1/6ページ

Download(463.7Kb)

<JAPAN> DOUBLE COLUMN GRINDING MACHINE ACC-CHiQ SERIES

Product Catalog

Document Information

| Document Title | <JAPAN> DOUBLE COLUMN GRINDING MACHINE ACC-CHiQ SERIES |

|---|---|

| Document Type | Product Catalog |

| File size | 463.7Kb |

| Category | |

| Company | OKAMOTO MACHINE TOOL WORKS,LTD (Documents List) |

Documents related to this company

Document Contents

Page1

Standard accessories Grinding wheel adaptor Specifi cations

Foundation plate or Anchor bolt

Filling nozzle for 4˝ wide grinding wheel DOUBLE COLUMN GRINDING MACHINE

Lifting bolt for grinding wheel adaptor Item Unit 32.80CH-iQ 32.100CH-iQ 32.140CH-iQ

Hydraulic overhead dresser with wheel wear compensation 32×80 32×100 32×140

Dresser stand with diamond tool Table working size (Length×Width×Height) in

Spindle speed controller 30 hp Max Dist. Under Wheel 23.5

Automatic oil temperature regulator Max. pass width in 41

Automatic circuit breaker Capacity Table working cap (Length×Width) in 33×81 33×101 33×140 ACC-CH iQ

iQ Software

Maximum weight of table (Including chuck) lbs 5512 (2601) 7055 (3263) 10580 (4564) SERIES

Optional accessories

Chuck size (Length×Width) in 32×79 32×98 32×138

Model Max. travel feed in 89 108 148

Item Specifi cations CH-iQ Longitudinal feed

32˝×80˝ 32˝×100˝ 32˝×140˝ Longitudinal feed rate ft/min 698

With magnetic dust separator ・Tank capacity: 160 gal

・Coolant pump:1/2 hp / 2ph, Separator disposal capacity: 32 gal/min ○ Max. travel feed in 36

Magnetic dust separator with ・Tank capacity: 160 gal

・Coolant pump:1/2 hp / 2ph, Separator disposal capacity: 32 gal/min ○ Minimum increment in 0.00001temperature regulator

・Temperature regulator: 1 hp

Max. rapid feed in 236

Coolant system 160 gal Magnetic dust separator with ・Tank capacity: 160 gal Cross feed

auto. paper fi lter ・Coolant pump:1/2 hp / 2ph, Separator disposal capacity: 32 gal/min ○

・Processing capacity: 32 gal/min (15-μm mesh) Automatic feed Continuous feed rate in/min 039.4

Magnetic dust separator with ・Tank capacity: 160 gal Hand feed per resolution 0.001/0.01/0.1

auto. paper fi lter and tempera- ・Coolant pump:1/2 hp / 2ph, Separator disposal capacity: 32 gal/min

・Processing capacity: (32gal/min with 15-μm mesh) ○

Manual feed in

ture regulator Temperature regulator: 1 hp Graduation of hand wheel 0.00001/0.0001/0.001・

Oil mist dust collector ・Dust collector motor: 2hp / 2ph, Air fl ow: 6000 gal/min ○ Max. travel feed in 24.4・Dust collection port: 6˝

Dust collection port Diameter for OKB-20: 6˝ ・Mounted to the top of "left rear cover with top" ○ Minimum increment in 0.00001

32˝×79˝×4˝ ○ - -

Electro-magnetic chuck 32˝×98˝×4˝ Max. rapid feed in/min 78.7- ○ -

32˝×138˝×4˝ - - ○ Vertical feed Rough grinding

32˝×79˝×4˝ ○ - - Automatic feed in 0.000010.04

Electro Permanent Magnetic 32˝×98˝×4˝ - ○ - Fine grindingchuck

32˝×138˝×4˝ - - ○ Hand feed per resolution 0.001/0.01/0.1

Demagnetizing controller With automatic 20-A elec-tro-magnetic adjustment ・Chuck "rated current" applicable range Max: 16 A ○

Manual feed in

Graduation of hand wheel 0.00001/0.0001/0.001

Grinding wheel external

diameter 24˝ 4˝ ・Applicable grinding wheel: 24˝×4˝×8” (both recess)φ ○ φ20×4×φ5

Spare grinding wheel diame- Size (OD×W×ID) in

ter: 20˝ 4˝ ・20˝×4˝×8” (both recess)φ ○ (Option:24×4×5 )

