1/10ページ

Download(4.4Mb)

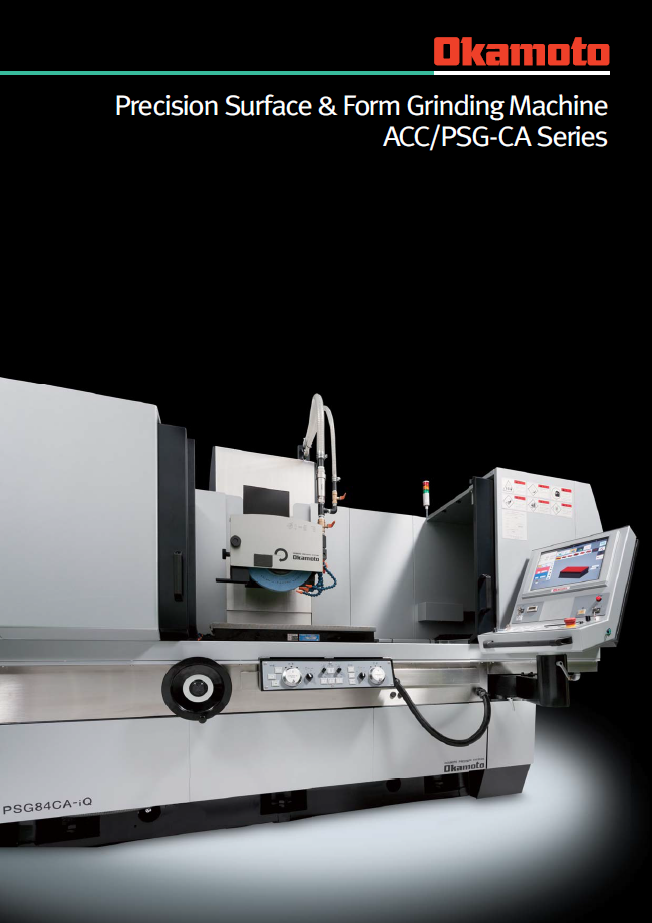

Precision Surface & Form Grinding Machine ACC/PSG-CA Series

Product Catalog

Document Information

| Document Title | Precision Surface & Form Grinding Machine ACC/PSG-CA Series |

|---|---|

| Document Type | Product Catalog |

| File size | 4.4Mb |

| Category | |

| Company | OKAMOTO MACHINE TOOL WORKS,LTD (Documents List) |

Documents related to this company

Document Contents

Page1

PSGCA_英文0723_1

Precision Surface & Form Grinding Machine

ACC/PSG-CA Series

OKAMOTO MACHINE TOOL WORKS, LTD.

2993 Gobara, Annaka, Gunma, Japan 379-0135

TEL : +81-27-388-9595 FAX : +81-27-385-1144

JQA-QMA10960

URL : www.okamoto.co.jp Annaka Factory

*Prior to and while using our products you are requested to thoroughly go through the articles on danger,

warning and attention for the sake of safety described in operation manual attached to the machine

and also in the warning plates mounted on the machine.

CAUTION *When the products fall under the eport controlled goods stipulated in “Foreign Exchange and Foreign

Trade Act” , it requires the license or approval of Goverment of Japan when exporting out of Japan.

*Specifications subject to change without notice.

