1/56ページ

Download(24.5Mb)

CAM-OPERATED SWITCH B TYPE, BH TYPE

Product Catalog

Document Information

| Document Title | CAM-OPERATED SWITCH B TYPE, BH TYPE |

|---|---|

| Document Type | Product Catalog |

| File size | 24.5Mb |

| Category | |

| Company | FUJI ELECTRIC INDUSTRY CO., LTD. (Documents List) |

Documents related to this company

Document Contents

Page1

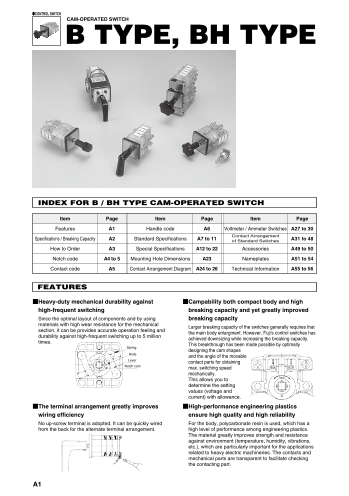

●CONTROL SWITCH

CAM-OPERATED SWITCH

B TYPE, BH TYPE

■Rolling action of contact mechanism

improves contact stability

Breaking starts Rolling action

In the contact mechanism, the movable contact makes

contact with the stationary contact at one point and then

gradually increases the contact area while rolling on it.

This rolling action minimizes the part exposed to the arc

that is generated at the first contact or breaking, thereby

maintaining much higher contact stability than the former Contact starts Rolling action Contact completes

product.

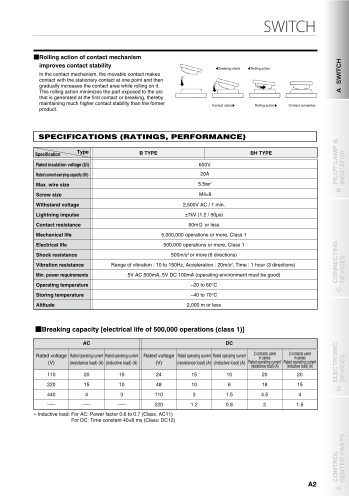

SPECIFICATIONS (RATINGS, PERFORMANCE)

Specification Type B TYPE BH TYPE

Rated insulation voltage (Ui) 600V

Rated current-carrying capacity (lth) 20A

Max. wire size 5.5㎜2

Screw size M4×9

INDEX FOR B / BH TYPE CAM-OPERATED SWITCH Withstand voltage 2,500V AC / 1 min.

Lightning impulse ±7kV (1.2 / 50µs)

Item Page Item Page Item Page

Contact resistance 50mΩ or less

Features A1 Handle code A6 Voltmeter / Ammeter Switches A27 to 30

A2 A7 Contact Arrangement Mechanical life 5,000,000 operations or more, Class 1

Specifications / Breaking Capacity Standard Specifications to 11 of Standard Switches A31 to 48

Electrical life 500,000 operations or more, Class 1

How to Order A3 Special Specifications A12 to 22 Accessories A49 to 50

Shock resistance 500m/s2 or more (6 directions)

Notch code A4 to 5 Mounting Hole Dimensions A23 Nameplates A51 to 54

Vibration resistance Range of vibration : 10 to 150Hz, Acceleration : 20m/s2, Time : 1 hour (3 directions)

Contact code A5 Contact Arrangement Diagram A24 to 26 Technical Information A55 to 56

Min. power requirements 5V AC 500mA, 5V DC 100mA (operating environment must be good)

FEATURES Operating temperature –20 to 60°C

Storing temperature –40 to 70°C

■Heavy-duty mechanical durability against ■Campability both compact body and high Altitude 2,000 m or less

high-frequent switching breaking capacity and yet greatly improved

Since the optimal layout of components and by using breaking capacity

materials with high wear resistance for the mechanical Larger breaking capacity of the switches generally requires that

section, it can be provides accurate operation feeling and the main body enlargment. However, Fuji's control switches has ■Breaking capacity [electrical life of 500,000 operations (class 1)]

durability against high-frequent switching up to 5 million achieved downsizing while increasing the breaking capacity.

times. This breakthrough has been made possible by optimally AC DC

Spring

designing the cam shapes

Rolle and the angle of the movable Rated voltage Rated operating current Rated operating current Rated voltage Rated operating current Rated operating current 2 contacts used 2 contacts used

Lever in series in series

contact parts for obtaining (V) (resistance load) (A) (inductive load) (A) (V) (resistance load) (A) (inductive load) (A) Rated operating current Rated operating current

Notch cam max. switching speed (resistance load) (A) (inductive load) (A)

mechanically. 110 20 15 24 15 10 20 20

This allows you to

determine the setting 220 15 10 48 10 6 18 15

values (voltage and

current) with allowance. 440 4 3 110 3 1.5 4.5 4

■The terminal arrangement greatly improves ■High-performance engineering plastics ―― ―― ―― 220 1.2 0.8 2 1.5

wiring efficiency ensure high quality and high reliability Inductive load: For AC: Power factor 0.6 to 0.7 (Class: AC11)

For DC: Time constant 40±6 ms (Class: DC12)

No up-screw terminal is adopted. It can be quickly wired For the body, polycarbonate resin is used, which has a

from the back for the alternate terminal arrangement. high level of performance among engineering plastics.

The material greatly improves strength and resistance

against environment (temperature, humidity, vibrations,

etc.), which are particularly important for the applications

related to heavy electric machineries. The contacts and

mechanical parts are transparent to facilitate checking

the contacting part.

A1

▲

▲

▲

▲

Page2

●CONTROL SWITCH

CAM-OPERATED SWITCH

B TYPE, BH TYPE SWITCH

■Rolling action of contact mechanism

improves contact stability

Breaking starts Rolling action

In the contact mechanism, the movable contact makes

contact with the stationary contact at one point and then

gradually increases the contact area while rolling on it.

This rolling action minimizes the part exposed to the arc

that is generated at the first contact or breaking, thereby

maintaining much higher contact stability than the former Contact starts Rolling action Contact completes

product.

SPECIFICATIONS (RATINGS, PERFORMANCE)

Specification Type B TYPE BH TYPE

Rated insulation voltage (Ui) 600V

Rated current-carrying capacity (lth) 20A

Max. wire size 5.5㎜2

Screw size M4×9

INDEX FOR B / BH TYPE CAM-OPERATED SWITCH Withstand voltage 2,500V AC / 1 min.