Spare grinding wheel diame- Grinding wheel

ter: 24˝ 4˝ ・24˝×4˝×8˝ (both recess)φ ○ Spindle speed rpm 400~1600

Vertical grinding attachment ・5 hp ○ Motor hp/ph 30 / 4

BW-5 type (with standard arbor) ・Applicable grinding wheel diameter: 20˝ max. balance type ○

Dynamic balancing apparatus

BW-6 type (with standard arbor) ・Applicable grinding wheel diameter: 24˝ max. balance type ○ Oil pressure unit Capacity gal 80

Balance arbor (balance type) L = 11˝, For both BW-5 and 6 types ・Grinding wheel internal diameter: 8˝ ○

・Full-automatic measurement and automatic correction Machine space Length×Width×Height in 259×152×140 305×152×140 402×152×140

Automatic dynamic balancing Full-automatic balancer ・3 electrical balance weights shift ・Rotational speed: Max. 1200 min-1

apparatus non-contact electric type ・Measurement range unbalanced vibration displacement: 0.01 to 100 μm ○ Machine weight Standard lbs 34,200 37,500 44,100

・Controller, ACC sensor-equipped, integrated controller

For standard ・20˝×4˝×8˝ ○

Grinding wheel adaptor

For full automatic balancer ・20˝×4˝×8˝ ○ OKAMOTO MACHINE TOOL WORKS, LTD.

T slots on table surface Number of grooves: 3 ・Size of T groove and pitch: Okamoto's standard ○ 3-5-7 Nakamachidai, Tsuzuki-ku, Yokohama, Kanagawa, 224-0041 Japan

High column specifi cation 8˝ up ○ TEL: +81-45-949-3881 FAX: +81-45-949-3787

Hydraulic oil ・Required amount: 80 gal ○ http://www.okamoto.co.jp

Cycle end power shut off For 30 hp spindle motor ・Power shut-off at cycle end ○

Spindle motor activates ・The spindle does not rotate unless the electro-magnetic chuck is "ON." ○

Electro-magnetic chuck inter- ・The table does not rotate unless the electro-magnetic chuck is "ON."

lock Table activates ・Should it switch to "OFF" while the table is rolling over, ○ OKAMOTO CORPORATION

the table stops immediately. 370 Corporate Woods Parkway, Vernon Hills, IL 60061, U.S.A.

・The table does not activate unless the door is "ON." TEL: (847)235-3500 FAX: (847)235-3274

Door interlock Table activates ・Should it switch to "OFF" while the table is rolling over, ○

the table stops immediately. http://www.okamotocorp.com/

Grinding head meter relay ○

Calendar timer ・A weekly timer turns the hydraulics "ON" at a set time. ○ CAUTION

Three-stage signal tower Red, Yellow, Green Signal meaning ・Yellow: Lights at the end of a cycle. ・Green: Lights during a cycle. ○ *When and before using our products, you are requested to well go through the articles on danger, warning and attention for the sake

Working light (LED) ・Mounted on the underside of the cross rail ○ of safety described in operation manual attached to the machine and also in the warning plates mounted on the machine.

G code program ○ *Specifications subject to change without notice.

iQ Software

Automatic programming UP CAM ○ *When a product manufactured at our factory comes under the Foreign Exchange And Foreign Trade Control Law and is exported or

carried overseas, it is necessary to receive permission or approval of the Japanese Government.

Printed in Japan in May 2019

Page2

ACC-CH iQ Series

This double-column grinding machine satisfi es demands for high accuracy and high effi ciency.

iQ software facilitates the processing of large workpieces

The ACC-CH iQ Series satisfi es the demands for high accuracy required for machin- with the double-column grinding machine.

ing the progressive dies used for motor cores or LC processing, while also offering the

high effi ciency needed by the die base processing industry. The innovative iQ software radically simplifi es data input.

Cycle time has been dramatically shortened.

