1/4ページ

Download(1.8Mb)

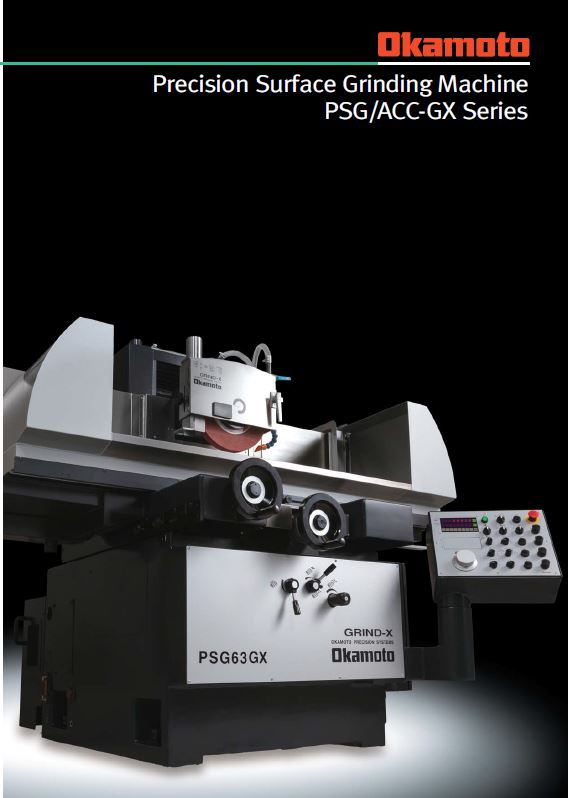

<JAPAN> Precision Surface Grinding Machine PSG/ACC-GX Series

Product Catalog

Document Information

| Document Title | <JAPAN> Precision Surface Grinding Machine PSG/ACC-GX Series |

|---|---|

| Document Type | Product Catalog |

| File size | 1.8Mb |

| Category | |

| Company | OKAMOTO MACHINE TOOL WORKS,LTD (Documents List) |

Documents related to this company

Document Contents

Page1

Precision Surface Grinding Machine

PSG/ACC-GX Series

�

OKAMOTO MACHINE TOOL WORKS, LTD.

2993 Gobara, Annaka, Gunma, Japan 379-0135

TEL : +81-27-388-9595 FAX : +81-27-385-1144 This printed matter uses environmentally friendly paper

URL : www.okamoto.co.jp and vegetable oil inks

When and before using our products, you are requested to well go through the articles on danger, warning and attention for the sake of safety described in operation

manual attached to the machine and also in the warning plates mounted on the machine.

*Specifications subject to change without notice.

CAUTION *When a product manufactured at our factory comes under the Foreign Exchange And Foreign Trade Control Law and is exported or carried overseas, it is necessary to

receive permission or approval of the Japanese Government.

