1/16ページ

Download(2.5Mb)

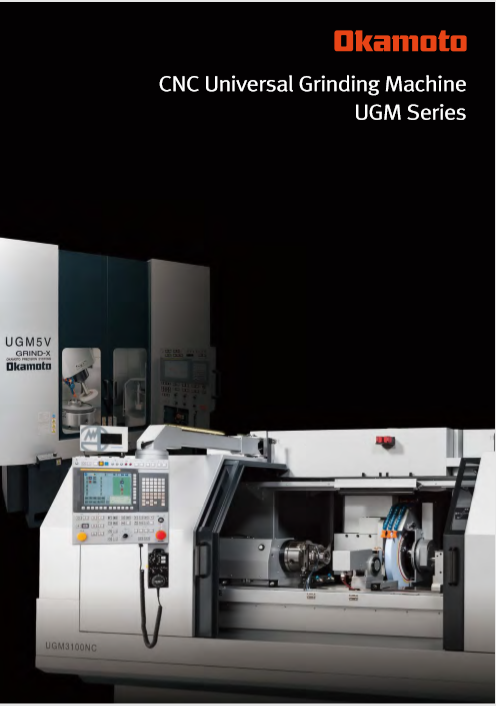

<JAPAN> CNC Universal Grinding Machine UGM Series

Product Catalog

Document Information

| Document Title | <JAPAN> CNC Universal Grinding Machine UGM Series |

|---|---|

| Document Type | Product Catalog |

| File size | 2.5Mb |

| Category | |

| Company | OKAMOTO MACHINE TOOL WORKS,LTD (Documents List) |

Documents related to this company

Document Contents

Page1

CNC Universal Grinding Machine

UGM Series

Page2

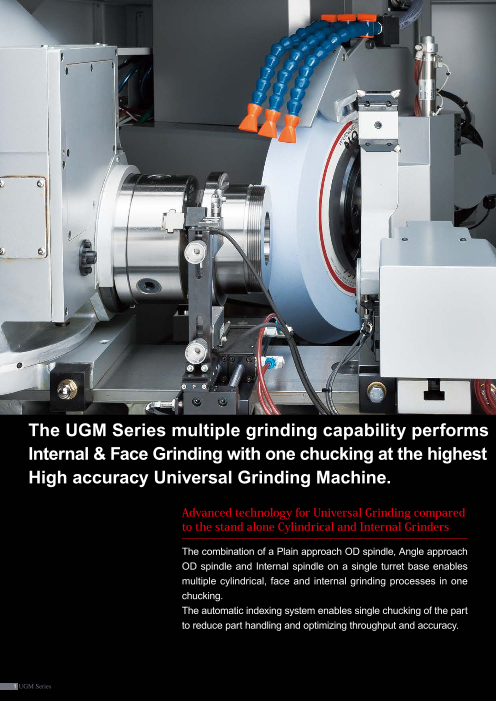

The UGM Series multiple grinding capability performs Cylindrical,

Internal & Face Grinding with one chucking at the highest level of accuracy.

High accuracy Universal Grinding Machine.

Advanced technology for Universal Grinding compared

to the stand alone Cylindrical and Internal Grinders

The combination of a Plain approach OD spindle, Angle approach

OD spindle and Internal spindle on a single turret base enables

multiple cylindrical, face and internal grinding processes in one

chucking.

The automatic indexing system enables single chucking of the part

to reduce part handling and optimizing throughput and accuracy.