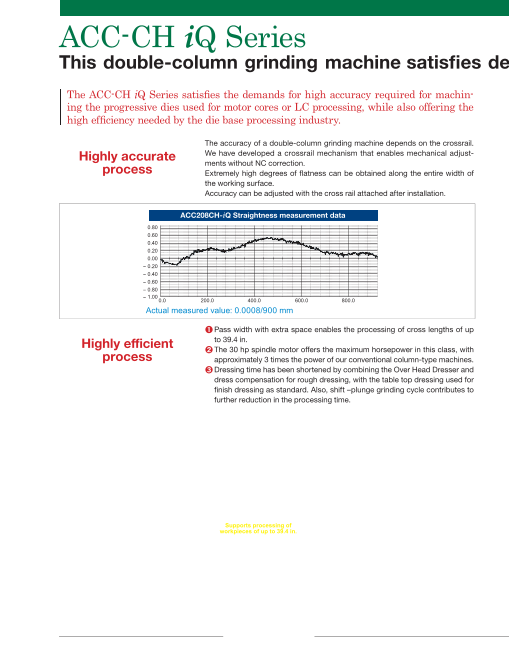

The accuracy of a double-column grinding machine depends on the crossrail.

Highly accurate We have developed a crossrail mechanism that enables mechanical adjust- iQ data is automatically generated by inputting the grinding wheel's grain size.

process ments without NC correction.Extremely high degrees of fl atness can be obtained along the entire width of Input the total machining allowance and precision machining allowance. Then, simply input the grinding wheel size to automatically create the optimum grinding wheel

the working surface. conditions based on our know-how and grinding process theory.

Accuracy can be adjusted with the cross rail attached after installation.

Data input can be completed using only two screens.

ACC208CH-iQ Straightness measurement data

There is no text on the screen.

0.80 The panel buttons cover the full range of surface grinding and complicated grinding operations.

0.60

0.40

0.20

0.00

- 0.20

- 0.40

- 0.60

- 0.80

- 1.00

0.0 200.0 400.0 600.0 800.0

Actual measured value: 0.0008/900 mm

Pass width with extra space enables the processing of cross lengths of up

Highly effi cient to 39.4 in. Grinding data setting screen Dress data setting screen The 30 hp spindle motor off ers the maximum horsepower in this class, with

process approximately 3 times the power of our conventional column-type machines. ACC32.80CH-iQ

Dressing time has been shortened by combining the Over Head Dresser and Diversifi ed iQ Functions

dress compensation for rough dressing, with the table top dressing used for

fi nish dressing as standard. Also, shift –plunge grinding cycle contributes to Keys to shortening cycle time

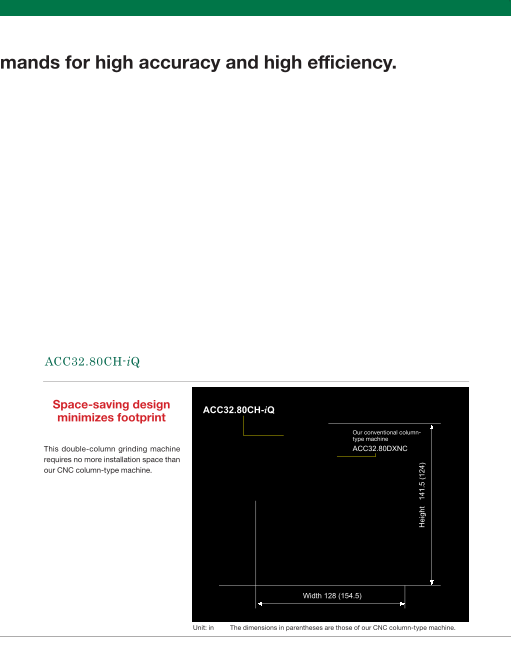

further reduction in the processing time. (Fine- and rough-dressing selection)Space-saving design ACC32.80CH-iQ Optimum combination of overhead dress for rough

minimizes footprint dressing and table top dress for fi nishing. An automatic diamond tracking device is provided with the overhead

Our conventional column- dresser with dress cycle function (optional).

type machine By using shift plunge grinding, the cycle time can be ef-

This double-column grinding machine ACC32.80DXNC fectively shortened.

requires no more installation space than

our CNC column-type machine. Automatic setting of process conditions

Grinding processes used to rely on the user’s skill and

intuition. To automate this processing, we developed a

function for automatically setting the recommended pro- Fine and rough dress setting

Pass width: 41 in cess conditions based on grinding process theory and Supports an optimal combination

our know-how. The basic data on which this automatic of upper dress for rough dressing and on-the-table dress for fine

Supports processing of setting is based is the grain size of the grinding wheel. dressing.

workpieces of up to 39.4 in. This software supports the use of both Alundum-type

grinding wheels and ultra-abrasive-coating grinding

Chuck width: 32 in wheels. Users can also input their own condition settings. Automatic setting of process conditions

Select either a general grinding wheel or ultra

i abrasive coating grinding wheel, and then enter Q graphical display of actual grinding position the grain size in the column below.