This printed matter uses environmentally friendly paper and vegetable oil inks

Printed in Japan in July 2024 2024071000MTR-1

Page2

PSGCA_英文0723_2

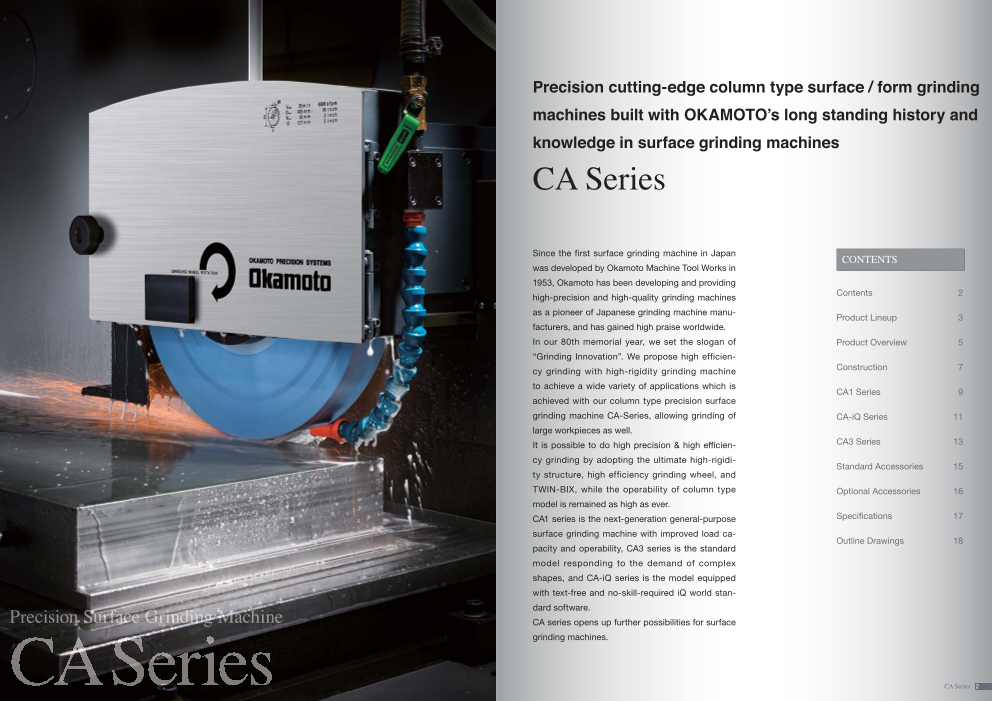

Precision cutting-edge column type surface / form grinding

machines built with OKAMOTO’s long standing history and

knowledge in surface grinding machines

CA Series

Since the first surface grinding machine in Japan CONTENTS

was developed by Okamoto Machine Tool Works in

1953, Okamoto has been developing and providing

high-precision and high-quality grinding machines Contents 2

as a pioneer of Japanese grinding machine manu- Product Lineup 3

facturers, and has gained high praise worldwide.

In our 80th memorial year, we set the slogan of Product Overview 5

“Grinding Innovation”. We propose high efficien-

cy grinding with high-rigidity grinding machine Construction 7

to achieve a wide variety of applications which is CA1 Series 9

achieved with our column type precision surface

grinding machine CA-Series, allowing grinding of CA-iQ Series 11

large workpieces as well.

It is possible to do high precision & high effi cien- CA3 Series 13

cy grinding by adopting the ultimate high-rigidi-

Standard Accessories 15

ty structure, high efficiency grinding wheel, and

TWIN-BIX, while the operability of column type Optional Accessories 16

model is remained as high as ever.

CA1 series is the next-generation general-purpose Specifi cations 17

surface grinding machine with improved load ca-

Outline Drawings 18

pacity and operability, CA3 series is the standard

model responding to the demand of complex

shapes, and CA-iQ series is the model equipped

with text-free and no-skill-required iQ world stan-

Precision Surface Grinding Machine dard software.

CA series opens up further possibilities for surface

grinding machines.

CA Series 2

Page3

PSGCA_英文0723_3

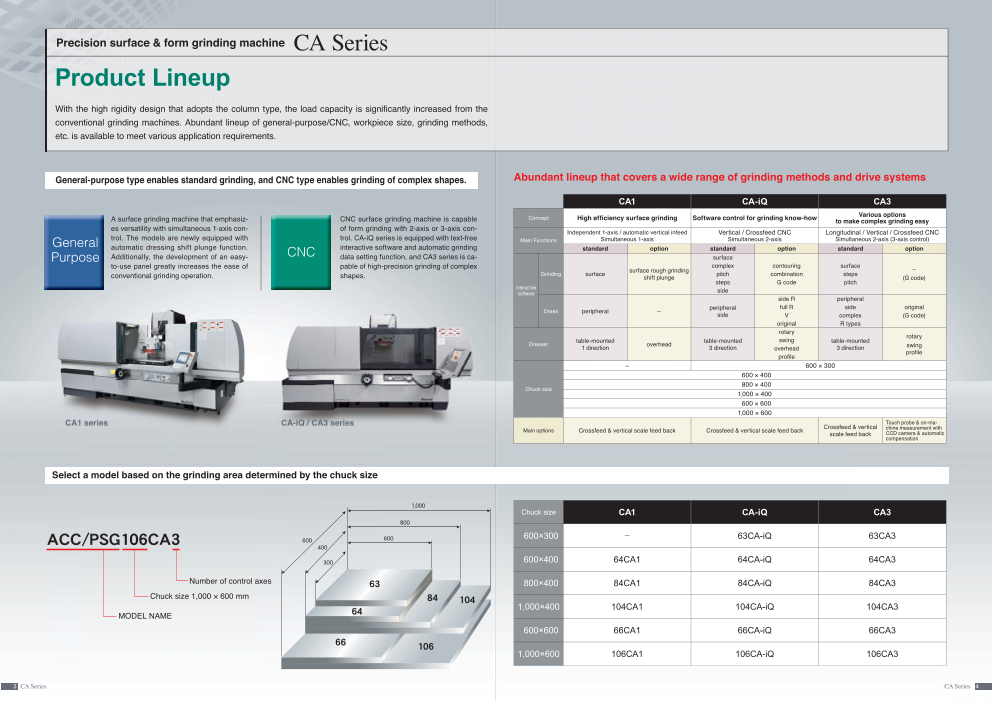

Precision surface & form grinding machine CA Series

Product Lineup

With the high rigidity design that adopts the column type, the load capacity is signifi cantly increased from the