1 UGM Series

Page3

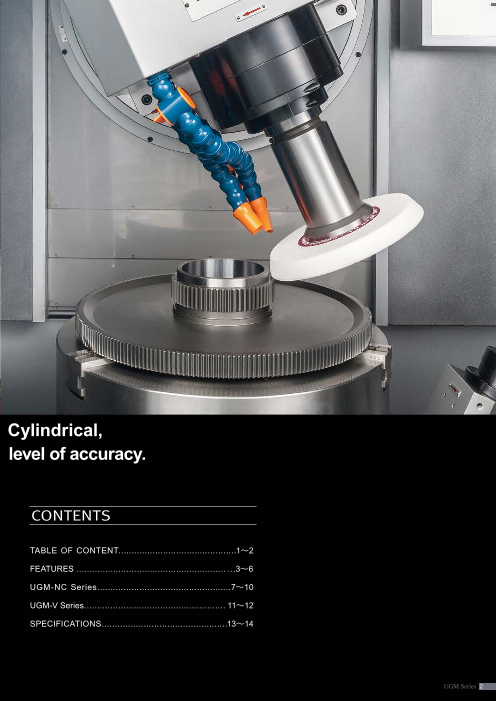

The UGM Series multiple grinding capability performs Cylindrical,

Internal & Face Grinding with one chucking at the highest level of accuracy.

High accuracy Universal Grinding Machine.

CONTENTS

TABLE OF CONTENT………………………………………1〜2

FEATURES ………………………………………………… …3〜6

UGM-NC Series……………………………………………7〜10

UGM-V Series……………………………………………… 11〜12

SPECIFICATIONS…………………………………………13〜14

UGM Series 2

Page4

Universal Grinding Machine Series

Capabilities of Cylindrical Grinding and Internal Grinding.

Suitable in precision for customers doing OD & ID features

■Proprietary Okamoto conversational software simplifies complicated data input.

■V-V table way construction reduces grinding pressure by one half and greatly improves

straightness accuracy when compared to V-Flat way systems.

UGM360NC

■ Solid single piece T-Frame casting provides superior rigidity and thermal stability.

UGM3100NC

■High-precision grinding performance is assured through the use of high accuracy posi-

tioning direct drive motor for spindle indexing.

■Built-in type high-precision spindle motors are temperature controlled to reduce thermal

expansion, minimizing spindle thrust for ultimate high precision.

UGM-12.40NC

3 Machine processes within 1 machine, reduces complete process time dramatically.

3 UGM Series

Page5

The Universal style machine has advantage for both productivity, and epecially accuracy for

perpendicularity, concentricity with great reduction of set up time.

Suitable for larger size workpieces which are more difficult

to chuck horizontally

For Larger size of Gears, Reducers, Construction & Excavator components.

■Okamoto's exclusive G.U.I. software with its easy-to-read icon graphical controller.

■Scale feedback is standard for wheel infeed and table longitudinal axis.

UGM5V ■Max of 4 different grinding wheel with Auto Tool Changer

■Precise index system with curvic coupling system for

spindle swivel to 0° or -30° (2-position).

■Compact and small footprint design.

■Built-in type high-precision spindle unit suitable for high

accuracy work.

■Equipped Rotary Dresser Unit capable of dressing Small to

large size wheels.

UGM5V

Saving multiple set ups with just One-chucking

UGM Series 4

Page6

Universal Grinding Machine Series

Feature

Choose Horizontal Type or Vertical Type by workpiece

1 Between centers type Horizontalworkpiece Type 2 Over φ12” size diameter

Vertical

Type

Only available on the Horizontal type Ma-

chine.

3 Longer size of workpiece HorizontalType 4 Taper grinding H o r i zTy o ntape l V eT ry tp icale

Steady rest also available for long & heavy Horizontal type machine is capable of swivel-

workpieces. ing either the work spindle or table for taper

grinding.

Horizontal

Type

Wheel form + 2 Axes simultaneously control

or Table swivel

Vertical

Type

Wheel form + 2 Axes simultaneously control

5 Various type of chucks Horizontal 6 Suitable for mass Horizontal Verticalare available Type production workpiece Type Type

Gauging, locator device and various type of Max. φ20” OD Grinding wheel size available.

chuck available. Large size of grinding wheel helps with im-

proved productivity.

5 UGM Series

Page7

Software

Conversational type Software

Okamoto’s exclusive G.U.I. software with its easy-to-read icon graphics enables

operator’s to easily input complicated grinding programs.

Touch screen control File management

Graphical type software with easy-to- 15 Programs for UGM-NC series, 21

read icon helps complete programs programs for UGM-V series can be

for complicated workpieces. stored internally.

