1/8ページ

Download(2.5Mb)

<JAPAN> High Precision Form Grinding Machine HPG500 Series Precision Form Grinding Machine PFG500 Series

Product Catalog

Document Information

| Document Title | <JAPAN> High Precision Form Grinding Machine HPG500 Series Precision Form Grinding Machine PFG500 Series |

|---|---|

| Document Type | Product Catalog |

| File size | 2.5Mb |

| Category | |

| Company | OKAMOTO MACHINE TOOL WORKS,LTD (Documents List) |

Documents related to this company

Document Contents

Page1

High Precision Form Grinding Machine

HPG500 Series

Precision Form Grinding Machine

PFG500 Series

OKAMOTO MACHINE TOOL WORKS, LTD.

2993 Gobara, Annaka, Gunma, Japan 379-0135

TEL : +81-27-388-9595 FAX : +81-27-385-1144

JQA-QMA10960

URL : www.okamoto.co.jp Annaka Factory

*Prior to and while using our products you are requested to thoroughly go through the articles on danger,

warning and attention for the sake of safety described in operation manual attached to the machine

and also in the warning plates mounted on the machine.

CAUTION *When the products fall under the eport controlled goods stipulated in “Foreign Exchange and Foreign

Trade Act” , it requires the license or approval of Goverment of Japan when exporting out of Japan.

*Specifications subject to change without notice.

This printed matter uses environmentally friendly paper and vegetable oil inks

Printed in Japan in September 2022 2022091000MTR-1

Page2

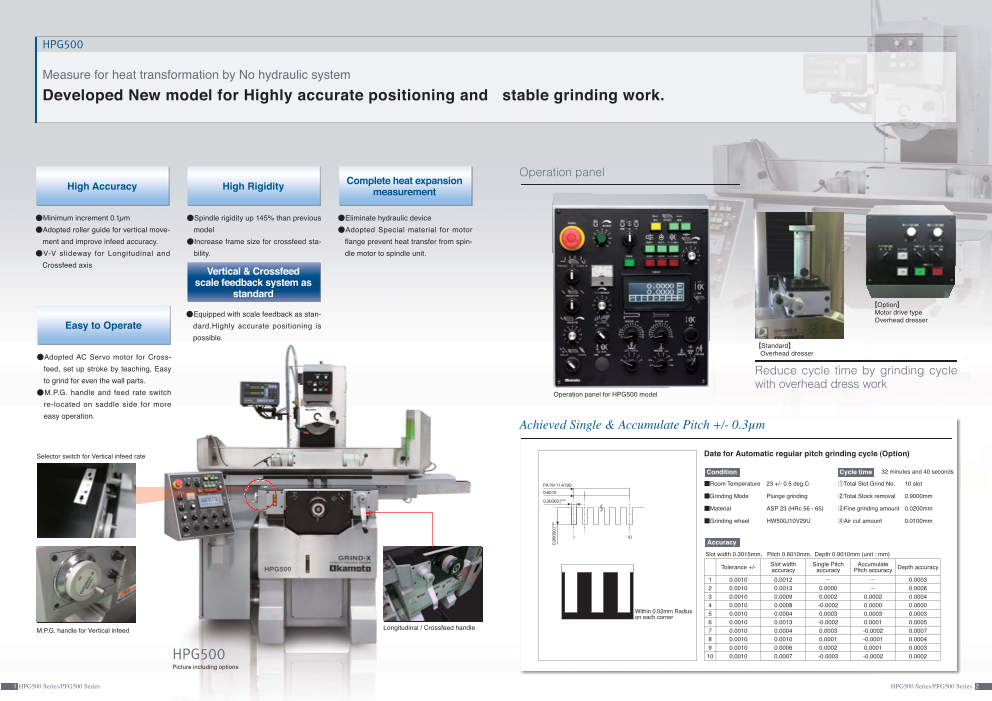

HPG500

Measure for heat transformation by No hydraulic system

Developed New model for Highly accurate positioning and stable grinding work.

Operation panel

High Accuracy High Rigidity Complete heat expansion

measurement

●Minimum increment 0.1μm ●Spindle rigidity up 145% than previous ●Eliminate hydraulic device

●Adopted roller guide for vertical move- model ●Adopted Special material for motor

ment and improve infeed accuracy. ●Increase frame size for crossfeed sta- fl ange prevent heat transfer from spin-

●V-V slideway for Longitudinal and bility. dle motor to spindle unit.