The position at which grinding is to be performed is dis- The optimal grinding/dressing conditions are au-

played on the screen. tomatically set based on the grain size.

Width 128 (154.5)

iQ cycle type projection

The cycle end time is displayed, thus saving setup time.

Unit: in The dimensions in parentheses are those of our CNC column-type machine.

Height 141.5 (124)

Page3

ACC-CH iQ Series

This double-column grinding machine satisfi es demands for high accuracy and high effi ciency.

iQ software facilitates the processing of large workpieces

The ACC-CH iQ Series satisfi es the demands for high accuracy required for machin- with the double-column grinding machine.

ing the progressive dies used for motor cores or LC processing, while also offering the

high effi ciency needed by the die base processing industry. The innovative iQ software radically simplifi es data input.

Cycle time has been dramatically shortened.

The accuracy of a double-column grinding machine depends on the crossrail.

Highly accurate We have developed a crossrail mechanism that enables mechanical adjust- iQ data is automatically generated by inputting the grinding wheel's grain size.

process ments without NC correction.Extremely high degrees of fl atness can be obtained along the entire width of Input the total machining allowance and precision machining allowance. Then, simply input the grinding wheel size to automatically create the optimum grinding wheel

the working surface. conditions based on our know-how and grinding process theory.

Accuracy can be adjusted with the cross rail attached after installation.

Data input can be completed using only two screens.

ACC208CH-iQ Straightness measurement data

There is no text on the screen.

0.80 The panel buttons cover the full range of surface grinding and complicated grinding operations.

0.60

0.40

0.20

0.00

- 0.20

- 0.40

- 0.60

- 0.80

- 1.00

0.0 200.0 400.0 600.0 800.0

Actual measured value: 0.0008/900 mm

Pass width with extra space enables the processing of cross lengths of up

Highly effi cient to 39.4 in. Grinding data setting screen Dress data setting screen The 30 hp spindle motor off ers the maximum horsepower in this class, with

process approximately 3 times the power of our conventional column-type machines. ACC32.80CH-iQ

Dressing time has been shortened by combining the Over Head Dresser and Diversifi ed iQ Functions

dress compensation for rough dressing, with the table top dressing used for

fi nish dressing as standard. Also, shift –plunge grinding cycle contributes to Keys to shortening cycle time

further reduction in the processing time. (Fine- and rough-dressing selection)Space-saving design ACC32.80CH-iQ Optimum combination of overhead dress for rough

minimizes footprint dressing and table top dress for fi nishing. An automatic diamond tracking device is provided with the overhead

Our conventional column- dresser with dress cycle function (optional).

type machine By using shift plunge grinding, the cycle time can be ef-

This double-column grinding machine ACC32.80DXNC fectively shortened.

requires no more installation space than

our CNC column-type machine. Automatic setting of process conditions

Grinding processes used to rely on the user’s skill and

intuition. To automate this processing, we developed a

function for automatically setting the recommended pro- Fine and rough dress setting

Pass width: 41 in cess conditions based on grinding process theory and Supports an optimal combination

our know-how. The basic data on which this automatic of upper dress for rough dressing and on-the-table dress for fine

Supports processing of setting is based is the grain size of the grinding wheel. dressing.

workpieces of up to 39.4 in. This software supports the use of both Alundum-type

grinding wheels and ultra-abrasive-coating grinding

Chuck width: 32 in wheels. Users can also input their own condition settings. Automatic setting of process conditions

Select either a general grinding wheel or ultra

i abrasive coating grinding wheel, and then enter Q graphical display of actual grinding position the grain size in the column below.

The position at which grinding is to be performed is dis- The optimal grinding/dressing conditions are au-

played on the screen. tomatically set based on the grain size.

Width 128 (154.5)

iQ cycle type projection

The cycle end time is displayed, thus saving setup time.

Unit: in The dimensions in parentheses are those of our CNC column-type machine.

Height 141.5 (124)

Page4

ACC-CH iQ Series

This double-column grinding machine satisfi es demands for high accuracy and high effi ciency.

iQ software facilitates the processing of large workpieces

The ACC-CH iQ Series satisfi es the demands for high accuracy required for machin- with the double-column grinding machine.

ing the progressive dies used for motor cores or LC processing, while also offering the

high effi ciency needed by the die base processing industry. The innovative iQ software radically simplifi es data input.

