1/8ページ

Download(2.6Mb)

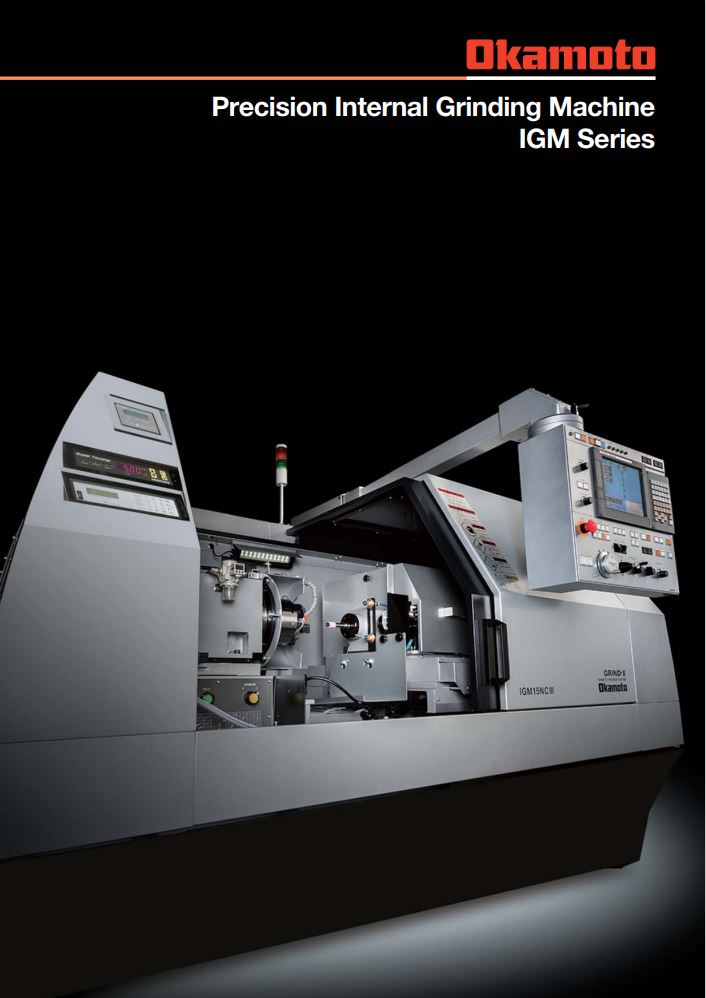

<JAPAN> Precision Internal Grinding Machine IGM Series

Product Catalog

Document Information

| Document Title | <JAPAN> Precision Internal Grinding Machine IGM Series |

|---|---|

| Document Type | Product Catalog |

| File size | 2.6Mb |

| Category | |

| Company | OKAMOTO MACHINE TOOL WORKS,LTD (Documents List) |

Documents related to this company

Document Contents

Page1

Precision Internal Grinding Machine

IGM Series

OKAMOTO MACHINE TOOL WORKS, LTD.

2993 Gobara, Annaka, Gunma, Japan 379-0135

TEL : +81-27-388-9595 FAX : +81-27-385-1144

URL : www.okamoto.co.jp

*Prior to and while using our products you are requested to thoroughly go through the articles on danger,

warning and attention for the sake of safety described in operation manual attached to the machine

and also in the warning plates mounted on the machine.

*When the products fall under the export controlled goods stipulated in “Foreign Exchange and Foreign

CAUTION Trade Act”, it requires the license or approval of Government of Japan whebn exporting out of Japan.

*Specification subject to change without notice. This printed matter uses environmentally friendly paper and vegetable oil inks

Printed in Japan in November 2021 2021101000MT-0

Page2

High Precision + High Effi ciency

IGM series will meet your demand for high precision internal grinding with a wide versatility.

Okamoto Machine Tool Works is known as the leader of grinding CONTENTS

machine manufacturing in Japan, and getting praise around the

world. We have been providing the high-precision high-quality Contents ………………………………………… 1 - 2

grinding machines since the development of the fi rst surface grind- Lineup & Machine Select …………………… 3 - 4

ing machine in Japan in 1953.