Crossfeed axis

Vertical & Crossfeed

scale feedback system as

standard

【Option】

●Equipped with scale feedback as stan- Motor drive type

Overhead dresser

Easy to Operate dard.Highly accurate positioning is

possible.

【Standard】

●Adopted AC Servo motor for Cross- Overhead dresser

feed, set up stroke by teaching, Easy Reduce cycle time by grinding cycle

to grind for even the wall parts. with overhead dress work

●M.P.G. handle and feed rate switch Operation panel for HPG500 model

re-located on saddle side for more

easy operation.

Achieved Single & Accumulate Pitch +/- 0.3μm

Selector switch for Vertical infeed rate Date for Automatic regular pitch grinding cycle (Option)

Condition Cycle time 32 minutes and 40 seconds

■Room Temperature 23 +/- 0.5 deg.C ①Total Slot Grind No. 10 slot

■Grinding Mode Plunge grinding ②Total Stock removal 0.9000mm

■Material ASP 23 (HRc 56 - 65) ③Fine grinding amount 0.0200mm

■Grinding wheel HW500J10V29U ④Air cut amount 0.0100mm

Accuracy

Slot width 0.3015mm, Pitch 0.6010mm, Depth 0.9010mm (unit : mm)

Tolerance +/- Slot width Single Pitch Accumulate

accuracy accuracy Pitch accuracy Depth accuracy

1 0.0010 0.0012 - - 0.0003

2 0.0010 0.0013 0.0000 - 0.0006

3 0.0010 0.0009 0.0002 0.0002 0.0004

4 0.0010 0.0008 -0.0002 0.0000 0.0000

Within 0.02mm Radius

on each corner 5 0.0010 0.0004 0.0003 0.0003 0.0003

6 0.0010 0.0013 -0.0002 0.0001 0.0005

M.P.G. handle for Vertical infeed Longitudinal / Crossfeed handle 7 0.0010 0.0004 0.0003 -0.0002 0.0007

8 0.0010 0.0010 0.0001 -0.0001 0.0004

9 0.0010 0.0006 0.0002 0.0001 0.0003

HPG500 10 0.0010 0.0007 -0.0003 -0.0002 0.0002

Picture including options

1 HPG500 Series/PFG500 Series HPG500 Series/PFG500 Series 2

Page3

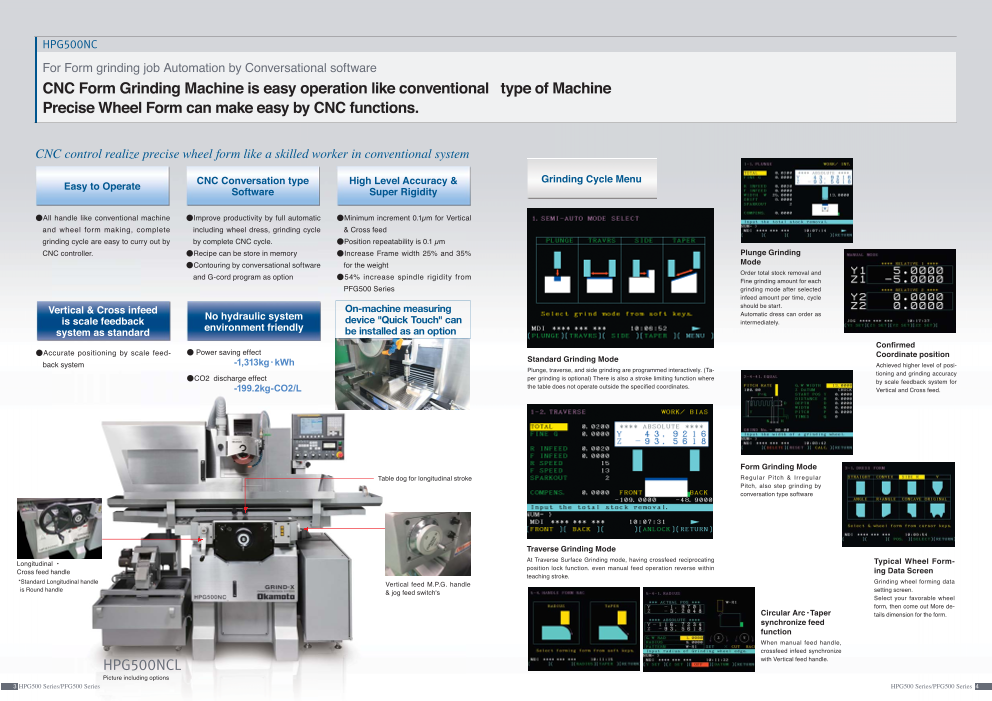

HPG500NC

For Form grinding job Automation by Conversational software

CNC Form Grinding Machine is easy operation like conventional type of Machine

Precise Wheel Form can make easy by CNC functions.

