1/6ページ

Download(2.1Mb)

CNC Precision Double Column Type Surface Grinding Machine Travelling Cross rail Type DCG-NC UDG-NC(Ultra Precision Type) Stationary Cross rail Type PSG-CHNC UPG-NC(Ultra Precision Type)

Product Catalog

Best machine for complex slideway of machine tool.

In order to get high level of accuracy in entire table area, crossrail have own designed adjustment mechanism for adjust the straightness.Cross making by crowning grind for against bend by head traveling.Having mechanical adjust mechanism for cross rail straightness to correct aging error without remove.

Prepared crowning system as option for suit machine tools frame.

Movie

Document Information

| Document Title | CNC Precision Double Column Type Surface Grinding Machine Travelling Cross rail Type DCG-NC UDG-NC(Ultra Precision Type) Stationary Cross rail Type PSG-CHNC UPG-NC(Ultra Precision Type) |

|---|---|

| Document Type | Product Catalog |

| File size | 2.1Mb |

| Category | |

| Company | OKAMOTO MACHINE TOOL WORKS,LTD (Documents List) |

Documents related to this company

Document Contents

Page1

CNC Precision Double Column Type Surface Grinding Machine

DCG-NC

Travelling Cross rail Type

UDG-NC(Ultra Precision Type)

Stationary Cross rail Type PSG-CHNC

UPG-NC(Ultra Precision Type)

OKAMOTO MACHINE TOOL WORKS, LTD.

2993 Gobara, Annaka, Gunma, Japan 379-0135

TEL : +81-27-388-9595 FAX : +81-27-385-1144

URL : https://www.okamoto.co.jp JQA-QMA10960

Annaka Factory

*Prior to and while using our products you are requested to thoroughly go through the articles on danger,

warning and attention for the sake of safety described in operation manual attached to the machine

and also in the warning plates mounted on the machine.

CAUTION *When the products fall under the export controlled goods stipulated in“ Foreign Exchange and Foreign

Trade Act”, it requires the license or approval of Government of Japan when exporting out of Japan.

*Specifications subject to change without notice. This printed matter uses environmentally friendly paper and vegetable oil inks

