1/12ページ

Download(2.8Mb)

<U.S.A>Rotary Surface Grinders PRG-DX/DXNC Series

Product Catalog

Movie

Document Information

| Document Title | <U.S.A>Rotary Surface Grinders PRG-DX/DXNC Series |

|---|---|

| Document Type | Product Catalog |

| File size | 2.8Mb |

| Category | |

| Company | OKAMOTO MACHINE TOOL WORKS,LTD (Documents List) |

Documents related to this company

Document Contents

Page1

Rotary Surface Grinders - PRG-DX / DXNC Series

Page2

PRG BRO NOV16.qxp_Layout 1 12/11/17 3:44 PM Page 3

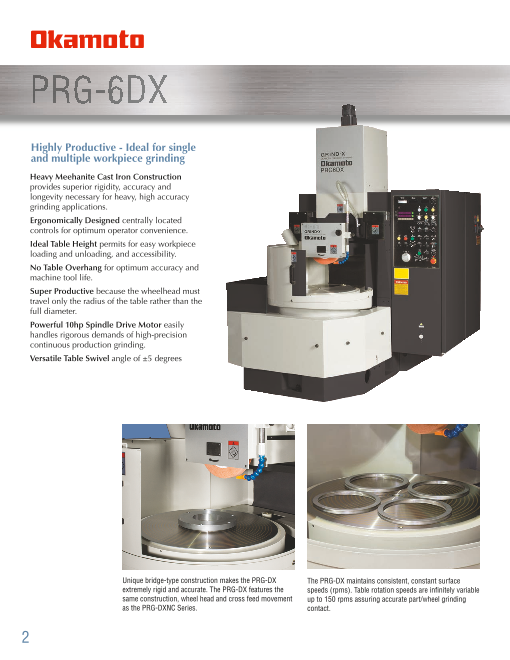

Highly Productive - Ideal for single

and multiple workpiece grinding

Heavy Meehanite Cast Iron Construction

provides superior rigidity, accuracy and

longevity necessary for heavy, high accuracy

grinding applications.

Ergonomically Designed centrally located

controls for optimum operator convenience.

Ideal Table Height permits for easy workpiece

loading and unloading, and accessibility.

No Table Overhang for optimum accuracy and

machine tool life.

Super Productive because the wheelhead must

travel only t he radius of the table rather than the

full diameter.

Powerful 10hp Spindle Drive Motor easily

handles rigorous demands of high-precision

continuous production grinding.

Versatile Table Swivel angle of ±5 degrees

Unique bridge-type construction makes the PRG-DX The PRG-DX maintains consistent, constant surface

extremely rigid and accurate. The PRG-DX features the speeds (rpms). Table rotation speeds are infinitely variable

same construction, wheel head and cross feed movement up to 150 rpms assuring accurate part/wheel grinding

as the PRG-DXNC Series. contact.

2

Page3

PRG BRO NOV16.qxp_Layout 1 12/11/17 3:44 PM Page 4

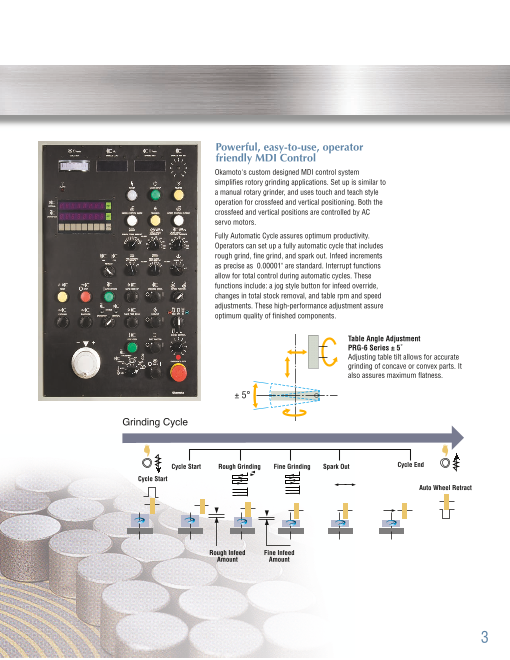

Powerful, easy-to-use, operator

friendly MDI Control

Okamoto's custom designed MDI control system

simplifies rotory grinding applications. Set up is similar to

a manual rotary grinder, and uses touch and teach style

operation for crossfeed and vertical positioning. Both the

crossfeed and vertical positions are controlled by AC

servo motors.