CNC control realize precise wheel form like a skilled worker in conventional system

CNC Conversation type High Level Accuracy & Grinding Cycle Menu

Easy to Operate Software Super Rigidity

●All handle like conventional machine ●Improve productivity by full automatic ●Minimum increment 0.1μm for Vertical

and wheel form making, complete including wheel dress, grinding cycle & Cross feed

grinding cycle are easy to curry out by by complete CNC cycle. ●Position repeatability is 0.1 μm

CNC controller. ●Recipe can be store in memory ●Increase Frame width 25% and 35% Plunge Grinding

●Contouring by conversational software for the weight Mode

Order total stock removal and

and G-cord program as option ●54% increase spindle rigidity from

Fine grinding amount for each

PFG500 Series grinding mode after selected

infeed amount per time, cycle

Vertical & Cross infeed On-machine measuring should be start.

Automatic dress can order as

is scale feedback No hydraulic system device "Quick Touch" can intermediately.

system as standard environment friendly be installed as an option

Confi rmed

●Accurate positioning by scale feed- ● Power saving effect Coordinate position

Standard Grinding Mode

back system -1,313kg・kWh Achieved higher level of posi-

Plunge, traverse, and side grinding are programmed interactively. (Ta-

tioning and grinding accuracy

●CO2 discharge effect per grinding is optional) There is also a stroke limiting function where

by scale feedback system for

-199.2kg-CO2/L the table does not operate outside the specifi ed coordinates.

Vertical and Cross feed.

Form Grinding Mode

Table dog for longitudinal stroke Regular Pi tch & I r regular

Pitch, also step grinding by

conversation type software

Traverse Grinding Mode

At Traverse Surface Grinding mode, having crossfeed reciprocating

Longitudinal ・ Typical Wheel Form-

position lock function. even manual feed operation reverse within

Cross feed handle ing Data Screen

teaching stroke.

*Standard Longitudinal handle Vertical feed M.P.G. handle Grinding wheel forming data

is Round handle & jog feed switch's setting screen.

Select your favorable wheel

form, then come out More de-

Circular Arc・Taper tails dimension for the form.

synchronize feed

function

When manual feed handle,

crossfeed infeed synchronize

with Vertical feed handle.

HPG500NCL

Picture including options

3 HPG500 Series/PFG500 Series HPG500 Series/PFG500 Series 4

Page4

HPG500NC High Speed Stroke

Performed for High Speed・High Precision・High Effi ciency Grinding

Best performance for Punch, small formed workpiece. Table high speed stroke model.

Table stopping accuracy and User friendly Operation system Mold punch grinding with High speed table reciprocation

High Speed Table Teaching screen for High-speed table reverse grinding is used to process die punches.

Easy to Operate Reciprocation table stroke Cycle time is greatly reduced by performing high-speed reverse grinding.

●Add high speed table reciprocate func- ●Achieved table stopping position error 2 ways for table stroke teaching

tion onto HPG500NC is less than 15μm. Easy make high ●Table position teaching button Grinding sample

●Grinding wheel minimum increment is level of shoulder grinding. ●By CNC screen set up

0.1μm, easy to fi ne infeed ●High-speed stroke specification HP-

G500NC has multi-position grinding

software as an option. 0

R9

50

Other Actuarial Software 6

Small Diameter Spindle

CCD camera

Wheel diameter detection

by air sensor

Typical Grinding Form Advantage Point for No-hydraulic force

Surface Contouring V-Slot HPG series adopt motor and belt drive system for table reciprocation improve heat expansion measure, maintenacebility as well

form

as environment measure than ordinary hydraulic drive system.

