1/10ページ

Download(2.5Mb)

Ultra Precision Form Grinding Machine UPZ Series

Product Catalog

Document Information

| Document Title | Ultra Precision Form Grinding Machine UPZ Series |

|---|---|

| Document Type | Product Catalog |

| File size | 2.5Mb |

| Category | |

| Company | OKAMOTO MACHINE TOOL WORKS,LTD (Documents List) |

Documents related to this company

Document Contents

Page1

Ultra Precision Form Grinding Machine

UPZ Series

OKAMOTO MACHINE TOOL WORKS, LTD.

2993 Gobara, Annaka, Gunma, Japan 379-0135

TEL : +81-27-388-9595 FAX : +81-27-385-1144

URL : www.okamoto.co.jp

*Prior to and while using our products you are requested to thoroughly go through the articles on danger, warning and attention for the sake of safety described in

operation manual attached to the machine and also in the warning plates mounted on the machine.

*When the products fall under the export controlled goods stipulated in“ Foreign Exchange and Foreign Trade Act”, it requires the license or approval of Government

CAUTION of Japan when exporting out of Japan.*Specifications subject to change without notice.

Printed in Japan in June 2020 2020061000AD-01

Page2

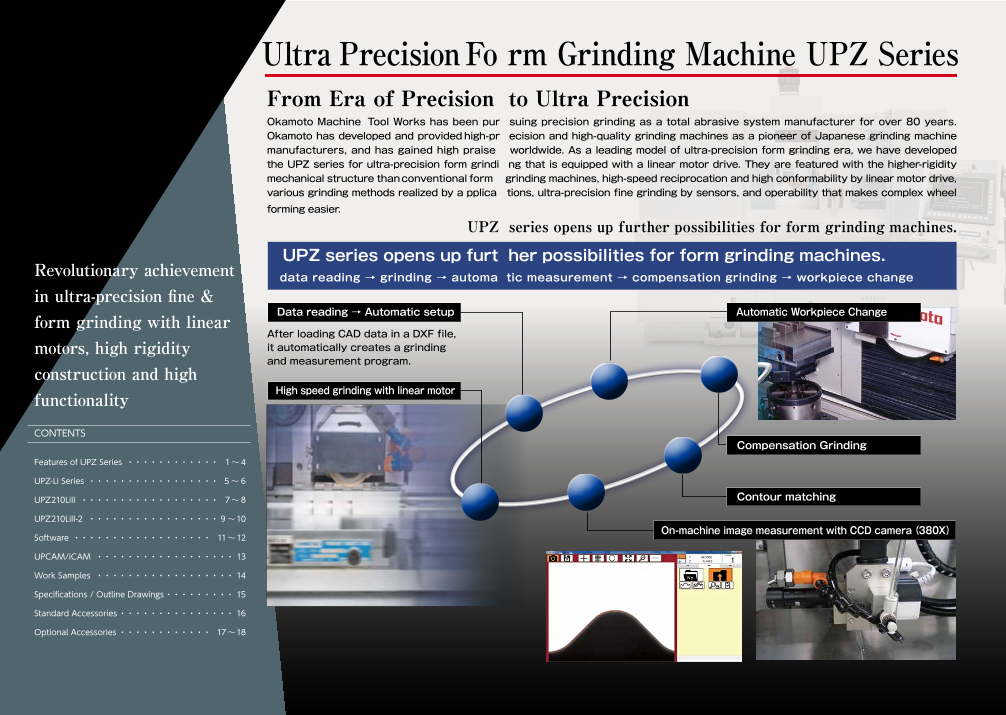

Ultra Precision Fo rm Grinding Machine UPZ Series

From Era of Precision to Ultra Precision

Okamoto Machine Tool Works has been pur suing precision grinding as a total abrasive system manufacturer for over 80 years.

Okamoto has developed and provided high-pr ecision and high-quality grinding machines as a pioneer of Japanese grinding machine

manufacturers, and has gained high praise worldwide. As a leading model of ultra-precision form grinding era, we have developed

the UPZ series for ultra-precision form grindi ng that is equipped with a linear motor drive. They are featured with the higher-rigidity

mechanical structure than conventiona l form grinding machines, high-speed reciprocation and high conformability by linear motor drive,

various grinding methods realized by a pplica tions, ultra-precision fine grinding by sensors, and operability that makes complex wheel

forming easier.

UPZ series opens up further possibilities for form grinding machines.

UPZ series opens up furt her possibilities for form grinding machines.