Printed in Japan in June 2022 2022061000MTR-2

Page2

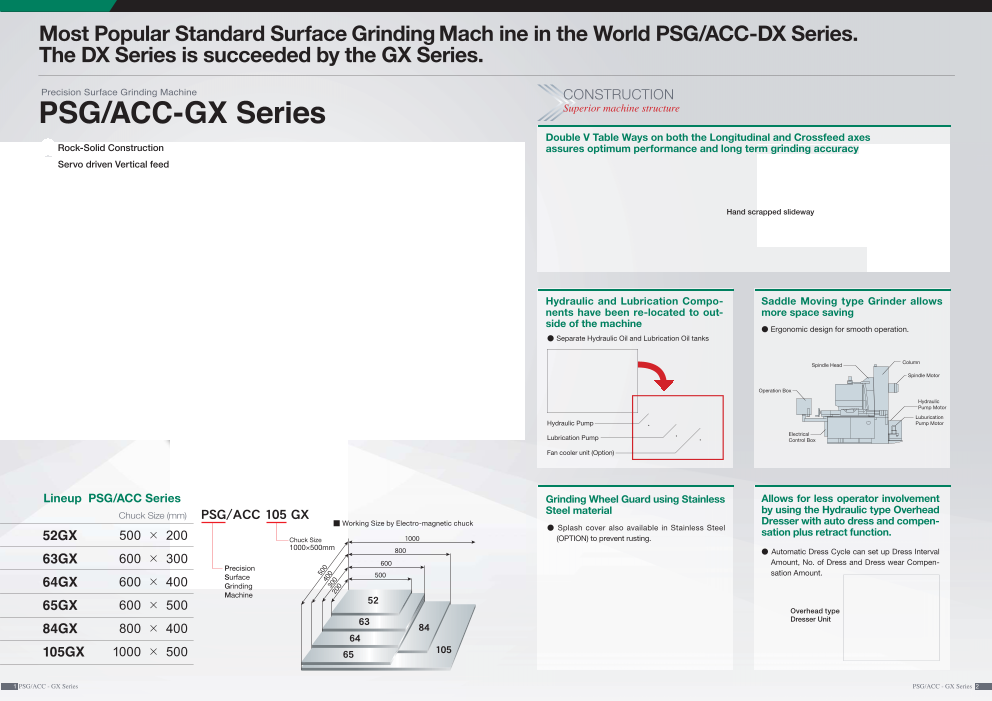

Most Popular Standard Surface Grinding Mach ine in the World PSG/ACC-DX Series.

The DX Series is succeeded by the GX Series.

Precision Surface Grinding Machine CONSTRUCTION

PSG/ACC-GX Series Superior machine structure

Double V Table Ways on both the Longitudinal and Crossfeed axes

Rock-Solid Construction assures optimum performance and long term grinding accuracy

Servo driven Vertical feed

Hand scrapped slideway

Hydraulic and Lubrication Compo- Saddle Moving type Grinder allows

nents have been re-located to out- more space saving

side of the machine

● Ergonomic design for smooth operation.

● Separate Hydraulic Oil and Lubrication Oil tanks

Spindle Head Column

Spindle Motor

Operation Box

Hydraulic

Pump Motor

Luburication

Hydraulic Pump Pump Motor

Lubrication Pump Electrical

Control Box

Fan cooler unit (Option)

Lineup PSG/ACC Series Grinding Wheel Guard using Stainless Allows for less operator involvement

Steel material by using the Hydraulic type Overhead

Chuck Size (mm)

■ Working Size by Electro-magnetic chuck Dresser with auto dress and compen-

● Splash cover also available in Stainless Steel

52GX 500 × 200 Chuck Size (OPTION) to prevent rusting. sation plus retract function.

1000×500mm ● Automatic Dress Cycle can set up Dress Interval

63GX 600 × 300 Amount, No. of Dress and Dress wear Compen-

Precision

Surface sation Amount.

64GX 600 × 400 Grinding

Machine

65GX 600 × 500 Overhead type

Dresser Unit

84GX 800 × 400

105GX 1000 × 500

1 PSG/ACC - GX Series PSG/ACC - GX Series 2

Page3

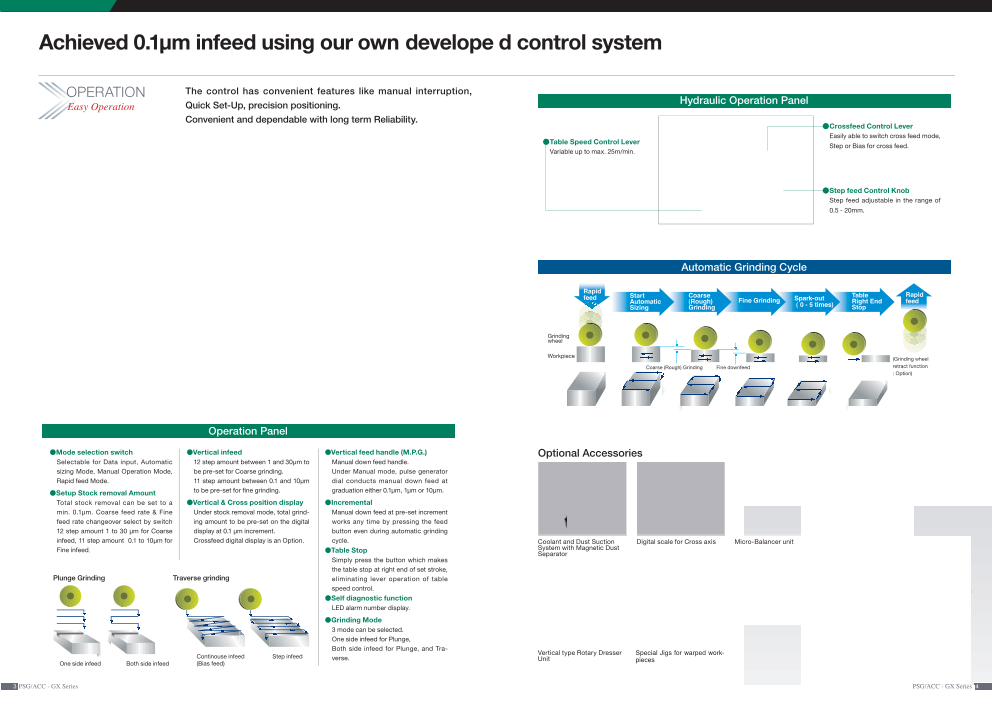

Achieved 0.1μm infeed using our own develope d control system

OPERATION The control has convenient features like manual interruption,

Easy Operation Quick Set-Up, precision positioning. Hydraulic Operation Panel

Convenient and dependable with long term Reliability.