Lightning impulse ±7kV (1.2 / 50µs)

Item Page Item Page Item Page

Contact resistance 50mΩ or less

Features A1 Handle code A6 Voltmeter / Ammeter Switches A27 to 30

A2 A7 Contact Arrangement Mechanical life 5,000,000 operations or more, Class 1

Specifications / Breaking Capacity Standard Specifications to 11 of Standard Switches A31 to 48

Electrical life 500,000 operations or more, Class 1

How to Order A3 Special Specifications A12 to 22 Accessories A49 to 50

Shock resistance 500m/s2 or more (6 directions)

Notch code A4 to 5 Mounting Hole Dimensions A23 Nameplates A51 to 54

Vibration resistance Range of vibration : 10 to 150Hz, Acceleration : 20m/s2, Time : 1 hour (3 directions)

Contact code A5 Contact Arrangement Diagram A24 to 26 Technical Information A55 to 56

Min. power requirements 5V AC 500mA, 5V DC 100mA (operating environment must be good)

FEATURES Operating temperature –20 to 60°C

Storing temperature –40 to 70°C

■Heavy-duty mechanical durability against ■Campability both compact body and high Altitude 2,000 m or less

high-frequent switching breaking capacity and yet greatly improved

Since the optimal layout of components and by using breaking capacity

materials with high wear resistance for the mechanical Larger breaking capacity of the switches generally requires that

section, it can be provides accurate operation feeling and the main body enlargment. However, Fuji's control switches has ■Breaking capacity [electrical life of 500,000 operations (class 1)]

durability against high-frequent switching up to 5 million achieved downsizing while increasing the breaking capacity.

times. This breakthrough has been made possible by optimally AC DC

Spring

designing the cam shapes

Rolle and the angle of the movable Rated voltage Rated operating current Rated operating current Rated voltage Rated operating current Rated operating current 2 contacts used 2 contacts used

Lever in series in series

contact parts for obtaining (V) (resistance load) (A) (inductive load) (A) (V) (resistance load) (A) (inductive load) (A) Rated operating current Rated operating current

Notch cam max. switching speed (resistance load) (A) (inductive load) (A)

mechanically. 110 20 15 24 15 10 20 20

This allows you to

determine the setting 220 15 10 48 10 6 18 15

values (voltage and

current) with allowance. 440 4 3 110 3 1.5 4.5 4

■The terminal arrangement greatly improves ■High-performance engineering plastics ―― ―― ―― 220 1.2 0.8 2 1.5

wiring efficiency ensure high quality and high reliability Inductive load: For AC: Power factor 0.6 to 0.7 (Class: AC11)

For DC: Time constant 40±6 ms (Class: DC12)

No up-screw terminal is adopted. It can be quickly wired For the body, polycarbonate resin is used, which has a

from the back for the alternate terminal arrangement. high level of performance among engineering plastics.

The material greatly improves strength and resistance

against environment (temperature, humidity, vibrations,

etc.), which are particularly important for the applications

related to heavy electric machineries. The contacts and

mechanical parts are transparent to facilitate checking

the contacting part.

A2

▲

▲

E CONTROL D ELECTRONIC DEVICES C

CONNECTING

DEVICES B

PILOT LAMP &

CENTER PARTS INDICATOR A SWITCH

▲

▲

Page3

●CONTROL SWITCH

CAM-OPERATED SWITCH

B TYPE, BH TYPE

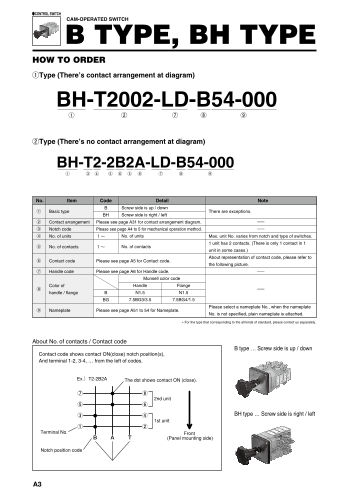

HOW TO ORDER ■Notch code

①Type (There’s contact arrangement at diagram) Code H HB HA K V T B TA T F

A B P P A B A T

BH-T2002-LD-B54-000 Notch B A B A B T A F

B A D K D K B

configuration

V

① ② ⑦ ⑧ ⑨

(90 °‐ 2)( 90 °‐ 2)( 90 °‐ 2)( 90 °‐ 3)( 90 °‐ 4)( 45 °‐ 2)( 45 °‐ 2)( 45 °‐ 3)( 45 °‐ 4)

Operation 2 notche s 2 notche s 2 notche s 3 notche s 4 notche s 2 notche s 2 notche s 3 notche s 4 notche s

②Type (There’s no contact arrangement at diagram) Manual return

BH-T2-2B2A-LD-B54-000 Code E G J O B A S TR 、T L FR 、F L

A T

① ③ ④ ⑤ ⑥ ⑤ ⑥ ⑦ ⑧ ⑨ B T A F

T T F T C

Notch T E A F B C C

A F A F A B A B

TR FR

B E B E A G B E

configuration A T

G B J O G B T A F

J B

No. Item Code Detail Note TL FL

B Screw side is up / down (45 °‐ 5)( 45 °‐ 6)( 45 °‐ 7)( 45 °‐ 8)( 45 °‐ 2)(45 °‐ 2)( 45 °‐ 3)( 45 °‐ 3)( 45 °‐ 4)

① Basic type There are exceptions.

BH Screw side is right / left Operation 5 notches 6 notches 7 notches 8 notches 2 notches 2 notches 3 notches 3 notches 4 notches

② Contact arrangement Please see page A31 for contact arrangement diagram. ー Manual return Automatic Combination of manual

return and automatic return

③ Notch code Please see page A4 to 5 for mechanical operation method. ー

④ No. of units 1~ No. of units Max. unit No. varies from notch and type of switches.

1 unit has 2 contacts. (There is only 1 contact in 1 Code FS 303 305 306 307 308 309 310 311

⑤ No. of contacts 1~ No. of contacts

unit in some cases.)

About representation of contact code, please refer to T B A T A T F T F E T F E T F E F E G T F ⑥ Contact code Please see page A5 for Contact code. E T F E

Notch A F

the following picture. B E A G A G A G T J A G A G

B B B J B J A O B J B J

⑦ Handle code Please see page A6 for Handle code. ー configuration O B D O O

Munsell color code P D K P D

Color of Handle Flange

⑧ ー

handle / flange B N1.5 N1.5 (45 °‐ 4)( 30 °‐3)( 30 °‐ 5)( 30 °‐ 6)( 30 °‐ 7)( 30 °‐ 8)( 30 °‐ 9)( 30 °‐ 10() 3 0 °‐ 11)

BG 7.5BG3/3.5 7.5BG4/1.5 Operation 4 notches 3 notches 5 notches 6 notches 7 notches 8 notches 9 notches 10 notches 11 notches

Combination of

Please select a nameplate No., when the nameplate manual and

⑨ Nameplate Please see page A51 to 54 for Nameplate. automatic return Manual return

No. is not specified, plain nameplate is attached.

For the type that corresponding to the all kinds of standard, please contact us separately.

Code 312 305S 307S 454S 454SR 455S

About No. of contacts / Contact code T F E A T F T F E T A T

T A F

Notch A G B E A G A F B

B type … Screw side is up / down

Contact code shows contact ON(close) notch position(s), B J B J B F B E

configuration V O

And terminal 1-2, 3-4, … from the left of codes. K P D

Ex.)T2-2B2A (30 °‐ 12)

The dot shows contact ON (close). ( 30 °‐ 5)( 30 °‐ 7)( 45°‐4)(45 °‐4)( 45 °‐ 5)

Operation 12 notches 5 notches 7 notches 4 notches 4 notches 5 notches

Manual

⑦ ⑧ return Automatic return

2nd unit

⑤ ⑥

③ ④ BH type … Screw side is right / left

1st unit

① ②

Terminal No. Front

B A T (Panel mounting side)

