Column type Precision Surface Grinding Machine Series

PSG-DX Series

PSG-iQ Series

PSG-DXNC Series

UPG-NC Series

OKAMOTO MACHINE TOOL WORKS, LTD.

2993 Gobara, Annaka, Gunma, Japan 379-0135

TEL : +81-27-388-9595 FAX : +81-27-385-1144

URL : https://www.okamoto.co.jp JQA-QMA10960

Annaka Factory

*Prior to and while using our products you are requested to thoroughly go through the articles on danger,

warning and attention for the sake of safety described in operation manual attached to the machine

and also in the warning plates mounted on the machine.

CAUTION *When the products fall under the export controlled goods stipulated in“ Foreign Exchange and Foreign

Trade Act”, it requires the license or approval of Government of Japan when exporting out of Japan.

*Specifications subject to change without notice. This printed matter uses environmentally friendly paper and vegetable oil inks

Printed in Japan in Sep. 2023 2023091000AD-01

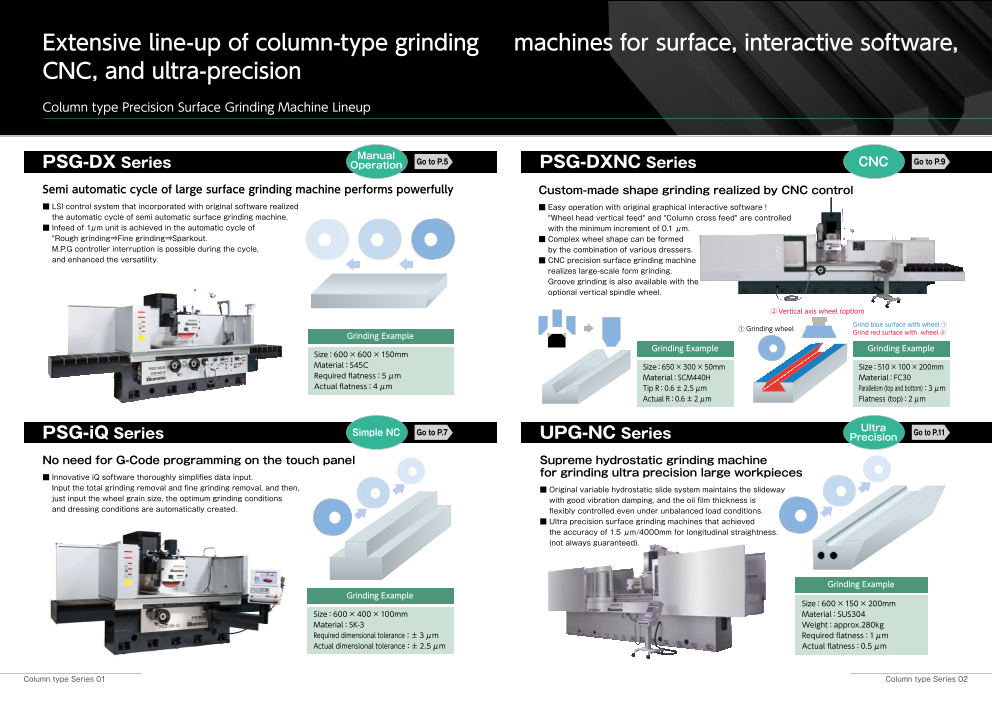

Extensive line-up of column-type grinding machines for surface, interactive software,

CNC, and ultra-precision

Column type Precision Surface Grinding Machine Lineup

PSG-DX Series Manual

Operation Go to P.5 PSG-DXNC Series CNC Go to P.9

Semi automatic cycle of large surface grinding machine performs powerfully Custom-made shape grinding realized by CNC control

■ LSI control system that incorporated with original software realized ■ Easy operation with original graphical interactive software !

the automatic cycle of semi automatic surface grinding machine. "Wheel head vertical feed" and "Column cross feed" are controlled

■ Infeed of 1μm unit is achieved in the automatic cycle of with the minimum increment of 0.1 μm.

"Rough grinding⇒Fine grinding⇒Sparkout. ■ Complex wheel shape can be formed

M.P.G controller interruption is possible during the cycle, by the combination of various dressers.

and enhanced the versatility. ■ CNC precision surface grinding machine

realizes large-scale form grinding.

Groove grinding is also available with the

optional vertical spindle wheel.

②Vertical axis wheel (option)

① Grinding wheel Grind blue surface with wheel ①

Grinding Example Grind red surface with wheel ②

Grinding Example Grinding Example

Size:600×600×150mm

Material:S45C Size:650×300×50mm Size:510×100×200mm

Required flatness:5μm Material:SCM440H Material:FC30

Actual flatness:4μm Tip R:0.6±2.5μm Parallelism (top and bottom):3μm

Actual R:0.6±2μm Flatness (top):2μm

PSG-iQ Series Simple NC Go to P.7 UPG-NC Series Ultra

Precision Go to P.11

No need for G-Code programming on the touch panel Supreme hydrostatic grinding machine

■ Innovative iQ software thoroughly simplifies data input. for grinding ultra precision large workpieces

Input the total grinding removal and fine grinding removal, and then, ■ Original variable hydrostatic slide system maintains the slideway

just input the wheel grain size, the optimum grinding conditions with good vibration damping, and the oil film thickness is

and dressing conditions are automatically created. flexibly controlled even under unbalanced load conditions.

■ Ultra precision surface grinding machines that achieved

the accuracy of 1.5 μm/4000mm for longitudinal straightness.

(not always guaranteed).