Grinding process and dress

data have auto edit function

Input grinding wheel grit, wheel width

and final sizing value, and allow the

machine to provide a suitable grinding

process program as well as dress

program.

UG M-NC Series

File management screen

Okamoto's exclusive G.U.I.

software Main screen

The same software as standard cylindrical Setup of 10 steps max.

& internal grinder. Easy to learn universal Simplify grinding process from

machine if the customer is already using complex form using separate

cylindrical & internal machines. process on OD, ID & angle

wheels.

Entry for grinding process

Wheel form display

Select grinding mode /

Grinding condition set up screen

Select grinding wheel /

Auto calculation software for Dress condition set up screen

setting up grinding process data

& dress data UGM-V Series

Grinding condition set up screen Grinding date set up screen Main screen

(Common) Using the same style software allows it to Set up grinding process for each grinding

Auto calculation for grinding condition with easily manage conventional grinding jobs wheel. Max 4-different grinding wheels in

our extensive experience in grinding and Multiple feature grinding jobs. one set up .

UGM Series 6

Page8

CNC Universal Cylindrical Grinding Machine UGM-NC Series

Line up

This UGM Series allows multiple

grinding capabilities and improves

productivity.

UGM360NC

UGM3100NC

■Higher efficiency of productivity is achieved with Larger Grinding wheels than Vertical type

machine.

■Equipped with independent spindle units for each wheel, which optimizes speed on each unit.

■Built-in type high-precision spindle unit contributes to high-efficiency grinding.

■The same graphics type software is used as seen on the cylindrical grinding machines.

T-Frame construction eliminates

table base overhang within Thorough thermal expansion

Double V table ways yields

measures high precision in straightness the machine’s grinding envelope and parellelism

Solid single piece T-Frame casting pro- Solid piece T-Frame casting and constant V-V table way construction reduces grind-

vides superior rigidity and thermal stability. over the table coolant allows a more stable ing pressure and greatly improves straight-

control of thermal growth. ness accuracy when compared to V-Flat

way system.

Thermal distribution map for Table and Wheel

7 UGM Series head slideway

Page9

Ultra-rigid construction delivers the ultimate in precision,

versatility and productivity.

3-Spindle Turret Head enables OD. Angle OD/Face and ID grinding

for optimum productivity

OD grinding Angle OD/facegrinding ID grinding

Plain OD spindle (OP) Angle OD spindle ID spindle

T2 ID

T1 + T3 T3 + T2

T3 Angle

T1 + T3 + T2 T1 + T3

T1 Plain

Spindle index by turret. Each spindle can be set to run at an independent speed.

UGM Series 8

Page10

CNC Universal Cylindrical Grinding Machine UGM-NC Series

Working range

UGM360NC

×

UGM3100NC

×

Various spindle layout

Select spindle unit based on your frequency of use

and increase your overall productivity

Angle + ID Spindle unit (Standard) Plain + ID Spindle unit (Option) Angle + Plain + ID Spindle unit (Option)

9 UGM Series

Page11

Various dressing software

Graphical conversational software supports data input.

Select Dress required spindle unit from T1, T2 & T3, input grinding wheel diameter, width and

grit. Software will calculate suggestions for recommended grinding conditions,and dressing

condition automatically.

Straight Wheel Dress screen Angle Wheel Dress screen Internal Grinding Wheel Dress screen

■ Straight ■ Straight ■ Straight

■ Right, Left, Both Shoulder ■ Left Face-R ■ Face

■ Multi-step straight (OP) ■ Multi-step straight (OP) ■ Taper (OP)

■ Taper (OP) ■ NC Forming (OP) ■ Radius Form (OP)

■ NC Forming (OP)

Polygon grinding with on-machine measurement (OP)

Polygon Grinding

Polygon shape grinding is available by

Work spindle axis CNC control (C-axis)

(OP)

Polygon grinding Polygon grinding software screen

On-machine measurement (OP)

Shoulder Locator, In-process gauging are

available as option ideal for mass produc-

tion work. Measuring takes place in pro-

cess to eliminate set up error.

