1/10ページ

Download(2.1Mb)

Movie

Document Information

| Document Title | <U.S.A>OGM Series |

|---|---|

| Document Type | Product Catalog |

| File size | 2.1Mb |

| Category | |

| Company | OKAMOTO MACHINE TOOL WORKS,LTD (Documents List) |

Documents related to this company

Document Contents

Page1

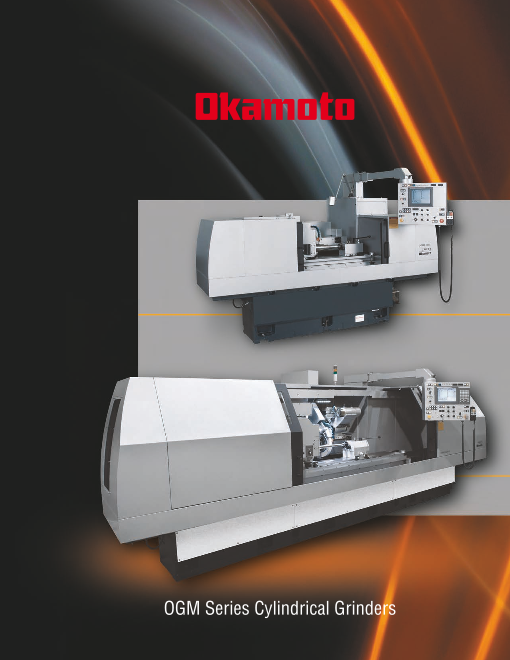

The only manufacturer in the world

supplying overall solutions for a total

Specifications abrasive process.

Models OGM-8 ●20 PIII, UIII, PNCIII, UNCIII & OGM-12 ●20 / 36 / 60 PIII, UIII, PNCIII, UNCIII

8l20 PIII & PNCIII 8l20UIII & UNCIII 12 PIII & PNCIII 12 UIII & UNCIII

CAPACITY 8l20 PIII & PNCIII 8l20UIII & UNCIII 12 PIII & PNCIII 12 UIII & UNCIII Okamoto Corporation Chicago USA

S CwAinPgA COIvTeYr Table: 8.6" 12.6" Standard

SDwisitnagn cOev eBre Ttwabeleen: Centers: 1 89..6"8 " 2 0 " / 3162". 6/ "5 9" (✲) Accessories

DMisatxainmcuem B eDtwiaemeent eCre tnot ebres :G round: 1 98..608" " 2 0 " / 3 162" ./0 6" 0" (✲)

Maaxxiimum DWiaemigehtte Br etotw beee nG rCoeunntde:r s: 1 1 0 l b s ( C8e.0n"t e r W o r k ) 3 3 0 l b s 1 (2C.e0n" ter Work) ◆ Grinding Wheel with

M GaxRiImNuDmIN WG eWigHhEt EBLetween Centers: 110 lbs (Center Work) 330 lbs (Center Work) Adaptor

S GizReI N(DD xIN WG Wx BH)E: EL 14" x 1.5" x 5" 12" x 1" x 5" 16" x 2" x 5" 14" x 1.5" x 5" ◆ Wheelguard

SGirzien d(Din gx W hxe Bel) :S peed (60 hz): 1 41", 6x1 10. 5r"p xm 5 " 1 12,"8 x8 01 "r xp m5" 16,4" 1x0 2 r" pxm 5 " 1 4 1" ,x6 10.5 r" pxm 5" ◆ Central Lubrication System

G rWinHdEinEgL HWEhAeDel Speed: 2,240 rpm 2,240 rpm 1,845 rpm 2,000 rpm

WHE ◆ Dressing Device with Total SEtLroHkEeA (DX-Axis): 8" 11.8" Diamond

TSowtaivl eSlt rAonkgel e(:X -Axis): N o n - S w i v e l 8" ± 3 0 d e g . N o n - S w i v e l 11.8" ± 30 deg.

SAwutivoeml aAtnicg lIen:f eed: N 0o.n0-0S0w0i1v"e ~l 0.002" (1 6 s ±et t3in0g dse)g /. 0.00001" ~ 0N.o0n0-4S" w(PivNeCl III & UN C I I I ±M 3o0d edlesg) . ◆ Variable Wheel Speed

AMuitnoimautmic IIncferemd: e n t : 0.00001" ~ 0.002" (190 .s0e0t0ti0n1g"s ()P /N 0C.0II0I 0&0 1U"N ~C 0II.I0 M04o" d(ePlNs COInIIl y&) UNCIII Models) ◆ Coolant Hoses and Nozzles

Miannimuaulm P uInlscer eFmeeedn t(:x .1, x1, x10): 0 . 0 0 0 0 1 0" .(0P0N0C0I1I"I, & 0 U.0N0C01II"I, M 0o.0d0e1ls" Only) ◆ Manual Pulse Generator

CRoanptiidn uFoeueds r aFteee: drate: 0~16 0 i p m ( 0 ~ 3 1 5 i p m for P N C I I I & U N C I I I1)5 7 i p0m~1 6 0 i p m (0~400 ipm f o r P N C III & UNCIII) ◆ Semi-Enclosed Splashguard

MGrainuda Fl ePeudls Oev Feereridd e(x: .1, x1, x10): 0 . 0 0 0 0 1 "0, ~0 .200000%1" , 0.001"

◆ Leveling Pads & Bolts Okamoto Machine ToolW ThAeBelLhEead Rapid Retract: 1.5" Europe GmbH Germany Okamoto Okamoto Machine Tool

RMaapxidim Fuemed r Taateb:l e Travel: 315 ipm 400 ipm

◆ Operation Manual

30" 34" / 50" / 73.5" ( ) Thai Company LTD.