Grinding Example

Grinding Example

Size:600×150×200mm

Size:600×400×100mm Material:SUS304

Material:SK-3 Weight:approx.280kg

Required dimensional tolerance:±3μm Required flatness:1μm

Actual dimensional tolerance:±2.5μm Actual flatness:0.5μm

Column type Series 01 Column type Series 02

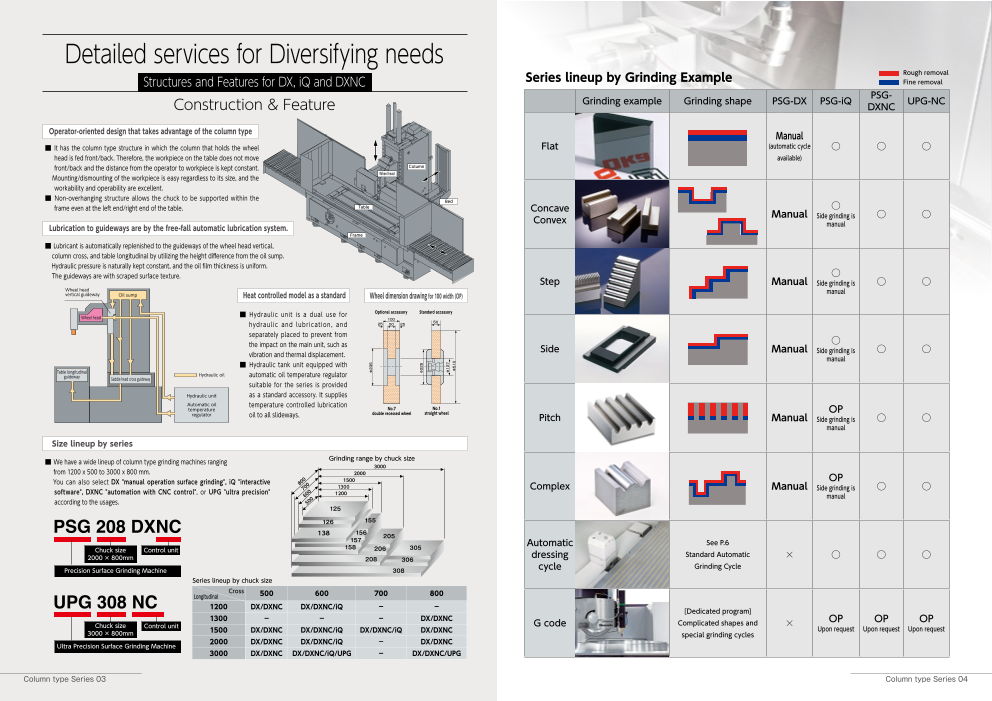

Detailed services for Diversifying needs

Rough removal

Structures and Features for DX, iQ and DXNC Series lineup by Grinding Example Fine removal

Construction & Feature Grinding example Grinding shape PSG-DX PSG-iQ PSG-

DXNC UPG-NC

Operator-oriented design that takes advantage of the column type Manual

■ It has the column type structure in which the column that holds the wheel Flat (automatic cycle ○ ○ ○

head is fed front/back. Therefore, the workpiece on the table does not move available)

front/back and the distance from the operator to workpiece is kept constant. Column

Wheel head

Mounting/dismounting of the workpiece is easy regardless to its size, and the

workability and operability are excellent.

■ Non-overhanging structure allows the chuck to be supported within the Bed

frame even at the left end/right end of the table. Table Concave ○

Convex Manual Side grinding is ○ ○

Lubrication to guideways are by the free-fall automatic lubrication system. manual

Frame

■ Lubricant is automatically replenished to the guideways of the wheel head vertical,

column cross, and table longitudinal by utilizing the height difference from the oil sump.

Hydraulic pressure is naturally kept constant, and the oil film thickness is uniform.

The guideways are with scraped surface texture. ○

Step Manual Side grinding is ○ ○

Wheel head

vertical guideway Oil sump Heat controlled model as a standard Wheel dimension drawing for 100 width (OP) manual

Wheel head ■ Hydraulic unit is a dual use for

hydraul ic and lubr icat ion , and

separately placed to prevent from

the impact on the main unit, such as ○

vibration and thermal displacement. Side Manual Side grinding is ○ ○

manual

■ Hydraulic tank unit equipped with

Table longitudinal

guideway Hydraulic oil automatic oil temperature regulator

Saddle head cross guideway

suitable for the series is provided

Hydraulic unit as a standard accessory. It supplies

Automatic oil temperature controlled lubrication

temperature

regulator oil to all slideways. OP

Pitch Manual Side grinding is ○ ○

manual

Size lineup by series

■ We have a wide lineup of column type grinding machines ranging Grinding range by chuck size

3000

from 1200 x 500 to 3000 x 800 mm. 2000

You can also select DX "manual operation surface grinding", iQ "interactive 80

0 1500 OP

70

0 1300

software", DXNC "automation with CNC control", or UPG "ultra precision" Complex Manual Side grinding is ○ ○

60

0 1200 manual

according to the usages. 50

0

125

PSG 208 DXNC 126 155

138 156 205

157 Automatic See P.6

Chuck size Control unit 158 206 305

2000 × 800mm dressing Standard Automatic

208 306 × ○ ○ ○

Precision Surface Grinding Machine cycle Grinding Cycle

308

Series lineup by chuck size

Cross

UPG 308 NC Longitudinal 500 600 700 800

1200 DX/DXNC DX/DXNC/iQ - - [Dedicated program]

1300 - - - DX/DXNC

Chuck size Control unit G code Complicated shapes and × OP OP OP

3000 × 800mm 1500 DX/DXNC DX/DXNC/iQ DX/DXNC/iQ DX/DXNC Upon request Upon request Upon request

special grinding cycles

Ultra Precision Surface Grinding Machine 2000 DX/DXNC DX/DXNC/iQ - DX/DXNC

3000 DX/DXNC DX/DXNC/iQ/UPG - DX/DXNC/UPG

Column type Series 03 Column type Series 04

Best selling large grinding machines which prioritize 1μm unit precision infeed and manual operation Operation panel

Column Type

Precision Surface Grinding Machine PSG-DX Series

❾ ❿

❻ ❽

⓫

❹

❷ ❺ ❼

❶ ❸

⓬

❶ Table longitudinal feed handle ❻ Column speed adjusting dial ❾ Table left travel switch

❷ Column cross selector switch ❼ Dressing speed adjusting knob ❿ Table right travel switch

❸ Column crossfeed handle and dressing cross direction ⓫ Table right end stop switch

❹ Vertical axis portable M.P.G. controller selector lever ⓬ Grinding mode selector switch