In-process gauging device Measurement software screen

UGM Series 10

Page12

CNC Precision Vertical type Internal Grinding Machine UGM-V Series

Line Up

Developed on existing Internal Grind-

ing machine and capable of doing larg-

er and heavier work precisely.

Roundness 0.9μm

0˚+Y

90˚ 270˚

-X +X

Workpiece 180˚-Y

UGM5V OD×ID×Length:φ210×φ125×100mm

Roundness (ID):0.9μm 10μm(×1000)

■Suitable for long size work pieces which may be difficult to keep straight.

■Suitable for heavier workpieces (i.e. large gear, casing, etc.).

■Max 4 ATC available for doing universal grinding.

ATC (Auto Tool changer) Function Automatic wheel head swivel function

Equipped with ATC (Max 4 tool) as stan- Using a Curvic Coupling for wheel head

dard. swivel, 0 deg. & -30 deg. For Precision

positioning.

11 UGM Series

Page13

Achieving high accurate grinding with multi-process

CNC Precision Vertical type Internal Grinding Machine UGM-V Series and high rigidity.

Maximum 4 grinding wheel selection in the ATC allows higher efficiency.

Achieving higher levels of cylindlicity, perpendicularity & concentricity with one chucking.

Angle grinding Internal grinding Cylindrical (OD) grinding Face grinding

Angle type grinding wheel Internal grinding wheel Straight grinding wheel

Grinding wheels are changed by the ATC, variety of grinding wheels can be equipped.

Dress form software screen

Graphical software with touch and teach capabilities allows for easier data input.

Dress form screen Angle wheel dress screen

for Internal grinding wheel

Grinding spindle swivel screen

UGM Series 12

Page14

UGM-12.24NC/UGM-12.40NC Specification

Standard accessories

Items Unit UGM360NC UGM3100NC Items

Work spindle type ― Heavy duty type work spindle (Live / Dead center type) Infeed axis closed loop control

Work spindle taper MT NO. 4

Diameter of through hole mm φ28 Angle type spindle

Work spindle

Spindle speed min-1 10〜500 Internal grinding spindle(10,000〜45,000min-1)

Swivel angle deg Non swivel type (OP : 90)

Swivel angle (Operator side) deg Non swivel type (OP : 30) Plan grinding spindle

Tailstock type ― Manual fine taper adjustable type tail stock

Standard internal grinding wheel

Tailstock Tailstock spindle movement mm 30

Center taper MT NO. 4 Wheel adaptor

Grinding wheel Spindle kW 11

ID spindle kW 12(36000min-1) Carbide tip center 2 pcs

Work spindle motor (C-axis/ AC servo motor) kW 1.8 Circuit breaker

Table feed motor (Z-axis/AC servo motor) kW 4.5

Motor

Spindle infeed motor (X-axis/AC Servo motor) kW 3.0 Table enclosure

Wheelhead swivel (B-axis/Servo motor) kW 5.6 (DD Motor) Work light

Lubrication pump motor W/P 3/4

Fluid temperature controller W 3800 Dress coolant

OD × Width × ID mm φ510×63 (OP80)×φ203.2

Grinding -1 Table top coolant supply for cleaning & thermal control

Wheel Speed min 900〜3200

Max. peripheral speed m/sec 50 Locator device

Grinding wheel Travel distance mm 360

spindle infeed Minimum increment (φ) mm 0.0001 Table swivel angle measurement device

(X-axis) Rapid feed (φ) m/min 10 MPG handle box

Grinding wheel Swivel angle deg CCW 0 deg.~ CW 240 deg.

head swivel for

grinding wheel Minimum increment deg 0.0001

Grinding Spindle speed meter

spindle (B-axis) Rapid feed min-1 15 Work spindle speed meter

Travel distance mm 850 1250

Table

longitudinal Swivel angle deg 0〜8.5 0〜6.0 Graphical type conversational software

movement Minimum increment mm 0.0001

(Z-axis) Leveling bolts with plate

Rapid feed m/min 20

Electric power consumption kVA 33 Necessary tools with box

Lubrication oil ℓ 3

Tank capacity

Coolant fluid ℓ 80 Primary transformer (Machine operate 400V 3-phase)