1 Cost Saving for Oil 2 Reduce for Carbon Emission CO2

Step Concave Convex form

form No need replace hydraulic oil for regular base as well Reduce for Carbon Emission 656 Kg/KWH for waste

as no cost for waste oil disposal oil disposal

Narrow Pitch Blind wall + Irregular No

Step form Pitch hydraulic oil

Hydraulic oil

Narrow Pitch Taper + Taper form

Multiple + Side Radius form 3 Saving electricity 60% annual base 4 Eliminate Heat Source

rench

t Compare with Hydraulic table movement machine, new HPG series saving Eliminate hydraulic source

60% electricity. which difficult to control tem-

perature.

Hydraulic type Table HPG Series

Formed Side Curve form Power consumption per hour 1.0 kWh 0.4 kWh

Parts (Concave)

Annual (8H/Day x 20 day/Month x 12 month) 1920 kWh 768 kWh Expansion

HPG500NC High Speed Stroke Charge by JPY20/KWH JPY38,400 JPY15,360

Picture including options Low Temperature

High Temperature

5 HPG500 Series/PFG500 Series HPG500 Series/PFG500 Series 6

4

0.5

Page5

PFG500DX Series PFG500 Series

Vertical feed by AC servo motor and M.P.G. handle Traditional type Conventional Machine

Set up automatic downfeed by 0.1 μm unit by own developed Up date machine from PFG500 Series

controller. Easy set up Automatic sizing cycle Increase Column rigidity and Dust protection

Vertical infeed by M.P.G. Automatic grinding Automatic Lubrication Increase Spindle Rigidity

Cycle System for Stable Grinding

Adopt AC servo motor for vertical feed, Coarse Grinding ➡ Fine Grinding ➡ ●Automatic Lubrication System for ●H i g h p o w e r c a r t r i d g e t y p e o f

select 0.1μm. 1μm or 10μm by gradua- Sparkout (0 - 5 times) ➡ Table stop Right Slideway, infeed screw after spindle cylindrical shape incorporating super

tion and have fi ne infeed easily. side Stroke end switch ON. precision angular contact bearing with

●Lubr icat ion system separate for thick spindle, and maintenance -free

Vertical slide and Crossfeed slide. thanks to permanent grease seal.

Operation Panel ●Consider for vibration too, top level

of accuracy if compare withsimpler

■ Vertical infeed ■ Vertical feed Select Switch machine in the market.

Infeed amount set up switch for Automat- Select Switch for Auto cycle/Stock re- Operation Panel PFG500PⅡ

ic downfeed amount, Inching amount. moval setup/Manual feed/Rapid feed no *Standard operation panel is Silver color

Both infeed amount is 0.001 - 0.03mm mix up each mode. ❶ Unit Name

by 15 steps

■ Total infeed amount ❼

❶ Vertical feed handle

Easy set up total infeed amount using

❸ ❷ Grinding wheel guard

digital display as minimum 0.1μm. Deep

❸ Overhead dresser unit

slot grinding also setup easily.

❹ Saddle unit

❺ Frame unit

■ Inching Button ❷

❻ Table unit

Even during automatic cycle, available

❼ Column unit

this inching button

❽ Operation panel

❻ 10 ❾ Table speed adjust lever

❾ 14

15 10 Table reciprocating dog

❹ 11

11 Microfeeder unit for crossfeed

16 17 12 Motor for Vertical rapid feed

13 Spindle motor

14 Crossfeed stop lever 12

❽ 15 Crossfeed handle

16 Table feed stop lever 13

17 Table feed handle

❺

Operation panel for PFG500DXALⅡ

*Standard operation panel is Silver color

PFG500DXAL PFG500P ❶Vertical feed handle

Picture including options Picture including options

7 HPG500 Series/PFG500 Series HPG500 Series/PFG500 Series 8

Page6

Standard Accessories

Items HPG500NC PFG500DXⅡ PFG500Ⅱ HPG500NC

High Speed Stroke HPG500 Series Series Items

High Speed Stroke HPG500 PFG500DXⅡ PFG500Ⅱ

Series Series

Grinding Wheel ○ ○ ○ ○ 6)Wheel Adaptor

Wheel adaptor (6 - 16mm width) ○ ○ ○ ○ 1. Spare wheel adaptor for 6 - 16mm wheel width ○ ○ ○ ○

Automatic demagnetizing controller (Chuck power adjustable type) ○ ○ ○ - 2. Spare wheel adaptor for 16 - 32mm wheel width ○ ○ ○ ○

