1/8ページ

Download(4.1Mb)

Document Information

| Document Title | COMPANY GUIDE |

|---|---|

| Document Type | Product Catalog |

| File size | 4.1Mb |

| Category | |

| Company | OKAMOTO MACHINE TOOL WORKS,LTD (Documents List) |

Documents related to this company

Document Contents

Page1

COMPANY GUIDE

Head Offi ce/Annaka Factory Access

By Train To Niigata

From JR Takasaki Station, Shinetsu Main Line to Isobe, Joetsu Shinkansen Kan-etsu

Expressway

then approx. 5min by taxi Annaka Hokuriku Shinkansen

Approx. 15min by taxi from the Hokuriku Shinkansen Anna- To Nagano

Haruna

Station

ka-Haruna Station The World’s Only Total Abrasive Process Machine Manufacturer

To Yokokawa Route 18

Isobe Takasaki JCT

By Car

Takasaki

Station

Kita Kanto

Station Expressway

JR Shin-etsu Line Fujioka JCT

From the Joshin-etsu Expressway Matsuida-Myogi IC, take Matsuida-Myogi IC

the exit for Annaka/Matsuida. Turn right onto Route 18 to- Joshin-etsu Expressway

wards Takasaki/Annaka. Turn right at the fourth set of lights OKAMOTO MACHINE TOOL WORKS, LTD.

(Annaka Kogyo Danchi Iriguchi). Approx. 7km (10min) from

To Tokyo

Matsuida-Myogi IC.

To Saku

To Karuizawa Route 18

7-Eleven

To

Takasaki

Shin-etsu Main Line

Fire station

Matsuida-Myogi IC

Okamoto

Machine Tool Route 18

To Fujioka Works Annaka

Kogyo Danchi

Iriguchi

〒

GS

Usui River

Head Office/

Parking Annaka Factory Sakuraya

Sakuemon GS

〒

Isobe Station

N

Shin-etsu Main Line W E

S

OKAMOTO MACHINE TOOL WORKS, LTD.

2993 Gobara, Annaka, Gunma, Japan 379-0135

TEL : +81-27-388-9595 FAX : +81-27-385-1144

http://www.okamoto.co.jp

202006100MTR-0

Page2

The World’s Only Total Abrasive Processing Machine Manufacturer

Technology the Right Way

From 1935 to 2035 and beyond

Development Production

Proposal Sale

Service

Machine Tools Semiconductor Equipment Gears Casting

World-class machine tools born of workmanship cultivated Trusted manufacturing equipment supported by proven tech- The roots of manufacturing Pursuing peak precision through integrated production sys-

over the course of more than 80 years. nology that sustains market needs Founder Okamoto Kakusaburo’s creed lives on in our origins tems and in-house manufacturing

Okamoto Machine Tool Works’ wide product range and global Cultivated over many years, our polishing technology is used Okamoto Machine Tool Works began with the fabrication of Casting sets the foundation for meticulous quality control

scale in grinding machines place the company among the best to produce the chips in smartphones, computers, and auton- gears. In 1926, Okamoto In-house casting allows us to

in the world. Since the developing of Japan’s first domestic omous vehicles, contributing to the future of interconnected Kakusaburo founded the implement meticulous quality

surface grinder in 1953, we have constantly sought to create lifestyles in an IoT world. Our unique expertise and technology Okamoto Specialized Ma- controls.

cutting-edge products as a leader in grinding machines. Our in abrasive processing enable the production of thinner, fl atter chine Tools Factory, which The foundry at our Okamo-

diverse product lineup caters to all customer needs, including semiconductor wafers and devices for use across a broad a few years later developed to factory in Thailand has

surface, form, cylindrical, internal, gear, and specialized grind- range of fi elds. Japan’s first domestical- a maximum monthly pro-

ers, from general-purpose to fully automated CNC type ma- Our Semiconductor Equipment Division offers products in a ly-produced gear grinder. duction capacity of 1,800t,

chines. wide range of categories: grinding, CMP/polishing, wrapping This development contribut- enabling us to manufacture

