical window: Glass

*6. Excluding differences per Laser Notice No. 50.

Model CDX-85A CDX-W85A CDX-150A CDX-W150A

Optical method Diffuse installation Specular installation Diffuse installation Specular installation Diffuse installation

Measurement range*1 85 +/-20 mm 81.5 +/-10.0 mm 85 +/-20 mm 81.5 +/-10.0 mm 150 +/-40 mm

Medium Red semiconductor laser

Light source Wavelength 655 nm I/O Circuit Diagram

Maximum output 0.39 mW

JIS/IEC Class 1 ¢ Connection and Circuit Diagram of Power Supply/External Input Cable DOL-1204-G0xM

Laser class

FDA*2 Class 1

Spot size*3 ø70 μm 70 × 2000 μm ø120 μm 120 × 4000 μm Blue: 0V

Meas. range 65 to 85 mm: Meas. range 110 to 150 mm:

+/-0.018% of F.S. +/-0.03% of F.S.

Linearity (+/-7.2 μm) +/-0.03% of F.S. +/-0.015% of F.S. +/-0.03% of F.S. (+/-24 μm) +/-0.015% of F.S. 5R5VMeas. range 85 to 105 mm: (+/-6.0 μm) (+/-6.0 μm) (+/-6.0 μm) Meas. range 150 to 190 mm: (±12 μm)

+/-0.03% of F.S. +/-0.04% of F.S.

(+/-12.0 μm) (+/-32 μm) White: External input (NPN)

Resolution*4 0.3 μm

Repeat accuracy*5 0.3 μm 3R3V

Sampling period 12.5 μs / 25 μs / 50 μs / 100 μs / 200 μs / 500 μs / 1 ms / Auto

Temperature -10 to +40°C +/-0.01% F.S./°C

drift Black: External input (PNP)+40 to +50°C +/-0.03% F.S./°C

Weight Approx. 280 g (including 500 mm connector cable)

The CDX series sensor heads mentioned above are products to which limits on resolution have been added to enable their non-applicability to “Export Trade Control Order Appended Table 1 2-(12)

Measurement devices.” For applicable products with no limited resolution, refer to P.8.

The measurement conditions are as follows unless otherwise designated: Brown: 24V DC

Measurement Ambient temperature: 25°C (normal temperature), Supply voltage: 24 VDC, Sampling period: 50 μs, Moving average performed: 256, Median filter: 31, Center of measurement range,

conditions Measurement target ([specular reflection: glass] for the 15 mm/30 mm type, [specular reflection: aluminum vapor deposition mirror] and [diffuse reflection: visible light shielding

ceramic] for the 85 mm type) Furthermore, the sensor head is fixed in place with an aluminum jig when measurements are performed.

*1. The measurement range will become narrower when the sampling period is set to the maximum speed of 12.5 μs. Please use by selecting from Near/Center/Far below.

Measurement range

Model ¢ Connection and Circuit Diagram of Amplifier Unit CDA-M

Near Center Far

CDX-L15A/-LW15A 14.0 to 14.6 mm 14.4 to 15.4 mm 15.3 to 16.0 mm With the NPN setting With the PNP setting

Diffuse installation 25.0 to 28.1 mm 27.8 to 31.9 mm 31.1 to 35.0 mm

CDX-30A/-W30A

Specular installation 22.5 to 24.0 mm 22.8 to 27.9 mm 26.7 to 28.5 mm Brown: 12 to 24V DC Brown: 12 to 24V DC

Diffuse installation 65.0 to 77.7 mm 73.5 to 90.8 mm 84.8 to 105.0 mm

CDX-85A/-W85A

Specular installation 71.5 to 74.3 mm 70.6 to 86.9 mm 81.0 to 91.5 mm LoadBlack: Output

CDX-150A/-W150A 110.0 to 134.4 mm 124.8 to 166.3 mm 150.2 to 190.0 mm Black: Output

Yellow: NC

*2. In accordance with the FDA provisions of Laser Notice No. 50, the laser is classified as Class 1 per the IEC 60825-1:2007 standard. Yellow: NC

*3. Defined with center strength 1/e2 (13.5%) at the center of measurement range. There may be leak light other than the specified spot size. Purple: NC

The sensor may be affected when there is a highly reflective object close to the detection area.

*4. The minimum step that can be identified when the distance between the sensor and target changes one step at a time (when performing moving average 65,536 times) Purple: NC

*5. Peak-to-peak value of measured value when measuring in stationary state (when performing moving average 65,536 times) 3.3 V Gray: External input Gray: External input

Pink: NC Pink: NC Load

White: Analog output White: Analog output

Analog output Analog output

evaluation evaluation

equipment equipment

Blue: 0V/Analog GND Blue: 0V/Analog GND

10 11

Internal circuit Main circuit

Internal circuit

Page12

Dimensions (Unit: mm) (Unit: mm)