Manual type demagnetizing controller (Knife switch) - - - ○ 3. Spare wheel adaptor for Micro Balancer ○ ○ ○ ○

Table mount type dresser block (with a Diamond tool) - ○ ○ ○ 4. Spare grinding wheel from GRIND-X item (refer GRIND-X catalogues) ○ ○ ○ ○

Table mount type 3-direction dresser unit ○ - - - 7)Work Light

Manual type overhead dresser - ○ ○ ○ 1. LED type light ○ ○ ○ ○

2. Halogen type light ○ ○ ○ ○

Rapid feeder for vertical axis ○ ○ ○ ○

8)Hydraulic Oil/Lubrication Oil/Cutting fl uid

Wheel guard - ○ ○ ○

1. GRIND-X Hydraulic oil 20 L x 2 can - - ○ ○

Wheel guard with Dust food ○ - - -

2. GRIND-X Hydraulic oil 20 L x 1 can ○ ○ - -

Microfeeder for Vertical axis ○ ○ ○Minimum input 0.1μm ○Only A & P- type

3. Cutting fl uid for tungsten carbide ○ ○ ○ ○

Microfeeder for Cross axis ○ ○ ○ ○

4. Circulate type Lubrication system Standard Standard ○ ○

Table right stroke end stop function ○ ○ ○Only A & P- type - 9)Specifi c painting color for the machine (Need color sample)

Spark-out device ○ ○ ○Only A & P- type - 10)Grinding Spindle Unit

Coarse & Fine feed switchover function ○ ○ ○Only A & P- type - 1. Spindle invertor for 1.5 kW or 2.2 kW Standard Standard ○ ○

Deep grinding function ○ ○ ○Only A & P- type - 2. Spindle motor power up to 2.2 kW Standard Standard ○ ○

Plunge cut function for both side infeed ○ ○ ○Only A & P- type - 3. Baby Spindle unit Max : 7,000rpm Wheel size φ80x8xφ25mm ○ ○ ○ ○

SUS Splash cover & Nozzle - ○ - - 4. Spidle taper nose modifi cation ○ ○ ○ ○

SUS Slide door (saddle fi xed) & Nozzle ○ - - - 11) Table Feed / Vertical Feed

Transformer (100/200V) ○ ○ ○ ○ 1. Microfeeder for Vertical 2μm/Graduation - - - ○

Necessary tool with Tool box ○ ○ ○ ○ 2. Vertical feed C.W. downfeed ○ ○ ○ -

Leveling bolt & Plate ○ ○ ○ ○ 3. Table longitudinal feed handle for Round type Standard ○ ○ ○

Scale feedback for Vertical & Crossfeed ○ ○ - - 12)Oil Temperature control

Spindle invertor ○ ○ - - 1. Hydraulic oil temperature regulator - - Except 500DXⅡ Except 500Ⅱ

Circulation type Publication ○ ○ - - 2. Oil cooling type spindle head ○ ○ ○ ○

Short circuit breaker ○ - - - 13)Dresser

1. Hydraulic type Overhead dresser - - Except 500DXⅡ Except 500Ⅱ

CNC controller ○ - - -

2. Motor drive type Overhead dresser with dress compensation function ○ ○ - -

Crank handle for table longitudinal - ○ ○ ○

3. Both side dresser, DRT-1 ○ ○ ○ ○

Round handle for table longitudinal ○ - - -

4. Side dresser SD 【GRIND-X Products】 ○ ○ ○ ○

5. Angle dresser sing-bar system, DRA-3 ○ ○ ○ ○

6. Angle dresser sing-bar system, DRA-5 ○ ○ ○ ○

Optional Accessories 7. 25 Radius dresser, DRR-25B ○ ○ ○ ○

8. 40 Radius dresser, DRR-40 ○ ○ ○ ○

Items HPG500NC

High Speed Stroke HPG500 PFG500DXⅡ PFG500Ⅱ

Series Series 9. Twin Rotary Dresser unit 【GRIND-X Products】 ○ ○ ○ ○

1)Coolant & Dust suction System 10. Vertical type Rotary Dresser unit OH-125P 【GRIND-X Products】 ○ ○ ○ ○

