1/6ページ

Download(1.7Mb)

<JAPAN> Precision Rotary Surface Grinding Machine PRG Series

Product Catalog

Document Information

| Document Title | <JAPAN> Precision Rotary Surface Grinding Machine PRG Series |

|---|---|

| Document Type | Product Catalog |

| File size | 1.7Mb |

| Company | OKAMOTO MACHINE TOOL WORKS,LTD (Documents List) |

Documents related to this company

Document Contents

Page1

PRG_english1030_1

Precision Rotary Surface Grinding Machine

PRG Series

OKAMOTO MACHINE TOOL WORKS, LTD.

2993 Gobara, Annaka, Gunma, Japan 379-0135

TEL : +81-27-388-9595 FAX : +81-27-385-1144

URL : www.okamoto.co.jp

*Prior to and while using our products you are requested to thoroughly go through the articles on danger, warning and attention for the sake of safety described in oper-

ation manual attached to the machine and also in the warning plates mounted on the machine.

*When the products fall under the export controlled goods stipulated in “Foreign Exchange and Foreign Trade Act”, it requires the license or approval of Government of

CAUTION Japan when exporting out of Japan. *Specifications subject to change without notice.

Printed in Japan in November 2019 2019111000MTR-0

Page2

PRG_english1030_2

Ultra Precision High Productivity High Effi ciency

Precision Rotary Surface Grinding Machine PRG Series CONTENTS

Rotary surface grinding machines have more than twice the productivity Contents ……………………………………………… 1~2

Product Line-up ……………………………………… 3~4

compared to reciprocating surface grinding machines. Construction and Features ……………………… 5~6

Examples of Test Grinding ………………………… 6

Achieving better stability & higher accuracy due to the highly rigid Specifi cations ………………………………………… 7

Standard Accessories & External Views ………… 8

construction, we can control infeeds as low as 0.1um. Optional Accessories ……………………………… 9

Examples of Workpieces …………………………… 10

Universal & Multi-Step Exotic & Diffi cult To Cut Materials Mass Production & Automation Capabilities

1 PRG Series PRG Series 2

Page3

PRG_english1030_3

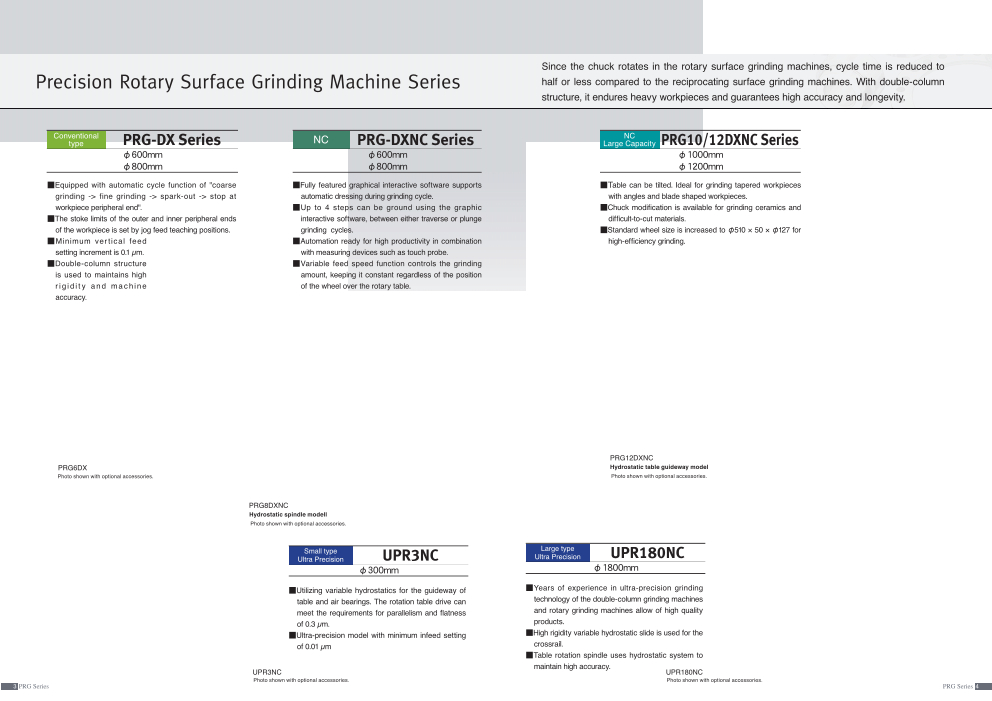

Since the chuck rotates in the rotary surface grinding machines, cycle time is reduced to

Precision Rotary Surface Grinding Machine Series half or less compared to the reciprocating surface grinding machines. With double-column

structure, it endures heavy workpieces and guarantees high accuracy and longevity.