Revolutionary achievement data reading → grinding → automa tic measurement → compensation grinding → workpiece change

in ultra-precision fine &

Data reading → Automatic setup Automatic Workpiece Change

form grinding with linear

After loading CAD data in a DXF file,

motors, high rigidity it automatically creates a grinding

and measurement program.

construction and high

functionality

High speed grinding with linear motor

CONTENTS

Compensation Grinding

Features of UPZ Series ・・・・・・・・・・・・ 1 〜 4

UPZ-Li Series ・・・・・・・・・・・・・・・・・ 5 〜 6

UPZ210LiII ・・・・・・・・・・・・・・・・・・ 7 〜 8 Contour matching

UPZ210LiII-2 ・・・・・・・・・・・・・・・・・ 9 〜10

On-machine image measurement with CCD camera (380X)

Software ・・・・・・・・・・・・・・・・・・ 11 〜12

UPCAM/iCAM ・・・・・・・・・・・・・・・・・・ 13

Work Samples ・・・・・・・・・・・・・・・・・・ 14

Specifications / Outline Drawings ・・・・・・・・・ 15

Standard Accessories ・・・・・・・・・・・・・・・ 16

Optional Accessories ・・・・・・・・・・・・ 17 〜18

Page3

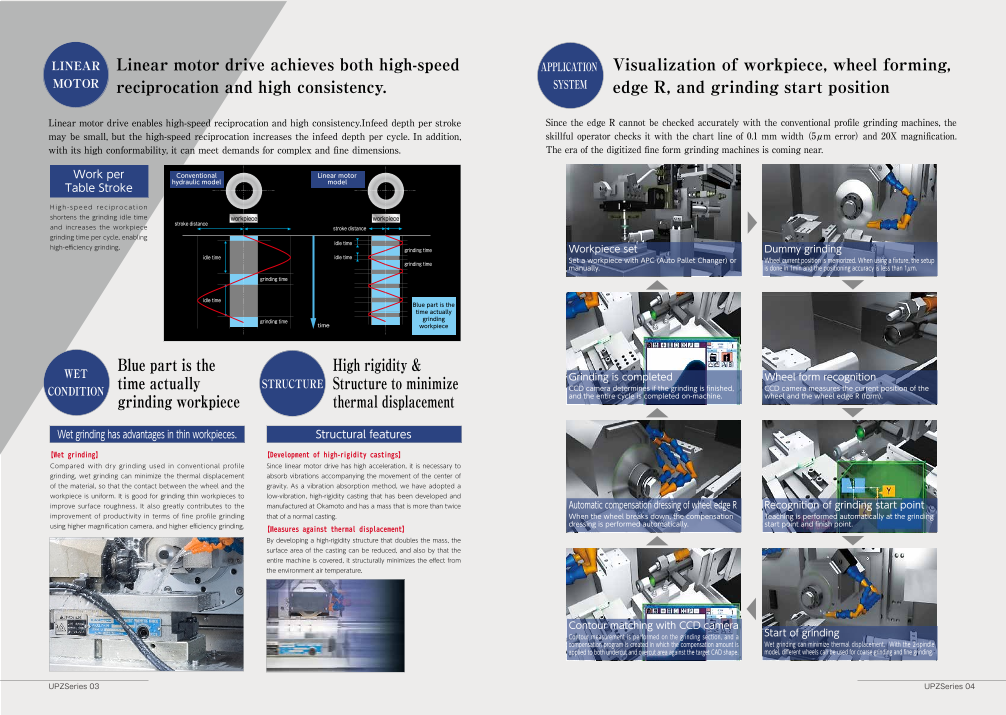

LINEAR Linear motor drive achieves both high-speed APPLICATION Visualization of workpiece, wheel forming,

MOTOR reciprocation and high consistency. SYSTEM edge R, and grinding start position

Linear motor drive enables high-speed reciprocation and high consistency.Infeed depth per stroke Since the edge R cannot be checked accurately with the conventional profile grinding machines, the

may be small, but the high-speed reciprocation increases the infeed depth per cycle. In addition, skillful operator checks it with the chart line of 0.1 mm width (5μm error) and 20X magnification.

with its high conformability, it can meet demands for complex and fine dimensions. The era of the digitized fine form grinding machines is coming near.

Work per Conventional Linear motor

Table Stroke

hydraulic model model

H i gh - sp e e d re c i p ro c a t i o n

shortens the grinding idle time workpiece workpiece

and increases the workpiece stroke distance stroke distance

grinding time per cycle, enabling

high-efficiency grinding.

idle time

grinding time Workpiece set Dummy grinding

idle time idle time

grinding time Set a workpiece with APC (Auto Pallet Changer) or Wheel current position is memorized. When using a fixture, the setup

manually. is done in 1min and the positioning accuracy is less than 1μm.

grinding time

idle time

Blue part is the

time actually

grinding time grinding

time workpiece

WET Blue part is the High rigidity &

time actually STRUCTURE Structure to minimize Grinding is completed Wheel form recognitionCONDITION CCD camera determines if the grinding is finished, CCD camera measures the current position of the

grinding workpiece thermal displacement and the entire cycle is completed on-machine. wheel and the wheel edge R (form).

Wet grinding has advantages in thin workpieces. Structural features

【Wet grinding】 【Development of high-rigidity castings】

Compared with dry grinding used in conventional profile Since linear motor drive has high acceleration, it is necessary to

grinding, wet grinding can minimize the thermal displacement absorb vibrations accompanying the movement of the center of

of the material, so that the contact between the wheel and the gravity. As a vibration absorption method, we have adopted a

workpiece is uniform. It is good for grinding thin workpieces to low-vibration, high-rigidity casting that has been developed and

improve surface roughness. It also greatly contributes to the manufactured at Okamoto and has a mass that is more than twice Automatic compensation dressing of wheel edge R Recognition of grinding start point

improvement of productivity in terms of fine profile grinding that of a normal casting. When the wheel breaks down, the compensation Teaching is performed automatically at the grinding

using higher magnification camera, and higher efficiency grinding. 【Measures against thermal displacement】

dressing is performed automatically. start point and finish point.