China

✲

GSrwinivde Fl eAendg Olev: erride: 0 ~ - 9 d e g 0 ~ 200 % 0 to -10 / 0 to - 8.5 / 0 to -5 deg (✲) ◆ Tools & Tool Box

T TraAvBeLrsEe Speed: 0 ~ 315 ipm 0 ~ 394 ipm

Mainximum P Traobglera Tmramvealb: le Increment: 30" 0 . 0 0 0 0 1 " (PNCIII & U N C I I I M o 3d4e"ls / O50n"ly /) 73.5" (✲)

SMwainvuela Al Pnuglsee: Feed (x.1, x1, x10): 0 ~ - 9 0.00001", 0.00 0 01 " ,t o 0 -.100 1/ "0 to - 8.5 / 0 to -5 deg (✲) Optional

TRraavpeidrs Fee Sedpreaetde:: 0 ~ 3 1 5 i p m f3o1r5 P iNpCmI II & UNCIII 0 ~ 3 49040 i pipmm

MFeinedimrautme O Pvreorgrirdaem: m a b l e I n c

Equipment

r e m e n t : 0 ~ 200% (Max. 03.1050 0ip0m1") (PNCIII & UN C I I I M o0d ~el s2 0O0n%ly )(Max. 394 ipm)

MSpaanruka-lO Puut:l se Feed (x.1, x1, x10): 0 - 1 0 S e c o n d s ( P lu n g e G r0in.0d0);0 00 1-" ,1 00 .C0y0c0le1s", o 0f .T0a0b1le" (Traverse Grind) ◆ Drive Dog Set

R a p i d F e e d r a t e : 1 6 0 i p m ( 3 1 5 i p m Ifnofir nPitNeClyI IVI a&ri aUbNleC IoInI) PNC I I I & U N C I I I M 4o0d0e lisp m

◆ Grinding Wheel Adaptor

F e WedOraRtKe HOEvAeDrride: 0 ~ 200% (Max. 160 ipm, 315 ipm for PNCIII & UNCIII) 0 ~ 200% (Max. 400 ipm)

SCpeanrtke-rO: ut: 0 - 1 0 S e c o n MdsT ( NPolu.n 3g e Grind); 0 - 10 Cycl e s o f T a b l e ( T r aMveTr sNeo Grind)

◆ Grinding Wheel Balancing

. 4 Okamoto Corporation

Infinitely Variable on PNCIII & UNCIII Models Stand Semi Conductor Equipment Division

Swivel Angle: Non-Swivel +30 to - 90 deg. Non-Swivel +30 to - 90 deg.

◆ Balancing Test Arbor CA USA S WpiOndRlKe HSEpAeDed: 10 ~ 500 rpm 10 ~ 500 rpm Annaka Factory Japan

C eTnAtIeLrS: TOCK MT No. 3 MT No. 4 ◆ Magnetic Separator

SCwenivteerl :A ngle: N o n - S w i v eMl T N o . 3 + 3 0 t o - 9 0 d e g . N o n - S w i v e lM T N o . 4 +30 to - 90 deg. ◆ Fully Enclosed Splashguard

SSppiinnddllee SSptreoekde:: 1 0 ~ 0 5.80"0 r p m 1 0 ~ 5 10.02 "rpm ◆ Workrest

TMAOILTSOTROSCK

CGernintedrin: g Wheel Spindle: 5 h p A MC TS Npion.d 3le M o t o r 7 . 5 MhpT SNpoi.n 4

◆ Steadyrests

dle Motor Okamoto Pte. Ltd Singapore

SWpoinrdkhlee aSdtr oSkpein: dle: 1 . 6 h p ,0 A.8C" Se r v o 2 . 4 h p 1, .A2C" Servo ◆ I.D. Grinding Attachment

MOTOR for Universal ModelsWheelheaSd Feed & Rapid Feed: 1.6 hp, AC Servo

GTaribnldei nFgee Wd h&e eRla Sppidin Fdelee:d : 5 h p , A C S p in d l e M o t o r 1.6 hp, AC S e r v o 7.5 hp, AC Spi n d le M o t o r ◆ Gauging System

W PoOrkWhEeaRd S SUpPinPdLlYe: 1.6 hp, AC Servo 2.4 hp, AC Servo ◆ Chucks

WDehseierelhde aPdo wFeeer dS &up Rpalyp Iidn cFleueddin: g 1.6 hp, AC Servo ◆ Dial Indicator for Table

TLaubbleri cFaeteiodn & & R Caopoidla Fnete Sdy: stem: 1 . 6 h 1p5, AKCV AS er v o 1 . 6 h 2p0, AKCV AS ervo Swivel

PFOLWOOER SPUAPCPELY

DWeisditrhe dx Powe

◆ Signal Light

Depthr Sx uHpepiglyh Itn: cluding 115" x 79" x 77" 134" / 166" / 220" x 92" x 77" (✲)

L uWbrEiIcGaHtioTn & Coolant System: 15 KVA 20 KVA (✲) ◆ Work Light

N FeLt OWOeRig ShPt ACE 7,500 lbs 10,500 / 11,500 / 13,500 lbs (✲)

Width x Depth x Height: 115" x 79" x 77" 134"/ 166" / 220" x 92" x 77" (✲)

( ✲W) E SIGpHeTcification matches corresponding center distance. Specifications Subject to Change Without Notice.

Net Weight 7,500 lbs 10,500 / 11,500 / 13,500 lbs (✲)

Emerging Abrasives Technology

(✲) Specification matches corresponding center distance. Specifications Subject to Change Without Notice.

Okamoto Corporation

370 Corporate Woods Parkway Vernon Hills, IL 60061 USA Tel: (847) 235-3500 Fax: (847) 235-3274 OGM Series Cylindrical Grinders

www.okamotocorp.com

9 PRINTED IN USA 07/13 5M REV 1

OMG_6_Pager.indd 1 7/1/13 11:39 AM

Page2

The OGM MDI Series grinds up to 10 different diameters

in all cycles, in any order - all in a single set-up.

Choose from 4 versatile grinding cycles.