IGM15EXⅢ/15NCⅢ…………………………… 5 - 6

We started developing the internal grinding machines in 1954, and

…………………………………………

the lineup has expanded from a versatile general-purpose type to IGM2MB 7 - 8

a specialty including automated type with use of robot loaders for IGM2TNCⅢ …………………………………… 9

mass production. IGM1V …………………………………………… 9

IGM series is widely used in a variety of automobile parts, gears,

Specifi cations ………………………………… 10

medical equipment, semiconductor manufacturing equipment, and

precision machinery industries. The roundness, concentricity and IGM1V Specifi cations,

Standard accessories, Optional accessories …… 11

cylindricity of manufactured workpieces are producted and repeat-

………………………

ed. Okamoto holds a high market share of internal grinding ma- Standard accessories 11

chines both in Japan and overseas. Outline drawing………………………………… 12

You can obtain higher level of precision grinding by utilizing the in- Optional accessories ……………………… 13 - 14 IGM Series

ternal grinding machine IGM series.

1 2

Page3

Lineup & Machine Select

IGM15EX /NC IGM15NC -2 IGM15NC -2B

Test result of internal mirror fi nish grinding

Model IGM15NCⅢ

Dimensions IDφ7.41mm, ODφ13.8mm, L: 22.5mm

Material Carbide

Wheel Diamond wheel

Surface roughness Ra0.0053μm

Roundness 0.156μm

Accuracy Edge R shape accuracy 0.31187mm

Cycle time 40 minutes (from non pre-

formed workpiece)

Simple data input with automatic measurement Complexity, Effi ciency, Automation Work Effi ciency is increased

function of grinding data with 2 spindles by driving 2 spindles independently

■Max. 10 Faces grinding by stan- ■Max. 10 Faces grinding by stan- ■Up to 10-face grinding with the Variety of Applications and models they

dard interactive software. dard interactive software. standard software. can be programmed on.

■It specializes for straight grinding ■AC servo motors for wheel ■AC servo motors for wheel

and end face grinding. (simple spindle and work spindle are spindle and work spindle are

NC: EX ) provided as standard acces- standard to achieve high accu- Straight Multi-step grinding

■Simultaneous 2-axis grinding, sories to achieve high accu- racy.

taper grinding, contour form racy. ■Two spindles are driven inde-

grinding software with G code ■High-precision model that use pendently, the grinding diame-

are available. (full NC: NC , some are optional) a closed-loop system for infeed axis (X-axis). ter is increased and versatility is greatly improved.

■AC servo motors for wheel spindle and work spindle are pro- ■Multi step grinding by 2 spindle system with high accuracy for ■Better Accessibility makes wheel replacement and work set-

vided as standard accessories to achieve high accuracy. concentricity & squareness. up easier.

■High-precision model that use a closed-loop system for infeed

axis (X-axis). Recommended model Recommended model

General purpose IGM2MB IGM15NC

N C

N C IGM15EX IGM15NC -2

IGM2MB IGM2TNC IGM1V

Wheel forming taper Table-swivel taper

grinding grinding

Recommended model Recommended model

N C IGM15NC N C IGM15NC

Option EDELAC Win Option Work spindle NC swiveling

Space saving and automation

Best-Seller CNC Internal Grinder Precision Internal Grinding for long workpiece with vertical machine Contour grinding Outer peripheral &

■ ■ ■ taper grinding

It has user-friendly layout It specializes in internal grind- It is small footprint and good for

with operation controllers on ing of long workpieces such as grinding small workpieces with

the front of the machine. spindles and cylinders. 840-mm machine width.

■Grinding recipes (36 types) ■It uses the software for text- ■Accuracy is stable even during

can be stored for grinding free panel screens. mass production grinding.

conditions and table speeds. ■The maximum length of straight ■Fully enclosed model to support

■High-precision ball screw workpieces is 1000 mm. (consult the robot.(optional)

and linear guide are used for Okamoto for the angle of work- Recommended model Recommended model

the table drive and guideway. pieces) N C IGM15NC IGM15NC -2

■ N C

It is equipped with an end face grinding device (optional), im- ■It is equipped standard with 1 spindle, optional 3 and 4 spin- Option EDELAC Win IGM15NC -2B

proving the versatility. dles models are also available with custom modifi cation.