❺ Crossfeed direction switch ❽ Table speed adjusting dial

⓬ Grinding mode selector switch

PSG156DX ⓭ ⓯

⓰ ⓲ Traverse…Infeed at the end of each column crossfeed reversal

⓱ ⓳ ●21 ●22 ●23 Plunge 1…One infeed per table stroke (right end infeed)

Optimum to manual grinding of large castings and die/mold plates ⓮ ⓴ Plunge 2… Two infeeds per table stroke (both ends infeed)

●24 ●25

Manual operation type large grinding machines integrated with original software. ❹ Vertical axis portable M.P.G. controller

Vertical feed mechanism is AC servo motor feed which enables the minimum increment of 1μm. Manual interruption during cycle operation is enabled, control system is putting priority in the

operability of manual grinding machine. When manually interrupted with the M.P.G. controller, the

Best selling series for flexibly grinding small to large sizes. current infeeding position is always feedbacked and displayed in digital, and immediately after release

of manual interruption, the automatic operation resumes to finish remaining grinding.The operation box

is a handy type that enables feed 1 graduation 0.001 mm and 1 revolution 0.1 mm, and when the tall

workpiece is ground which cannot be reached with the handle, the fine feeding is possible by visually

Operator-oriented design that takes advantage of column type checking the current position display. When not using, it can be hanged on the operation panel.

■ Taking advantage of that the operator can access to the table regardless of the ⓭Wheel head rapid feed switch ⓴Total grinding amount reset switch Grinding amount setting

workpiece size, the handwheels and operation panel are located at the operator's ⓮ Rapid feed/jog feed selector switch ●21 Mode selector switch The total grinding amount can be set in 1 μm scale

waist. ⓯ Vertical position display ●22 Rough infeed amount switch using LED digital display, and switching fine/rough

When operating the wheel spindle up and down, the infeed start position can be ●23 Fine grinding allowance switch grinding is done simply by setting the fine grinding

easily set with the portable M.P.G. controller. ⓰Cross position display (optional)

Rhythmical and accurate operability is realized. ⓱ Total grinding amount input switch ●24 Fine infeed amount switch (0.001 to 0.05 mm) amount with the fine grinding amount switch.

Safety is also fully considered such as the handwheels are interlocked during ⓲ Vertical reset switch ●25 Sparkout switch (0 to 5 times) Fine grinding amount setting is 8 steps of 2, 5, 10,

15, 20, 30, 40, 50 μm.

automatic operation, and the covers for reversing dogs are installed. ⓳ Cross reset switch

1μm scale high precision feed with AC servo motor pulse control Standard automatic grinding cycle

Vertical axis portable M.P.G. controller

■ Vertical AC servo motor feed is adopted. Feed range of 1 to 5μm

is achieved with simple handles and switches.

■ Dressing operation is easily performed with the overhead dresser

that comes as a standard accessory. Initial dressing

(done manually for DX) Rough gri Dressing before finishing Sparkout Manual

nding (done manually for DX) Fine grinding (0 to 5 times) rapid feed

Digital switch system makes the condition setup accurate and easy

■ The automatic grinding cycle of"Rough grinding ⇒ Fine grinding ⇒

Sparkout ⇒ Table right end stop" can be easily set.

It is also possible to set the total removal and the number of sparkouts

(0 to 5 times).

Overhead dresser (Vertical re tract function - option)

Column type Series 05 Column type Series 06

Latest grinding machines with the automatic dressing and automatic calculation function for grinding conditions Grinding data screen

Column Type

NC Precision Surface Grinding Machine PSG-iQ Series Mode selection menu

Table setting Dressing data Grinding data Combination Data save/

grinding recall/edit

Touch panel iQ software makes the surface grinding of large workpieces easy Grinding shape selection menu

iQ software thoroughly simplifies the data input with the novel idea. Flat Concave Convex Pitch Contouring

(upon request/optional) Step Side

(upon request/optional) (upon request/optional)

Cycle time is greatly shorten.

The functions to enable high precision Parameter

grinding are equipped as standard. Standard setting (the screen is work datum)

① Step/bias selection

② Chuck datum/work datum selection

③ Air cut amount setting

① Wheel shape display in grinding

❶ ② Changing the dressing conditions during a cycle

Corrective grinding

❷

❸ Datum selection

PSG126iQ

* The photo includes optional accessories.

Work datum

iQ automatic data creation function by inputting grinding wheel grain size Parameter Rough and fine

■ Input the total grinding removal and fine grinding removal, and then, just input the wheel grain ❶ Rough grinding infeed amount & cross feed speed (F key) grinding

Inching key

size, the optimum grinding conditions and dressing conditions are automatically created. ❷ Fine grinding infeed amount & cross feed speed (F key)

Data input is completed with only 2-screen touches ❸ Left side: Sparkout (timer setting)

Right side: iQ cycle time prediction Chuck datum

■ No text are shown on the screen. You just touch the screen while watching the panel buttons.

Versatile iQ functions Function and Accuracy are UP !

■ Tips to greatly shorten the cycle time ■ It is equipped with a wheel spindle continuous variable

The cycle time can be greatly reduced by combining the speed controller, an automatic oil temperature regulator,

overhead dresser correction function, shift plunge function, and an oil-cooled wheel head as standard accessories,

tabletop dresser function. which contribute to the

■ Cycle time prediction function improved accuracy.

iQ grinding screen iQ dressing screen Grinding completed The finish time display ease your time arrangement. ■ The front cover can be

■ Graphical current grinding position display changed to the slide

Grinding shape selection If you need side grinding, please contact us. The positions to be ground is displayed. type in option.

Red=rough g. Blue=fine g. (standard: insertion cover)

Slide type cover (option)

Dressing form selection Dresser selection

Flat Concave (top only) Convex (top only) Step (top only)

Straight Side (option) Single-direction dresser External dresser Three-direction dresser Rotary dresser

side grinding is performed manually. (standard) (standard) (special option, upon request) (special option, upon request)

Column type Series 07 Column type Series 08

CNC grinding machine with minimum increment of 0.1μm that meets a variety of grinding needs Graphical interactive software is equipped (typical screens)

■ PSG-DXNC series is equipped with the graphical interactive program software for the operators new to the NC program.