Printed in Japan in Apr. 2024 2024041000AD-01

Page2

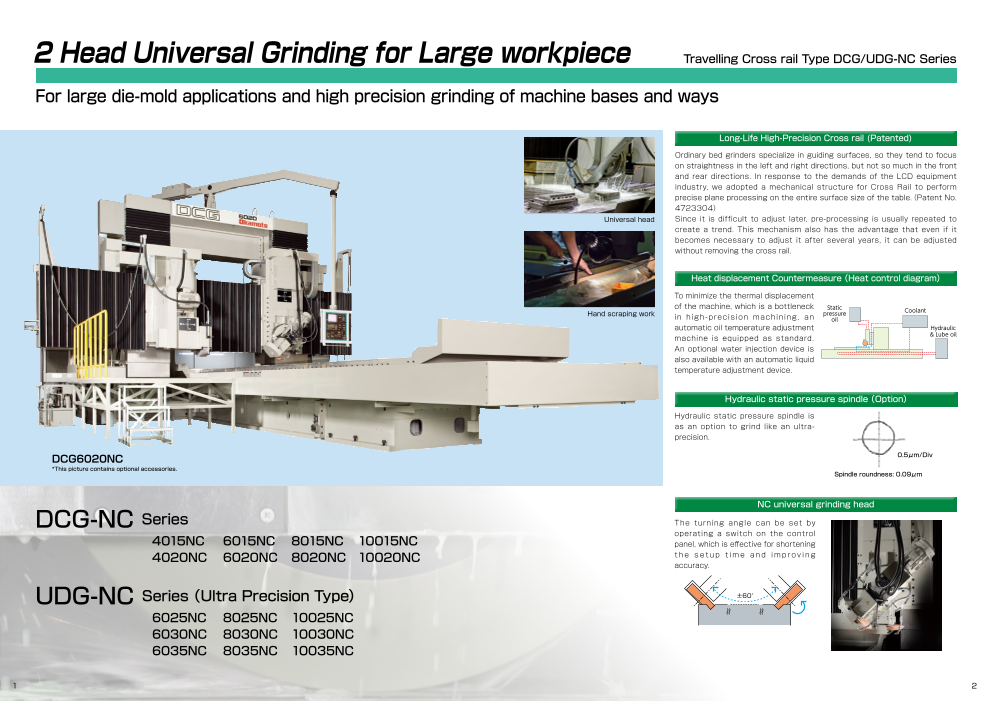

2 Head Universal Grinding for Large workpiece Travelling Cross rail Type DCG/UDG-NC Series

For large die-mold applications and high precision grinding of machine bases and ways

Long-Life High-Precision Cross rail (Patented)

Ordinary bed grinders specialize in guiding surfaces, so they tend to focus

on straightness in the left and right directions, but not so much in the front

and rear directions. In response to the demands of the LCD equipment

industry, we adopted a mechanical structure for Cross Rail to perform

precise plane processing on the entire surface size of the table. (Patent No.

4723304)

Universal head Since it is difficult to adjust later, pre-processing is usually repeated to

create a trend. This mechanism also has the advantage that even if it

becomes necessary to adjust it after several years, it can be adjusted

without removing the cross rail.

Heat displacement Countermeasure( Heat control diagram)

To minimize the thermal displacement

of the machine, which is a bottleneck Static

Hand scraping work pressure Coolant

in high -precision machining , an oil

automatic oil temperature adjustment Hydraulic

machine is equipped as standard. & Lube oil

An optional water injection device is

also available with an automatic liquid

temperature adjustment device.

Hydraulic static pressure spindle( Option)

Hydraulic static pressure spindle is

as an option to grind like an ultra-

precision.

DCG6020NC 0.5μm/Div

*This picture contains optional accessories.

Spindle roundness: 0.09μm

NC universal grinding head

DCG-NC Series The turning angle can be set by

operating a switch on the control

4015NC 6015NC 8015NC 10015NC panel, which is effective for shortening

4020NC 6020NC 8020NC 10020NC t he se tup t ime and imp r ov ing

accuracy.