◆ Plunge for rapid stock removal

◆ Shift-Plunge / Traverse for fast stock removal and fine

OGM10-Step finish MDI Series ... ◆ Traverse with infeed at right end, left end or both ends for fine finish

◆ Manual Traverse that eliminates the

the efficient way to grind multi-diameter work need for program input - saves time -

without CNC! ideal for single workpiece requirements

The OGM MDI Control Series The OGM's Servo Driven

Cylindrical Grinders embodies Wheelhead is designed to withstand the

the unique blend of performance rigors of high volume production work, yet

deliver consistent fine finish capability to

features and simplicity of operation

"tenths". Its built-in rapid advance/retract

that today's fine finisher demands. simplifies set-up - a real convenience

They are available in Plain and feature. The wheelhead incorporates a

Universal models. Superior quality cartridge type wheel spindle (lubed for

starts from the ground up with rigid life) that provides the utmost in reliability

and ease of maintenance. Wheelheads on

construction that utilizes heavily Universal models feature ±30o swivel.

ribbed Meehanite cast beds with

double Vee ways. All components

- servo motors, ball screws, control

components are of the highest grade.

It's our way of assuring that your OGM

Series grinder delivers many years of

peak performance and accuracy. OGM

MDI Series grinders deliver precision,

flexibility and operator convenience at

an astonishingly affordable price.

They are the real value in

OD Grinders.

Shown with options

2

Page3

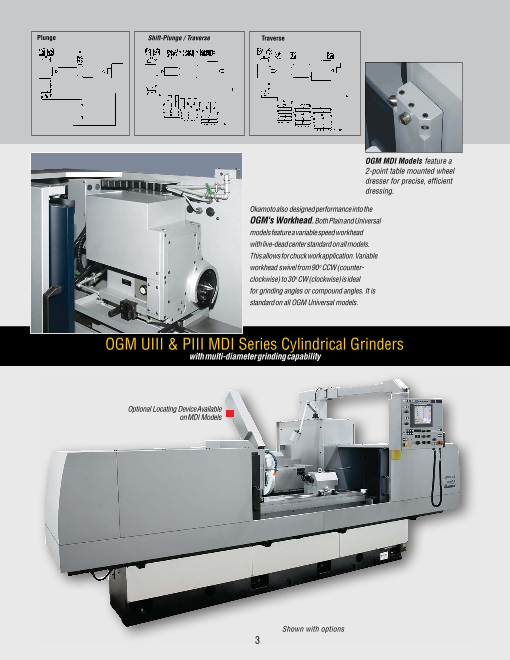

Plunge Shift-Plunge / Traverse Traverse

OGM MDI Models feature a

2-point table mounted wheel

dresser for precise, efficient

dressing.

Okamoto also designed performance into the

OGM's Workhead. Both Plain and Universal

models feature a variable speed workhead

with live-dead center standard on all models.

This allows for chuck work application. Variable

workhead swivel from 90o CCW (counter-

clockwise) to 30o CW (clockwise) is ideal

for grinding angles or compound angles. It is

standard on all OGM Universal models.

OGM UIII & PIII MDI Series Cylindrical Grinders

with multi-diameter grinding capability

Optional Locating Device Available

on MDI Models

Shown with options

3

Page4

OGM Series MDI & CNC

Control Cylindrical Grinders

incorporate numerous standard

features that optimize 1. Optional ID Grinding Attachment 2. High efficiency Coolant Systems are

expands grinding capability. Ideal for tool optional on all OGM Series Grinders.

performance and productivity. room work. Available on OGM Universal Magnetic Swarf Separators are also

Special options are also models. Automatic infeed on all models. available as options.

available to meet specific

1. 2.

customer applications.

Features

3. Automatic Lubrication System

assures reliable lubrication to all critical

way systems. Standard.

4.Table Swivel Dial Indicator assures

precise table swivel settings - a valuable

option for taper grinding applications.

Optional. 3. 4.

5. Marposs Size Gauge Optional on MDI

6.

and CNC models. 5.

6. A Marposs Flagging System simplifies

set-up and assures accurate

shoulder positioning.

Standard on all OGM CNC models.

Optional on MDI models.

Contact your Okamoto representative for a complete list of optional equipment including auto-loading systems.

4

Page5

Programmable The OGM MDI Series utilizes a "user-friendly" Fanuc electronic MDI control with a powerful teach function. Data input is so simple that even operators unfamiliar with

Grinding cylindrical grinding can quickly and easily learn to operate the machine and efficiently

and precisely grind up to 10 diameters in a single workpiece set-up. A built-in Manual

Pulse Generator is a real operator convenience in set-up and when grinding in the

manual mode. Another unique feature is a Dress Interrupt Function that enables the

operator to dress the grinding wheel, on demand, at any point during the grinding cycle.

The OGM will automatically stop its infeed, dress, and return to the exact point where

the interruption occurred and resume grinding. In addition, a Cycle Skip Function allows

the operator to skip the dress and roughing cycles and proceed directly to finish grind

plus size compensation.

MDI Control

Main Data Page Used to input grinding

data such as number of different steps,

type of grind cycle, transverse, plunge,

oscillation, shift plunge and optional

shoulder grinding.

OD Data Page Used to input grinding data Program Storage Page Used for naming Dressing Data Page Used to input wheel

such and table reversal position, rough, and storing of up to 21 individual programs width, diamond distance, wheel type, dress

medium, fine stock allowances, and initial internally, with external program storage to data (Infeed amount, speed, number of

air cut plus clearance amount to next grind. compact flash card capability. dresses).