(consult Okamoto)

3 4

Page4

Precision Internal Grinding Machine

IGM15EXⅢ/15NCⅢ・15NCⅢ-2・15NCⅢ-2B Interactive software is used in EXⅢ and NCⅢ

Interactive software (common to all models)

Same operation system as OKAMOTO

Just by inputting the wheel abrasive size There are no letters on the screen. Data Storage includes wheels (6) and cylindrical grinding machine OGM

(diameter and width) and workpiece size Utilizing the touch and teach functions, workpieces (21) as standard series is used.

Grinding dimensions, the optimum grinding con- Touch screen even complicated shapes can be ground. File

data auto set ditions and dressing conditions are auto-

function matically created. Computed values are input management

generated based on our expertise of the

grinding theoretical values.

[ Main menu ] [ Wheel shape select page ]

Program storage page Displaying selected fi le T1: wheel spindle 1, Dressing shape selection

T2: wheel spindle 2 Option

To setting page of each wheel shape

Direct sizing device setting

process display

Lights ON when the process is

selected Abrasive selection

Displaying selected wheel shape

e.g.) wheel spindle 1 is selected

Displaying selected wheel shape

e.g.) wheel spindle 2 is selected

Displaying

selected grinding method

To setting page for

each grinding method

Grinding method selection

Main pages EDELAC Win Program - dedicated software

for contour grinding option

Straight grinding setting page Taper grinding data setting page Mirror finish contour grinding for Optional software that enables com-

(standard on all models) (IGM15NC , 15NC -2 option) cold forge dies plex grinding and contour grinding

When grinding diffi cult-to-cut materials such as carbide, In the case of a workpiece to be ground along the shape,

the rigidity of the spindle itself is required in addition to contour grinding is possible by creating the passage to

the rigidity of the machine body. grind along the workpiece based on the workpiece draw-

In the carbide grinding, the stock removal often exceeds ings, creating the passage program, and reflecting the

φ1 mm, and if there is no rigidity, it will keep sparking due passage program to the interactive software.

to the bouncing of the wheel. This software not only allows you to create programs by

In addition, it is necessary to accurately synchronize the importing CAD data, but also simulates the passage of

contour grinding with the commands of simultaneous the wheel on the screen of your computer, so it is espe-

2-axis control. cially effective for complex internal features where it is

Okamoto machines have the advantages of supporting difficult to visually check the interference between the

it with the standard model, without having a costly high- wheel and the workpiece.

er-precision option.

Program fl ow

End face grinding setting page Contour grinding page

IGM15NC , 15NC -2 Passage drawing Simulation Programming It is uploaded into the

(standard on all models) ( option) interactive software

Create workpiece and wheel Activate the wheel and sim- If no problem is found, the The created program is reg-

passage in the same way as ulate the movement program is created. istered. Set the conditions

CAD to start grinding.

5 6

Page5

Precision Internal Grinding Machine

IGM2MB Best-selling IGM2M is upgraded

General purpose model

■ Main operation panel ■ Sub operation panel

Performance, accuracy, and productivity have been further improved.

Latest general-purpose internal grinding machine that enables program storage.

For the first time, it is equipped with a ● You can enter the table position data

digital conversion function that enable to easily with pressing the symbol mark

Program register the grinding conditions and table Ease of keys on the bottom of main menu.

speed settings set with the select switch. ● Variety of supporting functions are

storage (36) Data entered on the LCD control. Setup available such as dimension correction,

We have also solved the difficult task of dressing interruption, cycle skip.

versatile data input.

Grinding accuracy has been improved by ● The max table speed is 15 m/min. By

Various func- newly added fine grinding table speed shortening the acceleration/decelera-

tions that setting (rough grinding and 2-step setting) Short tion time during reversal, high-speed ■ Table position/ speed setting method

and 3 modes of intermittent infeed set- stroke of 500 strokes/min is possible

contribute to ting (right, left, both ends) to the standard cycle time even with a short stroke of 2 mm.

accuracy functions. ● In addition to the high-speed stroke How to set the positions How to set the speed

function, the cycle time is further short-

ened with the wheel spindle motor 3.7 You can set the stroke limit, coolant start point, dressing The table speed, dressing speed, tarry position and time

kW, retractable dresser of air cylinder position, and intermediate stop position by moving the can be easily set with the volume dial.

