1/2ページ

Download(459.6Kb)

Long Lifetime, High Reliability

Features, custom specifications, and reliability test data of Futaba's tab leads are introduced here. Please feel free to contact us for more detailed explanations, sample requests, or quotation requests.

Document Information

| Document Title | Tab Lead for Lithium-ion capacitors & Batteries |

|---|---|

| Document Type | Product Catalog |

| File size | 459.6Kb |

| Category | |

| Company | 双葉電子工業株式会社 (Documents List) |

Document Contents

Page1

For Lithium-ion capacitors & Batteries

Long Lifetime ・ High Reliability

Tab Lead

The tab leads, which are the terminals that take the electricity out of a laminated battery, are

an important component of a high-quality battery. The automotive industry demands the

highest level of quality and quality assurance systems, including IATF 16949.

Futaba supplies tab leads that can be made because of our extensive delivery experience of

touch sensors and OLEDs in the automotive industry.

Features

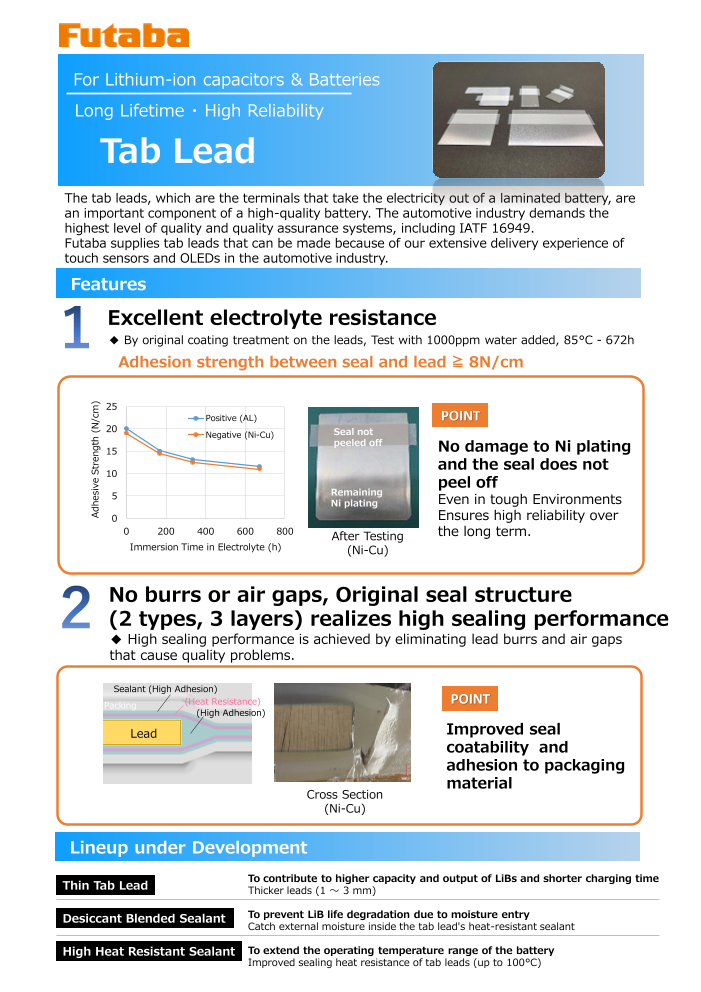

Excellent electrolyte resistance

◆ By original coating treatment on the leads, Test with 1000ppm water added, 85°C - 672h

Adhesion strength between seal and lead ≧ 8N/cm

25

Positive (AL) POINT

20

Negative (Ni-Cu) Seal not

peeled off

15 No damage to Ni plating

and the seal does not

10

peel off

5 Remaining

Ni plating Even in tough Environments

0 Ensures high reliability over

0 200 400 600 800 After Testing the long term.

Immersion Time in Electrolyte (h) (Ni-Cu)

No burrs or air gaps, Original seal structure

(2 types, 3 layers) realizes high sealing performance

◆ High sealing performance is achieved by eliminating lead burrs and air gaps

that cause quality problems.

Sealant (High Adhesion)

Packing (Heat Resistance) POINT

(High Adhesion)

Lead Improved seal

coatability and

adhesion to packaging

material

Cross Section

(Ni-Cu)

Lineup under Development

To contribute to higher capacity and output of LiBs and shorter charging time

Thin Tab Lead Thicker leads (1 ~ 3 mm)

Desiccant Blended Sealant To prevent LiB life degradation due to moisture entry

Catch external moisture inside the tab lead's heat-resistant sealant

High Heat Resistant Sealant To extend the operating temperature range of the battery

Improved sealing heat resistance of tab leads (up to 100°C)

Adhesive Strength (N/cm)

Page2

Specifications

Futaba can offer special shapes such as L-shape, hole, thick lead, L-bending, etc.

L Shape Hole Thick L Bending

■Specifications

Materials Coating t【mm】 W【mm】 L【mm】

AL (L)

Positive Non-Chromium 0.2~0.5 15~70 30~100 (t)

A1050-H24

(W)

Ni-Cu

Negative Non-Chromium 0.2~0.5 15~70 30~100

C1020-1/2H (t)

Structure Lead Edge (W)

Sealant 0.15 5~20

PP/Heat Resistance PP/PP +2~5 (L)

※We are pleased to consult with you regarding materials and shapes other

than those listed above, as well as dimensions outside the range.

■Standard Sample Specifications

Materials Coating t【mm】 W【mm】 L【mm】

AL

Positive Non-Chromium 0.4 50 60

A1050-H24

Ni-Cu

Negative Non-Chromium 0.2 50 60

C1020-1/2H

Structure Lead Edge

Sealant 0.15 15

PP/Heat Resistance PP/PP +3

Reliability Test Data

Teat Conditions Judgement

Adhesion Strength Sealant - Lead

Electrolyte Resistance Moisture 1000ppm, 85℃-672h

≧8N/cm

High Temperature Adhesion Strength Sealant - Lead

90℃-2400h (100 days)

Storage ≧15N/cm

-40℃ (15min)~70℃ (15min) Adhesion Strength Sealant - Lead

Thermal Shock

×800cycle ≧15N/cm

Quality & Process Control

We manufacture Touch Sensors (TS) and Organic Light

Emitting Diode (OLED) displays for automotive applications.

As with these products. Tab lead will also be controlled in

accordance with IATF16949. In addition, a two-dimensional

code is printed on each tab lead, and traceability is

controlled by quality analysis software.

Futaba Corporation

Futaba Web Site

< Contact us >

Electronic Components Business Center, Sales & Marketing Department

TEL:+81-3-4316-4815 FAX:+81-3-4316-4822 e-mail: ftbele@futaba.co.jp

The information in this leaflet is current as of April 2022. The information is subject to change without notice. 202204A