conventional grinding machines. Abundant lineup of general-purpose/CNC, workpiece size, grinding methods,

etc. is available to meet various application requirements.

General-purpose type enables standard grinding, and CNC type enables grinding of complex shapes. Abundant lineup that covers a wide range of grinding methods and drive systems

CA1 CA-iQ CA3

A surface grinding machine that emphasiz- CNC surface grinding machine is capable Concept Various options

High effi ciency surface grinding Software control for grinding know-how

to make complex grinding easy

es versatility with simultaneous 1-axis con- of form grinding with 2-axis or 3-axis con- Independent 1-axis / automatic vertical infeed Vertical / Crossfeed CNC Longitudinal / Vertical / Crossfeed CNC

General trol. The models are newly equipped with trol. CA-iQ series is equipped with text-free Main Functions Simultaneous 1-axis Simultaneous 2-axis Simultaneous 2-axis (3-axis control)

automatic dressing shift plunge function. interactive software and automatic grinding standard option standard option standard option

Purpose Additionally, the development of an easy- CNC data setting function, and CA3 series is ca- surface

to-use panel greatly increases the ease of pable of high-precision grinding of complex complex contouring surface

conventional grinding operation. shapes. Grinding surface surface rough grinding

shift plunge pitch combination steps -

(G code)

steps G code pitch

Interactive

software side

side R peripheral

Dress peripheral peripheral full R side original

- side V complex (G code)

original R types

rotary

swing rotary

Dresser table-mounted

1 direction overhead table-mounted table-mounted

3 direction overhead 3 direction swing

profi le

profi le

− 600 × 300

600 × 400

800 × 400

Chuck size

1,000 × 400

600 × 600

1,000 × 600

CA1 series CA-iQ / CA3 series Touch probe & on-ma-

Main options Crossfeed & vertical scale feed back Crossfeed & vertical scale feed back Crossfeed & vertical chine measurement with

scale feed back CCD camera & automatic

compensation

Select a model based on the grinding area determined by the chuck size

Chuck size CA1 CA-iQ CA3

600×300 - 63CA-iQ 63CA3

600×400 64CA1 64CA-iQ 64CA3

Number of control axes 800×400 84CA1 84CA-iQ 84CA3

Chuck size 1,000 × 600 mm

1,000×400 104CA1 104CA-iQ 104CA3

MODEL NAME

600×600 66CA1 66CA-iQ 66CA3

1,000×600 106CA1 106CA-iQ 106CA3

3 CA Series CA Series 4

Page4

PSGCA_英文0723_4

CA1 Series General purpose CA3 Series 3-axis CNC

Efficient automatic dressing function & Grinding of complex shapes is support-

general purpose surface grinding ed by adding custom specifi cations.

■ Rigid column drive system ■ Track record data of various complex shapes

■ Best-in-class workpiece load capacity Indexing of slits and couplings, R forming of vane

pumps, vertical grinding of inner ball grooves, etc.

■ Automatic dressing function reduces dressing setting time.

■ Various dressing methods

■ Shift plunge function reduces cycle time by approximately Simple wheel forming is automated with standard inter-

30%. active software.

■ Three-axis numerical control can achieve the same

■ Operability is improved by the color touch panel.

speed and infeed regardless of operator skill. These are

the optimum grinding machines to make the grinding

Operation panel

Example conditions uniform.

Workpiece: Flat surface work-

piece

Material: HRC60

Surface roughness Rz0.4 wheel Example

Cycle time 25 minutes

Total amount: 0.2mm

workpiece

Screen Page Example 300 8

Workpiece: Rack

Material: HRC65

CA-iQ Series Simple CNC Form accuracy: ±0.006mm

Grinding method: Plunge grinding

interactive software Cycle time: 110 minutes

Grinding and dressing conditions are au- On-machine measurement

Various grinding methods and on-machine mea-

tomatically calculated by using Okamoto's surement / automatic compensation that enable

original iQ software simultaneous 2-axis or 3-axis control

■ Semi-closed cover to provide safety and to prepare the

■ High precision ball screws are used on axes to achieve simultaneous

grinding environment

■ Text-free interactive screen which can be set easily with the 2-axis or 3 axis control.

touch panel ■ On-machine measurement and automatic compensation are possible

■ Simple surface, groove, pitch, by attaching a touch probe and CCD camera as options (OP).

steps and side grinding cycles ■ Various types of grinding cycles

are achievable.