Cycle time has been dramatically shortened.

The accuracy of a double-column grinding machine depends on the crossrail.

Highly accurate We have developed a crossrail mechanism that enables mechanical adjust- iQ data is automatically generated by inputting the grinding wheel's grain size.

process ments without NC correction.Extremely high degrees of fl atness can be obtained along the entire width of Input the total machining allowance and precision machining allowance. Then, simply input the grinding wheel size to automatically create the optimum grinding wheel

the working surface. conditions based on our know-how and grinding process theory.

Accuracy can be adjusted with the cross rail attached after installation.

Data input can be completed using only two screens.

ACC208CH-iQ Straightness measurement data

There is no text on the screen.

0.80 The panel buttons cover the full range of surface grinding and complicated grinding operations.

0.60

0.40

0.20

0.00

- 0.20

- 0.40

- 0.60

- 0.80

- 1.00

0.0 200.0 400.0 600.0 800.0

Actual measured value: 0.0008/900 mm

Pass width with extra space enables the processing of cross lengths of up

Highly effi cient to 39.4 in. Grinding data setting screen Dress data setting screen The 30 hp spindle motor off ers the maximum horsepower in this class, with

process approximately 3 times the power of our conventional column-type machines. ACC32.80CH-iQ

Dressing time has been shortened by combining the Over Head Dresser and Diversifi ed iQ Functions

dress compensation for rough dressing, with the table top dressing used for

fi nish dressing as standard. Also, shift –plunge grinding cycle contributes to Keys to shortening cycle time

further reduction in the processing time. (Fine- and rough-dressing selection)Space-saving design ACC32.80CH-iQ Optimum combination of overhead dress for rough

minimizes footprint dressing and table top dress for fi nishing. An automatic diamond tracking device is provided with the overhead

Our conventional column- dresser with dress cycle function (optional).

type machine By using shift plunge grinding, the cycle time can be ef-

This double-column grinding machine ACC32.80DXNC fectively shortened.

requires no more installation space than

our CNC column-type machine. Automatic setting of process conditions

Grinding processes used to rely on the user’s skill and

intuition. To automate this processing, we developed a

function for automatically setting the recommended pro- Fine and rough dress setting

Pass width: 41 in cess conditions based on grinding process theory and Supports an optimal combination

our know-how. The basic data on which this automatic of upper dress for rough dressing and on-the-table dress for fine

Supports processing of setting is based is the grain size of the grinding wheel. dressing.

workpieces of up to 39.4 in. This software supports the use of both Alundum-type

grinding wheels and ultra-abrasive-coating grinding

Chuck width: 32 in wheels. Users can also input their own condition settings. Automatic setting of process conditions

Select either a general grinding wheel or ultra

i abrasive coating grinding wheel, and then enter Q graphical display of actual grinding position the grain size in the column below.

The position at which grinding is to be performed is dis- The optimal grinding/dressing conditions are au-

played on the screen. tomatically set based on the grain size.

Width 128 (154.5)

iQ cycle type projection

The cycle end time is displayed, thus saving setup time.

Unit: in The dimensions in parentheses are those of our CNC column-type machine.

Height 141.5 (124)

Page5

Standard accessories Grinding wheel adaptor Specifi cations

Foundation plate or Anchor bolt

Filling nozzle for 4˝ wide grinding wheel DOUBLE COLUMN GRINDING MACHINE

Lifting bolt for grinding wheel adaptor Item Unit 32.80CH-iQ 32.100CH-iQ 32.140CH-iQ

Hydraulic overhead dresser with wheel wear compensation 32×80 32×100 32×140

Dresser stand with diamond tool Table working size (Length×Width×Height) in

Spindle speed controller 30 hp Max Dist. Under Wheel 23.5

Automatic oil temperature regulator Max. pass width in 41

Automatic circuit breaker Capacity Table working cap (Length×Width) in 33×81 33×101 33×140 ACC-CH iQ

iQ Software

Maximum weight of table (Including chuck) lbs 5512 (2601) 7055 (3263) 10580 (4564) SERIES

Optional accessories

Chuck size (Length×Width) in 32×79 32×98 32×138

Model Max. travel feed in 89 108 148

Item Specifi cations CH-iQ Longitudinal feed

32˝×80˝ 32˝×100˝ 32˝×140˝ Longitudinal feed rate ft/min 698

With magnetic dust separator ・Tank capacity: 160 gal

・Coolant pump:1/2 hp / 2ph, Separator disposal capacity: 32 gal/min ○ Max. travel feed in 36