Type of controller ― FANUC 0i-MF NC controller unit, FANUC 0i-MF

NC control

unit Numerical control axis ― Cross feed (X) Longitudinal (Z) 2 axes simultaneously

Interpolation ― Positioning, Linear, Circular Manual type tail stock unit (only UGM-12.40NC machine)

Working height Height of work spindle center from floor mm 1135

Floor space Width × Depth × Height(excluding maintenance space) mm 2780×2750×1900 3650×2750×1900 2-point steady rest Work rest

Machine weight kg 7000 7900

Machine overview

Drive dog set Automatic work driver

Coolant

unit * With magnetic dust

separator unit

B D

Table swivel measurement device Coolant tank

C

A

Example for Automatic loading system

E

Uni(t mm) ○A ○B ○C ○D ○E

UGM360NC 3800 3500 2780 2100 1900

UGM3100NC 4200 3500 3650 2100 1900

Automatic loading system by Robot IGM2TNCⅢ-4

13 UGM Series

Page15

UGM 5V Specification

Optional accessories

Items Items Unit UGM5V

Various type coolant system Max. workpiece swing mm φ550

Oil mist collector Max. grinding hole diameter mm φ70〜φ500

Grinding stroke mm 450

Hood for mist collector

Longitudinal feed Max. travel mm 1100

Cleaning spray nozzle

(X-axis) Rapid feed speed mm/min 20000

Various types of Chucks

Max. travel mm 450

3-Jaw scroll chuck Vertical feed (Z-axis)

Rapid feed speed mm/min 20000

Magnetic chuck Swivel angle deg. 0, 30

Various types of Dressing units Speed min-1 500〜8000

Grinding spindle

Rotary dresser unit Grinding wheel size mm φ60〜φ300

Radius dresser unit Motor power kW 11

Angle dresser unit Work spindle Speed min-1 10〜150

Option for Table mounting unit Electric power consumption kVA 45

Floor space (only machine) mm 2650×2380×3032

Various types of tailstock units

Machine weight kg 9000

2-point steady rest

3-point steady rest Standard accessories

Work rest

Items

Drive dog set (φ1/4 - φ3", 6 pcs) Conversational type graphic software

Automatic work driver Spindle swivel function

Various types of Grinding wheels ATC (4 pcs max.)

Wheel balancer unit, BW-5 Rotary dresser unit

Micro balancer, MB-4 Vertical, table longitudinal scale feed back system

Spare wheel adaptor Spindle cooling unit

Measurement LED work light

3-color signal tower

Gauge sizing device

Table enclosure

Gap eliminate sensor system

Leveling bolts and plates

Others

Necessary tools with tool box

Specific color painting for the machine

Table longitudinal scale feed back system Machine overview

(closed loop control)

Special dress cycle software Mist collector &

Temperature control unit

EDELAC Win

Coolant

system Hydraulic

tank unit

B

D

Gauge sizing device Locator device

Operation

box

UGM5V

E

C

A

Uni(t mm) ○A ○B ○C ○D ○E

UGM5V 2860 3938 2650 1813 2660

IGM & OGM Loading system

UGM Series 14

Page16

OKAMOTO MACHINE TOOL WORKS, LTD.

2993 Gobara, Annaka-shi, Gunma, Japan 379-0135 Tel: +81-27-388-9595

3-5-7 Nakamachidai, Tsuzuki-ku, Yokohama, Kanagawa, Japan 224-0041 Tel: +81-45-949-3881

CAUTION

*When and before using our products, you are requested to well go through the articles on danger, warning and attention for the sake of safety described in operation manual attached to

the machine and also in the warning plates mounted on the machine.

*When a product manufactured at our factory comes under the Foreign Exchange And Foreign Trade Control Law and is exported or carried overseas, it is necessary to receive permission

or approval of the Japanese Government.

*Specifications subject to change without notice.

Printed in Japan in August 2017

2017082000MTR-0