29 75 29 75

¢ CDX-L15A/-LW15A ¢ CDX-85A/-W85A

15 59.8 4.2 15 66.6 4.2

(Diffuse installation) 4.2

Optical axis

of receiver 2-ø4.3

Link indicator Link indicator

36.4 2-ø4.3 34.8 (green) (green)

54.7 Power indicator 61 Power indicator

(orange/green/blue/red) Optical axis of receiver90° (orange/green/blue/red)78 69.6 78

Optical axis 20°

of emitter

Optical axis of emitter

85+/-20

6.5 Measurement range 6.

5

15 ø ø+/-1

Measurement range

M12, 8-pin connector M12, 8-pin connector

50 50 00

86.1

(Specular installation)

77.7 4.2

9.9

10°

¢ CDX-30A/-W30A 29 75 38.8 Optical axis of receiver

(Diffuse installation) 15 66.6 4.2 4.2

20° 57 79.1 81

Link indicator

2-ø4.3 (green)

Optical axis of emitter

61 Power indicator

Optical axis (orange/green/blue/red)

of receiver 69.6 78

81.5+/-10.0

Measurement range

30°

Optical axis

of emitter

30+/-5 ¢ CDX-150A/-W150A

Measurement range 6.5ø

29 75

15 66.6 4.2

M12, 8-pin connector

50 2-ø4.30 Link indicator

(green)

61 Optical axis of receiver Power indicator

90.7 (orange/green/blue/red)

(Specular installation) 69.6 78

13°

82.3 4.2

15° 12.7

41.5 Optical axis of emitter

Optical axis

of receiver 150+/-40

Measurement range 6.5ø

30° 50 78.8 82

Optical axis

of emitter M12, 8-pin connector

500

25.5+/-3.0

Measurement range

12 13

4.2

4.2

Page13

Dimensions (Unit: mm) (Unit: mm)

29 75 29 75

¢ CDX-L15A/-LW15A ¢ CDX-85A/-W85A

15 59.8 4.2 15 66.6 4.2

(Diffuse installation) 4.2

Optical axis

of receiver 2-ø4.3

Link indicator Link indicator

36.4 2-ø4.3 34.8 (green) (green)

54.7 Power indicator 61 Power indicator

(orange/green/blue/red) Optical axis of receiver90° (orange/green/blue/red)78 69.6 78

Optical axis 20°

of emitter

Optical axis of emitter

85+/-20

6.5 Measurement range 6.

5

15 ø ø+/-1

Measurement range

M12, 8-pin connector M12, 8-pin connector

50 50 00

86.1

(Specular installation)

77.7 4.2

9.9

10°

¢ CDX-30A/-W30A 29 75 38.8 Optical axis of receiver

(Diffuse installation) 15 66.6 4.2 4.2

20° 57 79.1 81

Link indicator

2-ø4.3 (green)

Optical axis of emitter

61 Power indicator

Optical axis (orange/green/blue/red)

of receiver 69.6 78

81.5+/-10.0

Measurement range

30°

Optical axis

of emitter

30+/-5 ¢ CDX-150A/-W150A

Measurement range 6.5ø

29 75

15 66.6 4.2

M12, 8-pin connector

50 2-ø4.30 Link indicator

(green)

61 Optical axis of receiver Power indicator

90.7 (orange/green/blue/red)

(Specular installation) 69.6 78

13°

82.3 4.2

15° 12.7

41.5 Optical axis of emitter

Optical axis

of receiver 150+/-40

Measurement range 6.5ø

30° 50 78.8 82

Optical axis

of emitter M12, 8-pin connector

500

25.5+/-3.0

Measurement range

12 13

4.2

4.2

Page14

Dimensions (Unit: mm) System Configuration

¢ CDA-M ¢ SYL-1208-G0M

Power indicator B button

(Green/Red) Display screen Sensor head PC PLC Hub, router

ch2 A button

M8, 4P female connector 22 39

23

ch1 52

Output indicator Arrow buttons

(Orange)

Top cover If extending the cable

34 78

Sensor head extension cable

Cable length: 2 m

ø5.8

8-wire × 0.12 mm2

33.2 CDX-L15A/-LW15A

DSC-1208-G02MA Ethernet cable

10 8.4 DSC-1208-G05MA

SSL-2J04-G02ME-R

9.6 9.6 18.8 36.6 5P female connector DSC-1208-G10MA SSL-2J04-G05ME-R

SSL-2J04-G10ME-R

Spot Size (Typical Characteristic Data)

800 μm 1000 μm 1200 μm

¢ CDX-L15A ¢ CDX-LW15A

1

1 6

1 Branch connector

5 m 1

6

5

1 m m 1

mm

m mm (included with 4 m 4 m mm sensor head)CDX-30A/-W30A

Power supply/external input cable

ø50 μm ø30 μm ø50 μm 50 μm 30 μm 50 μm

0 19.8 21.2 22.6 0 19.8 21.2 22.6

Distance (mm) Distance (mm) SYL-1208-G0M DOL-1204-G02M

DOL-1204-G05M

700 μm 1000 μm 2000 μm

¢ CDX-30A ¢ CDX-W30A If using an amplifier

Sensor/amplifier connection cable

ø140 μm ø30 μm ø140 μm 140 μm 30 μm 140 μm DSL-1204-G02M

0 25 30 35 0 25 30 35

Distance (mm) Distance (mm) CDX-85A/-W85A

1500 μm 2000 μm 2500 μm

¢ CDX-85A ¢ CDX-W85A If extending the cable

Sensor-to-amplifier extension cable

DSL-0804-G02M

ø120 μm ø70 μm ø120 μm 120 μm 70 μm 120 μm

DSL-0804-G05M

0 65 85 105 0 65 85 105

Distance (mm) Distance (mm)