By developing a high-rigidity structure that doubles the mass, the

surface area of the casting can be reduced, and also by that the

entire machine is covered, it structurally minimizes the effect from

the environment air temperature.

Contour matching with CCD camera

Contour measurement is performed on the grinding section, and a Start of grinding

compensation program is created in which the compensation amount is Wet grinding can minimize thermal displacement. With the 2-spindle

applied to both undercut and overcut area against the target CAD shape. model, different wheels can be used for coarse grinding and fine grinding.

UPZSeries 03 UPZSeries 04

Page4

High speed stroke grinding with table longitudinal linear motor drive Mechanical structure that minimizes thermal displacement

■ Oil chilled grinding head Same height

Ultra Precision UPZ-Li series ■ Fan-free, liquid coolant, jacketed wheel spindle motor■ Machine structure that minimizes the effects of thermal Form Grinding Machine displacement by placing the column cross feed slide closer

to the grinding point

■ Hydraulic cylinder-free table drive system

LINEUP ■ It minimizes expansion in the spindle thrust direction which achieves stable movement much quicker.

UPZ315Li Grinding point and column slide surface height

UPZ52Li Text-free interactive software that supports easy use

Grinding condition setting page

The text-free interactive software developed as a global standard

software can be easily operated by touch input while looking at the

strokes/min infeed per stroke icons on the screen.

(reciprocations/min) (㎛)

UPZ315Li

600strokes

(300reciprocations) 1.2 Spindle elongation comparison

Hydraulic servo form

grinding machine of 380strokes(190reciprocations) 1.5Okamoto Variety of grinding is available

〜Grinding conditions〜

UPZ52Li 1. Material: Carbide 2. Grinding allowance: 0.6mm

3. Shape: Flat surface 4. Grinding time: 1min Crowning Contouring

5. Stroke: 20 mm

By controlling the longitudinal By controlling the crossfeed and

and vertical axes. vertical axes.

Grinding condition setting

■ High efficiency grinding with high speed ■ Variety of options such as wheel forming dressers,

reciprocation grinding indexing devices and measuring devices are Wheel Forming Coarse / Medium / Fine Cycle

Option

■ On-machine measurement & automatic available. Forming grinding wheel can be Three stages of (coarse, medium

and fine) grinding cycles and

compensation grinding with CCD camera.

Option

■ Fine and complex form grinding is simplified by

set by interactive software.

dress inter vent ion are a l so

■ High conformability with 3-axis scale feedback. graphic interactive software. possible.

Multi-position Option

High rigidity mechanical structure

Multiple workpieces with

dif ferent shapes can be

■ Column travelling structure ■ Long slide structure with downward mounted on the chuck and

■ Fully supported and stable feeding vertical column be ground simultaneously.

accuracy ■ High rigidity structure with wide Examples

■ T-shape in teg ra ted f rame column structure

structure

Workpiece:Test work

Material: SKD11

Hardness:HRC55

Form accuracy:

Multi-position grinding of LED die Multi-position grinding ± 0.002 mm

Column size / rigidity comparison

(compared to conventional model PFG450DXA) 5-axis Model Option

By controlling the 5 axes (vertical / longitudinal / crossfeed / tilt

/ rotation), complex aspherical faces can be ground. Workpiece:LED die

Material:STAVAX

Hardness:HRC58

Surface roughness:

Ra0.0093 μm

T-shape integrated frame Aspherical workpiece

Long slide structure

UPZSeries 05 UPZSeries 06

Page5

Ideal conformability with 3-axis linear motor drive Performs ultra-fine form grinding User-Friendly Interactive Software

by visualizing grinding of difficult-to-cut materials with a CCD camera

【Graphic Function】

Ultra Precision Form Grinding Machine UPZ210LiII ■ G code programs are displayed graphically without starting a cycle. Work efficiency including

programming and confirmation is improved.

【Program Diagnosis Function】

■ For difficult-to-cut materials (SUS, carbide, titanium, ■ Program diagnosis function and background Graphic display page

etc.), high-speed reciprocating grinding with a editing are equipped as standard accessories to

prevent input errors of G code program.

linear motor drive has an advantage.

【Automatic Programming Function】 G code contouring page

strokes/min infeed per stroke

(reciprocations/min) (㎛) ■ G code program is created simply by selecting

the grinding start position and finish position.