Notch position code

A3

Page4

●CONTROL SWITCH

CAM-OPERATED SWITCH

B TYPE, BH TYPE SWITCH

HOW TO ORDER ■Notch code

①Type (There’s contact arrangement at diagram) Code H HB HA K V T B TA T F

A B P P A B A T

BH-T2002-LD-B54-000 Notch B A B A B T A F

B A D K D K B

configuration

V

① ② ⑦ ⑧ ⑨

(90 °‐ 2)( 90 °‐ 2)( 90 °‐ 2)( 90 °‐ 3)( 90 °‐ 4)( 45 °‐ 2)( 45 °‐ 2)( 45 °‐ 3)( 45 °‐ 4)

Operation 2 notche s 2 notche s 2 notche s 3 notche s 4 notche s 2 notche s 2 notche s 3 notche s 4 notche s

②Type (There’s no contact arrangement at diagram) Manual return

BH-T2-2B2A-LD-B54-000 Code E G J O B A S TR 、T L FR 、F L

A T

① ③ ④ ⑤ ⑥ ⑤ ⑥ ⑦ ⑧ ⑨ B T A F

T T F T C

Notch T E A F B C C

A F A F A B A B

TR FR

B E B E A G B E

configuration A T

G B J O G B T A F

J B

No. Item Code Detail Note TL FL

B Screw side is up / down (45 °‐ 5)( 45 °‐ 6)( 45 °‐ 7)( 45 °‐ 8)( 45 °‐ 2)(45 °‐ 2)( 45 °‐ 3)( 45 °‐ 3)( 45 °‐ 4)

① Basic type There are exceptions.

BH Screw side is right / left Operation 5 notches 6 notches 7 notches 8 notches 2 notches 2 notches 3 notches 3 notches 4 notches

② Contact arrangement Please see page A31 for contact arrangement diagram. ー Manual return Automatic Combination of manual

return and automatic return

③ Notch code Please see page A4 to 5 for mechanical operation method. ー

④ No. of units 1~ No. of units Max. unit No. varies from notch and type of switches.

1 unit has 2 contacts. (There is only 1 contact in 1 Code FS 303 305 306 307 308 309 310 311

⑤ No. of contacts 1~ No. of contacts

unit in some cases.)

About representation of contact code, please refer to T B A T A T F T F E T F E T F E F E G T F ⑥ Contact code Please see page A5 for Contact code. E T F E

Notch A F

the following picture. B E A G A G A G T J A G A G

B B B J B J A O B J B J

⑦ Handle code Please see page A6 for Handle code. ー configuration O B D O O

Munsell color code P D K P D

Color of Handle Flange

⑧ ー

handle / flange B N1.5 N1.5 (45 °‐ 4)( 30 °‐3)( 30 °‐ 5)( 30 °‐ 6)( 30 °‐ 7)( 30 °‐ 8)( 30 °‐ 9)( 30 °‐ 10() 3 0 °‐ 11)

BG 7.5BG3/3.5 7.5BG4/1.5 Operation 4 notches 3 notches 5 notches 6 notches 7 notches 8 notches 9 notches 10 notches 11 notches

Combination of

Please select a nameplate No., when the nameplate manual and

⑨ Manual return

Nameplate Please see page A51 to 54 for Nameplate. automatic return

No. is not specified, plain nameplate is attached.

For the type that corresponding to the all kinds of standard, please contact us separately.

Code 312 305S 307S 454S 454SR 455S

About No. of contacts / Contact code T F E A T F T F E T A T

B T A F

B type … Screw side is up / down Notch B E A G A F

A G

configuration B J B J B F B E

Contact code shows contact ON(close) notch position(s),

V O

And terminal 1-2, 3-4, … from the left of codes. K P D

Ex.)T2-2B2A (30 °‐ 12)

The dot shows contact ON (close). ( 30 °‐ 5)( 30 °‐ 7)( 45°‐4)(45 °‐4)( 45 °‐ 5)

Operation 12 notches 5 notches 7 notches 4 notches 4 notches 5 notches

Manual

⑦ ⑧ return Automatic return

2nd unit

⑤ ⑥

③ ④ BH type … Screw side is right / left

1st unit

① ②

Terminal No. Front

B A T (Panel mounting side)

Notch position code

A4

E CONTROL D ELECTRONIC DEVICES C

CONNECTING

CENTER PARTS DEVICES B

PILOT LAMP &

INDICATOR A SWITCH

Page5

●CONTROL SWITCH

CAM-OPERATED SWITCH

B TYPE, BH TYPE

■Notch code ■Handle code

Code SB SBW BB AB SQ SQA SQR SQL SQRL Code LDP LD HDP HD LFP

Rose shape (large) Rose shape (large) Rose shape (small) Rose shape (small) Octagonal shape (large)

with one point with one point with one point

Notch

configuration Shape

55 55 45 45 55

4 4 4

7 0

4 0

7

30

Automatic rotating return

Operation

Automatic axial return Code LF HFP HF LP HP

Octagonal shape (large) Octagonal shape Octagonal shape (small) Stick shape (large) Stick shape (small)

(small) with one point 21 18

Code SR SRL SRR SY SN SM SUY□ SUB□ 60

45 Shape

Lock

55 45

45

Notch

30 2

5 25

configuration 15 1

3

Lock Code MP HR LS LE HE

Automatic rotating return Manual axial return Pistol shape (large) Pistol shape (small) Knob shape Egg shape (large) Egg shape (small)

Operation

Manual axial return Manual axial Automatic axial return Manual axial Automatic

return return axial return

Shape

88 57

19 55

47

Code HC TC FC SC HW TW FW EW φ2 6 2

φ 3 5

2 φ

0

8 2

2

Notch The handle is removable The stage is the dual body Code HSP USP

configuration as in H, T, F, and S. type as in H, T, F, and E. Beak shape (large) Beak shape (small)

(90 °‐ 2)( 45 °‐ 3)( 45 °‐ 4)( 45 °‐ 3)( 90 °- 2 )( 45 °‐ 3)( 45 °‐ 4)( 45 °‐ 5) Shape

Operation 2 notches 3 notches 4 notches 3 notches 2 notches 3 notches 4 notches 5 notches 58 39

Manual return Automatic

return Manual return The shaft for the LS handle is 13 mm shorter than the standard shaft.

Therefore, other types of handles cannot be replaced with the LS handle (knob shape).

(Note) In the above table, the ● mark indicates the ordinary stop position of the switch and the → mark shows that

the switch moves in this direction and then automatically stops in the arrowhead position.

●―― ● means that the switch is manually moved from ● to ●.

■Handle code (For dual body type / pulling lock and pushing lock type)

Code BD BF BP MD MF

■Contact code

Rose shape (large) Octagonal shape (large) Stick shape (large) Rose shape (small) Octagonal shape (small)

Code Graphic symbol Designation Description Code Graphic symbol Designation Description 21

60

B、A B, A, T···V M Contacts close between

Continuous

Normal left and center. Shape

55 55 45 45 closing

contact Closed in each notch position. contact Contacts close between

T …V N right and center. 4 4

7 0

30 25

U U (push) / Contacts open after pulling BX G Dual Closed in the B notch position. 15

L (pull)- contacts Code MQ

L contact MR

Contacts close after pulling AX G (Gold plating) Closed in the A notch position.

Stick shape (small) Pistol shape (small)

Contact closes after turning to the left

Y Just before one contact 18

Close keep and keep closed till turning to the right. Over-

lapping closes (ON) the other

L

contact Contact closes after turning to the right contact contact opens during

Z Shape 45

operation. 51 and keep closed till turning to the left.