■ Just by entering total and fi ne including multi-position, crown

grinding allowance, and then, shape and taper grinding are sup- Automation

wheel grain size, the optimum ported.

grinding and dressing condi- ■ Maximum table longitudinal speed

tions are automatically calcu-

is as fast as 40 m / min. (Excluding

lated. Operation Screen

64CA3)

Example Example

Various shapes of wheel forming are

supported.

wheel Example

wheel 40 wheel

100 workpiece workpiece Multiple axes

workpiece 10

400 450

30 rotary

dresser

Workpiece: Slider Workpiece: Die slide post

Material: SKD11 Material: SKD11

Form accuracy: ±0.005mm Total stock removal: 0.02μm Workpiece: Trochoid gear

Dressing method: Profi le rotary dressing (OP) Grinding method: Groove non-interference grinding Material: C60

Grinding time: 8 minutes Grinding time: 8 minutes Form accuracy: ±0.005mm

Grinding method: Index grinding

Grinding time: 5 minutes

5 CA Series CA Series 6

30

60

50

Page5

PSGCA_英文0723_5

Precision surface & form grinding machine CA Series

Structure High effi ciency grinding with stable accuracy achieved by the high rigidity column type grinding

Ideal machine structure suitable for high effi ciency grinding

T-frame structure with no overhang, longitudinal V-V guideway with excellent straightness, and high rigidity and

high precision structure with carefully adjusted slideway

Column travel type is ideal for large workpiece

* Please wear protective glasses in operations.

T-shape Integrated Structure

Good accessibility Frame

●Column type model simplifi es mount- ●Rigid T-shape integrated structure

ing/dismounting large workpieces. ●Fully supported table longitudinal

●The height of the table surface is low structure. Since the slideway of the

to facilitate mounting/dismounting of frame is longer than the table, high

workpieces. accuracy can be obtained over the

*Height from the fl oor to the top of table: 915mm entire chuck area regardless of the

87 mm lower when compared with Okamoto’s conven-

tional 84 type position of the workpiece on the

chuck.

High rigidity structure

Highly rigid linear guide is used on the

vertical and cross slideways.

The structure of the column is a high-ri-

gidity structure that has no negative

effect in crossfeed.

V-V Slideway

High drainage capacity

●The longitudinal guideway uses V-V

shape structure, which has good Full enclosure for production use is

straightness and also minimizes the equipped as a standard accessory.

imbalance of oil fi lm thickness. High coolant tank capacity supports

●By adopting the double cylinder large amount of coolant supply. The

structure, the load capacity is greatly machine designs are novel while the

increased compared with convention- electrostatic coating method is used to

al machines. Grinding is stable even *Photo shows CA-iQ series. improve sheet metal quality.

with heavy workpieces such as mold In addition to the two-tone standard

bases. colors, we offer special color designs

*Load capacity is 1,000 kg, which is 2.4 times when that meet the world’s top market share

compared with Okamoto's conventional 64 type

model. machines.

7 CA Series *CA3 series has a different structure. CA Series 8

Page6

PSGCA_英文0723_6

Making your work as fast, accurate and easy as ever. The shift plunge function with automatic dressing

General Purpose Precision Surface Grinding Machine

can reduce the conventional grinding time by up to 30%.

CA1 Series List of Operation Pages

Lineup

Grinding Setting page Wheel RPM setting page

ACC/PSG64CA1

ACC/PSG84CA1

ACC/PSG104CA1

ACC/PSG66CA1

ACC/PSG106CA1

Operation panel and Touch screen operation panel

new functions The buttons are well arranged on the page. Wheel spindle RPM can be set on the touch

New performance has been added, such as the higher effi ciency By adopting the color panel, simplifi ed grinding panel. RPM is displayed simply by numerical

grinding and the visualization of alarms with the adoption of color is capable of being achieved. value on the page.

screen.

Grinding status check page Dressing setting page

Automatic Dressing Function

“Automatic Dressing Function”

is newly equipped on CA1 series

lineups.

With this function, dressing can

be performed during the grinding

cycle, such as after rough grind-

ing and finish grinding, making

grinding further automated.