UDG-NC Series( Ultra Precision Type) ±60°

6025NC 8025NC 10025NC

6030NC 8030NC 10030NC

6035NC 8035NC 10035NC

1 2

Page3

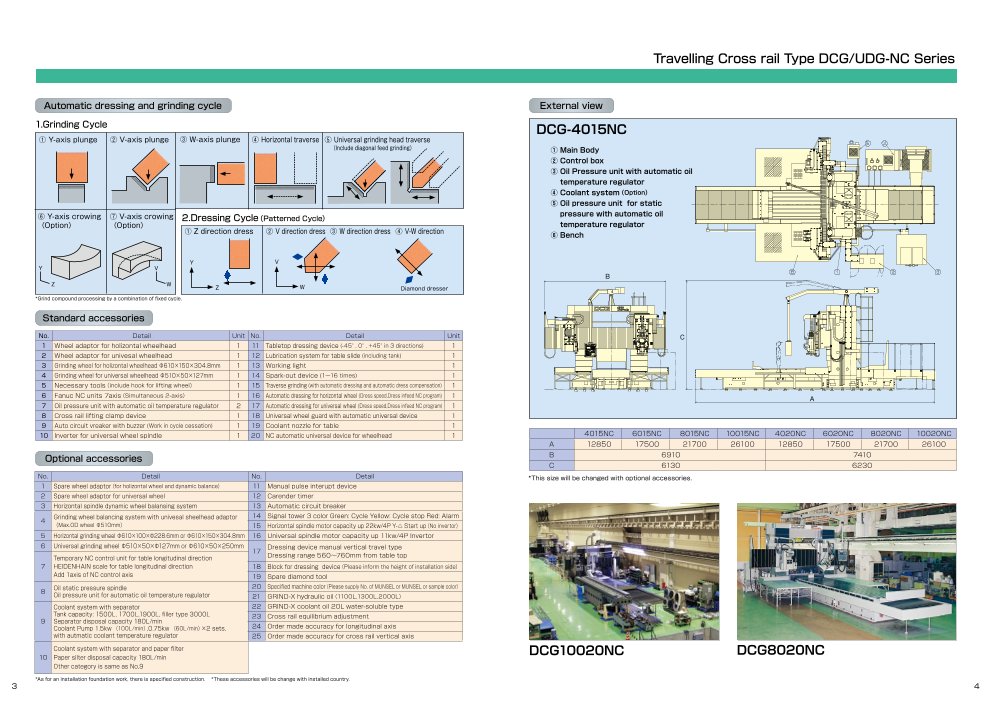

Travelling Cross rail Type DCG/UDG-NC Series

Automatic dressing and grinding cycle External view

1.Grinding Cycle DCG-4015NC

① Y-axis plunge ② V-axis plunge ③ W-axis plunge ④ Horizontal traverse ⑤ Universal grinding head traverse

(Include diagonal feed grinding) ① Main Body

② Control box

③ Oil Pressure unit with automatic oil

temperature regulator

④ Coolant system( Option)

⑤ Oil pressure unit for static

⑥ Y-axis crowing ⑦ V-axis crowing 2.Dressing Cycle(Patterned Cycle) pressure with automatic oil

(Option) (Option) temperature regulator

① Z direction dress ② V direction dress ③ W direction dress ④ V-W direction ⑥ Bench

Y V

Y V

B

Z W Z W Diamond dresser

*Grind compound processing by a combination of fixed cycle.

Standard accessories

No. Detail Unit No. Detail Unit C

1 Wheel adaptor for holizontal wheelhead 1 11 Tabletop dressing device (-45°, 0°, +45°in 3 directions) 1

2 Wheel adaptor for univesal wheelhead 1 12 Lubrication system for table slide (including tank) 1

3 Grinding wheel for holizontal wheelhead Φ610×150×304.8mm 1 13 Working light 1

4 Grinding wheel for universal wheelhead Φ510×50×127mm 1 14 Spark-out device (1~16 times) 1

5 Necessary tools(include hook for lifting wheel) 1 15 Traverse grinding (with automatic dressing and automatic dress compensation) 1

6 Fanuc NC units 7axis(Simultaneous 2-axis) 1 16 Automatic dressing for horizontal wheel (Dress speed,Dress infeed NC program) 1 A

7 Oil pressure unit with automatic oil temperature regulator 2 17 Automatic dressing for universal wheel (Dress speed,Dress infeed NC program) 1

8 Cross rail lifting clamp device 1 18 Universal wheel guard with automatic universal device 1

9 Auto circuit vreaker with buzzer (Work in cycle cessation) 1 19 Coolant nozzle for table 1

10 Inverter for universal wheel spindle 1 20 NC automatic universal device for wheelhead 1 4015NC 6015NC 8015NC 10015NC 4020NC 6020NC 8020NC 10020NC

A 12850 17500 21700 26100 12850 17500 21700 26100

Optional accessories B 6910 7410

C 6130 6230

No. Detail No. Detail *This size will be changed with optional accessories.

1 Spare wheel adaptor(for holizontal wheel and dynamic balance) 11 Manual pulse interupt device

2 Spare wheel adaptor for universal wheel 12 Carender timer

3 Horizontal spindle dynamic wheel balansing system 13 Automatic circuit breaker

4 Grinding wheel balancing system with univesal sheelhead adaptor 14 Signal tower 3 color Green: Cycle Yellow: Cycle stop Red: Alarm

(Max.OD wheel Φ510mm) 15 Horizontal spindle motor capacity up 22kw/4P Y-△ Start up(No invertor)

5 Horizontal grinding wheel Φ610×100×Φ228.6mm or Φ610×150×304.8mm 16 Universal spindle motor capacity up 11kw/4P Invertor

