1/4ページ

Download(1.2Mb)

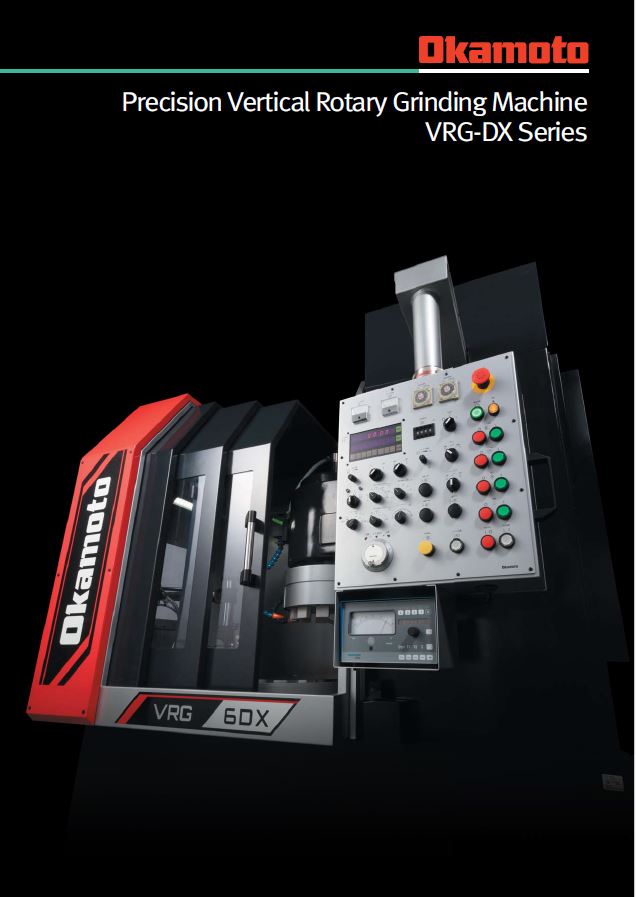

Precision Vertical Rotary Grinding Machine VRG-DX Series

Product Catalog

Document Information

| Document Title | Precision Vertical Rotary Grinding Machine VRG-DX Series |

|---|---|

| Document Type | Product Catalog |

| File size | 1.2Mb |

| Category | |

| Company | OKAMOTO MACHINE TOOL WORKS,LTD (Documents List) |

Documents related to this company

Document Contents

Page1

Precision Vertical Rotary Grinding Machine

VRG-DX Series

OKAMOTO MACHINE TOOL WORKS, LTD.

2993 Gobara, Annaka, Gunma, Japan 379-0135

TEL : +81-27-388-9595 FAX : +81-27-385-1144

JQA-QMA10960

URL : www.okamoto.co.jp Annaka Factory

*Prior to and while using our products you are requested to thoroughly go through the articles on danger,

warning and attention for the sake of safety described in operation manual attached to the machine

and also in the warning plates mounted on the machine.

CAUTION *When the products fall under the eport controlled goods stipulated in “Foreign Exchange and Foreign

Trade Act” , it requires the license or approval of Goverment of Japan when exporting out of Japan.

*Specifications subject to change without notice.

This printed matter uses environmentally friendly paper and vegetable oil inks

Printed in Japan in August 2024 2024081500MTR-1

Page2

NEW MODEL

Overview & User friendly, high rigidity, highly productive

Line-Up Control system Original control system makes grinding easy

new vertical rotary grinding machine VRG-DX Series

OKAMOTO's vertical axis rotary grinding machine is simple and easy to use ! OKAMOTO original FX Controller

■ High-efficiency and high-rigidity rotary grinding machine Lineup Chuck Size ■ Grinding amount setting

equipped with vertical wheel spindle.

VRG6DX Equipped with an automatic grinding cycle as standard.

■ 3-point support column structure for easy adjustment. Rough and fine finish grinding plus spark-out, and retract

The combination of made-in-house highly rigid column and VRG10DX functions enable mass production in a good setup.

bed allows you to maintain high precision for a long oper-

VRG6DX ■ Interlock function

ating time. Chuck diameter 650mm The fully enclosed cover is equipped with an interlock func-

■ Okamoto original FX controller can prevent operational tion as standard.

mistakes with minimum number of intuitive operations. In view of safety and the factory environment, the machin-

■ Fully enclosed cover for safety and regulatory factory re- ing cycle cannot be performed while the cover is open.

quirement. ■ Vertical grinding feed and current position display

Achieves a minimum vertical increment of 1 μm accuracy.

■ Ideal for grinding brittle materials such as glass/ceramics

The feed amount is changed by the magnifi cation, and the

as well as metals. current position is displayed on a clear LED.

VRG10DX

Chuck diameter 1,000mm ■ Down-feed grinding method

VRG6DX Equipped with continuous mode and intermittent mode for plunge grinding. Please select the mode according to

the workpieces to be ground and its application.

Series Name

Series Size

Vertical Rotary Grinding Machine The down-feed grinding method is signifi cantly diff erent in grinding effi ciency compared to an ordinary square slide grinding machine.