Ball screws and linear guide are used for drive, increased rapid feed speed for

the table drive and guideways. The ma- spindles, and revised movement timing. wheel to the desired position with the table feed control- The setting value is displayed on the main screen so it

Improved chine achieves high-precision positioning at ler on the sub operation panel. Then, pressing the symbol can be easily checked and saved as a program.

positioning the reversal points with high repeatability. keys at the bottom of the main menu. Quickly and simply.

accuracy Since this machine does not use hydrau- Compared to the numeric keypad, the position setting is

lics, it allows for temperature stability and quick and accurate.

no need for replacing hydraulic oil.

Various Auxiliary Functions

Surprisingly simple and accurate setting procedure of grinding conditions is a result of the ease of use.

●1 Dimension correction ●4 Wheel replacement position

After grinding, if the fi nish size of the workpiece is larger than If you enter the minimum specification diameter and set

the target size, the correction grinding can be performed [Griding Wheel Replacement Interlock] in the main menu to

with only [Correction] switch and the simple operations. [ON] (enable), the replacement lamp and buzzer notify you

when the minimum diameter is reached, and the next "cycle

●2 Cycle skip start" is skipped automatically.

When returning to automatic grinding after dimensional cor- ●5 Infeed Retract During Automatic Cycle

rection, if you keep pressing the [Cycle Skip] switch, it will

move rapid to just before the fixed size position and stop, If you press the [Starting Position Return] switch, it temporar-

and when you release the switch, it will be automatically in- ily reverses the infeed. When the wheel becomes dull during

feed to the corrected fi xed size position with the fi ne grinding the grinding of diffi cult-to-cut materials such as carbide, you

mode, which minimizes the time loss. don't have to stop the automatic cycle by temporarily re-

tracting the wheel.

●3 Repeat dressing

This repeats the stroke at the preset dressing position.

*Shown with options [Grinding Head Jog Feed] lever can feed the wheel for dress-

ing. This function is used mainly to remove the runout of a

wheel after it is replaced with new one.

7 8

Page6

IGM Series

CNC Precision Internal Grinding Machine

IGM2TNCⅢ Specifi cations

Item Unit IGM2MB IGM15EX IGM15NC IGM15NC -2 IGM15NC -2B IGM2TNC

Grinding hole diameter mm φ6~200 φ6~150 φ6~100 φ6~150 φ30~200

Grinding stroke mm max200 max125 max200

High-precision grinding of the tapered face Swivel on the table mm φ600 φ420

by swiveling the work spindle by 0 to 15° (manual operation) Swivel in the chuck cover mm φ350 φ260 φ350

Height from the bottom of the frame to

Interactive software is used. mm 1110 1000 1050 1070

the center of the chuck

Horsepower of wheel spindle and work Wheel

Main spindle motors are increased from the Maximum travel distance mm 230 170 300 360 230

spindle

previous model of IGM2TNC. Grinding feed speed mm/min 0.2~4 0.001~10000

functions infeed

It supports straight workpieces up to 1000 (X axis) Rapid feed speed mm/min 500 10000 16000 10000

mm length (consult Okamoto)

Table Maximum travel distance mm 500 510 500

longitudinal

Grinding feed speed mm/min 0.1~15000 10000 0.001~10000 10000

feed

(Z axis) Rapid feed speed mm/min 20000 10000 16000 10000

Interrupt dressing during cycle operation,

cycle pause, and infeed-retract are avail- Minimum X axis mm φ0.0001

increment

Manual-like able. Z axis mm 0.001 0.0001

operation Work Spindle Revolution Speed min−1 50~1200 100~850 50~400

Work spindle swivel angle deg. -5~30 -5~15 0~15

For main spindle kW 1.5 1.8 3.0

For wheel spindle kW 3.7 4.5 5.5×2 3.7

Motor

For X axis kW 0.75 1.2 2.2 1.2

For Z axis kW 3 1.2 2.2 1.2

Power requirement

kVA 16 12 18 22 15

(Including optional coolant unit)

Small Vertical Internal Grinder Floor space requirement 2450×2249 2525×3292 2500×1940 3655×3242

(width x depth x height) mm 2525×3092×1786

(including optional coolant unit) ×1848 ×1786 ×1600 ×1785

IGM1V

Net weight kg 3000 2600 2800 4500 5400

Power requirement, fl oor space requirement, and others are subject to change without notice.