6 Universal grinding wheel Φ510×50×Φ127mm or Φ610×50×250mm Dressing device manual vertical travel type

17

Temporary NC control unit for table longitudinal direction Dressing range 560~760mm from table top

7 HEIDENHAIN scale for table longitudinal direction 18 Block for dressing device(Please inform the height of installation side)

Add 1axis of NC control axis 19 Spare diamond tool

8 Oil static pressure spindle 20 Specified machine color(Please supply No. of MUNSEL or MUNSEL or sample color)

Oil pressure unit for automatic oil temperature regulator 21 GRIND-X hydraulic oil(1100L,1300L,2000L)

Coolant system with separator 22 GRIND-X coolant oil 20L water-soluble type

Tank capacity: 1500L, 1700L,1900L, filler type 3000L 23 Cross rail equilibrium adjustment

9 Separator disposal capacity 180L/min

Coolant Pump 1.5kw (100L/min),0.75kw (60L/min)×2 sets, 24 Order made accuracy for longitudinal axis

with autmatic coolant temperature regulator 25 Order made accuracy for cross rail vertical axis

Coolant system with separator and paper filter DCG10020NC DCG8020NC

10 Paper silter disposal capacity 180L/min

Other category is same as No,9

*As for an installation foundation work, there is specified construction. *These accessories will be change with installed country.

3 4

Page4

Travelling Cross rail Type UDG-NC Series

Machine Specification (DCG series) Ultra precision surface grinder with variable

4015NC 6015NC 8015NC 10015NC 4020NC 6020NC 8020NC 10020NC hydraulic static pressure system

Max.grinding height mm 1500 1600(Standard) 1800(Option)

Table working length mm 4050 6050 8050 10050 4050 6050 8050 10050 Long-Life High-Precision Cross rail( Patented) Variable hydraulic static pressure system

Table working width mm 1500 2000

Capacity The problem of the double column grinding machine was deflection Longitudinal guideway is variable hydraulic

Max. pass width mm 2000 2500 of deteriorated. Okamoto developed an original cross rail adjusting static pressure system. This system is ideal

Table load capacity kg 12000 10000 13000 16000 14000 12000 18000 18000 mechanism. Even after several years after delivery, the adjustment for ultra-precision grinding. Flexibly controls

T-slot (width×No.) mm/No. 28×7 28×9 is possible without removing the cross rail, and the high quality of the amount of oil on the slide to minimize

Longitudinal Max.travel mm 4500 6500 8500 10500 4500 6500 8500 10500 flatness is maintained in entire width of the work surface. changes in the oil film.

Feed Longitudinal feed rate m/min 5~30

Max. rapid feed mm/min 3000

Cross Feed

Minimum increment mm 0.0001 UDG10035NC

Y-axis vertical travel mm 250

Grinding wheel V-axis vertical travel mm 500

head Max. rapid feed mm/min 1000

Minimum increment mm 0.0001

Universal Max. travel deg ±60°

grinding wheel Max. rapid feed min-1 2

head Minimum increment deg 0.001°

Cross rail Max.travel mm 1550 1650

vertical Feed rate(50Hz/60Hz) mm/min 510

movement Minimum increment mm 0.0001

Wheel size mm ∅610×150×∅304.8

Main grinding

wheel head Speed min-1 940

Motor kW 15(Standard),22(Option)

Universal Wheel size mm ∅510×50×∅127,∅610×50×∅250(Option)

grinding wheel Speed min-1 900~3000

head Motor kW 7.5

Length mm 13400 17500 21700 26500 13400 17500 21700 26500 The biggest variable hydraulic static pressure double column grinder in the world.