φ2 2

13

A5

51 25

57 11 50 60 13

58 50

58 44 17 48

50

50 10 50

10

75 12 48 42

32 15

60

75 12 42

42

57 11 5848

48

Page6

●CONTROL SWITCH

CAM-OPERATED SWITCH

B TYPE, BH TYPE SWITCH

■Notch code ■Handle code

Code SB SBW BB AB SQ SQA SQR SQL SQRL Code LDP LD HDP HD LFP

Rose shape (large) Rose shape (large) Rose shape (small) Rose shape (small) Octagonal shape (large)

with one point with one point with one point

Notch

configuration Shape

55 55 45 45 55

4 4 4

7 0

4 0

7

30

Automatic rotating return

Operation

Automatic axial return Code LF HFP HF LP HP

Octagonal shape (large) Octagonal shape Octagonal shape (small) Stick shape (large) Stick shape (small)

(small) with one point 21 18

Code SR SRL SRR SY SN SM SUY□ SUB□ 60

45 Shape

Lock

55 45

45

Notch

30 2

5 25

configuration 15 1

3

Lock Code MP HR LS LE HE

Automatic rotating return Manual axial return Pistol shape (large) Pistol shape (small) Knob shape Egg shape (large) Egg shape (small)

Operation

Manual axial return Manual axial

return Automatic axial return Manual axial Automatic

return axial return

Shape 55

88 57

19

47

Code HC TC FC SC HW TW FW EW φ2 6 2

φ 3 5

2 φ

0

8 2

2

Notch The handle is removable The stage is the dual body Code HSP USP

configuration as in H, T, F, and S. type as in H, T, F, and E. Beak shape (large) Beak shape (small)

(90 °‐ 2)( 45 °‐ 3)( 45 °‐ 4)( 45 °‐ 3)( 90 °- 2 )( 45 °‐ 3)( 45 °‐ 4)( 45 °‐ 5) Shape

Operation 2 notches 3 notches 4 notches 3 notches 2 notches 3 notches 4 notches 5 notches 58 39

Manual return Automatic

return Manual return The shaft for the LS handle is 13 mm shorter than the standard shaft.

Therefore, other types of handles cannot be replaced with the LS handle (knob shape).

(Note) In the above table, the ● mark indicates the ordinary stop position of the switch and the → mark shows that

the switch moves in this direction and then automatically stops in the arrowhead position.

●―― ● means that the switch is manually moved from ● to ●.

■Handle code (For dual body type / pulling lock and pushing lock type)

Code BD BF BP MD MF

■Contact code

Rose shape (large) Octagonal shape (large) Stick shape (large) Rose shape (small) Octagonal shape (small)

Code Graphic symbol Designation Description Code Graphic symbol Designation Description 21

60

B、A B, A, T···V M Contacts close between

Continuous

Normal left and center. Shape

55 55 45 45 closing

contact Closed in each notch position. contact Contacts close between

T …V N right and center. 4 4

7 2

3 0

0 5

U U (push) / Contacts open after pulling BX G Dual Closed in the B notch position. 15

L (pull)- contacts

L AX G (Gold plating) Code MQ

contact MR

Contacts close after pulling Closed in the A notch position.

Stick shape (small) Pistol shape (small)

Contact closes after turning to the left

Y Just before one contact 18

Close keep and keep closed till turning to the right. Over-

L lapping closes (ON) the other

contact Contact closes after turning to the right

Z contact contact opens during Shape 45

and keep closed till turning to the left. operation. 51

φ2 2

13

A6

51 25

57 11 50 60 13

58 50

48 50 58 44 17

50 10 50

10

75 12 48 42

32 15

60

75 12 42

42

57 11 5848

48

E CONTROL D ELECTRONIC B PILOT LAMP & CENTER PARTS DEVICES C

CONNECTING

DEVICES INDICATOR A SWITCH

Page7

●CONTROL SWITCH

CAM-OPERATED SWITCH

B TYPE, BH TYPE

STANDARD SPECIFICATION SWITCHES

OUTLINES

Manual return and automatic return type

B-S,B,A,□(H,K,V,T,F,E,G,J,O) The BY type has the same dimensions and shape. (Unit color: Blue)

(305,306,307,308)

(B type)

t to (standard)

Terminal screw Mounting hole

No. of units 1 2 3 4 5 6 7 8 9 10

L(mm) 43 56 69 82 95 108 121 134 147 160

Max unit No. of the Automatic return type is 6 (12 contacts).

Max. 6 contacts for one side.

Manual return and automatic return type

BH-S,B,A,□(H,K,V,T,F,E,G,J,O) The BHY type has the same dimensions and shape. (Unit color: Blue)

(305,306,307,308)

(BH type)

Mounting hole

Mounting panel: = to

No. of units 1 2 3 4 5 6 7 8 9 10

L(mm) 43 56 69 82 95 108 121 134 147 160

Max unit No. of the Automatic return type is 6 (12 contacts).

Max. 6 contacts for one side.

Combination of manual and automatic return type

B-TR,TL,FR,FL,FS

(B type)

t to (standard)

Terminal screw Mounting hole

No. of units 1 2 3 4 5 6

L(mm) 43 56 69 82 95 108

A7

Page8

●CONTROL SWITCH

CAM-OPERATED SWITCH

B TYPE, BH TYPE SWITCH

STANDARD SPECIFICATION SWITCHES

OUTLINES Automatic return type by pulling

Manual return and automatic return type B-SB

B-S,B,A,□(H,K,V,T,F,E,G,J,O) The BY type has the same dimensions and shape. (Unit color: Blue) (B type)

(305,306,307,308) t to (standard)

(B type) Stroke:

t to (standard)

Mounting hole

No. of units 1 2 3 4 5 6

L( mm) 77 90 103 116 129 142

Terminal screw Mounting hole

Automatic return type by pulling

BHX-SB

No. of units 1 2 3 4 5 6 7 8 9 10 (BH type)

L(mm) 43 56 69 82 95 108 121 134 147 160

Max unit No. of the Automatic return type is 6 (12 contacts).

Manual return and automatic return type

BH-S,B,A,□(H,K,V,T,F,E,G,J,O) The BHY type has the same dimensions and shape. (Unit color: Blue)

(305,306,307,308)

(BH type) Mounting hole

Mounting panel:

= to

No. of units 1 2 3 4 5 6

Stroke:

L( mm) 77 90 103 116 129 142

Automatic or manual return type in axial direction

B-SQ ,SR,SY

(B type)

Mounting hole

Mounting panel: = to t to (standard)

Stroke:

No. of units 1 2 3 4 5 6 7 8 9 10

L(mm) 43 56 69 82 95 108 121 134 147 160

Mounting hole

Max unit No. of the Automatic return type is 6 (12 contacts).