Fully Automatic Cycle assures optimum productivity.

Operators can set up a fully automatic cycle that includes

rough grind, fine grind, and spark out. Infeed increments

as precise as 0.00001" are standard. Interrupt functions

allow for total control during automatic cycles. These

functions include: a jog style button for infeed override,

changes in total stock removal, and table rpm and speed

adjustments. These high-performance adjustment assure

optimum quality of finished components.

Table Angle Adjustment

PRG-6 Series ± 5˚

Adjusting table tilt allows for accurate

grinding of concave or convex parts. It

also assures maximum flatness.

± 5°

Grinding Cycle

Cycle Start Rough Grinding Fine Grinding Spark Out Cycle End

Cycle Start

Auto Wheel Retract

Rough Infeed Fine Infeed

Amount Amount

3

*

*

Page4

PRG BRO NOV16.qxp_Layout 1 12/29/17 11:19 AM Page 5

Productivity and versatility in a

compact package

Built on the proven PRG-DX Design Platform,

the PRG-DXNC Series delivers superior

machine design and construction coupled

with the power and versatility of user-friendly

CNC control.

Automatic Grinding Wheel Dress and Dress

Compensation is standard on all PRG-DXNC

Models. 2 selectable rough /fine infeed and

dressing speeds maximize grinding wheel

performance thereby optimizing grinding

cycles. This makes them ideal for totally

unmanned operation.

Ergonomically Designed centrally located

controls for optimum operator convenience.

Ideal Table Height permits for easy workpiece

loading and unloading, and accessibility.

No Table Overhang for optimum accuracy and

machine tool life.

Super Productive because the wheelhead must

travel only the radius of the table rather than the

full diameter.

Powerful 10hp Spindle Drive Motor easily

handles rigorous demands of high-precision

continuous production grinding.

Versatile Table Swivel

The PRG-DXNC is perfect for multi-step workpieces. The PRG-DXNC is the ideal choice for ultra-high precision

A table mounted dresser is standard. grinding of critical components,

4

Page5

PRG BRO NOV16.qxp_Layout 1 12/11/17 3:44 PM Page 6

Powerful 2-Axis CNC Control expands grinding capability

and allows for grinding a wider variety of components

2-Axis Simultaneous Control capability including a fully

automatic dress cycle

Shift-Plunge Grinding for fast stock removal, then Traverse-Grind

for fine finish

Easy Set-Up, automatic dress, multi-step grinding A

Step Grinding up to 4 Steps with High Accuracy and High Speed Simple Table Incline . . . Permits table movement of

Conversational programming system provides fast, easy set-ups of up to four different +/- 5, +/- 3 and +/- 0.4 degrees respectively for

flat surfaces. PRG-6DXNC, 8DXNC, 10DXNC and 12DXNC.

1 STEP 2 STEP 3 STEP 4 STEP

PRG-DXNC Series . . . Better by Design

Robust design and construction, and premium quality

components assure smooth axes travels and consistent,

precise table rotation. Z

X

5

Page6

PRG BRO NOV16.qxp_Layout 1 12/11/17 3:45 PM Page 7

Built-In Okamoto Conversational Programming System

Teach-Input Programming System . . . The operator simply manually

positions the grinding wheel to the grinding start position using an

input key. This "teaches" the grind start position to the machine. He

then moves the wheel to the cross reversal position using an input key.

This teaches the machine the reversal position. He then inputs stock

removal, aircut, dressing interval. The control automatically calculates

total movement and all start and stop points.

“Drawing” Input Programming System . . .Simply input the actual Select Grinding Mode

dimensions from the workpiece drawing - the control automatically

calculates the cycle sequence.

Vertical & Crossfeed

Incremental Feed . . . with

multipliers of 0.00001" /

0.0001"/ 0.001"

Built-in Chuck Control . . .

with variable holding power

control and automatic

release cycle.

Set Form Data

Fanuc 21i-TB Control This powerful high- Enter Grinding Condition

reliability control is standard on all PRG-DXNC

rotary grinders. It features an RS-232 Interface

for G&M code programming.

The easy-to-understand diagnostic screen and

recorded alarm history can be displayed on the

control screen to assists operator in most

situations.

Set Datum Position

6

Page7

PRG BRO NOV16.qxp_Layout 1 12/11/17 3:45 PM Page 8

Rigid Bridge Type Construction Assures Superb Long-Term Accuracy.