Conventional

type PRG-DX Series NC PRG-DXNC Series NC Large Capacity PRG10/12DXNC Series

■Equipped with automatic cycle function of "coarse ■Fully featured graphical interactive software supports ■Table can be tilted. Ideal for grinding tapered workpieces

grinding -> fine grinding -> spark-out -> stop at automatic dressing during grinding cycle. with angles and blade shaped workpieces.

workpiece peripheral end". ■Up to 4 steps can be ground using the graphic ■Chuck modifi cation is available for grinding ceramics and

■The stoke limits of the outer and inner peripheral ends interactive software, between either traverse or plunge diffi cult-to-cut materials.

of the workpiece is set by jog feed teaching positions. grinding cycles. ■Standard wheel size is increased to φ510 × 50 × φ127 for

■Minimum ver t ical feed ■Automation ready for high productivity in combination high-effi ciency grinding.

setting increment is 0.1 μm. with measuring devices such as touch probe.

■Double-column structure ■Variable feed speed function controls the grinding

is used to maintains high amount, keeping it constant regardless of the position

r i g i d i t y a n d ma c h in e of the wheel over the rotary table.

accuracy.

PRG12DXNC

PRG6DX Hydrostatic table guideway model

Photo shown with optional accessories. Photo shown with optional accessories.

PRG8DXNC

Hydrostatic spindle modell

Photo shown with optional accessories.

Small type Large type

Ultra Precision UPR3NC Ultra Precision UPR180NC

■Utilizing variable hydrostatics for the guideway of ■Years of experience in ultra-precision grinding

table and air bearings. The rotation table drive can technology of the double-column grinding machines

meet the requirements for parallelism and fl atness and rotary grinding machines allow of high quality

of 0.3 μm. products.

■Ultra-precision model with minimum infeed setting ■High rigidity variable hydrostatic slide is used for the

of 0.01 μm crossrail.

■Table rotation spindle uses hydrostatic system to

maintain high accuracy.

UPR3NC UPR180NC

Photo shown with optional accessories. Photo shown with optional accessories.

3 PRG Series PRG Series 4

Page4

PRG_english1030_4

Precision Rotary Surface Grinding Machine PRG Series Fully featured graphic

DXNC

interactive software

Construction and Features Graphical display thorough-

ly supports your data input.

1. Initial Setting

Input wheel dimensions.

Original double-column structure that supports Multi-step grind- Rotary grinding is ideal for mass production of

Standard DXNC Feature

stable feed and high-precision grinding ing up to 4 steps fl at surface grinding of round workpieces

Comparison between rotary

Double-column structure is utilized for high Since the table does not shift, the operator 4 steps maximum can be ground using grinding and surface grinding

rigidity during the wheel movement. can work without changing their position. the graphic interactive software, interac- 2. Selection of Workpiece Shape

Unlike other rotary grinding machines, the In addition, the height to the top of the tive software, between either traverse or Select the number of steps (4 steps max).

table does not move up and down or back chuck is low due to the structure, and the plunge grinding cycles.

wheel

and forth, resulting in better operability workpiece can easily be positioned or re-

and improved accuracy. moved.

wheel

1 step

2 steps on Rotary Grinding Machine on Reciprocating Grinding Machine

φ400mm(Bore 300 mm) φ400mm(Bore 300 mm) 3. Selection of Grinding Standard

grinding allowance: 0.5 mm grinding allowance: 0.5 mm Select the workpiece datum or chuck da-

Coarse 0.45mm 5 min Coarse 0.45mm 30 min tum as “0” point of dimension input.

Fine & Spark Out Grinding 0.05mm 8 min Fine & Spark Out Grinding 0.05mm 33 min

3 steps Total 13 min Total 63 min

Increased productivity with automatic cycle

4 steps DX

Wheel spindle for vertical and cross feed

High rigidity double-column Height to top of the chuck Blue color shows areas ground

structure built for longevity PRG-DXN……………800mm Equipped with automatic cycle function of “coarse grinding ->fi nd grinding -> spark-out -> stop 4. Selection of Grinding MethodSelect traverse or plunge cycle.

at workpiece peripheral end”

Possible to change the settings of downfeed by step infeed amount, table rotation speed, total

remaining grinding allowance and variable speed even during automatic cycle.