Grinding status can be confi rmed on the grind- Automatic dressing is set simply by numerical

Shift Plunge Function ing status check page, enabling effi cient setup values. Operation is automated by combining

and output. the automatic dressing into cycles.

Shift plunge function is ideal for grinding with large stock removal.

Self-diagnosis function (I / O check) Recipe registration function (OP)

Down to dressing

start poin

Retract up

Dressing before ressing before

Standard Grinding Cycle rough grinding Rough grinding D

finish grinding Finish grinding Spark-out End of grinding

wheel

workpiece

When a problem occurs with the machine body, When repeatedly using the same grinding condi-

it can check the failure and disconnection of the tions, registering the grinding conditions contrib-

defective part. utes to productivity improvement and versatility.

9 CA Series CA Series 10

Page7

PSGCA_英文0723_7

CNC Precision Surface Grinding Machine Surface and Form grinding were complex tasks. iQ Software makes it easy.

CA-iQ Series

Dressing iQ Software allows optional wheel forms with conversational software.

Lineup Dress Form Select Menu

ACC/PSG63CA-iQ Straight Side Side R Full R V shape Free form

ACC/PSG64CA-iQ

ACC/PSG84CA-iQ

ACC/PSG104CA-iQ

ACC/PSG66CA-iQ Option

ACC/PSG106CA-iQ

The operator only inputs total stock removal, and wheel work positions.

Grinding iQ software automatically calculates the optimal grinding conditions to

assist operator. iQ software also calculates cycle times.

Mode Selection Menu

Table setting Dressing data Grinding data Combination Data save / call / Numeric Key Input

grinding menu edit

Option Select the dressing shape according to

3-direction dresser the workpiece shape, and enter the values

with the touch keys.

*This monitor is metric version.

iQ automatic

data creation function

Optimum dressing condition is Dressing Shape

set by entering the wheel grain

size.

iQ graphical current

grinding position display

It displays live wheel position

during grinding cycles. Example of iQ grinding & iQ dressing page combinations OP

*This monitor is metric version.

iQ automatic data creation function Complex shape Contouring

After the stock removal data input, iQ

software will calculate efficient grinding

conditions. Grinding data Dressing data (side) Grinding data Dressing data (full R)

Cycle time estimate (convex shape) (contouring)

Grinding Form Select Menu

Surface Concave Convex Pitch Steps Side Free form

Pitch shape Profi le plunge

Grinding data Dressing data (V shape) Dressing simulation Dressing data (Free form)

(pitch shape)

11 CA Series Option CA Series 12

Page8

PSGCA_英文0723_8

3-axis control equipped on CA3 series enables complex form grinding.

CNC Precision Surface Grinding Machine

A variety of dressing and on-machine measurements break new grounds in grinding.

CA3 Series

Various Grinding Software & Cycle (OP)

Lineup In addition to the standard interactive grinding methods, various OP software is

available for CA

ACC/PSG63CA3

ACC/PSG64CA3

ACC/PSG84CA3

ACC/PSG104CA3

ACC/PSG66CA3

ACC/PSG106CA3 Crown shaped grinding Contour grinding Multi-position grinding

High precision crown shaped grinding The contoured part can be ground Workpieces with different height and

is available. by synchronizing the longitudinal and length can be mounted on the chuck

crossfeed axes. for grinding effi ciently in one cycle.

Various Dressers Grinding up to 5 areas in one cycle is

possible.

High-performance applications (OP)

■ 3-Direction Dresser ■ Rotary Dresser &

Standard Accessory Dress- Single-Point Dresser It realizes the automation of complex grinding with variety of OP for your

er. Dressing for surface Rough dressing is per- customized grinding.

grinding and simple form formed with a rotary dress-

grinding is available. er, and fi ne dressing is per-

formed with a single-stone

dresser.

Wheel forming is done effi -

ciently and precisely.

1 axis of swiveling wheel spindle Touch probe Multi-axis

■ is added

■ Swing type Profi le Rotary Dresser

single-point dresser This is a method to create For on-machine measurement after When performing multi-axis grinding

the required wheel shape For workpieces with complex grooving, grinding, a touch probe (contact type) such as aspherical grinding, we can

Single-point dresser is by pressing the wheel (pro- it is possible to equip one more axis can be equipped. Automatic grinding propose the combination with a work-

recommended for wheel file), which is suitable for of swiveling wheel spindle. It can grind compensation after checking can also piece indexing device.

micro forming, and rotary mass production grinding. workpieces such as helical gears and be equipped.

dresser is recommended broaches.

for mass production.