UPZ210LiⅡ 800strokes(400reciprocations) 1.43

Hydraulic servo form

Various Applications

grinding machine of

402strokes 2.5

Okamoto (201reciprocations) Tilt Head Ultra Thin Wheel Forming

〜Grinding conditions〜

1. Material: Carbide 2. Grinding allowance: 1mm 3. Shape: Flat surface

4. Grinding time: 1min 5. Stroke: 20 mm Like profile grinding machines, 【GRIND-X Twin Rotary Dresser】 Option

the wheel spindle can be swung

■ CCD camera with the maximum magnification 380X can in the crossfeed direction (±3°)

with a handwheel. It uses a sta-

enlarge the vision of a fine workpiece, and the image ble part of the wheel edge R to

measurement accuracy is less than 1μm.

form better surface roughness

and form accuracy.

UPZ315L(i CCDカメラ仕様) ■ Easy to import CAD data and ease of data input

■ A Workpiece after grinding is measured on-machine

and compensated automatically.

■ Detachable compact index device allows

Option

UPZ210LiⅡ indexing and grinding. Grinding with tilted spindle It has been very difficult to form the

■ Small size wheel φ30mm can be attached, which is ide- Example width of a wheel to smaller than 0.2

Option mm. Twin rotary dressers can solve the

al for fine and ultra-thin grinding of carbide workpieces. problem. The maximum formable width

is 8 mm, and the dressing can be per-

formed in a stable manner. Another ad-

Ultra fine grinding with CCD camera High rigidity mechanical structure Workpiece:Punch

vantage of this dresser is that the RPM

Material:KD20 is controlled by the inverter, so that

Dimensions:4×1.4×50mm the same speed condition mode can

■ The image of fine workpiece is output on the screen for ■ In order to adopt the high acceleration of linear motor Hardness:HRA90 be used to make the wheel peripheral

grinding, which is the same system as the profile grinding drive, the main unit weight of form grinding machine is Surface roughness:Ra0.0208μm speed and the dresser peripheral speed We have had experience of grind-

machines. 5700 kg even with its compact size. Form accuracy:±1.4μm the same.

ing with the wheel width: 0.05 mm

and sticking amount : 4 mm.

■ Measurement is automatically performed after grinding. ■ A fully-closed cover structure is used to shut the casting

■ After final automatic compensation grinding, the stable body from the ambient air, which minimizes thermal

product accuracy can be obtained. displacement of the main body.

Indexing Device

【Round Shape Grinding】 Option

Example

The design is compact with no interfere of

the grinding wheel so that it can be placed

parallel or perpendicular to the table axis

depending on the workpiece shape. There

is also an advantage that cycle time can be

shortened especially for double-sided grinding

of round carbide punch and thin punch.

Workpiece:Torque spin

Material:UF12 Hardness:HRA92

Dimensions:φ 1.6 × 20.5mm

Form accuracy:± 0.003mm

UPZSeries 07 UPZSeries 08

Page6

Specializing in contouring grinding with diamond wheel, Accurate form dressing

Achieve rough / finish grinding without exchanging grinding wheels.

GRIND-X Orthogonal Rotary Dresser Option

UPZ210LiII-2 By re-dressing the wheel edge R, automatic grinding of 2μm Ultra precision form grinding machine accuracy level is possible. Truing by Orthogonal Rotary Dresser

■ With ATC (Auto Tool Changer), it is difficult to

Before After

suppress runout in performing ultra-precision R shape 0.0567 0.0417

GRIND-X orthogonal

grinding, and it can affect the surface quality, so rotary dresser forms Roundness 0.0059 0.0011

it is ideal to use 2spindles for coarse and fine micron order round-

ness and R shape in

grinding.

Wheel: metal bond Shape after dressing

approximately 1 hour. Dressing time: 62min 06sec

■ By using APC (Auto Pallet Changer) model, an Flow chart of finishing grinding of die parts

unmanned automatic grinding system of fine die

parts can be built up to final finish grinding pro- ① Reference point measurement with CCD camera for dummy grinding cycle ② From start of grinding to compensation grinding

cess.

■ Combination of the left V and right V faces utiliz-

ing the tilt head function facilitates double-side

grinding.

■ Through a series of operations of CAD data read-

ing → fine grinding → automatic measurement Dummy Grinding Measurement with CCD camera Indexing is done automatically at the After grinding is completed, measured automatically.

with a CCD camera→ compensation grinding grinding start point and start grinding. Perform compensation grinding as necessary.

→ automatic workpiece change, grinding of fine Y -200.0000

Z - 10.0000 Z distance

workpieces is digitized and automated. R 0.0350 Grinding

UPZ210LiⅡ-2(standard model) reference point Y distance

palette

R measurement

Advantages of 2 spindles Memorize R shape measurement Automatic recognition of

Chuck

current point Offset of wheel edge R grinding reference point

Application

An example of punch

grinding with UPZ210LiII

by sharing the die pro-

cessing CAD data of a

wire electrical discharge

machine (W-EDM). W-EDM (die processing)

CAD

Left V + right V faces Fine V + coarse V faces Straight wheel + V faces data

Double-side grinding utilizing tilt head Cycle time is shortened by properly using Two dif ferent shaped wheels can be

function (±3°) is available. coarse and fine wheels. equipped, enabling efficient fully automatic

grinding without replacing wheels.