Fixed Variable feed speed Grinding with tilted ta- Automatic Grinding Cycle

Standard Standard stabilizes the grind- Standard ble allows for a wide

dressing point ing conditions range of applications Stop at Start of Coarse Fine Spark-out Workpiece

automatic (Rough) Grinding (0 - 5 times) Peripheral

infeed Grinding End

By fi xing the dressing point, we can elim- As the wheel strokes from the outer diam- With a simple operation, the table can be Rapid Feed Rapid Feed

inate inconsistencies and misalignments eter to the center of the table, the table tilted ± 5˚ maximum, making it ideal for Both Ends Infeed

caused by regular environmental chang- rotation speed increases, while the wheel grinding cylindrical taper shaped parts. Outside Peripheral End Infeed

5. Input of Grinding Conditions

Interruptions from M.P.G. and dress inter-

es, allowing us to achieve high-precision feed speed also increases, and the grind- rupt during cycling is also available.

grinding. ing amount remains constant regardless

of the position of the wheel over the rotary

table. Chuck Coarse FineInfeed Infeed

Operation which

DX

uses manual input 6. Setting Confi rmation

Confi rmation of input data

±5°

■Effi ciency is established by the manual

interruption function during the automat-

“PRG-6” next to 5 degree ic cycle.

"PRG-8” next to 3 degree ■Wheel spindle vertical and cross feed

is controlled by our original LSI control

Table-mounted dresser Processing mass-volume work- system and AC servo motor. Minimum

pieces with constant accuracy setting unit is 0.1 μm

DX series operation panel

5 PRG Series PRG Series 6

Page5

Specifi cations Standard Accessories

CNC Rotary Surface Grinding Machine Rotary Surface Grinding Machine CNC Rotary Surface Grinding Machine Rotary Surface Grinding Machine

Item Unit

PRG6DXNC PRG8DXNC PRG10DXNC PRG12DXNC PRG6DX PRG8DX Item PRG6DXNC PRG8DXNC PRG10DXNCPRG12DXNC PRG6DX PRG8DX

O.D. of Electromagnetic Chuck mm 600 800 1000 1200 600 800

GRIND-X Wheel

Working Diameter of Electromagnetic Chuck mm 552 752 930 1130 552 752

Grinding Wheel Adaptor

Maximum Travel of Wheel mm 750 950 1600 750 950

Distance from Electromagnetic ChuckCapacity Using 355 mm Wheel (50Hz) mm −60 250 − −60 250

Top of the Table Chuck Interlock

Using 305 mm Wheel (60Hz) mm −35 275 − −35 275

to Bottom of the Automatic Demagnetizing Controller, Adjustable Chuck Power

Wheel Using 510 mm Wheel mm − 500 −

Short Circuit Breaker

Table Load Capacity (not including chuck) kg 150 250 1200 1300 150 250

Color LED 8.4"

Rotation Speed (constant speed control, CVT) min−1 20 150 15 130 8 65 20 150 20 130

Table Splash Cover, Semi-Closed Style

Tilting Angle deg ±5 ±3 ±0.4 ±5 ±3

Table Mounted Dresser, Fixed Type

Driven By AC Servo Motor

Necessary Tools

Cross Travel Distance mm 450 550 860 450 550

Feed Speed Anchor BoltSetting Range 0 2000 (Volume) 200 - 2400

during Auto- mm/ Leveling Bolts and Plates

Override Max 2000 (0 - 150%) −

matic Opera- min

Wheel Head Program Memory Capacity 512KB

tion Rapid Feed 4000 5000 −

Cross Feed Display of Operation Time and Workpiece Qty (to be input in present location of LCD display)

(X axis) Feed per Handwheel Revolu-

tion ×1/×10/×100 mm 0.01/0.1/1.0 ×1/×10/×100 0.1/1.0 ×1/×10 Spindle invertor

Manual Pulse Feed per Handwheel Gradua- 0.0001/0.001/0.01 ×1/×10/×100 Fanuc Color LED Display - 8.4

tion ×1/×10/×100 mm 0.001/0.01 ×1/×10

Feed

Jog Feed (16 steps) mm/ 0 2000 200 2400

Rapid Feed min 4000 5000 − External View

Driven By AC Servo Motor

Cross Travel Distance mm 310 620 310 PRG6DXNC/8DXNC

Feed Speed Setting Range 0 2000 −

Dimensions in parentheses

during Auto- mm/

Override Max 2000 (0 - 150%) − are of PRG8DXNC. Coolant System (with Separator)

matic Opera- min

Wheel Head

tion Rapid Feed 4000 2000 −

Vertical Feed

(Z axis) Feed per Handwheel Revolu-

tion ×1/×10/×100 mm 0.01/0.1/1.0

Manual Pulse Feed per Handwheel Gradua-

tion ×1/×10/×100 mm 0.0001/0.001/0.01

Feed

Jog Feed (16 steps) mm/ 0 2000 −

Rapid Feed min 4000 2000 400/800

1665(1810) 925(1060) 1820(2120)

Grinding O.D. x W x B (50Hz/60Hz) mm 355/ 305×38 max50 × 127 510×50 OP: max75)× 127 355/ 305×38 max50 × 127 2218(2363)