Our mission is to produce the machines used in manufacture. and slicing. Our ongoing research and technical development ed signifi cantly to the manufacturing industry at the time. cast parts such as machinery frames and columns in-house

We are proud to supply the ‘mother machines’ that support the of both software and hardware ensure us to we can match the Today, gear fabrication falls within the operations of group from wooden molds. This greatly improves our rate of in-house

world’s production today. speed of our customers’ progress at the cutting edge. company Okamoto Koki Co., Ltd. The company uses automat- manufacturing, with an integrated production system that cov-

Seeking to maintain and reasonable price and in quality, de- The ever-evolving semiconductor industry requires the devel- ed production lines with articulated robots to effi ciently manu- ers everything from design and casting to parts processing,

livery and service as well as precision, and functions, we have opment of equipment that anticipates the future. Our Semicon- facture high-precision gears that are employed in fi elds such as coating and product assembly. In addition to improving quality,

established an integrated production system in handling from ductor Equipment Division constantly tackles this demanding automobiles, agricultural equipment, and the outboard motor this approach contributes signifi cantly to raising production ca-

supply to logistics in-house. Remaining sensitive to market challenge, off ering visionary ideas that contribute to the future. industry. Maintaining the entire production process in-house pacity, shortening delivery times, and reducing costs. It also al-

trends and technical advances, we continue to research and with our own gear fabrication machinery allows us to off er rap- lows us to cater to customers requiring specialized casting. We

develop the grinding processes the world demands. id, high-quality solutions. As the culmination of our cultivated produce high-rigidity casts in a diverse range of shapes and

expertise, we provide high-precision ‘zero noise, zero vibration’ sizes, supplying quality casting to fulfi lls the needs of various

gears and gear units. industries.

1 2

Page3

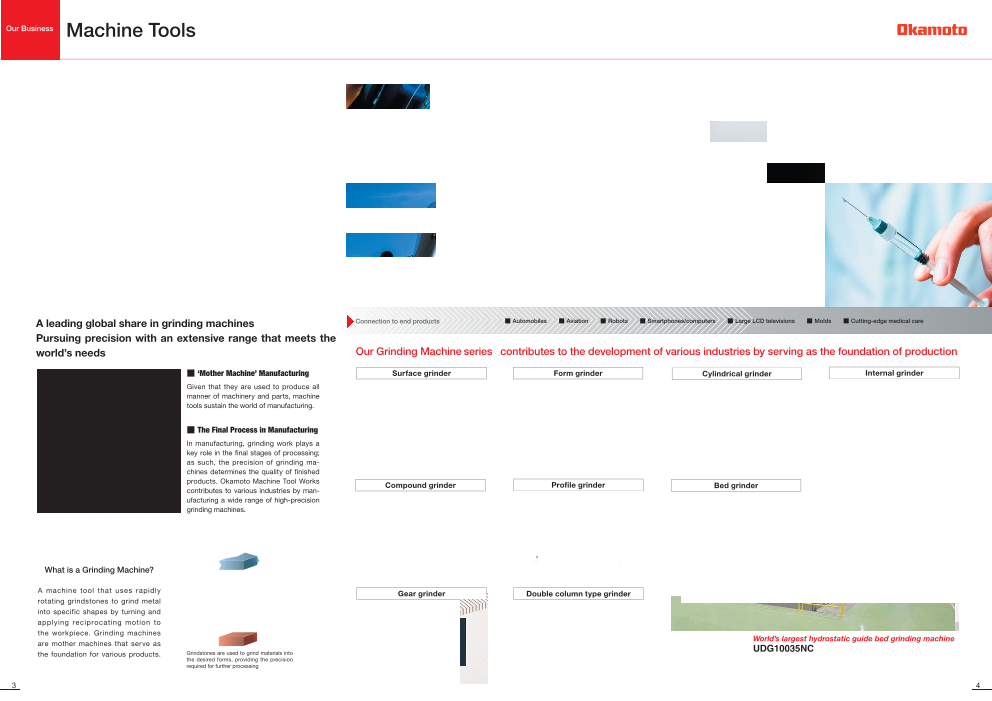

Our Business Machine Tools

The Origin of Precision

A leading global share in grinding machines Connection to end products ■ Automobiles ■ Aviation ■ Robots ■ Smartphones/computers ■ Large LCD televisions ■ Molds ■ Cutting-edge medical care