Column Type CNC Precision

Surface Grinding Machine PSG-DXNC Series MEIN Menu Dresser Menu Grinding wheel form menu

High spec CNC grinding machines that realize on-machine measuring, swiveling wheel spindle, and complex wheel forming.

Original graphic interactive software and high follow-up capability realize the high-performance grinding machines.

Various options are available such as on-machine measuring, swiveling wheel spindle,

complex wheel forming, and various dressers.

Wide variety of grinding operations are supported

by the 2-axis simultaneous

control with 0.1 μm Grinding pattern menu Dressing menu Grinding menu

minimum increment

of vertical feed.

PSG306DXNC

Systems that support high precision Various dressers (option) Work datum and chuck datum

■ High follow-up capability is guaranteed by the simultaneous ■ To support your various grinding, we prepared the dressers ■ The workpiece dimensions and remaining allowance, etc. can be perceived easier by using the

2-axis control (cross and vertical) as standard that add the trend on the wheel as an option.

■ Vertical feed minimum increment is controlled by 0.1μm positioning method of dressing datum and work datum than using the absolute coordinate.

■ Oil-cooled wheel head is equipped as a standard, the

detailed temperature control system is adopted everywhere. For workpiece datum grinding For chuck datum grinding For workpiece datum grinding Y Z

Grinding

■ The rough-middle-finishing automatic grinding cycle and wheel Mechanical origin position Mechanical origin position Dressing position datum -A -B

automatic dressing cycles by the interactive software are Work datum position 0.0000 0.0000

equipped as standard. Wheel forming by the interactive Sizing position -C 0.0000

software is also supported. Single-point dresser Grinding Grinding

Work datum position wheel wheel *In this setting, the absolute coordinate Y is the grinding start

(=dressing position datum) A position Y=0.000, and the grinding finish position Y=C.

On-machine measuring unit (option) Sizing position

Sizing position A

For chuck datum grinding Y Z

■ The high positioning accuracy

is achieved by adding the C Work Dressing position datum -A -B

Work C

longitudinal axis control. The Work datum position 0.0000 0.0000

on-machine measurement Sizing position C 0.0000

is realized by installing the Three-point dresser Work datum position B

B (=dressing position datum) *In this setting, the absolute coordinate Y is the grinding start position

optional measuring unit. Y=C+Grinding margin, and the grinding finish position Y=C.

Interruption dressing during cycle Ample experience and optional supports

■ If you press the "Manual Dress Interrupt" button during the

automatic cycle, dressing is interrupted at the position while

remaining the finish point setting. Rotary dresser

Wheel swiveling model (special option)

■ A model in which the wheel spindle

swivels to grind the inner grooves

on workpieces. This is provided as

a special option since it requires the

information of the swiveling angle, etc. Swivel dresser Workpiece indexing unit (option) Swiveling rotary dresser + single-point dresser (option)

Column type Series 09 Column type Series 10

High-class machine with non-contact guideway that realizes the ultimate surface grinding Optional accessories

Item & Model Specification DX iQ DXNC Item & Model Specification DX iQ DXNC

1). Coolant Unit 8). Specified color ○ ○ ○

CNC Ultra Precision Surface 1.Coolant unit with magnetic dust separator Tank capacity:300L ○ ○ ○ 9). Wheel spindle

Grinding Machine UPG-NC Series 2.Coolant unit with magnetic dust separator ○ ○ ○ 1.Wheel spindle inverter Wheel spindle:7.5kW ○ - ○

Tank capacity:600L

with automatic paper filter ○ ○ ○ 2.Wheel spindle inverter Wheel spindle:11kW ○ Standard ○

3.Coolant unit with magnetic dust separator ○ ○ ○ 3.Wheel spindle inverter Wheel spindle:15kW ○ ○ ○

Variable hydrostatic slide system realizes stable high accuracy with automatic paper filter Tank capacity:600L ○ ○ ○ 4.wheel spindle motor output increase 11kW 6P ○ Standard ○

with automatic oil temperature regulator ○ ○ ○ 5.wheel spindle motor output increase 15kW 6P ○ ○ ○

Variable hydrostatic system with the original 6-face holding slide is equipped on the longitudinal slideway 4.With high precision filter/filtration unit ○ ○ ○ Hydrostatic tank with automatic oil

6.Hydrostatic wheel spindle ○ ○ ○

compared to the fixed type hydrostatic guideways, 5.Coolant nozzle for 75 mm width wheel ○ ○ ○ temperature regulator, with spindle oil

6.Coolant nozzle for 100 mm width wheel ○ ○ ○

by flexibly controlling the flowrate to the guideway, Stroke:220mm

7.3-way coolant nozzle for 50 mm width wheel ○ ○ ○ Wheel spindle motor:2.2kw

the fluctuation can be reduced to 1/7, 2). Chuck Applicable model Standard chuck size Rotation speed:

2850/3460min-1(50/60Hz)

125 1200×500×100㎜ 2-ream ○ - ○ 7.Vertical wheel spindle unit With angle dresser (DRA-5) ○ ○ ○

and the stable flatness against the bias 155 1500×500×100㎜ 3-ream ○ - ○ and angle dresser for bottom

surface (DRA-3). When 50

load is realized. 205 2000×500×100㎜ 4-ream ○ - ○ mm width is mounted, 11).2

305 3000×500×100㎜ 6-ream ○ - ○ is required.