1. Dust suction unit ○ ○ ○ ○ 14)Precision vise

2. Coolant tank ○ ○ ○ ○ 1. Plane Vise ○ ○ ○ ○

2. Precision Right Angle Block UB-80/100 【GRIND-X Products】 ○ ○ ○ ○

3. Coolant tank with magnetic dust separator ○ ○ ○ ○

3. SUS type Sign Vise DV-100-1 【GRIND-X Products】 ○ ○ ○ ○

4. Coolant & Dust suction system with magnetic dust separator ○ ○ ○ ○

15)Tooling Items

5. Coolant & Dust suction system with manual or automatic Paper fi lter unit ○ ○ ○ ○

1. Precision Cylindrical Grinding Device 【GRIND-X Products】 ○ ○ ○ ○

6. Temperature control unit ○ ○ ○ ○

2. Index Device 【GRIND-X Products】 ○ - - -

2)Splash cover

3. Special Jigs for warpage remover, SG Master 【GRIND-X Products】 ○ ○ ○ ○

1. Table splash cover - Standard ○ ○

16)Measuring Device

2. Dust suction hood - ○ ○ ○ 1. CCD camera unit ○ - - -

3. Wheel guard with dust suction hood Standard ○ ○ ○ 2. Quick Touch (On-machine measuring device) ○ - - -

4. Splash cover table back side Standard ○ ○ ○ 3. Quick Touch (On-machine measuring device) In-cycle measurement mode ○ - - -

3)Magnetic Chuck 17)Others

1. Plane type electro-magnetic chuck ○ ○ ○ ○ 1. Demagnetizing device ○ ○ ○ ○

2. Inclining type electro-magnetic chuck - ○ ○ ○ 2. Precision square I-type : 500mm, Knife type : 100mm 2pcs/set ○ ○ ○ ○

3. Permanent magnetic chuck ○ ○ ○ ○ 3. Knife type straight edge 100mm & 200mm 1 pc each ○ ○ ○ ○

4. Electro-Permanente magnetic chuck ○ ○ ○ ○ 4. Centerless grinding attachment, GRIND-SMART ○ ○ ○ ○

5. Rotary table unit with permanent chuck ○ ○ ○ ○

6. Various type demagnetizing controller ○ ○ ○ ○

4)Digital scale HPG500NC SOFTWARE

1. Crossfeed digital scale system, display onto operation panel - - ○ - Standard

2. Vertical digital scale (independent display unit) - - ○ ○ Dress Software O.D./Both 凸 Radius/Single 凸 Radius/V/Angle/Radius + Taper/ Single 凹 Radius

3. Crossfeed digital scale (independent display unit) - - ○ ○ Grinding Software Plunge cut/ Traverse Cut/Regular Pitch/Irregular Pitch /凹/凸/Manual MPG Radius & Taper movement

4. Vertical & Crossfeed digital scale (independent display unit) - - ○ ○ Option

5)Grinding Wheel Balancer Dress Software Free form

1. Grinding Wheel Balancer unit Rolling type with an arbor BW-260R ○ ○ ○ ○ Conversation type Contouring software 1-kind of Program

2. Grinding Wheel Balancer unit Swing type with an arbor BW-260 ○ ○ ○ ○ G-Cord Program 1-kind of Program

3. Micro Balancer unit ○ ○ ○ ○ Specifi c workpiece grinding 1-kind of Workpiece

4. Balance arbor for Rolling type L=190mm ○ ○ ○ ○

Form Grinding automatic programing iCAM

5. Balance arbor for Swing type L=190mm ○ ○ ○ ○ software UPCAM

9 HPG500 Series/PFG500 Series HPG500 Series/PFG500 Series 10

Page7

Optional Accessories

1) 1. Dust suction system 2) 1. Table splash cover and coolant nozzle 3) 5. GRIND-X Rotary Chuck

Easy to use this Rotary Chuck

● Just mount onto table for Rotary grinding

● Compact size, powerful by DD motor.