Pursuing precision with an extensive range that meets the

world’s needs Our Grinding Machine series contributes to the development of various industries by serving as the foundation of production

■ ‘Mother Machine’ Manufacturing Surface grinder Form grinder Cylindrical grinder Internal grinder

Given that they are used to produce all

manner of machinery and parts, machine

tools sustain the world of manufacturing.

■ The Final Process in Manufacturing

In manufacturing, grinding work plays a

key role in the fi nal stages of processing;

as such, the precision of grinding ma-

chines determines the quality of finished

products. Okamoto Machine Tool Works

Compound grinder Profi le grinder

contributes to various industries by man-

Bed grinder

ufacturing a wide range of high-precision

grinding machines.

What is a Grinding Machine?

A machine tool that uses rapidly Gear grinder Double column type grinder

rotating grindstones to grind metal

into specific shapes by turning and

applying reciprocating motion to

the workpiece. Grinding machines

are mother machines that serve as

World’s largest hydrostatic guide bed grinding machine

the foundation for various products. Grindstones are used to grind materials into

UDG10035NC

the desired forms, providing the precision

required for further processing

3 4

Page4

Our Business Semiconductor Equipment

The Ultimate in

Planar Surfaces

Looking to the future Connection to end products ■ Next-generation power semiconductor Sic ■ Input wafers ■ Electric cars ■ IC chips ■ Smartphones/computers ■ Large lenses

with cutting-edge manufacturing for IoT societies

Trusted manufacturing equipment supported

by proven technology

■ Polishing Technology Semiconductor equipment – a key part of the

Our range of semiconductor equipment semiconductor manufacturing process

supports manufacturing with technology

that produces thinner, fl atter semiconduc-

tor silicon wafers. Semiconductor

Manufacturing Process

■ Contributing to cutting-edge Grinds/polishes wafer surfaces to a mirror fi nish Polishes wafer surfaces to smooth any unevenness in the pattern

technical innovation Final Polisher Wafer Polisher

Okamoto Machine Tool Works contributes 【Front-end process】

to the progress of IoT in society, including Pattern

fields such as robotics, AI technology,

Circuit/

pattern

Photomask Ingot Ingot Photoresist formation Ion

production building cutting Wafer grinding/polishing coating on wafer Etching implantation Planarization (CMP)

Electrode Inspection

formation of wafer

power devices for automobiles, fl at panel design surface

screen mother glass, and increasing the

capacity of electronics. Product

Wafer backgrinding

Wafer Chip Wire Trim &

dicing mounting bonding Mold form Burn-in

inspection/ Com-

reliability Marking pletion

inspection

【Back-end process】

What is a Semiconductor? Semiconductors are also used to con- Wafer fabrication grinder

trol social infrastructure, such as train

A substance that only conducts elec- operation systems, banking and bro- Grinds wafers from the back side to a customer’s ■ Large LCD panels ■ Photovoltaic cells, solar panels

desired thickness

tricity under given conditions. The term kerage functions, electricity, gas, and

generally refers to electronic compo- waterworks, underpinning our modern

nents made using this arrangement. culture and lifestyle.

All sorts of products are equipped

with semiconductors, including dig-

ital consumer electronics such as

smartphones, computers and LCD

televisions, as well as refr igera-

tors, washing machines and cars.