The wear on the slideways are less, 1.Electromagnetic 126 1200×600×100㎜ 2-ream ○ ○ ○ 8.Vertical wheel spindle inverter 1200~4500min-1 ○ ○ ○

and the machine life became longer. chuck, 156 1500×600×100㎜ 2-ream ○ ○ ○ 10). Table

oil-cooled chuck, 206 2000×600×100㎜ 4-ream ○ ○ ○ 1.Cross microfeeder unit ○ - -

electro-permanent Minimum increment:

306 3000×600×100㎜ 6-ream ○ ○ ○ 2.Slideways high-precision model (longitudinal/cross feed) ○ ○ ○

magnetic chuck 0.0001mm

157 1500×700×100㎜ 2-ream ○ ○ ○ 3.Table longitudinal feed NC control - - ○

138 1300×800×100㎜ 2-ream ○ - ○ 11). Cover

UPG306NC 158 1500×800×100㎜ 2-ream ○ - ○ 1.Sliding door table cover 125,155,205,126,156,206 ○ ○ ○

What is Variable Hydrostatic Slide System ? 208 2000×800×100㎜ 2-ream ○ - ○ 2.Wheel guard for vertical wheel spindle mounting ○ ○ ○

308 3000×800×100㎜ 3-ream ○ - ○ 12). Oil cooling unit

■ Ultra Precise surface grinding is achieved this way; 2.Chuck plate (rear) ○ ○ ○ 1.Oil cooling pump installed ○ Standard Standard

the pair of 1 & 2 controls the flowrate of the oil 3.Chuck plate (left side) ○ ○ ○ 2.Oil-cooled wheel head ○ Standard Standard

hydrostatic pocket constant in real time, and the gap 4.Automatic demagnetizing controller (5A) Applicable mode:l 125,155,205,126,156,157 ○ ○ ○ 13). Instrument

amount between slides 3 & 4 is also maintained W1 P1 P3 W2 5.Automatic demagnetizing controller(10A) Applicable mode:l 305,206,138,158 ○ ○ ○ 1.Elapsed time indicator ○ ○ ○

constant. 1 2 6.Automatic demagnetizing controller(20A) Applicable mode:l 306,208,308 ○ ○ ○ 2.Calendar timer ○ ○ ○

0.0 0.0 0.0 0.0 -0.3 0.0 0.0 0.0 0.0

-0.2 0.0 -0.2 -0.3 0.0 -0.3 -0.2 0.0 -0.4 3). Digital Scale 3.Grinding time end prediction - Standard -

0.0 -0.2 0.0 0.0 -0.3 0.0 0.0 0.0 0.0

1.Cross digital scale Min. unit display:0.001㎜ ○ ○ ○ 14). Safety measures related

3 P2 P4 4 4). Wheel flange/Wheel Yellow: Cycle completed

1.3-color signal tower continuous

The same accuracy is achieved at any position on the chuck 1.Spare wheel flange ○ ○ ○ Red: Alarm ○ ○ ○

ON type

2.Wheel flange for GRIND-X micro balancer ○ ○ ○ Green: In cycle

Straightness and accuracy Stable table height when moving right and left 3.Wheel flange for Automatic wheel balancer ○ ○ ○ Yellow: Cycle completed

2.3-color signal tower

4.Wheel flange for vertical wheel spindle unit ○ ○ ○ Red: Alarm ○ ○ ○

blinking type

■ The impact of the shock is minimized to within 1μm at the longitudinal ■ By controlling the oil film thickness, the amount of table shift-up is 5.Hoist hook for wheel flange ○ ○ ○ Green: In cycle

and crossfeed strokes, and the accuracy on the chuck top becomes ultra always stable, so the surface quality is ultra precise with the small 6.GRIND-X grinding wheel ○ ○ ○ 3.Revolving light Lights up and rotates when the cycle is complete ○ ○ -

precise. It achieved the straightness within 1.5μm/4000mm for longitudinal amount of oil. 7. Grinding wheel for vertical Plane type:φ150×25×φ31.75㎜ ○ ○ ○ 4.Auto shut down function ○ ○ ○

direction, and 0.4μm/800mm for cross direction (not always guaranteed). wheel spindle unit Cup type:φ150×55×φ31.75㎜ ○ ○ ○ 5.Chuck interlock ○ ○ ○

Measured result of table shift-up

テーブルの浮上り量の測定結果 5). Wheel balancer 15). Dresser

2.25.50

Lo左ng左i右tud右方ina方向l d向i【reチc【tチiャon【ッャCクッhu幅クck幅4 w,0i4d0,t0h0 04m,00m00mm�m� �】� 2.2.00 1.Wheel balancer with arbo(r O.D.φ500:BW-5,φ600:BW-6) ○ ○ ○ 1.Hydraulic overhead dresser For 75mm/100mm width ○ - -

左L左ef t 右右R igh t 1.51.50

1.01.00 2.Wheel flange for GRIND-X micro balancer ○ ○ ○ 2.Hydraulic overhead dresser Dressing points always perform

1.5μ m 0.05.50

0.0.00 3.Automatic wheel balancer Changed to dedicated wheel guard model ○ ○ ○ With automatic dressing fol low-up compensat ion to

correction function the wheel when the tabletop - ○ -

Relative 0 0 5 5 1010 1515 2020 2525

displacement between wheel テーブル送り速度【m/min】

spindle head and table(µm) Table feed speed(m/min) 6). Work light For 75mm/100mm width dressing cycle is used together.

前前 前前後後方方向向【 チ【 チャッャクッ奥ク奥行行80800m0mm �� � 1.LED light ○ ○ ○

Front Cross direction【Chuck width 800mm】 後後� R ea

16). GRIND-X peripherals

r 7). GRIND-X hydraulic oil/grinding fluid 1.Warpage correction jig (GRIND-X SG master) ○ ○ ○

0.4 μ m Compact machine design 1.GRIND-X hydraulic oil 20 ×10cans ○ ○ ○ 2.TWIN-BiX Need to consider cover ○ ○ ○

■ The hydrostatic tank 2.GRIND-X grinding fluid ○ ○ ○ 3.High efficiency grinding wheel ○ ○ ○

and water tank are ◆ UPG series is ultra precision model. Please contact us.

designed to save

floor space despite

the oil hydrostatic

model.