● Co-use sing-bar chuck for grind Concave/Convex shape

● Output : 0.75 kW

● Coolant applicable (Waterproof : IP63)

● For Dry Grinding Only ● Coolant nozzle is fl exible type

● Dust shake off from Filter : ● Use coolant tank Rotary chuck body Attachment

Main body φ180×75H Attachment φ125×43H

Manual Shake Method Size

With Magnet φ180×118H magnet 4.0kg

Main body 10.0kg V-Shape Block φ10~φ35

Weight

With Magnet 14.6kg

Standard torque 0.6N・m(6・12kgf・cm)

Rotation speed 400min-1

Power supply 3-phase AC

Amp 0.6A

1) 2. Coolant tank CT-1 2) 2. 2 Dust suction hood 6) 1.2. Spare wheel adaptor 13) 3. Both side dresser DRT-1

● Max. Wheel Width : Max. 36mm

● Form Length : Max. 45mm from

●For wheel width 6 - 16mm

● Coolant pump motor : 0.1 kW O.D.

(Standard type)

● Tank capacity : 36 L ●Dust suction unit including such ● One revolution : 2mm

●For wheel width 16 - 32mm

● Splash cover and Coolant nozzle hood ● One graduation : 0.01mm

13) 5. GRIND-X Angle Dress Device DRA-3

19

●Sing-bar type Angle setting ●Height for Block gauge θ=0˚-45˚

1) 4. Coolant and Dust suction system with magnetic dust separator, CT4BM 3) 1. Plane type Electro-magnetic chuck ●Setting Angle : +/- 45 deg. H=50 x sin (45 deg - β) + 7mm

●Dress stroke : 30mm H :Height of Block gauge (mm)

●Dress Form Angle : 180 deg. (In β :Angle (deg)

θ

● Size Perpendicular 90 deg. Left & Right) 50 :Distance swivel center &

● Dust suction motor : 0.4 kW

350 X 150mm (P=4,8,14) ●Right angle datum face can make Sing bar center (mm)

● Coolant pump motor : 0.04 kW 14φ

450 X 150mm (P=8,2+12) form for 0 - 45 deg. 45 - 90 deg.

● Tank capacity : 40 L 50

HPG500NC impossible to equipped

● Independent ON/OFF switch

450 x 150mm chuck 110

● Splash cover and Coolant nozzle,

● Using automatic type chuck

Co-use Dust Suction hood

controller

14) 3. Sing-bar type Precision Vise, Stainless Steel type 16) 1. CCD Camera Measuring System

●Using Block gauge for Angle setting

【Accuracy】

Parallelism : ●On machine measuring system by

Within 0.002/100mm CCD Camera

3) 2. Inclining type electro-magnetic chuck HSG-315

Perpendicular :

Within 0.005/100mm

● 315 x 110 x 135 mm (P=11mm)

Angle error :

● Inclining angle: L 29∞35

- 15 deg. ~ + 90 deg. Within 15 sec.

● Chuck controller A

● Usage sample

* Sing-bar system integrated 25.882 25.882

* Specifi c angle refer the angle 17) 4. Centerless Grinding Attachment GRIND-SMART

table.

* Surface grinding no need fi ne

adjustment 1) In case 0 deg. 2) + 29 deg. 35 ' ● Improve many things, like a ●Mont this unit to Surface Grinder

Please use master block From Angle table A = 49.368mm

Rigidity, Sealing for Prevent dust or Form Grinder, easy to grind

gauge as standard

Precision Round Pin.