Amplifier unit

2000 μm 4000 μm 6000 μm

¢ CDX-150A ¢ CDX-W150A

CDX-150A/-W150A

CDA-M

ø300 μm ø120 μm ø300 μm 300 μm 120 μm 300 μm Ensure that the overall cable length from the power supply to the sensor head is within 30 m, and the number of Sensor Head Extension Cables to be connected must be up to two.

Also ensure that the overall cable length when the CDA-M amplifier unit is used is within 10 m.

0 110 150 195 0 110 150 195 (This length restriction does not apply to the Ethernet cable.)

Distance (mm) Distance (mm)

14 15

Page15

Dimensions (Unit: mm) System Configuration

¢ CDA-M ¢ SYL-1208-G0M

Power indicator B button

(Green/Red) Display screen Sensor head PC PLC Hub, router

ch2 A button

M8, 4P female connector 22 39

23

ch1 52

Output indicator Arrow buttons

(Orange)

Top cover If extending the cable

34 78

Sensor head extension cable

Cable length: 2 m

ø5.8

8-wire × 0.12 mm2

33.2 CDX-L15A/-LW15A

DSC-1208-G02MA Ethernet cable

10 8.4 DSC-1208-G05MA

SSL-2J04-G02ME-R

9.6 9.6 18.8 36.6 5P female connector DSC-1208-G10MA SSL-2J04-G05ME-R

SSL-2J04-G10ME-R

Spot Size (Typical Characteristic Data)

800 μm 1000 μm 1200 μm

¢ CDX-L15A ¢ CDX-LW15A

1

1 6

1 Branch connector

5 m 1

6

5

1 m m 1

mm

m mm (included with 4 m 4 m mm sensor head)CDX-30A/-W30A

Power supply/external input cable

ø50 μm ø30 μm ø50 μm 50 μm 30 μm 50 μm

0 19.8 21.2 22.6 0 19.8 21.2 22.6

Distance (mm) Distance (mm) SYL-1208-G0M DOL-1204-G02M

DOL-1204-G05M

700 μm 1000 μm 2000 μm

¢ CDX-30A ¢ CDX-W30A If using an amplifier

Sensor/amplifier connection cable

ø140 μm ø30 μm ø140 μm 140 μm 30 μm 140 μm DSL-1204-G02M

0 25 30 35 0 25 30 35

Distance (mm) Distance (mm) CDX-85A/-W85A

1500 μm 2000 μm 2500 μm

¢ CDX-85A ¢ CDX-W85A If extending the cable

Sensor-to-amplifier extension cable

DSL-0804-G02M

ø120 μm ø70 μm ø120 μm 120 μm 70 μm 120 μm

DSL-0804-G05M

0 65 85 105 0 65 85 105

Distance (mm) Distance (mm)

Amplifier unit

2000 μm 4000 μm 6000 μm

¢ CDX-150A ¢ CDX-W150A

CDX-150A/-W150A

CDA-M

ø300 μm ø120 μm ø300 μm 300 μm 120 μm 300 μm Ensure that the overall cable length from the power supply to the sensor head is within 30 m, and the number of Sensor Head Extension Cables to be connected must be up to two.

Also ensure that the overall cable length when the CDA-M amplifier unit is used is within 10 m.

0 110 150 195 0 110 150 195 (This length restriction does not apply to the Ethernet cable.)

Distance (mm) Distance (mm)

14 15

Page16

Ultra High-Accuracy Laser Displacement Sensor

CDX series

New models added

Attention: Not to be Used for Personnel Protection.

Never use these products as sensing devices for personnel protection. Doing so could lead to serious injury or death.

These sensors do not include the self-checking redundant circuitry necessary to allow their use in personnel safety applications.

A sensor failure or malfunction can cause either an energized or de-energized sensor output condition.

Please consult our distributors about safety products which meet OSHA, ANSI and IEC standards for personnel protection.

● Specifications are subject to change without prior notice.

● Specifications and technical information not mentioned here are written in Instruction Manual. Or visit our website for details.

● All the warnings and cautions to know prior to use are given in Instruction Manual.

World’s No. 1 Linearity

91 Chudoji-Awata-cho Shimogyo-ku Kyoto 600-8815 JAPAN

TEL. +81-75-325-1314 FAX. +81-75-325-2936

http://www.optex-fa.com

Catalog content accurate as of January 2018. 78021-01-008-1801 OPTEX FA CO., LTD.