Magnetic dust separator with ・Tank capacity: 160 gal

・Coolant pump:1/2 hp / 2ph, Separator disposal capacity: 32 gal/min ○ Minimum increment in 0.00001temperature regulator

・Temperature regulator: 1 hp

Max. rapid feed in 236

Coolant system 160 gal Magnetic dust separator with ・Tank capacity: 160 gal Cross feed

auto. paper fi lter ・Coolant pump:1/2 hp / 2ph, Separator disposal capacity: 32 gal/min ○

・Processing capacity: 32 gal/min (15-μm mesh) Automatic feed Continuous feed rate in/min 039.4

Magnetic dust separator with ・Tank capacity: 160 gal Hand feed per resolution 0.001/0.01/0.1

auto. paper fi lter and tempera- ・Coolant pump:1/2 hp / 2ph, Separator disposal capacity: 32 gal/min

・Processing capacity: (32gal/min with 15-μm mesh) ○

Manual feed in

ture regulator Temperature regulator: 1 hp Graduation of hand wheel 0.00001/0.0001/0.001・

Oil mist dust collector ・Dust collector motor: 2hp / 2ph, Air fl ow: 6000 gal/min ○ Max. travel feed in 24.4・Dust collection port: 6˝

Dust collection port Diameter for OKB-20: 6˝ ・Mounted to the top of "left rear cover with top" ○ Minimum increment in 0.00001

32˝×79˝×4˝ ○ - -

Electro-magnetic chuck 32˝×98˝×4˝ Max. rapid feed in/min 78.7- ○ -

32˝×138˝×4˝ - - ○ Vertical feed Rough grinding

32˝×79˝×4˝ ○ - - Automatic feed in 0.000010.04

Electro Permanent Magnetic 32˝×98˝×4˝ - ○ - Fine grindingchuck

32˝×138˝×4˝ - - ○ Hand feed per resolution 0.001/0.01/0.1

Demagnetizing controller With automatic 20-A elec-tro-magnetic adjustment ・Chuck "rated current" applicable range Max: 16 A ○

Manual feed in

Graduation of hand wheel 0.00001/0.0001/0.001

Grinding wheel external

diameter 24˝ 4˝ ・Applicable grinding wheel: 24˝×4˝×8” (both recess)φ ○ φ20×4×φ5

Spare grinding wheel diame- Size (OD×W×ID) in

ter: 20˝ 4˝ ・20˝×4˝×8” (both recess)φ ○ (Option:24×4×5 )

Spare grinding wheel diame- Grinding wheel

ter: 24˝ 4˝ ・24˝×4˝×8˝ (both recess)φ ○ Spindle speed rpm 400~1600

Vertical grinding attachment ・5 hp ○ Motor hp/ph 30 / 4

BW-5 type (with standard arbor) ・Applicable grinding wheel diameter: 20˝ max. balance type ○

Dynamic balancing apparatus

BW-6 type (with standard arbor) ・Applicable grinding wheel diameter: 24˝ max. balance type ○ Oil pressure unit Capacity gal 80

Balance arbor (balance type) L = 11˝, For both BW-5 and 6 types ・Grinding wheel internal diameter: 8˝ ○

・Full-automatic measurement and automatic correction Machine space Length×Width×Height in 259×152×140 305×152×140 402×152×140

Automatic dynamic balancing Full-automatic balancer ・3 electrical balance weights shift ・Rotational speed: Max. 1200 min-1

apparatus non-contact electric type ・Measurement range unbalanced vibration displacement: 0.01 to 100 μm ○ Machine weight Standard lbs 34,200 37,500 44,100

・Controller, ACC sensor-equipped, integrated controller

For standard ・20˝×4˝×8˝ ○

Grinding wheel adaptor

For full automatic balancer ・20˝×4˝×8˝ ○ OKAMOTO MACHINE TOOL WORKS, LTD.