Compact and High Performance Required air source (standard specifi cation): 0.4~0.6 MPa, 300~400 L/min

We developed compact vertical internal grinding machines suitable

for medium-lot mass production, such as automotive parts. High-Level Software (standard on EX and NC )

■ Correction grinding Interrupt function during cycle operation

High productivity provides product cost reduction

■Space-saving with 840-mm width If you want to perform additional grinding after the automatic Interrupt dressing, infeed retract and cycle end are available.

■ grinding is completed, you can quickly approach the air cut position

Stable accuracy even during mass production grinding and perform grinding in fine grinding mode, so time loss can be

minimized. Wheel spindle load meter, work spindle &

1. Small Footprint wheel spindle inverter, additional components

We reviewed the mechanical components in detail on the premise that the

width should be within 1 m, and achieved 840-mm width. Automatic dressing on wheel replacement (for mass production)

2. High effi ciency grinding [cycle time improvement] In addition to the initial truing,

The vertical feed is equipped with a high-speed approach with a table if you want to repeatedly use

speed of 15 m/min and a high-speed function with a table speed of 490 the same specification wheel

strokes/min (stroke width of 2 mm), greatly shortening cycle time. Which for mass production, it can

contributes to product cost reduction. automatically perform the wheel

for 3. Fully enclosed model that supports the truing when you replace the

ed robot d.

ulat e

ic equipp

rt is robot usage (robot is optional). wheel.

al a ent

ertic rem of n 4. Maintenance Parts number display

all vm measu on tio

S rnal operati

ent→ Correc

exte

inuous m

eplace

ment→ In consideration of a production environment, all

ont

C iece r re

orkp →Measu

maintenance operations can be done from the Truing amount

W hing

Was

front side of the machine. Wheel spindle revolution meter

Wheel spindle load meter Work spindle revolution

(For 15NCⅢ-2, it is displayed

9 separately on the operation

panel.) 10

Page7

IGM Series

Standard accessories Outline drawing

Item IGM2MB IGM15EX IGM15NC IGM15NC -2 IGM15NC -2B IGM2TNC IGM2MB IGM15EX 15NC

X-axis (infeed axis) closed loop model - ○ ○ ○ ○ -

Wheel spindle and X-axis ball screw oil-chilled - - - ○ - - 120 862

950

Holder integrated type wheel spindle 20000 min-1 (oil mist type) ○ ○ ○ - ○ ○ 950

Oil mist lubrication unit (micro oil supply type) & drip-feed verifi er ○ ○ ○ ○ ○ ○ 100

Sleeve type grinding wheel spindle 10000min-1, 20000min-1 - - - - ○ -

26

High frequency spindle 10000min-1, 20000min-1 - - - ○ - -

Inverter for high frequency spindle - - - ○ - ○

Wheel spindle AC spindle motor - ○ ○ - ○ ○

Work spindle AC servo motor - ○ ○ ○ ○ ○

Tool nose radius correction - - ○ ○ ○ ○

10-Face grinding, no keyboard, straight & end face grinding model - ○ - - - -

930

10-Face grinding, with keyboard + G code input - - ○ ○ ○ ○

Dressing coolant, center coolant - ○ ○ ○ ○ ○ IN

555

Table washing nozzle - ○ ○ ○ ○ -

Dust collection port - ○ ○ ○ ○ -

LED light inside the cover - ○ ○ ○ ○ -

Main spindle shift base - ○ ○ ○ ○ -

Wheel spindle load meter ○ ○ ○ ○ ○ ○

Work spindle revolution meter ○ ○ ○ ○ ○ ○ IGM15NC -2 IGM15NC -2B

Cycle time display / components count display - ○ ○ ○ ○ ○

912

Small Vertical Internal Grinding Machine IGM1V 950 120

Specifi cations Optional accessories 400

Item Unit IGM1V Item 363

Swivel mm φ200 With magnetic separator, oil skimmer - processing capacity: 40 l/min

Grinding inner diameter mm φ6~100 Coolant Cyclone fi lter, coolant temperature automatic regulator