APC model (automatic workpiece changer) UPZ210LiⅡ-2(punch grinding)

The error at the time of pallet replacement can be

canceled by checking the grinding start position Example

from the reference position each time by image

processing with a CCD camera. Workpiece:Press punch

Material:G3

Hardness:HRA88〜89

Accuracy:±0.002mm

inside of APC UPZ210LiⅡ-2(APCmodel)

UPZSeries 09 UPZSeries 10

Page7

SOFTWARE SOFTWARE

UPZ-Li Series Software Description UPZ210LiII Series Software Description

Easy touch panel Various Grinding G Code Contouring

The screen uses touch input. By touching while looking at the panel buttons, it is possible to set up grinding of complex shapes. By combining of plunge and traverse, with calculation Just by entering the passage program number created by the

of various shapes using formulas, the obtained data is user in UPCAM / iCAM, it can synchronize with the automatic

transferred to pattern data. cycle.

【Grinding Data Automatic Setup Function】

Just by entering wheel grain size and wheel width, optimum It also supports the automatic compensation function of

grinding conditions and dressing conditions are automatically the grinding start position and the intermediate dressing in

created, incorporating Okamoto's abundant grinding know-how correspondence to the changes on the wheel offset value.

into grinding theory. It supports standard wheels, CBN wheels

and diamond wheels. Dressing

8 types of wheel dressing programs are standard in the

Dressing Compound grinding interactive software.

5types (7types in total) of wheel dressing programs are in- By combining plunge, traverse, side and pitch machining

stalled in the interactive software. After replacing the wheel, modes, various shapes can be machined in one cycle.

the grinding reference position is automatically set just by 40 pattern combinations are available such as even & uneven

teaching the dressing point. pitches and steps grinding.

【Wheel forming programs available in interactive software】

①Straight, Side ②Convex R, Side R, Double Concave, Side Concave After replacing the wheel, the grinding reference position is

③V shape, Angle, V+R ④R+Taper ⑤Original automatically set just by teaching the dressing point. (when

using a straight wheel)

Multi-position Option Crowning Grinding Option 【Wheel forming programs available in interactive software】You can check the next process and change the grinding & ①Straight ②Convex R ③Side R ④V ⑤Angle

Up to 5 workpieces with different heights and lengths can be It is possible to perform profile grinding with taper, arc, and dressing conditions during the cycle on the monitor screen . ⑥R+Taper ⑦Side Concave ⑧Original

placed on the chuck for grinding in one cycle. angle.

Data Store and Call Table Setup

You can store, call and edit all the grinding condition pattern By adding a reverse mode dedicated to dead-stop grinding,

data and wheel data, which can be managed by names and the usable length of the punch can be managed accurately and

comments. easily.

UPZSeries 11 UPZSeries 12

Page8

OPT UPZ series excels at precision grinding of ultra-fine, molded and Know-how grinding of ultra-fine metal parIts witOh fine forms are aNchieved here. WORK SAMPLE difficult-to-cut materials. Annaka Factory also provides test grinding Automatic grinding programming software service. Please contact your local sales representative for details.UPCAM / iCAM Workpiece:Stepped ejector pinMaterial:SKH51

Hardness:HRC59〜61

The CAM systems“ UPCAM” an d“iCAM” for form grinding are software Dimensions:100×2×0.7mm

that easily creates CNC programs using CAD drawings. Accuracy:Thickness 0〜0.002 mm

No warpage

Operators without knowledge of CNC programs (G code) can easily get used to form grinding.

Simplified Programming

Just by reading the DXF file of the work-

piece and selecting the start point and

finish point, the following is automatically Select start point and finish point Wheel passage programming is completed !

created:

① Coarse shift plunge grinding passage

② Coarse traverse grinding passage

③ Finish grinding passage

Workpiece: Press punch Workpiece:Carbide punch

Coarse Cycle Material:KD10 Material:EF10Hardness:HRA90〜92 Hardness:HRA92

Coarse grinding is performed with shift Coarse shift plunge Coarse traverse Finish contouring

Contour accuracy:±0.001mm Surface roughness:Ra0.0094μm

plunge and traverse, and the grinding Surface roughness:Ra0.0232μm Form accuracy:Within 0.5 μm

allowance for finish contouring is made

uniform.

Workpiece: Optical fiber array Workpiece: Test work

Material:ASP60 Material:G4

Dimensions:4×1.5×0.8mm Hardness:HRA92

Hardness:HRC67〜68 Contour accuracy:±0.002mm

Medium-Finish Grinding Passage Plunge & Traverse Dressing Normal Line Dressing Accuracy:Cumulative pitch ± 0.3μm

If there is a part where the wheel for Innovation in Form Dressing Method When the optional CNC swing dresser is

coarse grinding was not inserted and the Dressing time is reduced to 1/4 by the used in the wheel forming, a program is

remaining grinding allowance is more plunge dressing. created so that the dresser contact point

than the finish amount, a medium-finish is always the same.

grinding passage is created automati- Workpiece:Comparison of form dressing time Power transistor die parts

cally. Some unique ideas are adopted to High-speed dressing with Okamoto's Material:SKD-11

prevent from forming steps during finish software: 4min 2sec, Workpiece:Bending die Hardness:HRC64

grinding, although the wheel to be used Dressing with another company's dresser Material:DA30

Ground part:Slots (50 slots)

is limited to the side V shape. This re- Hardness:HRA89.5 Grinding allowance:0.7mm(by general method): 18min 56sec.

duces the damage to the wheel edge R Form accuracy:±0.001mm Cumulative pitch error:1.8μm

or less Single pitch error:1.2μm

and improves form accuracy.