T slots on table surface Number of grooves: 3 ・Size of T groove and pitch: Okamoto's standard ○ 3-5-7 Nakamachidai, Tsuzuki-ku, Yokohama, Kanagawa, 224-0041 Japan

High column specifi cation 8˝ up ○ TEL: +81-45-949-3881 FAX: +81-45-949-3787

Hydraulic oil ・Required amount: 80 gal ○ http://www.okamoto.co.jp

Cycle end power shut off For 30 hp spindle motor ・Power shut-off at cycle end ○

Spindle motor activates ・The spindle does not rotate unless the electro-magnetic chuck is "ON." ○

Electro-magnetic chuck inter- ・The table does not rotate unless the electro-magnetic chuck is "ON."

lock Table activates ・Should it switch to "OFF" while the table is rolling over, ○ OKAMOTO CORPORATION

the table stops immediately. 370 Corporate Woods Parkway, Vernon Hills, IL 60061, U.S.A.

・The table does not activate unless the door is "ON." TEL: (847)235-3500 FAX: (847)235-3274

Door interlock Table activates ・Should it switch to "OFF" while the table is rolling over, ○

the table stops immediately. http://www.okamotocorp.com/

Grinding head meter relay ○

Calendar timer ・A weekly timer turns the hydraulics "ON" at a set time. ○ CAUTION

Three-stage signal tower Red, Yellow, Green Signal meaning ・Yellow: Lights at the end of a cycle. ・Green: Lights during a cycle. ○ *When and before using our products, you are requested to well go through the articles on danger, warning and attention for the sake

Working light (LED) ・Mounted on the underside of the cross rail ○ of safety described in operation manual attached to the machine and also in the warning plates mounted on the machine.

G code program ○ *Specifications subject to change without notice.

iQ Software

Automatic programming UP CAM ○ *When a product manufactured at our factory comes under the Foreign Exchange And Foreign Trade Control Law and is exported or

carried overseas, it is necessary to receive permission or approval of the Japanese Government.

Printed in Japan in May 2019

Page6

Standard accessories Grinding wheel adaptor Specifi cations

Foundation plate or Anchor bolt

Filling nozzle for 4˝ wide grinding wheel DOUBLE COLUMN GRINDING MACHINE

Lifting bolt for grinding wheel adaptor Item Unit 32.80CH-iQ 32.100CH-iQ 32.140CH-iQ

Hydraulic overhead dresser with wheel wear compensation 32×80 32×100 32×140

Dresser stand with diamond tool Table working size (Length×Width×Height) in

Spindle speed controller 30 hp Max Dist. Under Wheel 23.5

Automatic oil temperature regulator Max. pass width in 41

Automatic circuit breaker Capacity Table working cap (Length×Width) in 33×81 33×101 33×140 ACC-CH iQ

iQ Software

Maximum weight of table (Including chuck) lbs 5512 (2601) 7055 (3263) 10580 (4564) SERIES

Optional accessories

Chuck size (Length×Width) in 32×79 32×98 32×138

Model Max. travel feed in 89 108 148

Item Specifi cations CH-iQ Longitudinal feed

32˝×80˝ 32˝×100˝ 32˝×140˝ Longitudinal feed rate ft/min 698

With magnetic dust separator ・Tank capacity: 160 gal

・Coolant pump:1/2 hp / 2ph, Separator disposal capacity: 32 gal/min ○ Max. travel feed in 36

Magnetic dust separator with ・Tank capacity: 160 gal

・Coolant pump:1/2 hp / 2ph, Separator disposal capacity: 32 gal/min ○ Minimum increment in 0.00001temperature regulator

・Temperature regulator: 1 hp

Max. rapid feed in 236

Coolant system 160 gal Magnetic dust separator with ・Tank capacity: 160 gal Cross feed

auto. paper fi lter ・Coolant pump:1/2 hp / 2ph, Separator disposal capacity: 32 gal/min ○

・Processing capacity: 32 gal/min (15-μm mesh) Automatic feed Continuous feed rate in/min 039.4

Magnetic dust separator with ・Tank capacity: 160 gal Hand feed per resolution 0.001/0.01/0.1

auto. paper fi lter and tempera- ・Coolant pump:1/2 hp / 2ph, Separator disposal capacity: 32 gal/min

・Processing capacity: (32gal/min with 15-μm mesh) ○

Manual feed in

ture regulator Temperature regulator: 1 hp Graduation of hand wheel 0.00001/0.0001/0.001・

Oil mist dust collector ・Dust collector motor: 2hp / 2ph, Air fl ow: 6000 gal/min ○ Max. travel feed in 24.4・Dust collection port: 6˝

Dust collection port Diameter for OKB-20: 6˝ ・Mounted to the top of "left rear cover with top" ○ Minimum increment in 0.00001