Mirror surface grinding of long workpiece Space-saving design for hydrostatic tank Mist collector and coolant system with magnetic UPG406NC constant temperature chamber model TWIN-BIX Freestanding operation panel

separator and with automatic oil temperature regulator (standard of DXNC&UPG)

Column type series 11 Column type Series 12

トイシ軸頭とテーブルの

相対変位量【μm】

PSG-DX series Specifications

Item Unit 125DX 155DX 205DX 305DX 126DX 156DX 206DX 306DX 157DX 138DX 158DX 208DX 308DX

Workpiece grinding range (length x width x height) mm 1200×500×595 1500×500×595 2000×500×595 3000×500×595 1200×600×595 1500×600×595 2000×600×595 3000×600×595 1500×700×695 1300×800×695 1500×800×695 2000×800×695 3000×800×695

Maximum travel (table longitudinal x column cross x wheel head vertical) mm 1450×560×620 1700×560×620 2250×560×620 3250×560×620 1450×660×620 1750×660×620 2250×660×620 3250×660×620 1750×760×720 1550×860×720 1750×860×720 2250×860×720 3250×860×720

Table working capacity (length x width) mm 1250×500 1550×500 2050×500 3050×500 1250×600 1550×600 2050×600 3050×600 1550×700 1350×800 1550×800 2050×800 3050×800

Capacity

Distance from the top of the table to the bottom of the wheel mm 595 595 695

Standard chuck dimensions (length x width x height) mm 1200×500×100 1500×500×100 2000×500×100 3000×500×100 1200×600×100 1500×600×100 2000×600×100 3000×600×100 1500×700×100 1300×800×100 1500×800×100 2000×800×100 3000×800×100

Table load capacity (including chuck ( )) kg 1200(440) 2500(555) 2400(740) 2100(1110) 2500(530) 2400(600) 2300(800) 2300(1200) 2700(774) 2700(700) 2700(900) 2600(1180) 2300(1770)

T-groove width (width x number) mm×No. 20×3 20×3

Table

Hydraulic feed rate (average) m/min 2~25 2~25

(longitudinal feed)

Longitudinal handwheel feed per revolution mm 25 25

Feed per handwheel revolution mm 5 5

Cross manual feed

Feed per handwheel graduation mm 0.02 0.02

Column Traverse feed amount

(cross feed) (a.k.a intermittent feed amount) mm 5~35 5~35

Cross automatic feed

Bias feed rate

(a.k.a continuous feed rate) mm/min 300~5000 300~5000

Feed per handwheel revolution mm 0.1(×1)/1(×10) 0.1(×1)/1(×10)

Manual infeed

Feed per handwheel graduation mm 0.001(×1)/0.01(×10) 0.001(×1)/0.01(×10)

Wheel head Automatic infeed Rough grinding mm

ding 10 steps) 0.001~0.05(Rough grinding 15 steps, Fine grinding 10 steps)

(vertical feed) (traverse & bias feed) 0.001~0.05(Rough grinding 15 steps, Fine grin

Fine grinding mm

Number of sparkout No. 0~5 0~5

Rapid feed rate mm/min 360 360

Grinding O.D. x W x I.D. mm φ510×50×φ127(75mm width and 100mm width optional) φ510×50×φ127(75 mm width and 100 mm width optional)

wheel Rotation speed(50/60Hz) min-1 1000/1200 1000/1200

Grinding wheel spindle kW/P 7.5/6(Standard)、11/6(Option)、15/6(Option) 7.5/6(Standard)、11/6(Option)、15/6(Option)

Motor Vertical feed (AC servo motor) kW 0.75 0.75

Hydraulic pumps kW/P 3.7/6 5.5/6 3.7/6 5.5/6

Operation power – AC200/220V, 50/60Hz 3-phase AC200/220V, 50/60Hz 3-phase

Power

Power consumption (main unit only) kVA 23.0 25.6 26.1 23.0 25.6 26.1 27.0 25.6 26.1 27.0

Floor space Width x Depth x Height mm 4915×3014×2195 5480×3014×2195 6680×3014×2195 9080×3014×2195 4735×3014×2195 5480×3014×2195 6680×3014×2195 9080×3014×2195 5480×3214×2395 4835×3340×2395 5480×3340×2395 6680×3340×2395 8760×3340×2395

Weight Net weight kg 7500 8000 9000 12000 7800 8400 9400 12400 10600 10850 10900 12200 16000

*Machine standard painting color is two tone color. A separate quotation is provided for specified colors.

*Power consumption and floor space will change by specifications.

PSG-DX series External view, Grinding range, Machine size

Grinding range

Coolant unit CT-40WPA

(optional)

Coolant unit Hydraulic

CT-30M tank unit

(optional) Automatic oil

temperature

Ⓔ regulator

Ⓓ

*1. C dimension is machine height from machine bottom.

*2. 35mm is the standard dimension from the floor to the machine bottom when the machine level is adjusted using the standard leveling plate. It may vary Ⓕ Ⓐ

depending on the leveling condition.

Item Unit 125DX 155DX 205DX 305DX 126DX 156DX 206DX 306DX 157DX 138DX 158DX 208DX 308DX

Ⓐ mm 4830 5480 6680 9080 4470 5480 6680 9080 5480 4670 5480 6680 8760

Ⓑ mm 2546 2696 2696 3031 3181

Ⓒ mm 2195 2195 2395

Ⓓ mm 1200 1500 2000 3000 1200 1500 2000 3000 1500 1300 1500 2000 3000

Ⓔ mm 500 600 600 700 800

Ⓕ mm 4915 5480 6680 9080 4735 5480 6680 9080 5480 4835 5480 6680 8760

Ⓖ mm 3014 3014 3214 3340

Ⓗ mm 850 850 950

Column type series 13 Column type Series 14

35 Ⓒ

Ⓑ

Ⓖ

P MAX. Ⓗ

Φ510

139

150

PSG-DXNC series Specifications

Item Unit 125DXNC 155DXNC 205DXNC 305DXNC 126DXNC 156DXNC 206DXNC 306DXNC 157DXNC 138DXNC 158DXNC 208DXNC 308DXNC

Workpiece grinding range (length x width x height) mm 1200×500×575 1500×500×575 2000×500×575 3000×500×575 1200×600×575 1500×600×575 2000×600×575 3000×600×575 1500×700×675 1300×800×675 1500×800×675 2000×800×675 3000×800×675

Maximum travel (table longitudinal x column cross x wheel head vertical) mm 1450×552×620 1750×552×620 2250×552×620 3250×552×620 1450×652×620 1750×652×620 2250×652×620 3250×652×620 1750×752×720 1550×852×720 1750×852×720 2250×852×720 3250×852×720