■ Rotary Dresser ■CNC indexing device

Rotary Dresser makes it & swing type rotary

possible to dress more dresser

effi ciently than 3-direction CNC indexing device can

dresser. grind round workpieces. Automation with robot Automation with sensors

Wear can be reduced, too. Grinding can be performed It also supports automatic workpiece We can propose the automation spe-

more effi ciently in combina- supply with an articulated robot con- cialized for surface grinding using vari-

tion with a rotary dressing. sult by Okamoto. ous sensors, based on your request.

*CA3 option *CA3 option

13 CA Series CA Series 14

Page9

PSGCA_英文0723_9

Accessories

Standard Accessories Optional Accessories

CA1 Series CA-iQ Series CA3 Series CA-iQ Series Standard Cycle CA1 Series CA-iQ Series CA3 Series

Coolant System with magnetic separator ● ● ●

Standard Wheel ● ● ● Surface grinding

Coolant System with manual paper fi lter ● ● ●

Grinding Wheel Adaptor ● ● ● Complex Coolant System with automatic paper fi lter ● ● ●

Coolant System with magnetic separator, with manual paper fi lter ● ● ●

Wheel Spindle Continuously Variable

Inverter ● ● ● Pitch Coolant System Coolant System with magnetic separator, with automatic paper fi lter ● ● ●

Coolant System with magnetic separator, with manual paper fi lter, with automatic coolant temperature regulator ● ● ●

Standard Electromagnetic Chuck ● ● - Steps

Coolant System with magnetic separator, with automatic paper fi lter, with automatic coolant temperature regulator ● ● ●

Automatic Demagnetizing Controller,

Adjustable Chuck Power ● ● - Side Dust Collection Hood ● ● ●

Oil Mist Collector ● ● ●

Fan Cooler for Oil Coolant ● ● - Peripheral dressing Electromagnetic Chuck, oil cooling type, with demagnetizing controller ● ● ●

Chuck Electro-Permanent Magnetic Chuck, with demagnetizing controller ● ● ●

Automatic Oil Temperature Regulator - - ● Side dressing

Electromagnetic Chuck Interlock ● ● ●

Grinding End Time Prediction - ● - CNC Overhead dresser (with compensation) - ● ●

Rotary Dresser (single-axis positioner, double-axis positioner) - ● ●

Short Circuit Breaker Dresser

● ● ● Foldable 3-Direction Dresser - ● -

1-Direction Dresser & Dressing Vertical Rotary Dresser (installed on chuck top face) ● ● ●

Coolant System ● - -

Spare Wheel Adaptor ● ● ●

3-Direction Dresser & Dressing Spare Wheel Adaptor Wheel Adaptor for Micro Balancer ● ● ●

Coolant System - ● ●

Wheel Adaptor for automatic wheel balancer ● ● ●

1-Direction Flexible Nozzle for

Coolant Supply ● - - Wheel Balancer (with balance arbor) ● ● ●

3-Direction Flexible Nozzle for Balance Arbor (roller type, for BW-360) ● ● ●

Coolant Supply - ● ● Wheel Balancer

Micro Balancer ● ● ●

Constant Water Supply for Drain Automatic Wheel Balancer ● ● ●

Gutter ● ● ●(Except 63)

Work Light LED Light ● ● ●

Necessary Tools and Tool Box ● ● ● Hydraulic & Lubricant ● ● ●

Custom Color ● ● ●

Leveling Bolts and Plates ● ● ●

Oil Cooled Wheel Head (oil cooled pump installed) ● ● ●

Auto Dressing Function ● ● ● Temperature Controllers Automatic Oil Temperature Regulator ● ● -

Constant Coolant Supply for Top of the Table ● ● ●

Shift Plunge Function ● ● ● On-Machine Measuring

Device Touch Probe - - ●

Graphic Interactive Software Surface, complex,

- Spindle Motor Power Up

pitch, steps, side Surface, pitch, steps

7.5kW, 11kW, 15kW (86,106: 7.5kW Standard) ● ● ●

(high rigidity wheel spindle & large taper for 11kW and 15kW)

Scale Feedback Model ● ● ●

Timer of Total Run Time ● ● ●

Others Calendar Timer ● ● ●

Proposal of High Effi ciency Grinding Auto Shut Down Function ● ● ●

Wheel Form Programing Software EDELAC Win - ● ●

Warpage Correction Jig: SG Master ● ● ●

Fine Bubble Generator TWIN-BIX ● ● ●

TWIN-BIX *We have more optional accessories not listed here. Please contact your local sales representative.