Pitch polisher Photovoltaic ingot compound grinder

5 6

Page5

Production Global Integrated Production System

Global Scale: Assured quality with a production system spread across 4 locations – Japan, Singapore, Thailand, China Global-standard quality management systems

Three ISO9000-certifi ed factories in Japan and

abroad

Japan Our fl agship factory complete with facilities Thailand Grinding machine integrated production

Head Offi ce / and systems such as cleanrooms and me- Okamoto (Thai) Co., Ltd. system factory offering everything from

Annaka Factory ticulous temperature control Integrated production system fl ow Ayudhaya, Thailand casting fabrication to machinery sales

Annaka, Gunma

Design Wood

Machine

molds Casting Coating proce Assembly Inspection

Shipment

-ssing /sale

Sheet-

metal Cleaning Coating

processing

All production processes completed

in-house! ◎ Wood mold factory

An effi cient network,

coordinating 4 production facilities

according to demand

◎ Casting fabrication plant

Monthly casting production capacity: 1,800t

■ Overview

■ Overview

Established: 1987

Established: 1982

2 Site area: 69,324m

2

Site area: 68,224m

2 Total fl oor area: 26, 585m

2

Total fl oor area: 27,648m

■ Wood molds

■ Basic design ■ Casting Automatic coating system ◎ Integrated production system factory

■ Processing using automated conveyors■ Coating Foundry coordination enables flexible machine de-

■ Assembly ■ Processing sign and manufacture

■ Coating ■ Testing

■ Testing

Check operations at

Singapore From design to manufacture of precision pro-all production facilities

Okamoto (Singapore) Pte Ltd cessing machines, alongside semiconductor

Woodlands Newtown, Singapore equipment production

China Gear fabrication and local

Okamoto Machinery (Changzhou) Co.,Ltd assembly/sale of grinding

Changzhou, China machines

■ Overview

Established: 2004

Site area: 8,778m2

Total fl oor area: 6,688m2

■ Assembly

■ Gear processing/fabrication ■ Overview ■ Processing

Established: 1973 ■ Assembly

Site area: 24,000m2 ■ Coating

Total fl oor area: 18,250m2 ■ Testing

7 8

Page6

Production Our flagship ‘mother machine’ factory – Head Office/Annaka Factory

Traditional techniques live on through hand scrapers

Our state-of-the-art main factory enables high quality and high precision Hand scrapers carry the tradition of more than 80 years of work-

manship in machine tool production. The combination of this tra-

ditional skill and the latest technology underpins manufacturing

at Okamoto Machine Tool Works.

■1 Large-scale processing line ■2 Sheet-metal processing line ■3 Mid-size processing line ■4 Temperature-controlled booth

The fusion of traditional techniques and cutting-edge technology

■6 Spindle processing/assembly ■5 World’s largest ultraprecision high rigidity bed grinder

■11 Semiconductor equipment assembly booth To meet the demand for ultraprecision grinding of liquid-crystal displays and other large

parts, we have set up the world’s largest bed grinding machine in a temperature-controlled

booth, with a processing range of L10m x W3.5m (W4m clearance).

2 5

3

■12 Semiconductor cleanroom Resource recycling through fi ltration

4 The large-scale grinder in our tempera-

1 ture-controlled booth integrates treatment of

grinding lubricant, helping to reduce industrial

6

waste and improve the environment. Similarly,

we also collect, fi lter, and reuse silicon fl uid

■7 Measuring room from test processing in our semiconductor

cleanroom.

7

9 Before fi ltering After fi ltering

8

11 ■13 Test grinding showroom

12

13

10

■8 Cylindrical/internal grinder

Batch fi ltration system for large-scale

grinding machines

assembly line

■9 Surface grinder assembly line

Batch fi ltration system

for semiconductors

Completely windowless to avoid

Double-walled structure with air temperature changes due to

inner insulation layer sunlight exposure

Semisubterranean construction ■10 Technical Development ■ Materials building

Headquarters

13.7m

[ Complete air conditioning ]

Semisubterranean, windowless factory

Embankment Complete air conditioning: temperature settings – Summer 26°C, Winter 20°C

Temperature change: ±2°C/day

5m

Factory floor 4.15m

Materials storage Temperature diff erence: less than 3°C between fl oor and height of 8m

Factory foundations

[ Insulation ]

Roof and exterior walls consist of a double-walled structure, with insulating

material inserted in between.