Capacity Grinding length mm 100 unit

Oil mist collector (with mist suction port stand) OKB-10

Grinding stroke mm 100

High frequency wheel spindle

Travel distance mm 200

3288

Wheel spindle 20000 Air drive unit for power chuck

-1

(High frequency spindle) min (option:10000~60000) Power chuck

X axis (longi- Positioning speed mm/min φ10000 Workpiece mounting check 930

tudinal axis) Minimum increment mm φ0.0001 Workpiece dedicated jaws (parent-child jaws)

Travel distance mm 250

Z axis Colet type quill 555

(vertical axis) Positioning speed mm/min 15000

Magnet with dedicated spindle (carbide spindle)

Minimum increment mm φ0.0001

Center taper MT MT NO.6 Work light (LED light)

Work head

Rotation speed min-1 10~2000 Inner diameter direct sizing device

Wheel spindle kW 3.8(option:3.8~4.6) Workpiece delivery device

Main spindle kW 3.7(FANUC) Dressing coolant unit Unit: mm

Motor Work head feed (for X axis) kW 1.0(FANUC) Table washing nozzle IGM2TNC Depth Depth

Work head feed (for Z axis) kW 2.7(FANUC) (machine

Air blow for chuck washing Width installation (including Height

Coolant unit pump W/P 180/2 width) coolant unit)

Auto shut down function

Power requirement kVA 20 R

Signal tower 3 colors 85 IGM2MB 2450 1361 2050 1848

0

Floor space width x depth x height mm 840x2760 (including coolant

requirement unit)x20000 Mounting checker IGM15EX

Weight Net weight kg 3800 Rotary dresser 1860 3092

IGM15NC 2525 1786

Automatic open/close door (front, left side)

Robot peripherals IGM15NC -2 2010 3292

Standard accessories ① Small vertical articulated robot, double-hand model IGM15NC -2B 2500 1941 3020 1560

External measurement by electric micrometer

Item ②

③ Workpiece washing IGM2TNC 3655 2010 3242 1785

Full-enclosed cover ④ Stocker: workpiece number maximum 1000 pcs

NC unit FANUC 50 Pieces/pallet x 20 pallets

Graphic interactive software

High frequency spindle (20000 min-1)

Oil mist lubricator

Diamond tool (single-point: 2 pcs)

Foundation bolts and plates

Necessary tools (with tool box)

11 12

1600 1150

1110 1040 800

1060 3118 840 602

800

1108

151

100

1361 45

400

1240 223 1289 498

1744 837 395 2010 887

N10

1600

1040

800

151

222 1139 498

395 1860 837

Page8

IGM Series

Optional accessories

Wheel Spindle Type and Grinding Hole Diameter

Item IGM2MB IGM15EXⅢ IGM15NCⅢ IGM15NCⅢ-2 IGM15NCⅢ-2B IGM2TNCⅢ Sleeve type wheel spindle

Peripheral speed:1885m/min(maximum wheel diameter)

1.Coolant unit Wheel Rotation Standar d wheel Standa rd quill Approximate grinding

spindle speed (min-1) dimension diameter ×length whole diameter

1) with magnetic separator B-7B-A 10,000 φ45×20 φ27×58 φ60~φ80

2) with magnetic separator and paper fi lter 13,000 φ25×15 φ16×40 φ42×60

with magnetic separator, paper fi lter and coolant B-23M 16,000 φ25×15 φ16×40 φ28×42

3) temperature automatic regulator 20,000 φ25×15 φ16×40 φ20×28

with magnetic separator, paper and cartridge fi lter, and 3. Sleeve type wheel spindle B-32M 30,000 φ20×15 φ14×32 φ14~φ20 7.1 Three-jaw scroll chuck 7.2 Four-jaw independent chuck

4) GS-5 40,000 φ8.5×8 ) )

φ5×25 φ8~φ17

coolant temperature automatic regulator 60,000 φ6.5×8 φ5×25 φ6~φ11

2.Sleeve type wheel spindle (high frequency spindle, mist lubrication type) Holder integrated type wheel spindle (mist lubrication type)

1) OH-10MB(10000min−1) Standard Peripheral speed:1885m/min(maximum wheel diameter)

Wheel Rotation Standard wheel

Standa rd quill Approximate grinding

2) OH-20MB(20000min−1) Standard spindle speed (min-1) dimension diameter ×length whole diameter