Fine bubble generator TWIN-BIX has the eff ect of CA-iQ Series Optional Software

Side R , Full R, V Shape,

improving grinding fl uid permeability and prevent- Original Shape Dressing Programs

G Code Program

ing clogging of the wheel by the Coanda effect Automatic Programing Software

EDELAC Win

and the cavitation phenomenon. Universal Grinding Software

Contouring Software

By increasing the permeability of the grinding fl uid, Coolant System Wheel Adaptor Micro Balancer Wheel Balancer

it is possible to improve the cooling performance CA3 Series Optional Software

and suppress grinding heat. Contouring

Crown shape

Multi position

On-Machine Measurement

Full automatic surface grinding SELF

CNC Overhead Dresser EDELAC Win LED Light Automatic Oil Temperature

Regulator

15 CA Series CA Series 16

Page10

PSGCA_英文0723_10

Specifi cation Outline Drawing

CA1 Series Specifi cations CA-iQ Series Specifi cations CA1 Series Outline Drawings

Item Unit 64CA1 84CA1 104CA1 66CA1 106CA1 63CA-iQ 64CA-iQ 84CA-iQ 104CA-iQ 66CA-iQ 106CA-iQ 64/84/104CA1 66/106CA1

Table Working Surface Size mm 605×400 805×400 1,016×400 605×600 1,016×600 605×300 605×400 805×400 1,016×400 605×600 1,016×600

Table Travel Distance mm 800×440 1,000×440 1,200×440 800×652 1,200×652 750×340 800×440 1,000×440 1,200×440 800×652 1,200×652 Coolant System (option) A: Width B: Depth C: Height A: Width B: Depth C: Height

Distance from Top of the Table to Bottom of 2.5 -2.5~497.5 -25~320 22.5~522.5 -2.5~497.5 64CA1 3,710 Coolant System (option) 66CA1 3,780

Capacity the Wheel (standard wheel) mm 22.5~52

84CA1 3,935 2,950 2,200 106CA1 4,450 3,420 2,280

Standard Chuck Dimensions mm 600×400 800×400 1,000×400 600×600 1,000×600 600×300 600×400 800×400 1,000×400 600×600 1,000×600

×85 ×85 ×100 ×100 ×100 ×80 ×85 ×85 ×100 ×100 ×100 104CA1 4,450 2,980

Table Load Capacity (including accessories) kg 1,000 1,500 700 1,000 1,500 B

Table

Longitudinal T Slot (Width x Qty) − − − B

Feed

(X axis) Longitudinal Feed Speed (average) m/min 3~25 3~25

Cross Feed per M.P.G. Handwheel Revolution mm 0.1/1.0/5.0 0.01/0.1/1.0/5.0

Column Manual

Cross Feed Feed per M.P.G. Handwheel Graduation mm 0.001/0.01/0.05 0.0001/0.001/0.01/0.05

Feed Cross Intermittent Feed mm

(Z axis) 0.5~20 0.5~20

Automatic

Feed Continuous Feed Speed mm/min 0.1~2,000 0~1,000

Manual Feed per M.P.G. Handwheel Revolution mm 0.01/0.1/1.0 0.01/0.1/1.0

Infeed Feed per M.P.G. Handwheel Graduation mm 0.0001/0.001/0.01 0.0001/0.001/0.01 C

Wheel Automatic C

Rough Grinding mm 0.0001

Head ~0.03 0.0001~0.03(can be set arbitrarily in unit of 0.0001)

Infeed (traverse

Vertical & plunge) Fine Grinding mm 0.0001~0.01 0.0001~0.01(can be set arbitrarily in unit of 0.0001) PSG64CA1

Feed

PSG66CA1

(Y axis) Feed Speed (F code command) mm/min − 1,000

Sparkout Count time 0~10 0~99 A

A

Vertical Rapid Feed Speed mm/min 0~1,000 0~1,000

O.D. x W x B mm φ350×38×φ127 φ400×50×φ127 φ350×38×φ127 φ400×50×φ127

Grinding

Wheel Rotation Speed (with Wheel Spindle

Continuously Variable Inverter) min-1 200~2,500 500~2,500

Wheel Spindle kW 5.5 7.5 3.7 5.5 7.5 CA-iQ Series

Hydraulic Pump kW 2.2 3.7 2.2 3.7 Outline Drawings

Motor

Vertical Feed kW 1.5 1.5 63/64/84/104CA-iQ 66/106CA-iQ

Cross Feed kW 0.75 1.0

Coolant System (option) Hydraulic System

Power Consumption KVA 15 20 17 20 Hydraulic System A: Width B: Depth C: Height A: Width B: Depth C: Height