32˝×79˝×4˝ ○ - -

Electro-magnetic chuck 32˝×98˝×4˝ Max. rapid feed in/min 78.7- ○ -

32˝×138˝×4˝ - - ○ Vertical feed Rough grinding

32˝×79˝×4˝ ○ - - Automatic feed in 0.000010.04

Electro Permanent Magnetic 32˝×98˝×4˝ - ○ - Fine grindingchuck

32˝×138˝×4˝ - - ○ Hand feed per resolution 0.001/0.01/0.1

Demagnetizing controller With automatic 20-A elec-tro-magnetic adjustment ・Chuck "rated current" applicable range Max: 16 A ○

Manual feed in

Graduation of hand wheel 0.00001/0.0001/0.001

Grinding wheel external

diameter 24˝ 4˝ ・Applicable grinding wheel: 24˝×4˝×8” (both recess)φ ○ φ20×4×φ5

Spare grinding wheel diame- Size (OD×W×ID) in

ter: 20˝ 4˝ ・20˝×4˝×8” (both recess)φ ○ (Option:24×4×5 )

Spare grinding wheel diame- Grinding wheel

ter: 24˝ 4˝ ・24˝×4˝×8˝ (both recess)φ ○ Spindle speed rpm 400~1600

Vertical grinding attachment ・5 hp ○ Motor hp/ph 30 / 4

BW-5 type (with standard arbor) ・Applicable grinding wheel diameter: 20˝ max. balance type ○

Dynamic balancing apparatus

BW-6 type (with standard arbor) ・Applicable grinding wheel diameter: 24˝ max. balance type ○ Oil pressure unit Capacity gal 80

Balance arbor (balance type) L = 11˝, For both BW-5 and 6 types ・Grinding wheel internal diameter: 8˝ ○

・Full-automatic measurement and automatic correction Machine space Length×Width×Height in 259×152×140 305×152×140 402×152×140

Automatic dynamic balancing Full-automatic balancer ・3 electrical balance weights shift ・Rotational speed: Max. 1200 min-1

apparatus non-contact electric type ・Measurement range unbalanced vibration displacement: 0.01 to 100 μm ○ Machine weight Standard lbs 34,200 37,500 44,100

・Controller, ACC sensor-equipped, integrated controller

For standard ・20˝×4˝×8˝ ○

Grinding wheel adaptor

For full automatic balancer ・20˝×4˝×8˝ ○ OKAMOTO MACHINE TOOL WORKS, LTD.

T slots on table surface Number of grooves: 3 ・Size of T groove and pitch: Okamoto's standard ○ 3-5-7 Nakamachidai, Tsuzuki-ku, Yokohama, Kanagawa, 224-0041 Japan

High column specifi cation 8˝ up ○ TEL: +81-45-949-3881 FAX: +81-45-949-3787

Hydraulic oil ・Required amount: 80 gal ○ http://www.okamoto.co.jp

Cycle end power shut off For 30 hp spindle motor ・Power shut-off at cycle end ○

Spindle motor activates ・The spindle does not rotate unless the electro-magnetic chuck is "ON." ○

Electro-magnetic chuck inter- ・The table does not rotate unless the electro-magnetic chuck is "ON."

lock Table activates ・Should it switch to "OFF" while the table is rolling over, ○ OKAMOTO CORPORATION

the table stops immediately. 370 Corporate Woods Parkway, Vernon Hills, IL 60061, U.S.A.

・The table does not activate unless the door is "ON." TEL: (847)235-3500 FAX: (847)235-3274

Door interlock Table activates ・Should it switch to "OFF" while the table is rolling over, ○

the table stops immediately. http://www.okamotocorp.com/

Grinding head meter relay ○

Calendar timer ・A weekly timer turns the hydraulics "ON" at a set time. ○ CAUTION

Three-stage signal tower Red, Yellow, Green Signal meaning ・Yellow: Lights at the end of a cycle. ・Green: Lights during a cycle. ○ *When and before using our products, you are requested to well go through the articles on danger, warning and attention for the sake

Working light (LED) ・Mounted on the underside of the cross rail ○ of safety described in operation manual attached to the machine and also in the warning plates mounted on the machine.

G code program ○ *Specifications subject to change without notice.

iQ Software

Automatic programming UP CAM ○ *When a product manufactured at our factory comes under the Foreign Exchange And Foreign Trade Control Law and is exported or

carried overseas, it is necessary to receive permission or approval of the Japanese Government.

Printed in Japan in May 2019