Earthquake-resistant

loam tableland Semisubterranean construction sunk 4.15m beneath the ground’s surface,

with concrete exterior walls reaching 5m from fl oor level.

9 10

Page7

Sales Global Network

Key hubs effi ciently linked by a global network spanning manufacture to sales America

Off erings tailored to the needs of customers with global ambitions Reaching users around the world

Beginning with America, the history of our

overseas operations is a testament to quality.

We now off er products tailored to each region

– Asia, America, Europe, and Oceania.

Sales staff offer first-class advice

on grinding

Our sales staff are experts in grinding pro-

cessing, equipped with a wealth of knowledge

to offer optimal suggestions. In coordination Japan

with our Technology Research Division, we

Okamoto Machine Tool Okamoto Machinery organize training seminars for staff around the

Europe GmbH (Changzhou) Co., Ltd. Okamoto Corporation world, constantly sharing the latest informa-

tion. We are committed to a sales approach

Herford Shanghai that always puts our customers fi rst.

Sales Offi ce (D) Sales Offi ce Santa Fe Springs, Louisville,

CA Sales Offi ce KY Sales Offi ce

Nottingham Shenzhen Dalian Exhibitions, private shows -

Sales Offi ce Sales Offi ce Sales Offi ce Windsor, Pursuing true quality by engaging

CT Sales Offi ce with our customers

In addition to offering a broad range of infor-

mation and ideas through our daily operations,

Germany

we also hold large-scale exhibitions and regu-

lar private shows that allow us to grasp the di-

verse needs of our customers in the constant

pursuit of greater quality.

Okamoto Koki Co., Ltd.

An affi liated company specializing in the fabrication of ‘zero noise, zero

vibration’ gears

Head Offi ce / Annaka Factory /

North Kanto Sales Offi ce

Toyama Sendai

Hiroshima Sales Offi ce Sales Offi ce

Sales Offi ce

Greater Tokyo

Fukuoka Sales Offi ce

Sales Offi ce

Giken Co., Ltd.

Production & Sales Facilities (Okamoto Overhaul Division)

Japan 10 locations Shizuoka

Sales Offi ce

Head Offi ce/Fukuyama Factory Onomichi Factory Fuchu Factory

North America 4 locations Nagoya

Sales Offi ce

Europe 3 locations

Osaka

Sales Offi ce

China 4 locations

Okamoto (Thai) Co., Ltd. Okamoto (Singapore)

Pte, Ltd. Asia 2 locations

11 12

Page8

Personnel Bringing together Professionals in Grinding – A Company Powered by People

The Right People

[ Technology the Right Way ]

The relentless quest ◆Individuals who keep striving to improve their capabilities, knowledge and skills

for ultraprecision ◆Individuals who consider what they can off er, determine what needs to be done, and act

◆Individuals who can use experience to grow

◆Ethical individuals whose actions align with social progress

We seek talented people who value these aspects and seek

success on a global stage.

Abrasive processing professionals

In our constant quest for ultraprecision – from micro to nano and angstrom – Okamoto

Machine Tool Works strives to create a ‘grinding revolution’, a new total solution that

will transform established ideas. As a group of professionals in complex abrasive

processing technology (fi xed and free abrasive machining), we continue to challenge

ourselves to meet the market’s demand for precision.

Taking world-class technology to a new dimension

We offer a higher level of abrasive processing solutions, including fully-automated

surface grinding systems, highly efficient systems powered by IoT technology, and

environmentally-friendly grinding machines. Constantly striving to be a leader in

grinding machines, we will continue to off er the market world-class technology.

Keeping traditional techniques alive

By using traditional techniques such as hand scrapers in the production of machine

tools, we strive to share Japanese manufacturing with future generations. Amid the

globalization of manufacturing and increasingly high-tech approaches, we aim to

provide younger staff with opportunities to fl ourish.

Technology Fabrication Sales Control

13 14