Machine Space Width mm 6700 7900 8400 Table working length : 10m Table working width : 3.5m(Max pass width : 4.0m)

Height mm 5800 6000 UDG-CHLi Series -ATC/AWC System- Machine Specification

Power supply kVA 95 120 150

Machine Net Weight kg 74000 80000 88000 105000 79000 85000 95000 115000 UDG-CHLI series can be attached ATC/AWC system. Table linear Unit UDG10035NC

mortar drive system is as an option. UDG-CHLi series has good Max.grinding height mm 1800

Table working length mm 10050

positioning accuracy and high-speed stroke. Capacity Table working width mm 3500

Machine Specification (UDG series) Max. pass width mm 4000

Table load capacity kg 40000

Table straightness *Not guarantee

Cross rail slideway Longitudinal slideway Horizontal spindle Max.travel mm 10750

Longitudinal Feed

Wheel Size(mm) Longitudinal feed rate m/min 5~30

Size Specification Size Specification Specification Longitudinal :0.5µm/m Max. rapid feed mm/min 4800

Cross feed: 0.3µm/m Cross Feed

Minimum increment mm 0.0001

Horizontal ∅610×150×∅304.8 Machine Net Weight kg 250000

2500 6000

Standard:

Roller type slide Universal ∅510×50×∅127

(OP:∅610×150×∅250)

UDG-NC Standard: Standard:

Series Option: Hydraulic static slide Hydraulic static spindle

Hydraulic static

3000 slide 8000 Horizontal ∅760×150×∅304.8

3500 10000 Universal ∅510×50×∅127

(OP:∅610×150×∅250)

*Please contact us which size machine need.

Horizontal Spindle Universal Spindle Measuring Device

5 6

Page5

Single Head Surface Grinding for Large workpiece Stationary Cross rail Type PSG-CHNC Series

For large die-mold applications and high precision grinding of machine bases Long-Life High-Precision Cross rail (Patented) High precision specification

Ordinary bed grinders specialize in guiding surfaces, V-V guide way is standard for table longitudinal.

so they tend to focus on straightness in the left and Automatic oil temperature regulator countermeasure to

right directions, but not so much in the front and rear heat displacement of machine body.

directions. In response to the demands of the LCD Fully auto balancing system is as an option, this option

equipment industry, we adopted a mechanical structure is very comfortable for large wheel.

for Cross Rail to perform precise plane processing

on the entire surface size of the table. (Patent No.

4723304)

Since it is difficult to adjust later, pre-processing is

usually repeated to create a trend. This mechanism

also has the advantage that even if it becomes

necessary to adjust it after several years, it can be

adjusted without removing the cross rail.

Easy operation Shift plunge mode Semi-automatic mode

C o nve r sa t i o n p r o g r am o f a l l I n the rough g r ind ing cyc le , Semi-automatic mode can grind like

automatic cycle from grinding to gr inding al lowance is ground manual grind such as easy surface

dressing. e f f ic ient l y w i th sh i f t p lunge grinding.

Input the positioning for wheel grinding cycle.

PSG4025CHNC stroke with teaching.

*This picture contains optional accessories. Shift amount

Wheel ● ● ● Fine grind

amount

Finish

Standard accessories

No. Detail Unit No. Detail Unit

1 Wheel adaptor 1 6 Lifting bolt for grinding wheel adaptor 1

2 GRIND-X wheel(Φ510×100×Φ203.2) 1 7 Tabletop dresser (with 3 ct of diamond tool) 1

3 Foundation plate or Anchor bolt 1 8 Conversational software 1

4 Necessary tools (with tool box) 1 9 Table full wide shower coolant system and pump 1

5 Working light 1 10 Manual pulse interruption device 1

PSG-CHNC Series PSG3020CHNC

*This picture contains optional accessories. Optional accessories

2010CHNC 3010CHNC No. Detail No. Detail

1 Coolant system with separator and temperature 12 Automatic circuit breaker

2015CHNC 3015CHNC 4015CHNC 2 Coolant system with separator, paper filter and temperature 13 Signal tower *3 Colors

3020CHNC 4020CHNC 3 Coolant system with separator, bag filter and temperature 14 Order made accuracy for longitudinal and cross feed

4 Electro magnetic chuck for each size machines 15 Large size of wheel guard *For Φ610mm

UPG-NC 5 Automatic demagnetizing controller for electro magnetic chuck 16 Grind-X hydraulic oil 600L