−1 OH-06M 6,000 φ100×40 φ40×100 φ80~φ120

3) OH-30MB(30000min ) OH-10M 10,000 φ60×30 φ27×80 φ60~φ80

4) OH-40MB(40000min−1) OH-15M 15,000 φ40×25 φ22×70 φ35~φ60

5) OH-50MB(50000min−1) OH-20M 20,000 φ30×25 φ16×50 φ20~φ35

OH-30M 30,000 φ20×15 φ14×40 φ14~φ20

6) OH-60MB(60000min−1) 7.4)Diaphragm chuck 7.5)Collet chuck

OH-40M 40,000 φ15×10 φ10×25 φ8 ~φ17

3.Sleeve type wheel spindle (mist lubrication type) OH-60M 60,000 φ10 × 8 φ6×20 φ6 ~φ11

1) GS-5 (60000min−1、40000min−1) Holder integrated type wheel spindle (grease lubrication type)

4,5. Holder integrated type Peripheral speed:1885m/min(maximum wheel diameter)

2) B-32M(30000min−1) wheel spindle Wheel Rotation Standard wheel Standa rd quill Approximate grinding

spindle speed (min-1) dimen sion diameter ×length whole diameter

3 B-23M

) −1 −1 −1 OH-10G 10,000 φ60×30 φ27×80 φ60~φ80

(20000min ,16000min ,13000min ) OH-15G 15,000 φ40×25 φ22×70 φ35~φ60

4) R-7B-A(10000min−1) OH-20G 20,000 φ30×25 φ16×50 φ20~φ35

4.Holder integrated type wheel spindle (grease lubrication type) OH-30G 30,000 φ20×15 φ14×40 φ14~φ20

OH-40G 40,000 φ15×10 φ10×25 φ8~φ17

1) OH-10G(10000min−1) 7.6)Finger chuck 7.7)Diaphragm fi nger chuck

OH-50G 50,000 φ10× 8 φ6×20 φ6~φ11

2) OH-15G(15000min−1) High frequency wheel spindle

3) OH-20G(20000min−1) Peripheral speed: Used at 2000 m/min or less

Wheel Rotation Standard wheel Standa rd quill Approximate grinding

4) OH-30G(30000min−1) spindle speed (min-1) dimen sion diameter ×length whole diameter

−1 OH-10MB 10,000 φ60×30 φ27×80 φ40~φ120

5) OH-40G(40000min ) OH-20MB 20,000 φ40×25 φ22×70 φ20~φ80

6) OH-50G(50000min−1) OH-30MB 30,000 φ30×25 φ16×50 φ14~φ35

5.Holder integrated type wheel spindle (mist lubrication type) OH-40MB 40,000 φ20×15 φ14×40 φ8~φ20

OH-60MB 60,000 φ15×10 φ10×25 φ6~φ17

1) OH-10M(10000min−1) 7.8)Gear chuck 8. End face grinding device

2) OH-20M(20000min−1) Standard Standard Standard Standard IGM15NC -2

3) OH-30M 30000min−1 Autoloader supporting model (optional)

( )

4) OH-40M(40000min−1)

5) OH-60M(60000min−1)

6.Sleeve type wheel spindle holder

7.Various chucks *specifi cations shall be selected depending on the workpiece.

1) Three-jaw scroll chuck

2) Four-jaw independent chuck

3) Microcentric chuck

4) Diaphragm chuck

5) Collet chuck

6) Finger chuck

9. Steady rest (IGM2TNCⅢ) 16. Automatic programming software EDELAC Win

7) Diaphragm fi nger chuck

8) Gear chuck

9) Various power chucks

10) Air drive unit for power chuck

8. End face grinding device

9. Steady rest

10. Dresser coolant system Standard Standard Standard Standard

11. Work spindle nc swiveling, minimum increment: 0.00001°

12. Graphic interactive software for setting the work spindle nc swivel angle

13.Work spindle rotation constant control

14.Simultaneous 2-axis taper and contour grinding software

15.Wheel form grinding software (taper, free shape)

16.Automatic programming software EDELAC Win

17.Automatic shut down system

18.Direct sizing device

19.Rotary dresser

20.Signal light tower

21. Work light Standard Standard Standard Standard

*Some of the above optional accessories need to be discussed before installation. 18. Direct sizing device 19. Rotary dresser

13 14