Workpiece:Connector

Material:SKD-11

Hardness:HRC56〜59 Workpiece:Cut punch

Ground part:Slots (52 slots) Material:EF20

Slot depth:3.2±0.0011mm Dimensional accuracy:

Cumulative pitch error: 0.04±0.001mm

Medium-finish grinding passage Plunge & Traverse Dressing Normal line dressing 25.05±0.0012mm Flatness:0.002mm or less

UPZSeries 13 UPZSeries 14

Page9

Specifications Standard Accessories UPZ315Li / UPZ52Li

unit UPZ315Li UPZ52Li UPZ210LiⅡ UPZ210LiⅡ-2 DOUBLE EAGLE Standard Accessories UPZ315Li UPZ52Li

Table Working Surface Size mm 450×170 550×220 200×110 200×105 1. GRIND-X Wheel (15X60H2G) O.D. φ205mm ○ ○

Table Travel Distance (longitudinal) mm 500 600 270×120 500×120 2. Wheel Adaptor ○ ○

Capacity Distance from Top of the Table to Bottom of the Wheel mm 12.5~395 235 (when O.D. specification is φ80 ) 225 (when O.D. specification is φ80 )

3. Fan-free, liquid coolant, jacketed wheel spindle motor ○ ○

Electromagnetic Chuck Dimensions (length x width x height) mm 350×150×80 400×200×80 175×100×49(electro-permanent magnetic)

4. Wheel Spindle Continuously Variable Inverter 3.7kW (high/low 2-speed setting) ○ ○

Chuck Load Capacity kg 28 41 5

Feed Speed m/min 0.1~30 0.1~60

5. Oil chilled grinding wheel head (also used as a linear motor cooling system) ○ ○

Maximum Travel Distance mm 500 600 270 500 6. Vertical, Crossfeed, Longitudinal Scale Feed Back ○ ○

Longitudinal Rapid Feed Speed (jog feed) mm/min 2000 7. Short Circuit Breaker ○ ○

Feed (X-axis) Minimum Input Increment mm 0.0001 8. 3-Direction Dresser ○ ○

1 graduation mm 0.001/0.01/0.05 0.0001/0.001/0.01/0.1 9. 3-Direction Flexible Nozzle ○ ○

Feed per M.P.G.

1 revolution mm 0.1/1.0/5.0 0.01/0.1/1.0/10.0 10. Wheel Spindle Taper is the same as PFG500 ○ ○

Feed Speed mm/min 1~2000 1~1000 11. Longitudinal Mechanical M.P.G. Controller ○ ○

Maximum Travel Distance mm 180 230 120 120 12. Coolant oil for Linear Motor 40Lit ○ ○

Cross Feed Rapid Feed Speed (jog feed) mm/min 2000 1000

13. Lubricant 3Lit ○ ○

(Z-axis) Minimum Input Increment mm 0.0001

14. Graphic Interactive Software ○ ○

1 graduation mm 0.0001/0.001/0.01/0.05 0.0001/0.001/0.01/0.025 0.0001/0.001/0.01/0.05

Feed per M.P.G.

1 revolution mm 0.01/0.1/1.0/5.0 0.01/0.1/1.0/2.5 0.01/0.1/1.0/5.0

15. Necessary Tools and Toolbox ○ ○

Feed Speed mm/min 1~2000 1~1000 16. Leveling Bolts and Plates ○ ○

Maximum Travel Distance mm 382.5 217(when using permanent magnetic chuck)

Vertical Feed Rapid Feed Speed (jog feed) mm/min 2000 1000 Standard Accessories UPZ210LiII / UPZ210LiII-2 DOUBLE EAGLE

(Z-axis) Minimum Input Increment mm 0.0001

1 graduation mm 0.0001/0.001/0.01

Feed per M.P.G. Standard Accessories UPZ210LiⅡ

UPZ210LiⅡ-2

DOUBLE EAGLE

1 revolution mm 0.01/0.1/1.0

1. GRIND-X Wheel O.D. φ180mm (for chuck grinding) ○ ○ (O.D. φ90mm)

Dimensions (O.D. x W x B) mm φ205×13×φ31.75 Maximum wheel diameterφ180 Maximum wheel diameterφ150

Grinding Wheel

Rotation Speed min-1 500~3600 1000~15000 2. Wheel Adaptor I.D. φ31.75mm balance piece type I.D. φ24mm balance piece type

For Wheel Spindle kW 3.7/2 1.8 1.5 3. Permanent Magnetic Chuck 175×100×49mm ○ ○

For Longitudinal Feed kW 3.0×2 2.0×2 4. Rear Chuck Rail ○ ○

Motor

For Vertical Feed kW 1.3 2.0×2 5. Vertical, Crossfeed, Longitudinal Scale Feed Back ○ ○