Infeed amount

Cycle end

Cycle start

Rough grinding

conditions

(0~40μm)

Intermittent infeed method

Fine grinding retract function

amount

Fine grinding conditions

(0~100μm)

Sparkout

(0~100min)

Time

Wheel spindle Infeed amount

Cycle end

Cycle start

Rough grinding

conditions

(speed: set with

Rotary table magnification)

Fine grinding

amount

Continuous infeed method Fine grinding conditions

(set with Retract function

magnification)

Sparkout

(0~100min)

Time

Cycle start Infeed amount

Rough grinding Workpiece #1 Cycle end Workpiece #2 Cycle end

conditions

(speed: set with

magnification)

Intermittent / Fine grinding

amount

continuous infeed method Fine grinding Retract function

(coordinate correction function) conditions

(set with

magnification)

Sparkout

Correction infeed is controlled with Unreached (0~100min) Sparkout

numeric values. The cycle is optimum sizing point Correction infeed (0~100min)

to the mass production in consider- Workpiece of +10 μm

ation with the grinding segment wear ! sizing point e.g.) unreached to 10 μm sizing point (size error by grinding segment wear, etc.) Time

Infeed amount

Cycle start Cycle end

Rough grinding

conditions

(speed: set with

magnification)

Intermittent /

continuous infeed method Fine grinding

amount

Option: direct sizing device Fine grinding Direct sizing device Retract function

VRG6DX conditions

(set with

Directly controls the sizing during magnification)

grinding ! Stable grinding unaffected Sparkout

with the grinding segment wear is Workpiece (0~100min)

sizing point

realized. Time

Direct sizing device

1 VRG-DX Series VRG-DX Series 2

Page3

Structure and Simple structure and operability that makes use of the features of vertical axis.

features It achieves high effi ciency and high productivity.

Switches are all laid on the front side of the machine to facilitate easy operation and access.

Easy-to-replace wheel segments.

Achieves high-precision machining of the order of

1 μm.

Fully enclosed cover slide is adopted Coolant unit is laid at the back

as standard in consideration of safety for easy maintenance.

and the factory environment.

Uses Okamoto original FX controller.

Minimal intuitive operation can prevent mistakes.

Grinding of brittle material workpieces such as ceramics and

quartz glass with a diamond wheel is also available.

VRG6DX

Highly effi cient grinding is achieved with a vertical

By adopting a 3-point support column

axis wheel.

structure, accuracy adjustment and

Greatly supports the needs for productivity.

surface quality adjustment are easily

performed.

Equipped with a rotary table foot switch

as standard. Signifi cantly improved setup

and operability.

Rotary pattern Cross hatch pattern

3 VRG-DX Series VRG-DX Series 4

Page4

Specifi cations

Characteristics Lineup of 2 types of rotary grinding machines.

and The optimum series can be selected Items Unit VRG6DX VRG10DX

comparison according to the grinding application! Table OD mm φ800 φ1,100

Electromagnetic chuck OD mm φ650 φ1,000

Table rotation speed rpm 1~30 1~26

Table

Vertical axis & rotary table Horizontal axis & rotary table Horizontal axis & square table Distance from chuck top face to segment bottom end

When protrusion amount of grinding segments is 20 mm mm 290 400

VRG series PRG series PSG series

Load capacity (excl chuck) kg 250 500

VRG6DX PRG8-iQ PSG63GX Vertical stroke mm 300 400

Wheel head Maximum wheel spindle feed speed mm/min 300

Vertical feed Minimum infeed setting amount mm 0.001

Continuous infeed speed mm/min 0.06 to 2.4 (at 100% Override)

Wheel diameter (segment) mm φ350 φ550

Grinding Grinding segment (Length x Thk x Width) mm 49.5×25×125

wheel Maximum number of grinding segment pcs 12 18

Grinding wheel rotation rpm 1,000/1,200 (50/60Hz) 590/710(50/60Hz)

Table rotation motor horsepower kW 1.5 3.5

Motors

Wheel spindle motor horsepower kW 11 37

Grinding methods Grinding methods Grinding methods Power supply - 3-phase AC200V

Down feed grinding Plunge or traverse grinding Plunge or traverse grinding Power requirement kVA 20 68

Main unit

Machine weight (incl load) kg 4,000 6,500

Wheel Spindle Machine dimension mm 2,065×1,691×2,692 2,732×2,025×3,354

Wheel Spindle ※Specifi cations are subjected to change without prior notice due to improvements.

Wheel Spindle

Table Standard accessories External view VRG6DX VRG10DX

Rotary table Rotary table

Length ○A 2,065 2,732

Items Width ○B 1,691 2,025

Standard grinding wheel Height ○C 2,692 3,354

Wheel fl ange (adaptor) ※ Exclude coolant unit

Electromagnetic chuck, controller

Fully enclosed cover

LED work light

Cover interlock

Leveling plate C

Foot switch for table jogging

Necessary tools

Center coolant

B A

Vertical axis & rotary table Horizontal axis & rotary table Horizontal axis & square table

Grinding wheel work area Big General General Optional accessories Recommended workpiece materials

Productivity Maximum Big Normal Glass / Quartz

Items

Grinding load Big Small Small Sapphire

Coolant unit

Surface pattern Cross hatch or rotary pattern Rotary pattern Grinding pattern SiC

Mist collector

Square surface grinding

Generally recommend- Direct sizing device Die / Mold

Round surface grinding, many numbers, large surface area High geometric tolerance items

ed workpieces Signal tower Steel

Items that require form grinding

Custom color Hydraulic & Pneumatic Parts

*Results will vary depending on the workpiece, grinding wheel used, and target value. Bearings

5 VRG-DX Series VRG-DX Series 6