5

Page6

OGM NC Series Cylindrical Grinders

Powerful Control Capability

The OGM NC Series rounds out

the Okamoto Cylindrical Grinder

line-up. They are designed, ◆ Powerful state-of-the-art

engineered and built with the Fanuc CNC

◆ Quick, easy set-up. Designed

same dedication to quality, for optimum operator convenience

performance and value as the ◆ No prior CNC experience necessary - Short learning curve

OGM MDI line. These two axis ◆ Fanuc reliability

simultaneous controlled grinders ◆ Conversational or G and M code programming standard

utilize a powerful, easy-to-use

Fanuc control. The combination

of proven machine design, superb

control capability and Okamoto

grinding machine expertise

makes for a grinder that delivers

long term optimum accuracy,

productivity and true operator

convenience.

Shown with options

6

Page7

The OGM MDI Series grinds up to 10 different diameters

in all cycles, in any order - all in a single set-up.

Choose from 4 versatile grinding cycles.

◆ Plunge for rapid stock removal

◆ Shift-Plunge / Traverse for fast stock removal and fine

1 finishOOGGMM NC S0er-ieSs tCeylinpd rMicaDl IG Srinedrieers ... ◆ Traverse with infeed at right end, Grinding Data Entry Dressing left end or both ends for fine finish Cycles Patterns Floor Plans

◆ Manual Traverse that eliminates the

the efficient way to grind multi-diameter work need for program input - saves time -

without CNC! ideal for single workpiece requirements Front View

Powerful Control Capability A

TThhee OOGGMM MNDC IS Ceroinetsr rool uSnedrise os ut The OGM's Servo Driven

Cthyeli nOdkraicmaol tGor Cinydlienrds reicmabl oGdriiensd er Wheelhead is designed to withstand the Plunge

line-up. The rigors of high volume production work, yet the unique byle anrde odfe psiegrnfoerdm, ance ◆ Powerful state-of-the-art

feenagtuinreese raendd asnimd pbluicilitt yw oitfh o the

deliver consistent fine finish capability to Fanuc CNC

peration "tenths". Its built-in rapid advance/retract ◆ Quick, easy set-up. Designed

tshaamt teo ddeayd'isc afitnioen fi tnoi sqhuear lditey,m ands. simplifies set-up - a real convenience for optimum operator convenience C

Tpheeryfo armrea anvcaei l an

◆ No prior CNC experience

abled i nva Plulaei na sa nthde feature. The wheelhead incorporates a necessary - Short learning curve

UOnGivMer sMalD mI olidneel.s T. hSeuspee trwioor aqxuias

Straight Std.

l ity cartridge type wheel spindle (lubed for ◆ Fanuc reliability Traverse

life) that provides the utmost in reliability ◆ Conversational or G and M code

sstiamrtus lftraonmeo tuhse cgoronutrnodll eudp gwriinthd errigs id

and ease of maintenance. Wheelheads on programming standard

cuotinlisztreu ac tpioonw tehrafut lu, teilaizseys-t oh-euasveil y Universal models feature ±30o swivel. Distance X Set Automatically sets Work Distance Z Set Automatically locates Work

rFibanbuedc cMoenetrhoaln. iTthe ec acsotm bbeidnsa wtioitnh Reference Point (X-Axis). Datum (Z-Axis). Corrects for workpiece

Left End

variations. Face & R Std.

doof upbrolev Vene em waacyhsi.n Ae ldl ecsoimgnp, osnuepnetrsb Top View

-c soenrtvroo lm coatpoarbs,i lbitayl la sncdr eOwksa, mcoontotr ol Plunge Oscillation

cgorimndpionnge mntas cahrein oef etxhpee hrtiigshee st grade.

Taper Opt.

Imt'sa okeusr fwoar ya ogfr iansdsuerr itnhga tt hdaetl iyvoeursr OGM

Sloernige st egrrmin doeprt idmeulimve rasc mcuarnayc yy, ears of

pperaokd upcetrifvoirtym aanndc et rauned o apcecrautroarc y. OGM

Plunge + Fine B

McoDnIv Seenriieensc ger.i n ders deliver precision, Grinding Oscillation NC Format Std.

fl exibility and operator convenience at

an astonishingly affordable price. Locator Initial Set Minimizes set-up times. Grinding Data Set Simplifies Grinding

They are the real value in Data Input.

Multistage

OD Grinders. Straight Opt. Dimensions

OGM-8l20 OGM-12 l20 OGM-12 l36 OGM-12l60

Shift-Plunge + Traverse

A 115.0" 134.0" 166.0" 220.0"

B 79.0" 92.0" 92.0" 92.0"

C 77.0" 77.0" 77.0" 77.0"

OGM CNC Grinders feature a

table-mounted 3-point dresser.

Manual Traverse The dressing arm is mounted

to the lower portion of the table.

Dress Position Set Menu This allows taper adjustments

Dress Infeed - Rough, Medium, Fine. Provides System Parameters. without changing dressing.

Dress Speed - Rough, Medium, Fine. Machine Set-Up.

Dress Frequency. Grinding Data.

Dressing Data.

Shown with options Machine Data.

Contour Opt.

Shown with options

62 7 8

OMG_6_Pager.indd 2 7/1/13 11:39 AM

Page8

The OGM MDI Series grinds up to 10 different diameters

in all cycles, in any order - all in a single set-up.

Choose from 4 versatile grinding cycles.

◆ Plunge for rapid stock removal

◆ Shift-Plunge / Traverse for fast stock removal and fine

1 finishOOGGMM NC S0er-ieSs tCeylinpd rMicaDl IG Srinedrieers ... ◆ Traverse with infeed at right end, Grinding Data Entry Dressing left end or both ends for fine finish Cycles Patterns Floor Plans

◆ Manual Traverse that eliminates the

the efficient way to grind multi-diameter work need for program input - saves time -

without CNC! ideal for single workpiece requirements Front View

Powerful Control Capability A

TThhee OOGGMM MNDC IS Ceroinetsr rool uSnedrise os ut The OGM's Servo Driven

Cthyeli nOdkraicmaol tGor Cinydlienrds reicmabl oGdriiensd er Wheelhead is designed to withstand the Plunge

line-up. The rigors of high volume production work, yet the unique byle anrde odfe psiegrnfoerdm, ance ◆ Powerful state-of-the-art

feenagtuinreese raendd asnimd pbluicilitt yw oitfh o the

deliver consistent fine finish capability to Fanuc CNC

peration "tenths". Its built-in rapid advance/retract ◆ Quick, easy set-up. Designed

tshaamt teo ddeayd'isc afitnioen fi tnoi sqhuear lditey,m ands. simplifies set-up - a real convenience for optimum operator convenience C