Thoughtful design for optimum ease of use and operator convenience and safety.

Bridge type construction assures optimum rigidity,

vibration damping and thermal stability. This

provides consistent, precise wheelhead movement

for optimum long-term machine accuracy and

reliability. Unlike competitive rotary grinders the

PRG Series utilizes travelling column design with a

stationery table. This assures the highest degree of

accuracy, maximum productivity and simplified

workpiece loading / unloading for optimum

operator convenience and safety.

PRG Series grinders are designed for today’s

machining environment.The use of premium grade

components, energy efficient motors, high

performance coolant systems and many other

environmentally-friendly design features make the

PRG Series the right machine for today’s

progressive shops.

PRG-6DXNC shown with available optional

high splashguard enclosure

Double-walled Column Construction . . .

"H" shaped guideways with tapered gibs

provide the strength and rigidity

necessary for heavy duty and

high-precision extra fine grinding.

Unique Wheelhead

Moving System

TURCITE

Slide Surface

User-Friendly

Operation Zone

7

Page8

PRG BRO NOV16.qxp_Layout 1 12/11/17 3:45 PM Page 9

Now machining professionals faced with large workpiece processing

challenges can realize the extraordinary production benefits that have

made the PRG Series the “go-to” choice in rotary grinders.

These large capacity grinders are designed and built for the most

demanding applications and have the rigidity and power necessary to

deliver both efficient stock removal and consistent fine-finish

accuracies.

The perfect machine for high precision grinding of large components

Ceramic Tables & Components Large Turbine Rings Jet Engine Components

8

Page9

PRG BRO NOV16.qxp_Layout 1 12/11/17 3:45 PM Page 10

PRG-DX/DXNC The Series Specifications

PRG-6DX PRG-6DXNC PRG-8DXNC PRG-10DXNC PRG-12DXNC

MDI CONTROL

CAPACITY

Diameter of Electromagnetic Chuck 23.6" dia 23.6" dia 31.5" dia 39.4" dia 47.2" dia

Swing Inside Table Cover 29.5" dia 29.5" dia 37.4" dia 62.4" dia 62.9" dia

Distance from Chuck Top to Wheel Underside

50Hz - 2.36" ~ 9.84" - 2.36" ~ 9.84" na

60Hz - 1.38" ~ 10.8: - 1.38" ~ 10.8" na

510 Dia. Wheel 19.69"

Table Load Capacity 330 lbs 330 lbs 550 lbs 2,640 lbs 2,860 lbs

TABLE

Revolution Speed (Peripheral Speed ~

Controlled to be Constant, Stepless) 20 ~ 150 rpm 20 ~ 150 rpm 15 ~130 rpm 8 ~ 65 rpm

Inclinable angle ±5 deg ±5 deg ±3 deg ± 0.4 deg

COLUMN CROSS FEED (X-AXIS)

Drive Unit AC servo motor (FX) AC servo motor (NC)

Travel 17.7" 17.7" 21.7" 31.5" 33.9"

Feed Rate During Automatic Cycle

Set Range 8 ~ 95 ipm 0 ~ 78.75 ipm

Override Max.78.75 ipm (0 ~150%) Max.78.75 ipm (0 ~150%)

Manual Pulse Feed

Per Revolution (100 scale) 0.01"- 0.1" 0.001"(×1), 0.01"(×10), 0.1"(×100)

Per Scale 0.0001"- 0.001" 0.00001"(×1), 0.0001"(×10), 0.001"(×100)

Jog Feed (16 steps) 0 ~ 78.75 ipm

Rapid Feed 95 ipm 157.5 ipm 196.9 ipm

WHEEL HEAD VERTICAL FEED (Z-AXIS)

Drive Unit AC servo motor (FX) AC servo motor (NC)

Travel 12.21" 12.21" 19.7"

Feed Rate During Automatic Cycle

Set Range 7.8 ~ 94.5 ipm 0 ~ 78.75 ipm

Override 0 ~ 150% 15 Steps Max. 78.75 ipm (0 ~ 150%)

Rapid Feed 94.5 ipm 157.5 ipm

Manual Feed

Per Revolution 0.01"(×1), 0.1"(×10) 0.001"(×1), 0.01"(×10), 0.1"(×100)

Pulse Feed

Per Scale 0.00001" (x1), 0.0001" (x10) 0.00001"(×1), 0.0001"(×10), 0.001"(×100)