Series( Ultra Precision type) 6 Electro permanent magnetic chuck for each size machines 17 Grind-X coolant oil 20L

7 Spindle inverter 18 Spindle oil for hydrostatic spindle 80L

6025CHNC 8025CHNC 10025CHNC 8 Hydrostatic spindle with tank and temperature 19 Pendant type operation panel

6030CHNC 8030CHNC 10030CHNC 9 Fully automatic wheel balancer 20 T-slot table *Size of T and pitch are Okamoto standard

10 Fully automatic wheel balancer adopter 21 Order made color

6035CHNC 8035CHNC 10035CHNC 11 Crowning mode *Longitudinal

7 8

Page6

Stationary Cross rail Type PSG-CHNC Series

Machine Specification( PSG-CHNC series) Various order made customizations are available

Horizontal type 2 spindle type based on the CHNC series.

(Horizontal type・Universal type)

1000 Series 1500 Series 2000 Series 1000 Series

Unit

2010CHNC 3010CHNC 2015CHNC 3015CHNC 4015CHNC 3020CHNC 4020CHNC 2010CHVNC 3010CHVNC PSG3010CVNC ( Universal spindle type)

Horizontal type: Horizontal type:

Workpiece Max.Grinding size mm 2000×1050 3000×1050 2000×1550 3000×1550 4000×1550 3000×2050 4000×2050 2000×1050 3000×1050

*without Universal type: Universal type:

chuck 1500×1050 2570×1050

condition Max.Grinding height mm 700

Max.Pass width mm 1300 1800 2500 1300

Table Working size mm 2050×1050 3050×1050 2050×1550 3050×1550 4050×1550 3050×2050 4050×2050 2050×1050 3050×1550

*includeing Table load capacity kg 4600 6900 5400 8100 10800 9200 12300 4600 69000

chuck Chuck weight kg 1560 2340 2360 3540 4720 4620 6160 1560 2340

Longitudinal Max.travel mm 2250 3250 2250 3250 4250 3250 4250 2250 3250

Feed Longitudinal feed rate m/min 2~30

Cross Max.Travel mm 1170 1670 2170 ー

Feed Rapid feed rate mm/min 5000 1500

Max.Travel mm 740 860 740

Vertical

Rapid feed rate mm/min 1500 1500

Tilt Rapid feed rate deg/min ー 150 720

axis Minimum increment deg/min ー 0.0001 0.001

Horizontal type: Horizontal type:

∅510×100×∅ ∅510×100×∅

Wheel size mm ∅510(Option:∅610)×100×∅203.2 ∅610×100×∅203.2 203.2 304.8 Dressing

Universal Universal type:

grinding ∅510×50×∅127

wheel Horizontal type:980

head Speed min-1 980(Option:850) 850

Universal type:300~2400

Horizontal type:15

Motor kW 15(Option:22)

Universal type:7.5

Length mm 7300 8650 7300 8650 10950 8650 11310 7943 9320

Machine

Space Width mm 4100 4100 4600 4600 4600 4800 6833 7470 6870 Grinding

Height mm 4100 4100 4100 4100 4100 4100 4100 4330 4415

Machine Net Weight kg 18500 21000 21500 24500 28000 35000 40000 26000 40000

* Floor space changes with options.

Machine Specification( UPG-CHNC series)

Cross rail slideway Longitudinal slideway Horizontal spindle

Wheel Size(mm)

Size Specification Size Specification Specification

2500 6000 ∅610×150×∅304.8 PSG2010CHVNC (2 spindle type)

Standard:

Roller type slide

UPG-CHNC Series 3000 8000 Standard:Hydraulic Standard:Hydraulic

static slide static spindle Horizontal

Option:

Hydraulic static slide ∅760×150×∅304.8

3500 10000

*Please contact us which size machine need.

ATC(Auto Tool Changer)

ATC can be attached as a special accessories

for UDG-CHLi series.

PSG2010CHVNC

Max is 4 wheels

9 10