Tpheeryfo armrea anvcaei l an

◆ No prior CNC experience

abled i nva Plulaei na sa nthde feature. The wheelhead incorporates a necessary - Short learning curve

UOnGivMer sMalD mI olidneel.s T. hSeuspee trwioor aqxuias

Straight Std.

l ity cartridge type wheel spindle (lubed for ◆ Fanuc reliability Traverse

life) that provides the utmost in reliability ◆ Conversational or G and M code

sstiamrtus lftraonmeo tuhse cgoronutrnodll eudp gwriinthd errigs id

and ease of maintenance. Wheelheads on programming standard

cuotinlisztreu ac tpioonw tehrafut lu, teilaizseys-t oh-euasveil y Universal models feature ±30o swivel. Distance X Set Automatically sets Work Distance Z Set Automatically locates Work

rFibanbuedc cMoenetrhoaln. iTthe ec acsotm bbeidnsa wtioitnh Reference Point (X-Axis). Datum (Z-Axis). Corrects for workpiece

Left End

variations. Face & R Std.

doof upbrolev Vene em waacyhsi.n Ae ldl ecsoimgnp, osnuepnetrsb Top View

-c soenrtvroo lm coatpoarbs,i lbitayl la sncdr eOwksa, mcoontotr ol Plunge Oscillation

cgorimndpionnge mntas cahrein oef etxhpee hrtiigshee st grade.

Taper Opt.

Imt'sa okeusr fwoar ya ogfr iansdsuerr itnhga tt hdaetl iyvoeursr OGM

Sloernige st egrrmin doeprt idmeulimve rasc mcuarnayc yy, ears of

pperaokd upcetrifvoirtym aanndc et rauned o apcecrautroarc y. OGM

Plunge + Fine B

McoDnIv Seenriieensc ger.i n ders deliver precision, Grinding Oscillation NC Format Std.

fl exibility and operator convenience at

an astonishingly affordable price. Locator Initial Set Minimizes set-up times. Grinding Data Set Simplifies Grinding

They are the real value in Data Input.

Multistage

OD Grinders. Straight Opt. Dimensions

OGM-8l20 OGM-12 l20 OGM-12 l36 OGM-12l60

Shift-Plunge + Traverse

A 115.0" 134.0" 166.0" 220.0"

B 79.0" 92.0" 92.0" 92.0"

C 77.0" 77.0" 77.0" 77.0"

OGM CNC Grinders feature a

table-mounted 3-point dresser.

Manual Traverse The dressing arm is mounted

to the lower portion of the table.

Dress Position Set Menu This allows taper adjustments

Dress Infeed - Rough, Medium, Fine. Provides System Parameters. without changing dressing.

Dress Speed - Rough, Medium, Fine. Machine Set-Up.

Dress Frequency. Grinding Data.

Dressing Data.

Shown with options Machine Data.

Contour Opt.

Shown with options

62 7 8

OMG_6_Pager.indd 2 7/1/13 11:39 AM

Page9

The only manufacturer in the world

supplying overall solutions for a total

Specifications abrasive process.

Models OGM-8 ●20 PIII, UIII, PNCIII, UNCIII & OGM-12 ●20 / 36 / 60 PIII, UIII, PNCIII, UNCIII

8l20 PIII & PNCIII 8l20UIII & UNCIII 12 PIII & PNCIII 12 UIII & UNCIII

CAPACITY 8l20 PIII & PNCIII 8l20UIII & UNCIII 12 PIII & PNCIII 12 UIII & UNCIII Okamoto Corporation Chicago USA

S CwAinPgA COIvTeYr Table: 8.6" 12.6" Standard

SDwisitnagn cOev eBre Ttwabeleen: Centers: 1 89..6"8 " 2 0 " / 3162". 6/ "5 9" (✲) Accessories

DMisatxainmcuem B eDtwiaemeent eCre tnot ebres :G round: 1 98..608" " 2 0 " / 3 162" ./0 6" 0" (✲)

Maaxxiimum DWiaemigehtte Br etotw beee nG rCoeunntde:r s: 1 1 0 l b s ( C8e.0n"t e r W o r k ) 3 3 0 l b s 1 (2C.e0n" ter Work) ◆ Grinding Wheel with

M GaxRiImNuDmIN WG eWigHhEt EBLetween Centers: 110 lbs (Center Work) 330 lbs (Center Work) Adaptor

S GizReI N(DD xIN WG Wx BH)E: EL 14" x 1.5" x 5" 12" x 1" x 5" 16" x 2" x 5" 14" x 1.5" x 5" ◆ Wheelguard

SGirzien d(Din gx W hxe Bel) :S peed (60 hz): 1 41", 6x1 10. 5r"p xm 5 " 1 12,"8 x8 01 "r xp m5" 16,4" 1x0 2 r" pxm 5 " 1 4 1" ,x6 10.5 r" pxm 5" ◆ Central Lubrication System

G rWinHdEinEgL HWEhAeDel Speed: 2,240 rpm 2,240 rpm 1,845 rpm 2,000 rpm

WHE ◆ Dressing Device with Total SEtLroHkEeA (DX-Axis): 8" 11.8" Diamond

TSowtaivl eSlt rAonkgel e(:X -Axis): N o n - S w i v e l 8" ± 3 0 d e g . N o n - S w i v e l 11.8" ± 30 deg.