Table working capacity (length x width) mm 1250×500 1550×500 2050×500 3050×500 1250×600 1550×600 2050×600 3050×600 1550×700 1350×800 1550×800 2050×800 3050×800

Capacity

Distance from the top of the table to the bottom of the wheel mm 575(Origin position) 575(Origin position) 675(Origin position)

Standard chuck dimensions (length x width x height) mm 1200×500×100 1500×500×100 2000×500×100 3000×500×100 1200×600×100 1500×600×100 2000×600×100 3000×600×100 1500×700×100 1300×800×100 1500×800×100 2000×800×100 3000×800×100

Table load capacity (including chuck ( )) kg 1200(440) 2500(555) 2400(740) 2100(1110) 2500(530) 2400(600) 2300(800) 2300(1200) 2700(774) 2700(700) 2700(900) 2600(1180) 2300(1770)

Width of T-groove (width x number) mm×No. 20×3 20×3

Table

Hydraulic feed rate (average) m/min 3~25 3~25

(longitudinal feed)

Longitudinal handwheel feed per revolution mm 25 25

Feed per handwheel revolution mm 0.01(×1)/0.1(×10)/1(×100) 0.01(×1)/0.1(×10)/1(×100)

Cross manual feed

Feed per handwheel graduation mm 0.0001(×1)/0.001(×10)/0.01(×100) 0.0001(×1)/0.001(×10)/0.01(×100)

Column

(cross feed) Feed rate (F code command) mm/min 0~5000 0~5000

Rapid feed rate mm/min 1250(×25%)/2500(×50%)/5000(×100%) 1250(×25%)/2500(×50%)/5000(×100%)

Jog feed rate mm/min 0~1000 0~1000

Feed per handwheel revolution mm 0.01(×1)/0.1(×10)/1(×100) 0.01(×1)/0.1(×10)/1(×100)

Manual infeed

Feed per handwheel graduation mm 0.0001(×1)/0.001(×10)/0.01(×100) 0.0001(×1)/0.001(×10)/0.01(×100)

Automatic infeed Rough grinding mm

(traverse & bias feed) Fine grinding mm

Wheel head Rough grinding air cut amount mm Setup on the graphical interactive software Setup on the graphical interactive software

(vertical feed) Fine grinding air cut amount mm

Number of sparkout No.

Feed rate (F code command) mm/min 0~2000 0~2000

Rapid feed rate mm/min 500(×25%)/1000(×50%)/2000(×100%) 500(×25%)/1000(×50%)/2000(×100%)

Jog feed rate mm/min 0~1000 0~1000

Grinding O.D. x W x I.D. mm φ510×50×φ127(75mm width and 100mm width optional) φ510×50×φ127(75mm width and 100mm width optional)

wheel Rotation speed(50/60Hz) min-1 1000/1200 1000/1200

Wheel spindle kW/P 7.5/6(Standard)、11/6(Option)、15/6(Option) 7.5/6(Standard)、11/6(Option)、15/6(Option)

Vertical feed (AC servo motor) kW 1.8 1.8

Motor

Cross feed (AC servo motor) kW 1.8 1.8

Hydraulic pumps kW/P 5.5/6 5.5/6

Operation power – AC200/220V,50/60Hz 3-phase AC200/220V,50/60Hz 3-phase

Power

Power consumption (main unit only) kVA 28.7 29.1 28.7 28.7 29.1 30.0 28.7 22.8 23.7

Floor space Width x Depth x Height mm 6004×3011×3170 6244×3011×3170 6844×3011×3170 9080×3011×3170 6004×3011×3170 6244×3011×3170 6844×3011×3170 9080×3011×3170 6244×3211×3380 6004×3346×3380 6244×3346×3380 6844×3346×3380 8760×3346×3380

Weight Net weight kg 7500 8000 9000 12000 7800 8400 9400 12400 10600 10700 10800 13000 16000

*Machine standard painting color is two tone color. A separate quotation is provided for specific colors. *Power consumption and floor space will change by specifications.

PSG-DXNC series External view, Grinding range, Machine size

Grinding range

Coolant unit CT-MPA

(optional) Automatic oil

temperature

regulator

Electric

Coolant unit cabinet

CT-30M Hydraulic tank

(optional) unit

Ⓓ Ⓔ

600 24 Operation panel

*1. C dimension is machine height from machine bottom. Ⓐ

*2. 35mm is the standard dimension from the floor to the machine bottom when the machine level is adjusted using the standard leveling plate. It may vary depending on the leveling condition. Ⓕ

Item Unit 125DXNC 155DXNC 205DXNC 305DXNC 126DXNC 156DXNC 206DXNC 306DXNC 157DXNC 138DXNC 158DXNC 208DXNC 308DXNC

Ⓐ mm 4830 5480 6680 9080 4470 5480 6680 9080 5480 4670 5480 6680 8760

Ⓑ mm 2776 2946 2946 3196 3346

Ⓒ mm 3170 3170 3380

Ⓓ mm 1200 1500 2000 3000 1200 1500 2000 3000 1500 1300 1500 2000 3000

Ⓔ mm 500 600 600 700 800

Ⓕ mm 6004 6244 6844 9080 6004 6244 6844 9080 6244 6004 6244 6844 8760

Ⓖ mm 3011 3011 3211 3346

Ⓗ mm 830 830 930

Column type series 15 Column type Series 16

1420

35 Ⓒ

Ⓑ

Ⓖ

P MAX. Ⓗ

Φ510

139

150

PSG-iQ series Specifications Standard Accessories

Item Unit 126-iQ 156-iQ 206-iQ 306-iQ 157-iQ No. Item DX iQ DXNC No. Item DX iQ DXNC

Workpiece grinding range (length x width x height) mm 1200×600×575 1500×600×575 2000×600×575 3000×600×575 1500×700×675 1 GRIND-X wheel (28 x 36/46G 2E) ○ ○ ○ 10 Oil-cooled wheel head △ ○ ○

Table longitudinal mm 1450 1750 2250 3250 1750

Maximum travel 2 Wheel flange (adaptor) ○ ○ ○ 11 Wheel spindle continuous variable speed controller 11 kW △ ○ △