Coolant System (option) Automatic

Automatic

Oi 63CA-iQ 2,680 2,900 Oil Temperature

Regulator 66CA-iQ 3,780

Floor Width x Depth x Height 3,710×2,950 3,935×2,950 4,450×2,980 3,780×3,420 4,450×3,420 2,680×2,900 3,710×2,920 3,940×2,920 4,440×2,920 3,780×3,100 4,440×3,100 Oil l Temperature (option)

Regulator (option)

Mist

Space (Incl Hydraulic・Coolant unit) mm ×2,200 ×2,200 ×2,200 ×2,280 ×2,280 ×2,200 ×2,200 ×2,200 ×2,200 ×2,280 ×2,280 Collector 64CA-iQ 3,710 Oil

Mist 106CA-iQ 4,440 3,100 2,280

Electric Collector Electric

Component

Component

Box 84CA-iQ 3,940 2,920 2,200

Box

Weight Net Weight kg 4,500 5,500 7,000 6,300 7,500 4,500 5,500 7,000 6,300 7,500 104CA-iQ 4,440 B

B

CA3 Series Specifi cations

Item Unit 63CA3 64CA3 84CA3 104CA3 66CA3 106CA3

Table Working Surface Size mm 605×300 605×400 805×400 1,005×400 605×600 1,016×600

Table Travel Distance mm 750×340 800×440 1,000×440 1,200×440 800×652 1,200×652

Distance from Top of the Table to Bottom of C

Capacity the Wheel (standard wheel) mm -25~320 5~505 -20~480 C

Standard Chuck Dimensions mm 600×300×80 600×400×85 800×400×100 1,000×400×100 600×600×100 1,000×600×100

Table Load Capacity (including accessories) kg 700 700 (for table speed 40 m/min) 1,500

Table Top Height (from fl oor) mm 915 935 A

T Slot (Width x Qty) mm×No. − 17×3 A

Feed per Handwheel Revolution mm 0.01/0.1/1/10

Table Feed per Handwheel Graduation mm 0.0001/0.001/0.01/0.1

Longitudinal

Feed Feed Speed (F code command) mm/min 0~40,000 0~25,000 0~40,000

(X axis) Jog Feed Speed mm/min 0~1,000

Rapid Feed Speed mm/min 40,000 25,000 40,000

(Manual: 10,000) (Manual: 10,000) (Manual: 10,000) CA3 Series Outline Drawings

Feed per Handwheel Revolution mm 0.01/0.1/1 63/64/84/104CA3 66/106CA3

Wheel

Head Feed per Handwheel Graduation mm 0.0001/0.001/0.01

Vertical Feed Speed (F code command) mm/min 0~2,000

Feed A: Width B: Depth C: Height A: Width B: Depth C: Height

Lubricant Tank Lubricant Tank

(Y axis) Jog Feed Speed mm/min 0~1,000 63CA3 3,600 3,200 2,250 66CA3 4,150

Rapid Feed Speed mm/min 2,000 Control

Box 64CA3 4,120 Control

Box 106CA3 4,450 3,650 2,280

Feed per Handwheel Revolution mm 0.01/0.1/1/10 Coolant

System 84CA3 4,140 3,300 2,200 Coolant

System

(option)

Column Feed per Handwheel Graduation mm 0.0001/0.01/0.01/0.1 B (option)

104CA3 4,440 B

Cross

Feed Feed Speed (F code command) mm/min 0~2,000 0.0001/0.01/0.01/0.1

(Z axis) Jog Feed Speed mm/min 0~1,000

Rapid Feed Speed mm/min 2,000 4,000

Grinding O.D. x W x B (type 1 fl at) mm φ350×38×φ127 φ350×38(Max50)×φ127 φ400×50×φ127

Wheel Rotation Speed (with spindle invertor) min-1 500~2,500

Wheel Spindle kW 3.7 5.5 7.5 C C

Longitudinal Feed kW 5.5

Motor Vertical Feed kW 1.2 2.5

Cross Feed kW 0.75 1

Oil Cooling /Lubrication W 0.005 (lubrication) 180 A A

Power Consumption KVA 25 28 30 22 25

Floor Width x Depth x Height

Space (Incl Hydraulic・Coolant unit) mm 3,600×3,200×2,250 4,120×3,300×2,200 4,140×3,300×2,200 4,440×3,300×2,200 4,150×3,650×2,280 4,450×3,650×2,280

Weight Net Weight kg 4,500 5,500 7,000 6,300 7,500

17 CA Series CA Series 18

油油圧圧装装置置

OOIILL UUNNIITT