SAwutivoeml aAtnicg lIen:f eed: N 0o.n0-0S0w0i1v"e ~l 0.002" (1 6 s ±et t3in0g dse)g /. 0.00001" ~ 0N.o0n0-4S" w(PivNeCl III & UN C I I I ±M 3o0d edlesg) . ◆ Variable Wheel Speed

AMuitnoimautmic IIncferemd: e n t : 0.00001" ~ 0.002" (190 .s0e0t0ti0n1g"s ()P /N 0C.0II0I 0&0 1U"N ~C 0II.I0 M04o" d(ePlNs COInIIl y&) UNCIII Models) ◆ Coolant Hoses and Nozzles

Miannimuaulm P uInlscer eFmeeedn t(:x .1, x1, x10): 0 . 0 0 0 0 1 0" .(0P0N0C0I1I"I, & 0 U.0N0C01II"I, M 0o.0d0e1ls" Only) ◆ Manual Pulse Generator

CRoanptiidn uFoeueds r aFteee: drate: 0~16 0 i p m ( 0 ~ 3 1 5 i p m for P N C I I I & U N C I I I1)5 7 i p0m~1 6 0 i p m (0~400 ipm f o r P N C III & UNCIII) ◆ Semi-Enclosed Splashguard

MGrainuda Fl ePeudls Oev Feereridd e(x: .1, x1, x10): 0 . 0 0 0 0 1 "0, ~0 .200000%1" , 0.001"

◆ Leveling Pads & Bolts Okamoto Machine ToolW ThAeBelLhEead Rapid Retract: 1.5" Europe GmbH Germany Okamoto Okamoto Machine Tool

RMaapxidim Fuemed r Taateb:l e Travel: 315 ipm 400 ipm

◆ Operation Manual

30" 34" / 50" / 73.5" ( ) Thai Company LTD.

China

✲

GSrwinivde Fl eAendg Olev: erride: 0 ~ - 9 d e g 0 ~ 200 % 0 to -10 / 0 to - 8.5 / 0 to -5 deg (✲) ◆ Tools & Tool Box

T TraAvBeLrsEe Speed: 0 ~ 315 ipm 0 ~ 394 ipm

Mainximum P Traobglera Tmramvealb: le Increment: 30" 0 . 0 0 0 0 1 " (PNCIII & U N C I I I M o 3d4e"ls / O50n"ly /) 73.5" (✲)

SMwainvuela Al Pnuglsee: Feed (x.1, x1, x10): 0 ~ - 9 0.00001", 0.00 0 01 " ,t o 0 -.100 1/ "0 to - 8.5 / 0 to -5 deg (✲) Optional

TRraavpeidrs Fee Sedpreaetde:: 0 ~ 3 1 5 i p m f3o1r5 P iNpCmI II & UNCIII 0 ~ 3 49040 i pipmm

MFeinedimrautme O Pvreorgrirdaem: m a b l e I n c

Equipment

r e m e n t : 0 ~ 200% (Max. 03.1050 0ip0m1") (PNCIII & UN C I I I M o0d ~el s2 0O0n%ly )(Max. 394 ipm)

MSpaanruka-lO Puut:l se Feed (x.1, x1, x10): 0 - 1 0 S e c o n d s ( P lu n g e G r0in.0d0);0 00 1-" ,1 00 .C0y0c0le1s", o 0f .T0a0b1le" (Traverse Grind) ◆ Drive Dog Set

R a p i d F e e d r a t e : 1 6 0 i p m ( 3 1 5 i p m Ifnofir nPitNeClyI IVI a&ri aUbNleC IoInI) PNC I I I & U N C I I I M 4o0d0e lisp m

◆ Grinding Wheel Adaptor

F e WedOraRtKe HOEvAeDrride: 0 ~ 200% (Max. 160 ipm, 315 ipm for PNCIII & UNCIII) 0 ~ 200% (Max. 400 ipm)

SCpeanrtke-rO: ut: 0 - 1 0 S e c o n MdsT ( NPolu.n 3g e Grind); 0 - 10 Cycl e s o f T a b l e ( T r aMveTr sNeo Grind)

◆ Grinding Wheel Balancing

. 4 Okamoto Corporation

Infinitely Variable on PNCIII & UNCIII Models Stand Semi Conductor Equipment Division

Swivel Angle: Non-Swivel +30 to - 90 deg. Non-Swivel +30 to - 90 deg.

◆ Balancing Test Arbor CA USA S WpiOndRlKe HSEpAeDed: 10 ~ 500 rpm 10 ~ 500 rpm Annaka Factory Japan

C eTnAtIeLrS: TOCK MT No. 3 MT No. 4 ◆ Magnetic Separator

SCwenivteerl :A ngle: N o n - S w i v eMl T N o . 3 + 3 0 t o - 9 0 d e g . N o n - S w i v e lM T N o . 4 +30 to - 90 deg. ◆ Fully Enclosed Splashguard

SSppiinnddllee SSptreoekde:: 1 0 ~ 0 5.80"0 r p m 1 0 ~ 5 10.02 "rpm ◆ Workrest

TMAOILTSOTROSCK

CGernintedrin: g Wheel Spindle: 5 h p A MC TS Npion.d 3le M o t o r 7 . 5 MhpT SNpoi.n 4

◆ Steadyrests

dle Motor Okamoto Pte. Ltd Singapore

SWpoinrdkhlee aSdtr oSkpein: dle: 1 . 6 h p ,0 A.8C" Se r v o 2 . 4 h p 1, .A2C" Servo ◆ I.D. Grinding Attachment

MOTOR for Universal ModelsWheelheaSd Feed & Rapid Feed: 1.6 hp, AC Servo

GTaribnldei nFgee Wd h&e eRla Sppidin Fdelee:d : 5 h p , A C S p in d l e M o t o r 1.6 hp, AC S e r v o 7.5 hp, AC Spi n d le M o t o r ◆ Gauging System