Combination of manual and automatic return type No. of units 2 3 4 5 6 7 8

B-TR,TL,FR,FL,FS L( mm) 116 129 142 155 168 181 194

(B type) Automatic return type by pulling and pushing

t to (standard) BHW- SQ ,SR,BHX-SY

(BH type)

Terminal screw Mounting hole Mounting hole

Mounting panel: = to

Stroke:

No. of units 2 3 4 5 6 7 8

No. of units 1 2 3 4 5 6

L( mm) 116 129 142 155 168 181 194

L(mm) 43 56 69 82 95 108

A8

E CONTROL D ELECTRONIC DEVICES C

CONNECTING

DEVICES B

PILOT LAMP &

CENTER PARTS INDICATOR A SWITCH

Page9

●CONTROL SWITCH

CAM-OPERATED SWITCH

B TYPE, BH TYPE

OUTLINES

Pulling lock and pushing lock type Removable handle type

B-SN,SM The handle returns to orepating position after pushing the lock release button. B-H C,T C, FC, SC

(B type) (B type)

Lock release button

t to

Mounting panel: = to (standard)

Stroke:

Mounting hole

Mounting hole

Handle BP No. of units

(Press-pull unit plus switching unit) 2 3 4 5 6 7 8

L( mm) 131 144 157 170 183 196 209 No. of units 1 2 3 4 5 6 7 8 9 1 0

The shaft shape is different from the basic one. L( mm) 64 77 90 103 116 129 142 155 168 181

Please select a handle shape from page A6. (for pulling lock Max. unit No. of the automatic return type is 6 (12 contacts).

and pushing lock type)

Manual / Automatic axial return type Removable handle type

B-SUB □, SU Y( □ H,HB,HA,K,V,TB TA,T,F,E,G,J,O ) A phrase in brackets insert to the blank. BHK-HC,TC,FC,SC

(B type) (BH type)

Mounting panel: = to

7

Mounting hole

Mounting panel:

Mounting hole

Stroke: (5) = 2.3 to 3.2

21 13

45 15 L

No. of units 1 2 3 4 5 6 7 8 9 1 0

No. of units 2 3 4 5 6 7 8 L( mm) 64 77 90 103 116 129 142 155 168 181

L(mm) 119 132 145 158 171 184 197

■Handle removal position HC TC FC SC

Manual / Automatic axial return type Removal position is selectable.

(More than one positions are available.) C

BHX-SUB □ ,S U Y (□ H,HB,HA,K,V,TB TA,T,F,E,G,J,O ) A phrase in brackets insert to the blank. A T

B A B T A F

(BH type) B

Mounting panel: = to

7

■Key coding system (optional extra)

Key coding system is available as an option. Key combination numbers (KB1~4) are selectable,

and same number combination of the handle and the body is operational.

<Cross-section view>

Body

Mounting hole

Pulling stroke: (5) Conbination Concave of

key shaft 2 Key shaft

21 13 diagram

45 15 L Convex of

spring pin Spring pin

1

2 3 4 5 6 7 8 Key Nameplate

No. of units KB1 KB2 KB3 KB4 Flange Spring pin Handle

conbination No.

L( mm) 119 132 145 158 171 184 197

When the keyshaft and body are muching, it’s pasible to remove and insert of the key.

1, 2 Diagram from right figure shape.

A9

φ42

φ42

Body2 Key shaft1

5 6

1 2

Page10

●CONTROL SWITCH

CAM-OPERATED SWITCH

B TYPE, BH TYPE SWITCH

OUTLINES

Pulling lock and pushing lock type Removable handle type

B-SN,SM The handle returns to orepating position after pushing the lock release button. B-HC ,T C, FC, SC

(B type) (B type)

Lock release button

t to

Mounting panel: = to (standard)

Stroke:

Mounting hole

Mounting hole

Handle BP No. of units

(Press-pull unit plus switching unit) 2 3 4 5 6 7 8

L( mm) 131 144 157 170 183 196 209 No. of units 1 2 3 4 5 6 7 8 9 1 0

The shaft shape is different from the basic one. L( mm) 64 77 90 103 116 129 142 155 168 181

Please select a handle shape from page A6. (for pulling lock Max. unit No. of the automatic return type is 6 (12 contacts).

and pushing lock type)

Manual / Automatic axial return type Removable handle type

B-SUB □, SU Y( □ H,HB,HA,K,V,TB TA,T,F,E,G,J,O ) A phrase in brackets insert to the blank. BHK-HC,TC,FC,SC

(B type) (BH type)

Mounting panel: = to

7

Mounting hole

Mounting panel:

Mounting hole

Stroke: (5) = 2.3 to 3.2

21 13

45 15 L

No. of units 1 2 3 4 5 6 7 8 9 1 0

No. of units 2 3 4 5 6 7 8 L( mm) 64 77 90 103 116 129 142 155 168 181

L(mm) 119 132 145 158 171 184 197

■Handle removal position HC TC FC SC

Manual / Automatic axial return type Removal position is selectable.

(More than one positions are available.) C

BHX-SUB □ ,S U Y (□ H,HB,HA,K,V,TB TA,T,F,E,G,J,O ) A phrase in brackets insert to the blank. A T

B A B T A F

(BH type) B

Mounting panel: = to

7

■Key coding system (optional extra)

Key coding system is available as an option. Key combination numbers (KB1~4) are selectable,

and same number combination of the handle and the body is operational.

<Cross-section view>

Body

Mounting hole

Pulling stroke: (5) Conbination Concave of 2 Key shaft

key shaft

21 13 diagram

45 15 L Convex of

spring pin Spring pin

1

2 3 4 5 6 7 8 Key Nameplate

No. of units KB1 KB2 KB3 KB4 Spring pin Handle

conbination No. Flange

L( mm) 119 132 145 158 171 184 197

When the keyshaft and body are muching, it’s pasible to remove and insert of the key.

1, 2 Diagram from right figure shape.

A10

φ42

φ42

Body2 Key shaft1

E CONTROL D ELECTRONIC DEVICES C

CONNECTING

DEVICES B

PILOT LAMP &

CENTER PARTS INDICATOR A SWITCH

5 6

1 2

Page11

●CONTROL SWITCH

CAM-OPERATED SWITCH

B TYPE, BH TYPE

OUTLINES SPECIAL SPECIFICATION SWITCH CODING FOR ORDERING

Dual body type

B-HW,TW,FW,EW 1 Key handle type ●Available notch : S, H, T, F, E ●Max. unit No. is 4.

A key is used as the handle. ●C-88 and C-110 that made by Takigen is used. No. K6510 of C-88 is a standard key.

(B type) ●Please see page A14 for information of key system.

1) C-88 key (Not available for master key system)

124

Mounting panel: t = to L

20 B-KMC-H2-2B2A-B NUKI B C-88 K6510

Notch code Color of Key lock position Key No.

Code Switch No. of units handle / flange Key type K6510 - K6520 Standard

B-KMC B type No. of contacts Contact code C-88 Not available for ∗ Specified No.

Mounting hole master key system

BHO BH type

7

55 15 2) C-110 key (Available for master key system)

B-KMC-H2-2B2A-B NUKI B C-110(AAA111) FUJI13

Notch code Color of lock position ∗Master key No. Key No. (change key)

Code Switch No. of units handle / flange Key type ∗ Specified No. ∗ Specified No.

B-KMC B type No. of contacts Contact code C-110 Available for

master key system ∗Available character for master key No. / key No. (change key)

BHO BH type Max. number Master key No. Within 6 (7 for number only)

Dual body type of character Key No. Within 7

Available Number (0 - 9), Alphabet (A - Z)

BH-HW,TW,FW,EW character ∗Blank is not available.

(BH type) TOP Mounting panel: t = to

OUTLINES

Shaft: Handle: BD

B-KMC

(B type) ∗ The screw side is on the right/left in this type. In case of B type, it's generally on the up/down.