Wheel Rotation Speed (50Hz/60Hz) min−1 1500/1800 1000/1200 1500/1800

PRG10DXNC/12DXNC

For Wheel Spindle 11 7.5 7.5

For Rotary Table Drive 2.2 3.7 7.5 2.2 3.7

For Vertical Feed (AC Servo Motor) 3.0 1.8 0.75

Motor kW

For Cross Feed (AC Servo Motor) 1.6 1.8 0.75

For Slideway 0.1 2.2 0.1 Coolant

Lubricant System

For Collecting Table Lubricant 0.04 − 0.04 CT-30M

Power Supply Power Consumption kVA 31 34 35 20 23

Distance from Floor to Top of the Chuck mm 800 1260 800

Width x Depth x Height (including coolant 1665×3250 1810×3450 1665×3025 1810×3450

Floor Space mm 5135×4300×3581

system) ×2576 ×2616 ×2576 ×2616

Weight Net Weight kg 4000 5000 12800 13000 4000 5000

*Power consumption and fl oor space etc. may vary depending on the specifi cations & options. 1710.4

1290 3915.73180

CNC Ultra Precision Rotary Surface Grinding Machine

Item Unit PRG6DX/8DX

UPR3NC UPR180NC Coolant System (with Separator)

Dimensions in parentheses

Chuck O.D. mm 300 1800 are of PRG8DX.

Maximum Travel of Wheel mm 400 2000

Distance from Floor to Top of the Chuck mm 205 600

Table Load Capacity kg 180 1000

Table Rotation Speed min−1 10~300 5~50

Tilting Angle deg ±0.3 ±0.15

1665(1810) 925(1060) 1820(2120)

Net Weight kg 2500 45000 2218(2363)

7 PRG Series PRG Series 8

4300

3915.7

1785.4

2443(2931) 2560(2931)

3025(3450)

3250(3450)

1700 1700

30 2546 30 2546

2576 2576

1700

45 2000

2045

800 118~428 1260 75~775 800 118~428

2486(min2176) 2533(min2223)

3581

45

Page6

Optional Accessories Example of Workpieces

CNC Rotary Surface Grinding Machine Rotary Surface Grinding Machine

PRG6DXNC PRG8DXNC PRG10DXNCPRG12DXNC PRG6DX PRG8DX

1. Coolant System

1 Coolant System with Magnetic Dust Separator

2 Coolant System with Magnetic Dust Separator, with Paper Filter

3 Coolant System with Magnetic Dust Separator, with Automatic Coolant Temperature Regulator

4 Oil Mist Collecter

5 Dust Collection Hood for Oil Mist Collecter

2. Wheel Balancer

1 BW-360 with Balance Arbor −

2 BW-500 with Balance Arbor − − − −

3. Micro-Balancer Wafer Thin Workpieces & Blades

4. Spare Grinding Wheel Adaptor We have experiences in grinding silicon, SiC, glass Diffi cult thin workpieces can be ground without warping.

5. Spare Grinding Wheel Adaptor for Micro-Balancer and quartz.

6. Crane for Wheel Adaptor − − − −

7. Overhead Dresser, Hydraulic − − −

8. 2-direction Dresser (for OD, side-front dressing) − −

9. Power Up of Wheel Spindle, 11kW − − −

10. Power Up of Wheel Spindle, 15kW − −

11. Spindle invertor for 11kW − − −

12. Spindle invertor for 15kW − −

13. Wheel Spindle Meter Relay (emergency stop by spindle overload)

14. Table Rotation Speed Meter

15. Automatic Oil Temperature Regulator

16. Constant Coolant Supply for Table Drain Gutter

17. Manual Interruption (M.P.G. Interruption) − −

18. Timer of Accumulated Time

1 Display of Accumulated Time of Hydraulic "ON" − −

2 Display of Accumulated Time of Wheel Spindle "ON" − − Gear & Multiple Diameter Workpieces Ceramics

19. Auto Shut Down Function − − Suitable for mass production equipment and can grind Ideal for grinding brittle materials due to its rigid dou-

20. Signal Tower 3 Colors (on/off type, fl ashing type) − − multiple workpieces in one cycle. ble column construction

21. Calendar Timer (weekly timer, hydraulic "ON") − −

22. Work Light

23. GRIND-X Hydraulic Oil (to be used as lubricant)

Complex Workpiece Ultra Precision Spacer (UPR3NC)

GRIND-BIX Model Raised Table Cover 300 mm CE Mark Complied Workpiece that has corrugated shape in the center Small workpieces that require ultra-precision fl atness,

can be easily ground by CNC model. such as bearing spacers for high-speed spindles can

be ground.

Overhead Dresser Dust Collection Hood & Hose Oil Mist Collecter

Steps Bearings

Workpiece with multiple steps can be easily ground Ideal for mass production of various bearing parts.

using the interactive software.

Work Light Wheel Balancer Touch Probe

9 PRG Series PRG Series 10