W PoOrkWhEeaRd S SUpPinPdLlYe: 1.6 hp, AC Servo 2.4 hp, AC Servo ◆ Chucks

WDehseierelhde aPdo wFeeer dS &up Rpalyp Iidn cFleueddin: g 1.6 hp, AC Servo ◆ Dial Indicator for Table

TLaubbleri cFaeteiodn & & R Caopoidla Fnete Sdy: stem: 1 . 6 h 1p5, AKCV AS er v o 1 . 6 h 2p0, AKCV AS ervo Swivel

PFOLWOOER SPUAPCPELY

DWeisditrhe dx Powe

◆ Signal Light

Depthr Sx uHpepiglyh Itn: cluding 115" x 79" x 77" 134" / 166" / 220" x 92" x 77" (✲)

L uWbrEiIcGaHtioTn & Coolant System: 15 KVA 20 KVA (✲) ◆ Work Light

N FeLt OWOeRig ShPt ACE 7,500 lbs 10,500 / 11,500 / 13,500 lbs (✲)

Width x Depth x Height: 115" x 79" x 77" 134"/ 166" / 220" x 92" x 77" (✲)

( ✲W) E SIGpHeTcification matches corresponding center distance. Specifications Subject to Change Without Notice.

Net Weight 7,500 lbs 10,500 / 11,500 / 13,500 lbs (✲)

Emerging Abrasives Technology

(✲) Specification matches corresponding center distance. Specifications Subject to Change Without Notice.

Okamoto Corporation

370 Corporate Woods Parkway Vernon Hills, IL 60061 USA Tel: (847) 235-3500 Fax: (847) 235-3274 OGM Series Cylindrical Grinders

www.okamotocorp.com

9 PRINTED IN USA 07/13 5M REV 1

OMG_6_Pager.indd 1 7/1/13 11:39 AM

Page10

The only manufacturer in the world

supplying overall solutions for a total

Specifications abrasive process.

Models OGM-8 ●20 PIII, UIII, PNCIII, UNCIII & OGM-12 ●20 / 36 / 60 PIII, UIII, PNCIII, UNCIII

8l20 PIII & PNCIII 8l20UIII & UNCIII 12 PIII & PNCIII 12 UIII & UNCIII

CAPACITY 8l20 PIII & PNCIII 8l20UIII & UNCIII 12 PIII & PNCIII 12 UIII & UNCIII Okamoto Corporation Chicago USA

S CwAinPgA COIvTeYr Table: 8.6" 12.6" Standard

SDwisitnagn cOev eBre Ttwabeleen: Centers: 1 89..6"8 " 2 0 " / 3162". 6/ "5 9" (✲) Accessories

DMisatxainmcuem B eDtwiaemeent eCre tnot ebres :G round: 1 98..608" " 2 0 " / 3 162" ./0 6" 0" (✲)

Maaxxiimum DWiaemigehtte Br etotw beee nG rCoeunntde:r s: 1 1 0 l b s ( C8e.0n"t e r W o r k ) 3 3 0 l b s 1 (2C.e0n" ter Work) ◆ Grinding Wheel with

M GaxRiImNuDmIN WG eWigHhEt EBLetween Centers: 110 lbs (Center Work) 330 lbs (Center Work) Adaptor

S GizReI N(DD xIN WG Wx BH)E: EL 14" x 1.5" x 5" 12" x 1" x 5" 16" x 2" x 5" 14" x 1.5" x 5" ◆ Wheelguard

SGirzien d(Din gx W hxe Bel) :S peed (60 hz): 1 41", 6x1 10. 5r"p xm 5 " 1 12,"8 x8 01 "r xp m5" 16,4" 1x0 2 r" pxm 5 " 1 4 1" ,x6 10.5 r" pxm 5" ◆ Central Lubrication System

G rWinHdEinEgL HWEhAeDel Speed: 2,240 rpm 2,240 rpm 1,845 rpm 2,000 rpm

WHE ◆ Dressing Device with Total SEtLroHkEeA (DX-Axis): 8" 11.8" Diamond

TSowtaivl eSlt rAonkgel e(:X -Axis): N o n - S w i v e l 8" ± 3 0 d e g . N o n - S w i v e l 11.8" ± 30 deg.

SAwutivoeml aAtnicg lIen:f eed: N 0o.n0-0S0w0i1v"e ~l 0.002" (1 6 s ±et t3in0g dse)g /. 0.00001" ~ 0N.o0n0-4S" w(PivNeCl III & UN C I I I ±M 3o0d edlesg) . ◆ Variable Wheel Speed

AMuitnoimautmic IIncferemd: e n t : 0.00001" ~ 0.002" (190 .s0e0t0ti0n1g"s ()P /N 0C.0II0I 0&0 1U"N ~C 0II.I0 M04o" d(ePlNs COInIIl y&) UNCIII Models) ◆ Coolant Hoses and Nozzles

Miannimuaulm P uInlscer eFmeeedn t(:x .1, x1, x10): 0 . 0 0 0 0 1 0" .(0P0N0C0I1I"I, & 0 U.0N0C01II"I, M 0o.0d0e1ls" Only) ◆ Manual Pulse Generator

CRoanptiidn uFoeueds r aFteee: drate: 0~16 0 i p m ( 0 ~ 3 1 5 i p m for P N C I I I & U N C I I I1)5 7 i p0m~1 6 0 i p m (0~400 ipm f o r P N C III & UNCIII) ◆ Semi-Enclosed Splashguard

MGrainuda Fl ePeudls Oev Feereridd e(x: .1, x1, x10): 0 . 0 0 0 0 1 "0, ~0 .200000%1" , 0.001"

◆ Leveling Pads & Bolts Okamoto Machine ToolW ThAeBelLhEead Rapid Retract: 1.5" Europe GmbH Germany Okamoto Okamoto Machine Tool

RMaapxidim Fuemed r Taateb:l e Travel: 315 ipm 400 ipm

◆ Operation Manual

30" 34" / 50" / 73.5" ( ) Thai Company LTD.