Mounting panel: t = to

Mounting hole

Key

Key lock position

S H T F E

NUKI B NUKI A NUKI B NUKI A NUKI A NUKI T NUKI A NUKI T

NUKI C

Mounting hole NUKI A NUKI B NUKI T NUKI F NUKI F

No. of stages 1 2 3 4 5 6 7 8 9

L( mm) 63 76 89 102 115 128 141 154 167 BHO The key is used to directly operate the switch.

For the key, pleas see the specifications of the key.

∗ Please select a handle shape from page A6. (for dual body type) (BH type) If the another key lock position is needed,

∗ The mounting hole is on the vertical in this type. In case of BH type, it's generally on the horizontal. please contact us.

∗ 「NUKI」 means key lock position.

Mounting panel: t = to

No. of units 1 2 3 4

L( mm) 78 91 104 117

Key

The standard key is C-88 (Takigen). If the

master key is needed, please request us. Mounting hole

C-110 (Takigen) key is provided as a

master key.

A11

50

64

Page12

SWITCH

SPECIAL SPECIFICATION SWITCH CODING FOR ORDERING

1 Key handle type ●Available notch : S, H, T, F, E ●Max. unit No. is 4. There are exceptions.

A key is used as the handle. ●C-88 and C-110 that made by Takigen is used. No. K6510 of C-88 is a standard key.

●Please see page A14 for information of key system.

1) C-88 key (Not available for master key system)

B-KMC-H2-2B2A-B NUKI B C-88 K6510

Notch code Color of Key lock position Key No.

Code Switch No. of units handle / flange Key type K6510 - K6520 Standard

B-KMC B type No. of contacts Contact code C-88 Not available for Specified No.

master key system

BHO BH type

2) C-110 key (Available for master key system)

B-KMC-H2-2B2A-B NUKI B C-110(AAA111) FUJI13

Notch code Color of lock position Master key No. Key No. (change key)

Code Switch No. of units handle / flange Key type Specified No. Specified No.

B-KMC B type No. of contacts Contact code C-110 Available for

master key system Available character for master key No. / key No. (change key)

BHO BH type Max. number Master key No. Within 6 (7 for number only)

of character Key No. Within 7

Available Number (0 - 9), Alphabet (A - Z)

character Blank is not available.

OUTLINES

B-KMC

(B type) The screw side is on the right/left in this type. In case of B type, it's generally on the up/down.

Mounting panel: t = to

Key

Key lock position

S H T F E

NUKI B NUKI A NUKI B NUKI A NUKI A NUKI T NUKI A NUKI T

NUKI C

Mounting hole NUKI A NUKI B NUKI T NUKI F NUKI F

BHO The key is used to directly operate the switch.

For the key, pleas see the specifications of the key.

(BH type) If the another key lock position is needed,

The mounting hole is on the vertical in this type. In case of BH type, it's generally on the horizontal. please contact us.

「NUKI」 means key lock position.

Mounting panel: t = to

No. of units 1 2 3 4

L( mm) 78 91 104 117

Key

The standard key is C-88 (Takigen). If the

master key is needed, please request us.

C-110 (Takigen) key is provided as a

master key.

Exclusive cover which a resin molded for

the key also available. It cannot be install

Mounting hole at a later time.

A12

E CONTROL D ELECTRONIC DEVICES C

CONNECTING

DEVICES B

PILOT LAMP &

CENTER PARTS INDICATOR A SWITCH

Page13

●CONTROL SWITCH

CAM-OPERATED SWITCH

B TYPE, BH TYPE

SPECIAL SPECIFICATION SWITCH CODING FOR ORDERING

2 Cylinder key type ●Available notch : S, H,

Locked with an insert key. To open / close the switch, unlock the key and then operate the handle. T, F, E, K, W, and SB.

●Max. unit No. is 10.

1) C-88 key (Not available for master key system) There are exceptions.

B-KM-H2-2B2A-LD-B NUKI B C-88 K6510 ●C-88 and C-110 that

made by Takigen is

used. No. K6510 of

Notch code Key No.

No. of units Handle code Key lock position

Standard C-88 is a standard key.

Contact code Key type K6510 - K6520

Code Switch Key position ●Please see page A14

No. of contacts C-88 Not available for Specified No.

B-KM B type Right Color of master key system for information of key

BHC BH type Bottom handle / flange system.

2) C-110 key (Available for master key system)

B-KM-H2-2B2A-LD-B NUKI B C-110(AAA111) FUJI13

Notch code

No. of units Handle code Key lock position Master key No. Key No. (change key)

Key type Specified No. Specified No.

Code Switch Key position Contact code

C-110 Not available for

master key system

B-KM B type Right Color of

No. of contacts

BHC BH type Bottom handle / flange Available character for master key No. / key No. (change key)

Max. number Master key No. Within 6 (7 for number only)

of character Key No. Within 7

Available Number (0 - 7), Alphabet (A - Z)

character Blank is not available.

OUTLINES

B-KM

(B type)

t to

Key lock position

S/SB H T F E K

NUKI BA NUKI BA NUKI BT NUKI ATNUKI BAT

Key NUKI C NUKI BATF NUKI BATFE NUKI DPK

NUKI B NUKI A NUKI B NUKI A NUKI T

Mounting hole

Key lock position

BHC

(BH type) Mounting panel: t = 1 to 3.2 Normaly, the key removal position is upside.

No. of units 1 2 3 4 5 6 7 8

L(mm) 64 77 90 103 116 129 142 155

The standard key is C-88 (Takigen). If the

master key is needed, please request us.

C-110 (Takigen) key is provided as a

Key master key.

Exclusive cover which a resin molded for

the key also available. It cannot be install

at a later time.

Mounting hole

A13

Page14

1

1 1

Page15

●CONTROL SWITCH

CAM-OPERATED SWITCH

B TYPE, BH TYPE

SPECIAL SPECIFICATION SWITCH CODING FOR ORDERING

3 Switch with padlock mechanism ●Available notch : S, H, T, F, and SB. 4 High-frequent type switch ●Available notch : S, H, T, F, and SB. The 30°

Locked with a padlock. To open / close the switch, unlock the padlock and ●Max. unit No. is 10. This cam switch is designed for high-frequent heavy-duty uses, version is also available.

then open / close the key while pushing or pulling the unlocking lever. in iron manufacture and chemical plants, etc.

● ●High-frequent operation type.

Normaly a padlock is attached to the down

●Please specify if you need the oil-proof type. In

B-KH-H2-2B2A-LD-B NUKIB side of the switch. BM-H2-2B2A-LD-B

● the case of oil-proof type, PBT resin is used for

Padlock is not attached.

the case.

●Please use a padlock with diameter of 6 mm.

Code Switch Unlocking Color of Notch code Handle

lever type Contact code handle / flange

B-KH B type Pushing type Code Switch No. of contacts Color of

No. of contacts

BH type Pulling type Handle code Key lock position BM B type Contact code handle / flange

BHP

No. of units

BHM BH type No. of units

Notch code

OUTLINES OUTLINES

B-KH BM

(B type) ∗ The screw side is on the right/left, and the mounting hole is on the horizontal in this type. (B type)

In case of B type, generally the screw side is on the up/down, and the mounting hole is on the vertical. Mount the flange and main

t to (standard) body with M5 × 12

t to (standard) countersunk screws.

(at vertical pitches of 30 mm)

Mount the switch directly to the

panel with M5 × 10 pan head

screws.