Column cross mm 652 752 3 Necessary tools ○ ○ ○ 12 Tabletop dresser (with automatic dressing cycle function) - ○ ○

Capacity Table working capacity (length x width) mm 1250×600 1550×600 2050×600 3050×600 1550×700

4 Leveling bolt ○ ○ ○ 13 Hydraulic overhead dresser for 50 mm width wheel ○ - -

Distance from top of the table to bottom of the wheel mm 575 675

5 Leveling plate or anchor bolts ○ ○ ○

Standard chuck dimensions (length x width x height) mm 1200×600×100 1500×600×100 2000×600×100 3000×600×100 1500×700×100 Hydraulic overhead dresser (with automatic dressing cycle function)

14 - ○ -

Table load capacity (including chuck ( )) kg 2500(530) 2400(600) 2300(800) 2300(1200) 2700(774) 6 Longitudinal handwheel ○ ○ ○ for 50 mm width wheel

Table T-groove width (width x number) mm×No. 20×3 DX・DXNC(157,138,158,208,308) ○ - ○ Yellow: cycle complete

7 Table raise unit 15 Signal tower 2-color △ △ ○

(longitudinal feed) Hydraulic feed rate (average) m/min 2~25 iQ(all models) - ○ - Red: Alarm

Feed per handwheel revolution mm 0.01(×0.1)/0.1(×1)/1(×10)/5(×50) 8 Wheel guard with magnet base ○ ○ ○ 〇 : Standard model △ : Optional model -: Not covered by specifications

Cross manual feed

Feed per handwheel graduation mm 0.0001(×0.1)/0.001(×1)/0.01(×10)/0.05(×50) 9 Hydraulic unit with automatic oil temperature regulator ○ ○ ○

Column

(cross feed) Rapid feed rate mm/min 4000

Feed rate (F code command) mm/min 0~4000

Jog feed rate mm/min 0~1000 UPG-NC series Specifications

Feed per handwheel revolution mm 0.01(×0.1)/0.1(×1)/1(×10,×50)

Manual infeed

Feed per handwheel graduation mm 0.0001(×0.1)/0.001(×1)/0.01(×10,×50) ■ Since the UPG-NC series ultra precision surface grinding machines are specially modified, please contact your sales representative separately.

Automatic infeed Rough grinding mm 0.0001~0.9999 Longitudinal (variable hydrostatic) Cross (variable hydrostatic) Wheel spindle Wheel dimensions

(traverse & bias feed) Fine grinding mm 0.0001~0.9999

Wheel head mm mm mm

Rough grinding air cut amount mm 0~0.9999

(vertical feed) 3000

Fine grinding air cut amount mm 0~0.9999 600 φ510×50(OP100)×φ203.2

4000 Hydrostatic

Number of sparkout No. 0~99

3000

Rapid feed speed mm/min 600 800 φ610×100(OP150)×φ304.8

4000

Feed rate (F code command) mm/min 0~600

Grinding O.D. x W x I.D. mm φ510×50×φ127(75mm width and 100mm width optional)

wheel Rotation speed (inverter) min-1 400~1500

Wheel spindle kW/P 11/6(Standard)、15/6(Option) Warpage correction jig SG Master Grinding Data

Hydraulic pumps kW/P 5.5/6 Front Side Grinding Measuring point Unit 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Max.

Motor Vertical feed (AC servo motor) kW 1.6 difference

Cross feed (AC servo motor) kW 1.2 Before grinding μm 0 -42 -84 -56 0 -1 -43 -52 -9 0 -43 -82 -48 -3 84

Overhead dresser (AC servo motor) kW 0.35 Grinding 0.010mm infeed x 8times μm 0 -4 -4 -3 9 0 -11 -4 2 5 -4 -3 -3 12 23

Operation power – AC200/220V,50/60Hz 3-phase condition 0.003mm infeed x 8times + sparkout x 2times μm 0 0 1 0 -1 1 1 2 1 1 1 2 2 1 3

Power

Power consumption (main unit only) kVA 35 37 39 37

Floor space Width x Depth x Height mm 5952×3937×2195 6192×3937×2195 6792×3937×2195 9080×3937×2195 6192×4137×2395 Back Side Grinding Measuring point Unit 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Max.

difference

Weight Net weight kg 7800 8400 9400 12400 10600 Before grinding μm 0 58 114 59 -3 12 72 73 1 4 55 96 50 -8 122

*Machine standard painting color is two tone color. A separate quotation is provided for specific colors. *Power consumption and floor space will change by specifications. Grinding 0.010mm infeed x 8times μm 0 -2 -3 -2 -1 -1 -3 -1 -1 2 -1 -2 0 1 5

PSG-iQ series External view, Grinding range, Machine size condition 0.003mm infeed x 8times + sparkout x 2times μm 0 -1 0 0 1 -1 -1 -1 -1 2 -1 -2 0 1 2

Item Unit 126-iQ 156-iQ 206-iQ 306-iQ 157-iQ

Ⓐ mm 4470 5480 6680 9080 5480

Ⓑ mm 3637 3982

Ⓒ mm 2195 2395

Ⓓ mm 1200 1500 2000 3000 1500

Ⓔ mm 600 700

Ⓕ mm 5952 6192 6792 9080 6192

Ⓖ mm 3937 4137

Ⓗ mm 830 930 Warpage correction jig SG Master Vertical rotary dresser Wheel balancer GRIND-X hydraulic oil GRIND-X grinding fluid

Coolant unit Grinding range

CT-40MPA (optional)

Coolant unit Hydraulic tank Control

CT-30M unit box

(optional) Automatic oil

temperature

regulator

Ⓓ Ⓔ

Operation panel

*1. C dimension is machine height from machine bottom.

*2. 35mm is the standard dimension from the floor to the machine bottom when the machine level is adjusted using the standard leveling plate. It may vary depending on the leveling condition. Ⓐ Ⓕ

Column type series 17 Column type series 18

35 Ⓒ

Ⓑ

Ⓖ

P MAX. Ⓗ

Φ510

139

150