●Crossfeed Control Lever

Easily able to switch cross feed mode,

●Table Speed Control Lever Step or Bias for cross feed.

Variable up to max. 25m/min.

●Step feed Control Knob

Step feed adjustable in the range of

0.5 - 20mm.

Automatic Grinding Cycle

Rapid

feed Start Coarse Spark-out Table Rapid

Automatic (Rough) Fine Grinding

Sizing Grinding ( 0 - 5 times) Right End feed

Stop

Grinding

wheel

Workpiece (Grinding wheel

Coarse (Rough) Grinding Fine downfeed retract function

: Option)

Operation Panel

●Mode selection switch ●Vertical infeed ●Vertical feed handle (M.P.G.) Optional Accessories

Selectable for Data input, Automatic 12 step amount between 1 and 30μm to Manual down feed handle.

sizing Mode, Manual Operation Mode, be pre-set for Coarse grinding. Under Manual mode, pulse generator

Rapid feed Mode. 11 step amount between 0.1 and 10μm dial conducts manual down feed at

●Setup Stock removal Amount to be pre-set for fi ne grinding. graduation either 0.1μm, 1μm or 10μm.

Total stock removal can be set to a ●Vertical & Cross position display ●Incremental

min. 0.1μm. Coarse feed rate & Fine Under stock removal mode, total grind- Manual down feed at pre-set increment

feed rate changeover select by switch ing amount to be pre-set on the digital works any time by pressing the feed

12 step amount 1 to 30 μm for Coarse display at 0.1 μm increment. button even during automatic grinding

infeed, 11 step amount 0.1 to 10μm for Crossfeed digital display is an Option. cycle. Coolant and Dust Suction Digital scale for Cross axis Micro-Balancer unit

Fine infeed. ●Table Stop System with Magnetic Dust

Separator

Simply press the button which makes

the table stop at right end of set stroke,

Plunge Grinding Traverse grinding eliminating lever operation of table

speed control.

●Self diagnostic function

LED alarm number display.

●Grinding Mode

3 mode can be selected.

One side infeed for Plunge,

Both side infeed for Plunge, and Tra-

Continouse infeed Step infeed Vertical type Rotary Dresser Special Jigs for warped work-

verse. Unit

One side infeed Both side infeed (Bias feed) pieces

3 PSG/ACC - GX Series PSG/ACC - GX Series 4

Page4

Specifi cations Optional Accessories

Item Unit 52GX 63GX 64GX 65GX 84GX 105GX Item Specifi cation 52GX 63GX 64GX 65GX 84GX 105GX

Table working capacity (Length×Width) 505×200 605×300 605×400 610×500 805×400 1016×500 1) Coolant and Dust Suction System

with Magnetic Dust Separator Tank Capacity 40 ◯ -

Max. Table Travel (Manual : Longitudinal×Cross) 650×230 750×340 750×440 750×540 950×440 1150×540

Coolant and Dust Suction System

Distance from 50/60Hz 205mm 47.5~397.5 − 2) with Magnetic Dust Separator Tank Capacity 120 - ◯

Top of the Ta- 355mm wheel (50Hz) mm

Capacity ble to Bottom − 22.5~322.5 22.5~522.5 Coolant system with Magnetic Dust

of the Wheel 305mm wheel (60Hz) − 47.5~347.5 47.5~547.5 3) Separator with Automatic type Tank Capacity 120 - ◯

Standard chuck size (L×W×H) 500×200 600×300 600×400 600×500 800×400 1000×500 Paperfi lter

×75 ×75 ×85 ×100 ×85 ×100

Max. stroke 35mm

Table Load Capacity including Chuck kg 200 420 700 4) Manual type Overhead Dresser ◯ -

Max. Wheel Width 25mm

Longitudinal Feed Rate (Average) m/min 0.3~25 3~25

Hand feed per Revolution 47 Max. stroke 35mm

5) Hydraulic type Overhead Dresser ◯ -

Hand feed per Revolution 5.0 Max. Wheel Width 25mm

Table Manual Feed mm

Graduation of Handwheel 0.02 Max. stroke 60mm

6) Manual type Overhead Dresser - ◯ -

Automatic Intermittent Feed 0.5~12 0.5~20 Max. Wheel Width 50mm

Feed Continuous Feed Rate m/min 0.1~1.0 0.2~1.0 Max. stroke 70mm

7) Hydraulic type Overhead Dresser - ◯

Auto. Downfeed (Traverse & Plunge Cycle) 0.0001~0.03 (15 Positions) Max. Wheel Width 50mm