(at horizontal pitches of 30 mm)

Lock Mounting hole

release

lever

102 L

Key lock position

S H T F E K

∗ Padlock is not attached. NUKI BA NUKI BA NUKI BT NUKI AT NUKI BAT

NUKI C NUKI BATF NUKI BATFE NUKI DPK

(Use a padlock with diameter of 6 mm).

NUKI B NUKI A NUKI B NUKI A NUKI T

Mounting hole

BHP BHM

(BH type) (BH type)

Mounting panel: = to ○Remove the padlock and push the lock release lever for

handle operation. The switch will be locked automatically

after releasing your hand, then please lock with a padlock.

No. of units 1 2 3 4 5 6 7 8

L( mm) 67 80 93 106 119 132 145 158

Padlock: 6

Mounting panel: = to Mounting hole

Lock release lever

102

No. of units 1 2 3 4 5 6 7 8 9

∗ Padlock is not attached. Mounting hole

(Use a padlock with diameter of 6 mm). L( mm) 65 78 91 104 117 130 143 156 167

A15

Page16

●CONTROL SWITCH

CAM-OPERATED SWITCH

B TYPE, BH TYPE SWITCH

SPECIAL SPECIFICATION SWITCH CODING FOR ORDERING

3 Switch with padlock mechanism ●Available notch : S, H, T, F, and SB. 4 High-frequent type switch ●Available notch : S, H, T, F, and SB. The 30°

Locked with a padlock. To open / close the switch, unlock the padlock and ●Max. unit No. is 10. This cam switch is designed for high-frequent heavy-duty uses, version is also available.

then open / close the key while pushing or pulling the unlocking lever. in iron manufacture and chemical plants, etc.

● ●High-frequent operation type.

Normaly a padlock is attached to the down

●Please specify if you need the oil-proof type. In

B-KH-H2-2B2A-LD-B NUKIB side of the switch. BM-H2-2B2A-LD-B

● the case of oil-proof type, PBT resin is used for

Padlock is not attached.

the case.

●Please use a padlock with diameter of 6 mm.

Code Switch Unlocking Color of Notch code Handle

lever type Contact code handle / flange

B-KH B type Pushing type Code Switch No. of contacts Color of

No. of contacts

BH type Pulling type Handle code Key lock position BM B type Contact code handle / flange

BHP

No. of units

BHM BH type No. of units

Notch code

OUTLINES OUTLINES

B-KH BM

(B type) ∗ The screw side is on the right/left, and the mounting hole is on the horizontal in this type. (B type)

In case of B type, generally the screw side is on the up/down, and the mounting hole is on the vertical. Mount the flange and main

t to (standard) body with M5 × 12

t to (standard) countersunk screws.

(at vertical pitches of 30 mm)

Mount the switch directly to the

panel with M5 × 10 pan head

screws.

(at horizontal pitches of 30 mm)

Lock Mounting hole

release

lever

102 L

Key lock position

S H T F E K

∗ Padlock is not attached. NUKI BA NUKI BA NUKI BT NUKI AT NUKI BAT

NUKI C NUKI BATF NUKI BATFE NUKI DPK

(Use a padlock with diameter of 6 mm).

NUKI B NUKI A NUKI B NUKI A NUKI T

Mounting hole

BHP BHM

(BH type) (BH type)

Mounting panel: = to ○Remove the padlock and push the lock release lever for

handle operation. The switch will be locked automatically

after releasing your hand, then please lock with a padlock.

No. of units 1 2 3 4 5 6 7 8

L( mm) 67 80 93 106 119 132 145 158

Padlock: 6

Mounting panel: = to Mounting hole

Lock release lever

102

No. of units 1 2 3 4 5 6 7 8 9

∗ Padlock is not attached. Mounting hole

(Use a padlock with diameter of 6 mm). L( mm) 65 78 91 104 117 130 143 156 167

A16

E CONTROL D ELECTRONIC DEVICES C

CONNECTING

DEVICES B

PILOT LAMP &

CENTER PARTS INDICATOR A SWITCH

Page17

●CONTROL SWITCH

CAM-OPERATED SWITCH

B TYPE, BH TYPE

SPECIAL SPECIFICATION SWITCH CODING FOR ORDERING

5 Switch with indicator lamp (separate) ●The notches and specification are the same as 6 Switch with indicator lamp (built-in) ●Available notch: S, H, T, F and SB, SR, SY also

This is a switch that an indicator lamp is attached on top. those of the standard switches. This is a switch that a signal indicator is attached on top. available.

An indicator mounting hole is additionally required. ●For the circuit, voltage, and display color of the Part of lamp display ●For the circuit, voltage, and display color of the

Part of lamp display indicator, please see the following table and indicator lamp, please see the following table and

specify the corresponding numbers. specify the corresponding numbers.

BL-H2-2B2A-215-LD-B BHS-S2-2B2A-235-LP-B

Circuit Voltage Display color Circuit Voltage Display color

1 For 1 indicator lamp 1 24V DC 1 W (Milky white) Notch code Circuit Handle code 1 For 1 indicator lamp 1 24V DC 1 W (Milky white)

Notch code Circuit Display Color of 2 For 2 indicator lamps 2 48V DC 2 R (Red) No. of units Contact code Display Color of 2 For 2 indicator lamps 2 48V DC 2 R (Red)

color handle / flange Code Switch

Code Switch Contact code 3 For 3 indicator lamps 3 100 / 110V DC 3 G (Green) color handle / flange 3 For 3 indicator lamps 3 100 / 110V DC 3 G (Green)

BHS BH type No. of contacts

BL B type No. of contacts

Voltage Handle code 4 125V DC 4 O (Orange) Voltage 4 125V DC 4 O (Orange)

BH type

BHI BH type No. of units 5 100 / 110V AC 5 GR 5 100 / 110V AC 5 GR

BHS-B (with rear

6 200 / 220V AC 6 GWR terminal block) 6 200 / 220V AC 6 GWR

7 30V DC 7 GOR 7 30V DC 7 GOR

9 Special 9 Special 9 Special 9 Special 9 Special 9 Special

OUTLINES OUTLINES

BL BHS

(B type) 55 (BH type)

8.57

Panel mounting:

t=1 to 6mm Panel cutout

50 +0.5 0

2-φ6

φ13

(5) N P

L1 Mounting hole

15 Mounting panel: = to

(72) 60

Mounting hole

●Lamp position

No. of units 1 2 3 4 5 6 7 8 9 10

L(mm) For 1 indicator 116 129 142 155 168 181 194 207 220 233 1 lamp

L(mm) For 2 indicators 129 142 155 168 181 194 207 220 233 246 2 lamps

BH I L(mm) For 3 indicators 142 155 168 181 194 207 220 233 246 259

3 lamps

(BH type) With indicator lamp (built-in) and rear terminal block type

55 8.57

BHS-B

Panel mounting:

t=1 to 6mm (BH type)

(dimensions with rear terminal block)

Mounting hole

(5)

L1

15

(72) Mounting hole

Mounting panel: = to

For the BHS-B type, the maximum number of unit is 3. (6 contacts)

Pulling stroke:

●Lamp position ●Lamp position

No. of units 1 2 3 4 5 6 7 8 9 10

L(mm) For 1 indicator 1 lamp 1 lamp

56 69 82 95 108 121 134 147 160 173

L(mm) For 2 indicators 2 lamps 2 lamps

L(mm) For 3 indicators 69 82 95 108 121 134 147 160 173 186

3 lamps 3 lamps

The lamp power supply unit is not included in the above number of units.