For Cross Feed kW 0.85 2.0 6. Wheel Spindle Swiveling Function ± 3° ○ ○

Power Power Consumption (varies by specifications) kVA 26 21 31 7. 3-Direction Dresser ○ ○

Weight Net Weight kg 4000 4500 6000 4600 8. Small Size Wheel Guard – ○

9. Large Size Wheel Guard ○ –

10. SUS Cover ○ ○

11. Automatic Oil Temperature Regulator (for cooling linear motor & spindle) ○ ○

Outline Drawings 12. Coolant oil for Linear Motor & Spindle 20Lit ○ ○

13. Wheel Spindle Built-in Motor ○ ○

14. Wheel Spindle Load Amp Meter ○ ○

15. Wheel Spindle Tilt Mechanism ○ ○

16. Wheel Spindle Continuously Variable Inverter 3.7kw ○ ○

17. Automatic Form Grinding Programing Software (UP-CAM or iCAM) ○ ○

18. LED Light ○ ○

C CC C C C 19. Short Circuit Breaker ○ ○

20. Graphic Interactive Software ○ ○

21. Necessary Tools and Toolbox ○ ○

22. Leveling Bolts and Plates ○ ○

Form Grinding

Automatic Programing Software

D D

D DD D Automatic Form Grinding Programing Software UP-CAM / iCAM

CAD Data Reading Function

Simulation Function

B B B B B B

A A A A A Automatic Programming FunctionA

Coarse Plunge, Traverse Function, Finishing Contouring

Ⓐ Ⓑ Ⓒ Ⓓ Ⓐ Ⓑ Ⓒ Ⓓ CAD Data Comparison Function

Width Width Depth

(including optional accessories) (machine) (including optional accessories) Height

Width Width Depth

(including optional accessories) (machine) (including optional accessories) Height

UPZ315Li 2600 2100 2750 2237 UPZ210LiⅡ 1750 1122 3000 1920

UPZ52Li 2700 2300 2750 2237 UPZ210LiⅡ-2 1880 1602 3665 1907

UPZSeries 15 UPZSeries 16

Page10

Optional Accessories UPZ315Li / UPZ52Li Optional Accessories UPZ210LiII / UPZ210LiII-2 DOUBLE EAGLE

UPZ315Li・UPZ52Li UPZ315Li・UPZ52Li UPZ210Li Ⅱ UPZ210Li Ⅱ -2DOUBLE EAGLE

1 )Chuck, Base 7 )Dresser 1)Chuck Base

1. Electromagnetic Chuck (350 × 150 × 70 mm /400 × 200 × 70mm / 500 × 200 × 75mm) 7. Dresser Coolant System 1. Left Side Chuck Rail ○ ○

2. Electro-Permanent Magnetic Chuck (300 × 200 × 80mm / 350 × 150 × 80mm / 400 × 200 × 80mm) 8. Swing type Dresser(Need a meeting) 2. Jig for Grinding (Fixture) ○ ○

3. Demagnetizing Controller 8 )Electric Related 3. Sign Plate ○ ○

4. Rear and Side Chuck Rails 1. Auto Shut Down Function 4. Permanent Magnetic Chuck 100 × 100 × 40mm ○ ○

5. Constant Coolant Over the Table 2. Timer of Total Run Time 2)Coolant System (possible to be combined with coolant system magnet separator 210 Lit)

2 )Coolant System (possible to be combined with coolant system magnet separator) 3. Signal Tower Light 1. Magnetic Separator ○ ○

1. Magnetic Separator (120Lit) 4. Calendar Timer 2. Manual Paper Filter ○ ○

2. Manual Paper Filter (120Lit) 5. LED Light 3. Automatic Paper Filter ○ ○

3. Automatic Paper Filter (120Lit) 6. Chuck Interlock 4. Automatic coolant temperature regulator ○ ○

4. Automatic Coolant Temperature Regulator (250Lit) 9 )Cylindrical Grinding & Indexing device 5. Cartridge Filter ○ ○

5. Cartridge Filter (250Lit) 1. GRIND-X Horizontal CNC Index 6. Mist Collector, with mounting base ○ ○

6. Mist Collector, with mounting base (250Lit) 2. GRIND-X Vertical CNC Indexing table 3 )Grinding Wheel & Wheel Spindle

3 )Grinding Wheel & Wheel Spindle 3. GRIND-X Precision Cylindrical Grinding Device 1. Big Size Adaptor 500 taper (I.D. 31.75mm) balance piece mobile type ○ -

1. Wheel Spindle Taper Nose Change, PSG52 taper model 4. Precision High Speed Vertical Cylindrical Grinding Device 2. Big Size Adaptor 500 taper (I.D. 31.75mm) micro balancer type ○ -

2. Large Diameter Adaptor 500 taper (for I.D. 31.75mm) balance piece mobile type 5. CNC axis added 3. Small Size Adaptor (I.D. 24.00mm) multi balance piece type ○ ○