Jog Feed 16 Steps 0 ~ 78.75 ipm

Rapid Feed 15.7 / 37.4 157.5 ipm

GRINDING WHEEL

Diameter × Width × Bore <50/60Hz> ø14"/ø12" × 1.5" (max.2) × ø5" ø14"/ø12" × 1.5" (max.2) × ø5" ø20" × ø2" (OP: max.3) × ø5

Spindle Speed 1800 1500 / 1800 1000 / 1200

MOTOR

Grinding Wheel Spindle 10 hp 10 hp

Rotary Table 3 hp DC 3 hp 5 hp 10 hp

MACHINE SPACE W x D x H 106"× 86" × 79" 66" × 101" × 102" 71" × 115" × 102" 179" × 169" ×141"

WEIGHT

Machine P roper 8,820 lbs 8,800 lbs 11,000 lbs 28,220 lbs 28,600 lbs

Specifications Subject To Change Without Notice 9

Page10

PRG BRO NOV16.qxp_Layout 1 12/11/17 3:45 PM Page 11

PRG-DX/DXNC The Series

EXTERNAL VIEW Figures in ( ) Represent PRG-8DXNC

PRG-6DXNC / (8DXNC)

65.5" (71.3") 36.4"(41.7") 71.6" (83.5")

87.3" (93.1")

PRG-10DXNC / 12DXNC

67.4"

154.2"

121.6" 50.0"

10

169.1"

154.1"

70.3"

100.8" (115.4")

119.1" (133.7")

67"

1.2" 101.0"

103.0"

31.5"(32.9") 4.6" ~ 16.8"

67.0"

1.8" 78.7"

80.5"

49.6" 2.9" ~ 30.5"

100.0"

140.9"

1.8"

Page11

PRG BRO NOV16.qxp_Layout 1 12/11/17 3:45 PM Page 12

PRG-DX/DXNC The Series Standard and Optional Accessories

STANDARD ACCESSORIES OPTIONAL ACCESSORIES

Built-In Okamoto Conversational Control (MDI on PRG-DX) Coolant System with Magnetic Separator and Dust Suction

Fanuc 21i-TB 2 Axis Control Programming System Coolant System with Magnetic Separator

Splash Cover with Coolant Nozzle Coolant System with Paper Filter

0.00001” Minimum Increment Coolant System with Paper Filter & Magnetic Separator

Built-in Chuck Controller Grinding Wheel Balancing Stand with Arbor

Grinding Wheel (12") with Adapter Balancing Arbor

Built in 32" Magnetic Chuck Grinding Wheel Adapter 5” bore

Diamond Dressing Tool with Holder Work Light

Automatic Lubrication System Grinding Wheel Motor 15 hp

Necessary Tools & Tool Box Hydro-Dynamic-Type Wheel Spindle

Cartridge Style Spindle with Direct Drive Machine Light

10 hp Spindle Motor Fine Line Chuck

Leveling Bolts and Plates Metric Conversion Kit

Instruction Manuals & Inspection

Manual Table Angle Adjustment Reports

Coolant System Mist Collector

Dynamic Wheel Balance System Star Pole Chuck Ring Pole Chuck

11

Page12

PRG BRO NOV16.qxp_Layout 1 12/11/17 3:44 PM Page 1

The on ly manufac turer in the wor ld

supp ly ing overa l l so lu t ions for

a to ta l abras ive process .

Okamoto Corporation Chicago USA

Okamoto Machine Tool Okamoto Machine Tool

Europe GmbH Germany Okamoto China Okamoto Corporation

Thai Company LTD. Semi Conductor Equipment Division

CA US A

MIdwest Sales

KY

East Coast Sales

CT

West Coast Sales

CA

Annaka Factory Japan

Okamoto Pte. Ltd Singapore

Emerging Abrasives Technology

Okamoto Corporation 370 Corporate Woods Parkway Vernon Hills, IL 60061 USA Tel: (847) 235-3500 Fax: (847) 235-3274

California Office: 14944 Shoemaker Ave., Unit J Santa Fe Springs, CA 90670 Tel: (562) 921-0099 Fax: (562) 921-0199

Kentucky Office: 140 Production Ct. Louisville, KY 40299 Tel: (502) 749-1506 Fax: (502) 749-1525

Connecticut Office: 425-D Hayden Station Rd. Windsor, CT 06095 Tel: (860) 219-1006 Fax: (860) 219-1007

www.okamotoco rp .com

PRINTED IN USA 12/17 3M