Hand Feed per Revolution 0.01/0.1/1.0 No. of Dress 0~9 times

Manual Down (×0.1/×1/×10) mm

Vertical Feed 8) Hydraulic type Overhea Dresser

Feed Hand Feed per Graduation d Wheel wear compensation

0.0001/0.001/0.01 (with dress compensation function) amount 0~50μm ◯

(×0.1/×1/×10)

No. of Spark-Out Times 0~5 Dress Interval amount 0~990μm

Feed Rate mm/min 600 9) Hydraulic type Overhead Dresser

(with Retract Function) Retract amount 0~9.999mm ◯

Grinding Diameter (50/60 Hz)×Width×Bore mm 205×19

× 50.8 355/ 305×38× 127 10) Oil Mist collector With Mounting Base ◯

Wheel

Speed (50/60 Hz) min−1 3000/3600 1500/1800 11) Digital scale for Cross axis Display unit 0.001mm ◯

Grinding Wheel Spindle 1.5 3.7 12) Digital scale for Cross axis display

kW unit built into operation panel Display unit 0.001mm ◯

Motors Hydraulic Oil Pump 0.75 1.5 2.2 Worm Wheel type

Vertical Rapid Feed & Downfeed kW 0.4 (AC Servo Motor) 0.75 (AC Servo Motor) 13) Microfeeder for Cross axis (Graduation) 0.001mm ◯

Power supply 200V, 3-phase (50/60Hz), 220V, 3-phase (60Hz) 14) Hydraulic cooling type

Power Electro-Magnetic Chuck ◯

supply Required Power Consumption including Cool-

ant and Magnetic chuck kVA 5 10 11 15) Electro-Permanent Chuck

with Chuck controller ◯

Floor Width×Depth×Height mm 2420×1650 2740×1950 2740×2250 2740×2500 3330×2260 4330×2500

Space ×1850 ×1850 ×1850 ×2160 ×2160 ×2160 16) Hydraulic Oil Temperature control

unit ◯

Weight Net Weight kg 2100 2800 3000 3500 3900 4600

17) Oil Cooling type Spindle Head Necessary for 「Cooling Pump」「Oil Temperature

Control unit」 ◯

* Floor Space does not include Coolant tank 18) Spindle Inverter unit ◯

External View 19) Spindle Motor Power Up Please contact Sales ◯

20) Higher Column Specifi cation Extend Vertical Stroke 200mm - ◯ -

Max. wheel width 25mm

21) Spare Wheel adapter ◯ -

Wheel adapter Diameter 111

A B C

Max. wheel width 38mm

52GX 2420 1650 22) Spare Wheel adapter - ◯

Wheel adapter Diameter 175

63GX 1950 1850

C 23) Micro-Balancer unit Auto measure and Conversation type manual cor-

64GX 2740 2250 rection ◯

65GX 2500 24) Spare wheel adapter

for Micro-Balancer unit Exclusive Balance Piece for Micro-Balancer ◯

PSG63GX 84GX 3330 2260 2160

25) Static type Wheel balancer unit Max. Wheel Diameter

105GX 4330 2500 BW-260 with an Arbor ×Width 260×75mm ◯ -

Length 178mm

26) Balance Arbor for BW-260 unit Diameter for ◯ -

A Both End x Length 15×15mm

B

27) Static type Wheel balancer unit Max. Wheel Diameter

BW-360 with an Arbor ×Width 360×75mm - ◯

Standard Accessories Length 178mm

28) Balance Arbor for BW-360 unit Diameter for - ◯

Both End×Length 15×15mm

Sample Grinding Wheel (WA46H8V8J) Splash Cover Automatic sizing Device 29) Work light LED ◯

Wheel adapter Automatic Demagnetizing Controller, Plunge cut Device 30) Hydraulic & Lubrication Oil Please use only Recommend Oil 4 6 8 9

Table Dresser with a Diamond tool Chuck Power adjustable type (Single Side or Both side downfeed) 31) Special Color Painting Color sample required ◯

Necessary Tools with Tool Box Electro-Magnetic Chuck Automatic Rough & Fine Feed Change over 32) Vertical type Rotary Dresser Unit Spindle inverter unit is required ◯

Leveling Bolts and Plates Spark-Out Counter (0 - 5 times) Device 33) Special Jigs for warped workpieces ◯

5 PSG/ACC - GX Series PSG/ACC - GX Series 6