3. Large Diameter Adaptor 500 taper (for I.D. 31.75mm) micro balancer type 10 )Peripherals & Others 4. Ultra-Small Size Adaptor (I.D. 8.00mm) multi balance piece type ○ ○

4. Large Diameter Adaptor 52 taper (for I.D. 50.80mm) balance piece mobile type 1. On-Machine Image Processing System, digital CCD camera of automatic lifting light, manual measurement 5. PFG500 type Adaptor (width: 6 ~ 16mm) ○ -

5. Large Diameter Adaptor 52 taper (for I.D. 50.80mm) micro balancer type 2. On-Machine Image Processing System, digital CCD camera of automatic lifting light, automatic measurement 6. Wheel Spindle Taper Nose Change, PFG500 taper model ○ -

4 )Wheel Balancer 3. Form Grinding Automatic Programing Software (UP-CAM or iCAM) 4 )Wheel Balancer

1. Micro Balancer 4. Prism Lens 1. Balance Arbor for standard adaptor ○ ○

2. Precision Motion Balancer 5. Reflected Light Source 2. Balance Arbor for PFG500 taper ○ ○

3. Balance Arbor 6. On-Machine Measuring Device touch probe 3. Precision Motion Balancer ○ ○

5 )Custom Color 11 )Software 5 )Custom Color

6 )Hydraulic & Grinding Fluid 1. Grinding Software, M.P.G. R/T added 6 )Oil & Grinding Fluid

1. Oil Mist Collector 2. Program Transfer Tool 1. Lubricant for wheel spindle bearing and table guide 20Lit ○ ○

2. Grinding Fluid for Carbide 20Lit 3. Installation and Operation Training 2. Coolant Oil for linear motor & wheel spindle bearing 40Lit ○ ○

7 )Dresser 4. Specified Workpiece Grinding 2. Grinding Fluid for carbide 20Lit ○ ○

1. GRIND-X Orthogonal Rotary Dresser 5. Multi Position Grinding 7 )Dresser

2. GRIND-X 2-point Rotary Dresser + Single-point Diamond 6. Crowning Grinding 1. 3-Direction Dresser (with DT-3 : 1pc & DT5 : 2pcs) standard ○

3. GRIND-X Twin Rotary Dresser (with 2 pcs of Metal Diamond #325) 7. 3axes Grinding CAM 2. GRIND-X Orthogonal Rotary Dresser ○ ○

4. GRIND-X Twin Rotary Dresser (with 2pcs of Metal Diamond #325), with measurement function 8. Full Auto Grinding CAM MAP Grinding System 3. GRIND-X Twin Rotary Dresser (with metal diamond wheel #325 : 2pcs) ○ ○

5. Super Dresser 9. 3D On-Machine measurement software OKAMOTO NC gauge 4. GRIND-X Twin Rotary Dresser (with metal diamond wheel #325 : 2pcs), with measuring function ○ ○

6. X Power 12 )Fully enclosed cover 5. GRIND-X 2-Point Rotary Dresser + Single-Point Diamond ○ -

*Please contact your local sales representative for other optional specifications. 6. Super Dresser ○ ○

7. Swing type Dresser(Need a meeting) ○ ○

8 )Electric related

1. Signal Tower Light ○ ○

2. Auto Shut Down Function ○ ○

9 )Cylindrical Grinding & Indexing Device

1. GRIND-X Small CNC Index ○ ○

2. GRIND-X Vertical CNC Indexing table ○ ○

2-Point Rotary Dresser + Single-Point Diamond GRIND-X Twin Rotary Dresser GRIND-X Indexing Device Orthogonal Rotary Dresser 3. GRIND-X Precision Cylindrical Grinding Device ○ ○

4. Cylindrical Grinding Device ○ ○

5. Additional CNC Axis ○ ○

2-Point Rotary Dresser + Single-Point Diamond 10 )Peripherals & Others

1. On-Machine Image Processing System, digital CCD camera with automatic lifting/retracting light, manual measurement ○ ○

【R Part / Pitch Grinding】 2. On-Machine Image Processing System, digital CCD camera with automatic lifting/retracting light, automatic measurement & automatic compensation ○ ○

While the rotary dresser has the advantage of less 3. Air Dryer ○ ○

diamond wear, it is difficult to correct the shape 4. Reflected light ○ ○

when it deforms. We developed a dresser that 11 )Software

CCD Camera

uses a single-point diamond for the bottom straight 1. Automatic Form Grinding Programing Software (UP-CAM or iCAM) ○ ○

part where diamond wear is severe, and a 2-point 2. Installation and Training ○ ○

rotary dresser for R / taper shapes. 3. Specified Workpiece Grinding ○ ○

4. 3axe Grinding CAM ○ ○

Material:DC53

Hardness:HRC58 〜 60 12 )Automatic Workpiece Changer

Slots:113 slots 1. Automatic Workpiece Changer - ○

Single pitch:1μm 2point rotary dresser + single-point diamond

Workpiece Enlarged Photo Cumulative pitch:2 μm or less

Touch Probe

UPZSeries 17 UPZSeries 18