A17

82.5 82.5

44.5 44.5

50

50

50

60

50

30

20

+0.5

53 0

Page18

●CONTROL SWITCH

CAM-OPERATED SWITCH

B TYPE, BH TYPE SWITCH

SPECIAL SPECIFICATION SWITCH CODING FOR ORDERING

5 Switch with indicator lamp (separate) ●The notches and specification are the same as 6 Switch with indicator lamp (built-in) ●Available notch: S, H, T, F and SB, SR, SY also

This is a switch that an indicator lamp is attached on top. those of the standard switches. This is a switch that a signal indicator is attached on top. available.

An indicator mounting hole is additionally required. ●For the circuit, voltage, and display color of the Part of lamp display ●For the circuit, voltage, and display color of the

Part of lamp display indicator, please see the following table and indicator lamp, please see the following table and

specify the corresponding numbers. BHS-S2-2B2A-235-LP-B specify the corresponding numbers.

BL-H2-2B2A-215-LD-B Circuit Voltage Display color Circuit Voltage Display color

1 For 1 indicator lamp 1 24V DC 1 W (Milky white) Notch code Circuit Handle code 1 For 1 indicator lamp 1 24V DC 1 W (Milky white)

Notch code Circuit Display Color of 2 For 2 indicator lamps 2 48V DC 2 R (Red) No. of units Contact code Display Color of 2 For 2 indicator lamps 2 48V DC 2 R (Red)

color handle / flange Code Switch

Code Switch Contact code 3 For 3 indicator lamps 3 100 / 110V DC 3 G (Green) color handle / flange 3 For 3 indicator lamps 3 100 / 110V DC 3 G (Green)

BHS BH type No. of contacts

BL B type No. of contacts Voltage 4 125V DC 4 O (Orange)

Voltage Handle code 4 125V DC 4 O (Orange)

BH type

BHI BH type No. of units 5 100 / 110V AC 5 GR 5 100 / 110V AC 5 GR

BHS-B (with rear

6 200 / 220V AC 6 GWR terminal block) 6 200 / 220V AC 6 GWR

7 30V DC 7 GOR 7 30V DC 7 GOR

9 Special 9 Special 9 Special 9 Special 9 Special 9 Special

OUTLINES OUTLINES

BL BHS

(B type) 55 (BH type)

8.57

Panel mounting:

t=1 to 6mm Panel cutout

50 +0.5 0

2-φ6

φ13

(5) N P

L1 Mounting hole

15 Mounting panel: = to

(72) 60

Mounting hole

●Lamp position

No. of units 1 2 3 4 5 6 7 8 9 10

L(mm) For 1 indicator 116 129 142 155 168 181 194 207 220 233 1 lamp

L(mm) For 2 indicators 129 142 155 168 181 194 207 220 233 246 2 lamps

BH I L(mm) For 3 indicators 142 155 168 181 194 207 220 233 246 259

3 lamps

(BH type) With indicator lamp (built-in) and rear terminal block type

55 8.57

BHS-B

Panel mounting:

t=1 to 6mm (BH type)

(dimensions with rear terminal block)

Mounting hole

(5)

L1

15

(72) Mounting hole

Mounting panel: = to

For the BHS-B type, the maximum number of unit is 3. (6 contacts)

Pulling stroke:

●Lamp position ●Lamp position

No. of units 1 2 3 4 5 6 7 8 9 10

L(mm) For 1 indicator 1 lamp 1 lamp

56 69 82 95 108 121 134 147 160 173

L(mm) For 2 indicators 2 lamps 2 lamps

L(mm) For 3 indicators 69 82 95 108 121 134 147 160 173 186

3 lamps 3 lamps

The lamp power supply unit is not included in the above number of units.

A18

82.5 82.5

44.5 44.5

50

50

50

60

50

30

20

+0.5

53 0

E CONTROL D ELECTRONIC DEVICES C

CONNECTING

DEVICES B

PILOT LAMP &

CENTER PARTS INDICATOR A SWITCH

Page19

●CONTROL SWITCH

CAM-OPERATED SWITCH

B TYPE, BH TYPE

SPECIAL SPECIFICATION SWITCH CODING FOR ORDERING

7 Lockout relay switch (Coil type) ●Max. unit No. is 8.

●Please see page A55 for the operation time.

BA-6 2A2B-DC24V-LP-B

Handle code Color of handle / flange

Code Switch

Code Operation voltage Code Operation voltage

BA-6 B type Contact code

DC24V 24V DC DC220V 200 / 220V DC

BHE BH type No. of contacts DC48V 48V DC AC110V 100 / 110V AC

DC110V 100 / 110V DC AC220V 200 / 220V AC

DC125V 125V DC

Circuit voltage 24V DC 48V DC 100 / 110V DC 125V DC 200 / 220V DC

Coil resistance 5.3Ω 25Ω 55Ω 80Ω 350Ω

OUTLINES

BA-6

(B type)

t =2.3 to 3.2 (standard)

(LOCK)

A

B

45°

Notch

Mounting hole

BHE

(BH type)

t = 1 to 3.2

Protective relay contact

(1)

(5) (7) (9) (11)

(2)

Coil

(4)

(6) (8) (10) (12)

(3)

Mounting hole

No. of units 1 2 3 4 5 6 7 8

L(mm) 104 117 130 143 156 169 182 195

Caution Reset operation on existence of external signal to coil is prohibited.

This may cause severe malfunction. (Ex. Coil burnout)

A19

Page20

SWITCH

8 Lockout relay switch (Solenoid type) ●Max unit No. is 10.

●High speed operation type.

●10 types of coils are available.

B-MR-2001-B-LP B

Contact arrangement Handle code Color of handle / flange

Code Operation method Code Operation voltage Code Operation voltage

MR Manual reset A 24V DC F 200 / 220V AC

B 100 / 110V DC G 48V DC

Code Switch C 125V DC H 125V DC

B B type D 200 / 220V DC I 100 / 110V AC・DC Coil code A B C D E F G H I J

BH BH type E 100 / 110V AC J 200 / 220V AC・DC Coil resistance 3.3Ω16.5Ω 27Ω 60Ω16.5Ω60Ω 13Ω 75Ω 60Ω 240Ω

OUTLINES

B-MR

(B type)

50 45°

(LOCK)

(2) A

B

(5) 7 45°

A 37

L 15 55 50 Notch

55

2- 6

Make contact Break contact

13 operation time operation time

Operating time T1 T2 T3

Mounting hole 8ms or less 16ms or less 8ms or less

BH-MR

(BH type)

Protective relay contact

50 (1)

45°

55

(2) (5) (7) (9) (11)

(2)

Coil

(4)

(6) (8) (10) (12)

(3)

7

(5)

A 37 At rated voltage

L 15 55 50 Coil input

30

Make (a)

No. of units 2 3 4 5 6 7 8 9 10 contact T1 Bounce

T2

A(mm) 57 70 83 96 109 122 135 148 161 Break (b)

13 contact

2- 6 L(mm) 94 107 120 133 146 159 172 185 198 T3

Mounting hole

Caution Reset operation on existence of external signal to coil is prohibited.

This may cause severe malfunction. (Ex. Coil burnout)

A20

55 40

55 40

30

60

50

58 58

55 55

95 95

E CONTROL D ELECTRONIC DEVICES C

CONNECTING

DEVICES B

PILOT LAMP &

CENTER PARTS INDICATOR A SWITCH