China

✲

GSrwinivde Fl eAendg Olev: erride: 0 ~ - 9 d e g 0 ~ 200 % 0 to -10 / 0 to - 8.5 / 0 to -5 deg (✲) ◆ Tools & Tool Box

T TraAvBeLrsEe Speed: 0 ~ 315 ipm 0 ~ 394 ipm

Mainximum P Traobglera Tmramvealb: le Increment: 30" 0 . 0 0 0 0 1 " (PNCIII & U N C I I I M o 3d4e"ls / O50n"ly /) 73.5" (✲)

SMwainvuela Al Pnuglsee: Feed (x.1, x1, x10): 0 ~ - 9 0.00001", 0.00 0 01 " ,t o 0 -.100 1/ "0 to - 8.5 / 0 to -5 deg (✲) Optional

TRraavpeidrs Fee Sedpreaetde:: 0 ~ 3 1 5 i p m f3o1r5 P iNpCmI II & UNCIII 0 ~ 3 49040 i pipmm

MFeinedimrautme O Pvreorgrirdaem: m a b l e I n c

Equipment

r e m e n t : 0 ~ 200% (Max. 03.1050 0ip0m1") (PNCIII & UN C I I I M o0d ~el s2 0O0n%ly )(Max. 394 ipm)

MSpaanruka-lO Puut:l se Feed (x.1, x1, x10): 0 - 1 0 S e c o n d s ( P lu n g e G r0in.0d0);0 00 1-" ,1 00 .C0y0c0le1s", o 0f .T0a0b1le" (Traverse Grind) ◆ Drive Dog Set

R a p i d F e e d r a t e : 1 6 0 i p m ( 3 1 5 i p m Ifnofir nPitNeClyI IVI a&ri aUbNleC IoInI) PNC I I I & U N C I I I M 4o0d0e lisp m

◆ Grinding Wheel Adaptor

F e WedOraRtKe HOEvAeDrride: 0 ~ 200% (Max. 160 ipm, 315 ipm for PNCIII & UNCIII) 0 ~ 200% (Max. 400 ipm)

SCpeanrtke-rO: ut: 0 - 1 0 S e c o n MdsT ( NPolu.n 3g e Grind); 0 - 10 Cycl e s o f T a b l e ( T r aMveTr sNeo Grind)

◆ Grinding Wheel Balancing

. 4 Okamoto Corporation

Infinitely Variable on PNCIII & UNCIII Models Stand Semi Conductor Equipment Division

Swivel Angle: Non-Swivel +30 to - 90 deg. Non-Swivel +30 to - 90 deg.

◆ Balancing Test Arbor CA USA S WpiOndRlKe HSEpAeDed: 10 ~ 500 rpm 10 ~ 500 rpm Annaka Factory Japan

C eTnAtIeLrS: TOCK MT No. 3 MT No. 4 ◆ Magnetic Separator

SCwenivteerl :A ngle: N o n - S w i v eMl T N o . 3 + 3 0 t o - 9 0 d e g . N o n - S w i v e lM T N o . 4 +30 to - 90 deg. ◆ Fully Enclosed Splashguard

SSppiinnddllee SSptreoekde:: 1 0 ~ 0 5.80"0 r p m 1 0 ~ 5 10.02 "rpm ◆ Workrest

TMAOILTSOTROSCK

CGernintedrin: g Wheel Spindle: 5 h p A MC TS Npion.d 3le M o t o r 7 . 5 MhpT SNpoi.n 4

◆ Steadyrests

dle Motor Okamoto Pte. Ltd Singapore

SWpoinrdkhlee aSdtr oSkpein: dle: 1 . 6 h p ,0 A.8C" Se r v o 2 . 4 h p 1, .A2C" Servo ◆ I.D. Grinding Attachment

MOTOR for Universal ModelsWheelheaSd Feed & Rapid Feed: 1.6 hp, AC Servo

GTaribnldei nFgee Wd h&e eRla Sppidin Fdelee:d : 5 h p , A C S p in d l e M o t o r 1.6 hp, AC S e r v o 7.5 hp, AC Spi n d le M o t o r ◆ Gauging System

W PoOrkWhEeaRd S SUpPinPdLlYe: 1.6 hp, AC Servo 2.4 hp, AC Servo ◆ Chucks

WDehseierelhde aPdo wFeeer dS &up Rpalyp Iidn cFleueddin: g 1.6 hp, AC Servo ◆ Dial Indicator for Table

TLaubbleri cFaeteiodn & & R Caopoidla Fnete Sdy: stem: 1 . 6 h 1p5, AKCV AS er v o 1 . 6 h 2p0, AKCV AS ervo Swivel

PFOLWOOER SPUAPCPELY

DWeisditrhe dx Powe

◆ Signal Light

Depthr Sx uHpepiglyh Itn: cluding 115" x 79" x 77" 134" / 166" / 220" x 92" x 77" (✲)

L uWbrEiIcGaHtioTn & Coolant System: 15 KVA 20 KVA (✲) ◆ Work Light

N FeLt OWOeRig ShPt ACE 7,500 lbs 10,500 / 11,500 / 13,500 lbs (✲)

Width x Depth x Height: 115" x 79" x 77" 134"/ 166" / 220" x 92" x 77" (✲)

( ✲W) E SIGpHeTcification matches corresponding center distance. Specifications Subject to Change Without Notice.

Net Weight 7,500 lbs 10,500 / 11,500 / 13,500 lbs (✲)

Emerging Abrasives Technology

(✲) Specification matches corresponding center distance. Specifications Subject to Change Without Notice.

Okamoto Corporation

370 Corporate Woods Parkway Vernon Hills, IL 60061 USA Tel: (847) 235-3500 Fax: (847) 235-3274 OGM Series Cylindrical Grinders

www.okamotocorp.com

9 PRINTED IN USA 07/13 5M REV 1

OMG_6_Pager.indd 1 7/1/13 11:39 AM