Workpiece

Roller CCW

11 HPG500 Series/PFG500 Series HPG500 Series/PFG500 Series 12

14

H 30

Page8

HPG500 Series / PFG500DXⅡ Series Machine External View

HPG500NC Full Automatic Vertical & Table Auto Table Auto only Full Manual feed

Items Unit HPG500NC HPG500

High Speed Stroke PFG500DXAⅡ PFG500DXPⅡ PFG500DXCⅡ PFG500DXⅡ

Table Working Space (Length x Width) mm 500×150 600×140 HPG500NC

Table Movement (Longitudinal x Cross) mm 540(In Auto. Feed 520)×180 520×180

Capacity Distance from Table top to Grinding Wheel Under mm 390 300 HPG500NC

Chuck size OP : For Surface Grinding High Speed Stroke

(Longitudinal x Crossfeed) mm 350×150 450×150

Load capacity (include Magnetic chuck) kg 80

T-Slot (Width x No.) mm×No. without T-Slot 12×1

Speed (Hydraulic) m/min 0.1~20 *1 0.1~18 -

Longitudinal

Feed Hand feed per revolution mm 0.01/0.1/1/20 Approx.115 Approx.100 Approx.115

Hand feed

per revolution Graduation for handwheel mm 0.0001/0.001/

0.01/0.2 -

Hand feed per revolution mm 0.01/0.1/1/5 5.0

Manual

feed Graduation for handwheel mm 0.0001/0.001/0.01/0.05 0.02 700 882.5

Cross Feed Graduation for Microfeeder mm - 0.005 1920 1109 Necessary Space for

Automatic intermittent feed mm 0.008~4 0.5~4 - Table reciprocate 2400mm

Automatic continuous feed mm/min 0.8~1000 0.8~800 -

Automatic Coarse downfeed mm - 0.001~0.03(12 Step) -

Downfeed Fine downfeed mm - 0.0001~0.01(11 Step) -

Hand feed per revolution mm 0.01/0.1/1/5 0.01×0.1×1

Vertical feed Manual

downfeed HPG500

Graduation for handwheel mm 0.0001/0.001/

0.01/0.05 0.0001×0.001×0.01

Spark-Out time 0~5 -

Vertical Rapid feedrate mm/min 1000 500 400

Grinding Diameter (50/60Hz) x Width x Bore mm φ180×6~32×φ31.75

wheel Speed (50/60Hz) min-1 1000~5000 1000~3600 3000/3600

Grinding Wheel Spindle kW/P 2.2/2 1.5/2

Hydraulic Oil Pump kW/P - 0.75/4 -

Vertical Rapid & Downfeed (AC Servo) kW 0.5 0.4

Motor

Crossfeed (AC Servo) kW 0.5 0.4 -

Crossfeed (Torque Motor) kg・cm/P - 0.8/4 -

Longitudinal feed(AC Speed Control Motor) kW 0.5 0.4 -

Power supply Required power Consumption (including 700 882.5

Coolant tank with Mag.-separator) kVA 5.8 5.5 4.0 3.5 2.5 1843 1109 Necessary Space for

Air source 0.25~0.4MPa 60L/min - Table reciprocate 2400mm

Machine Space Width x Depth x Height mm 2460×1446.7×1717 2260×1470×1850 2200×1375×1727

Weight Net Weight kg 1600 1200 1150 1100 1050

*1 Teble speed is the NC input value. 2200

Reference value: 15 mm stroke = 324 fl ip

PFG500Ⅱ Series PFG500DX Series 1680

Full Automatic Vertical & Table Auto Table Auto only Full Manual feed

Items Unit

PFG500AⅡ PFG500PⅡ PFG500CⅡ PFG500Ⅱ

Table Working Space (Length x Width) mm 600×140

Table Movement (Longitudinal x Cross) mm 520×180 540×180

Capacity Distance from Table top to Grinding Wheel Under mm 310

Chuck size OP : For Surface Grinding

(Longitudinal x Crossfeed) mm 450×150

Load capacity kg 80

PFG500DXAL

T-Slot (Width x No.) mm×No. 12×1

Longitudinal

Feed Speed (Hydraulic) m/min 0.1~18 -

Hand feed per revolution mm 100 Approx.115

Hand feed per revolution mm 5 745

Necessary Space for

1372 700

Manual feed Graduation for handwheel mm 0.02 Table reciprocate 2400mm

Cross Feed

Graduation for Microfeeder mm 0.005

Automatic intermittent feed mm 0.5~4 -

Automatic Downfeed mm 0.002~0.02 -

Hand feed per revolution mm 1 PFG500 Series

Vertical feed Manual 2200

downfeed Graduation for handwheel mm 0.002

1680

Vertical Rapid feedrate (50/60Hz) mm/min 300/360

Grinding Diameter (50/60Hz) x Width x Bore mm φ180×6~32×φ31.75(Possible to fi t upto Φ205mm)

wheel Speed (50/60Hz) min-1 3000/3600

Grinding Wheel Spindle kW/P 1.5/2

Hydraulic Oil Pump kW/P 0.75/4 -

Motor Vertical Rapid & Downfeed kW/P 0.1/4

Crossfeed (Torque Motor) N/cm 78(8)/4 -

(kg cm)/P

Power Required power Consumption (including PFG500A

supply Coolant tank with Mag.-separator) kVA 3.0 2.5 1.5

Machine Space Width x Depth x Height mm 2200×1351×1720

Weight Net Weight kg 1200 1150 1100 1050 Necessary Space for

700 745 Table reciprocate 2400mm

13 HPG500 Series/PFG500 Series HPG500 Series/PFG500 Series 14

1727

1720

1717 1717