1/20ページ

Download(1Mb)

Document Information

| Document Title | I2C to CAN-Physical Transceiver LT3960 |

|---|---|

| Document Type | Product Catalog |

| File size | 1Mb |

| Company | Mouser Electronics (Documents List) |

Documents related to this company

Document Contents

Page1

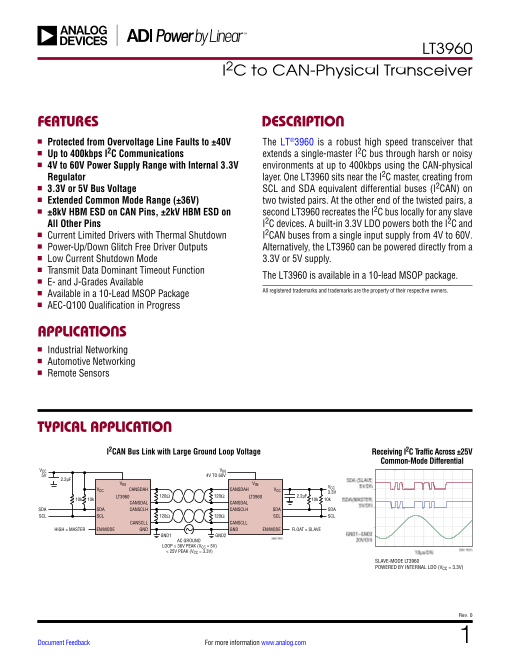

Features、Applications、Typical Application 、Description

LT3960

I2C to CAN-Physical Transceiver

FEATURES DESCRIPTION

n Protected from Overvoltage Line Faults to ±40V The LT®3960 is a robust high speed transceiver that

n Up to 400kbps I2C Communications extends a single-master I2C bus through harsh or noisy

n 4V to 60V Power Supply Range with Internal 3.3V environments at up to 400kbps using the CAN-physical

Regulator layer. One LT3960 sits near the I2C master, creating from

n 3.3V or 5V Bus Voltage SCL and SDA equivalent differential buses (I2CAN) on

n Extended Common Mode Range (±36V) two twisted pairs. At the other end of the twisted pairs, a

n ±8kV HBM ESD on CAN Pins, ±2kV HBM ESD on second LT3960 recreates the I2C bus locally for any slave

All Other Pins I2C devices. A built-in 3.3V LDO powers both the I2C and

n Current Limited Drivers with Thermal Shutdown I2CAN buses from a single input supply from 4V to 60V.

n Power-Up/Down Glitch Free Driver Outputs Alternatively, the LT3960 can be powered directly from a

n Low Current Shutdown Mode 3.3V or 5V supply.

n Transmit Data Dominant Timeout Function The LT3960 is available in a 10-lead MSOP package.

n E- and J-Grades Available

Available in a 10-Lead MSOP Package All registered trademarks and trademarks are the property of their respective owners.

n

n AEC-Q100 Qualification in Progress

APPLICATIONS

n Industrial Networking

n Automotive Networking

n Remote Sensors

TYPICAL APPLICATION

I2CAN Bus Link with Large Ground Loop Voltage Receiving I2C Traffic Across ±25V

Common-Mode Differential

VCC VIN

5V 4V TO 60V

2.2µF SDA (SLAVE)

VIN VIN 5V/DIV

VCC CANSDAH CANSDAH V VCC

CC 3.3V

10k 10k LT3960 120Ω 120Ω LT3960 2.2µF

10k 10k SDA(MASTER)

CANSDAL CANSDAL 5V/DIV

SDA SDA CANSCLH CANSCLH SDA SDA

SCL SCL 120Ω 120Ω SCL SCL

CANSCLL CANSCLL

HIGH = MASTER EN/MODE GND GND EN/MODE FLOAT = SLAVE

GND1 GND2 GND1–GND2

AC GROUND 3960 TA01 20V/DIV

LOOP ≤ 36V PEAK (VCC = 5V)

< 25V PEAK (VCC = 3.3V) 3960 TA01b

10µs/DIV

SLAVE-MODE LT3960

POWERED BY INTERNAL LDO (VCC = 3.3V)

Rev. 0

Document Feedback For more information www.analog.com 1

Page2

Absolute Maximum Ratings、Order Information、Pin Configuration

LT3960

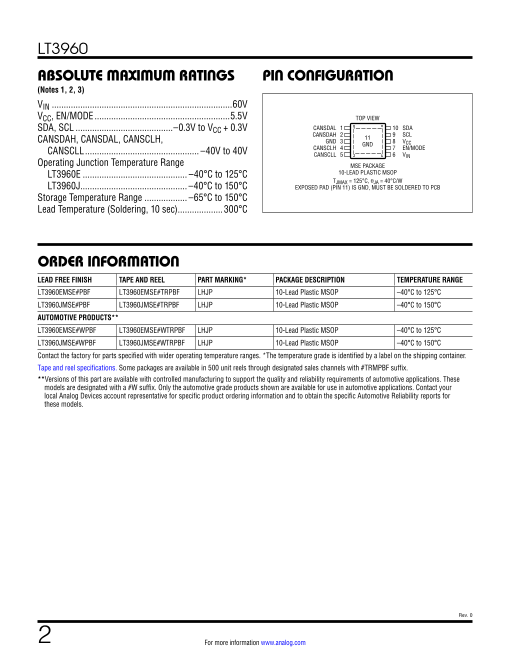

ABSOLUTE MAXIMUM RATINGS PIN CONFIGURATION

(Notes 1, 2, 3)

VIN ............................................................................60V

VCC, EN/MODE .........................................................5.5V TOP VIEW

SDA, SCL .........................................–0.3V to VCC + 0.3V CANSDAL 1 10 SDA

CANSDAH, CANSDAL, CANSCLH, CANSDAH 2

GND 3 11 9 SCL

GND 8 VCC

CANSCLL ................................................ –40V to 40V CANSCLH 4 7 EN/MODE

CANSCLL 5 6 VIN

Operating Junction Temperature Range MSE PACKAGE

LT3960E ............................................ –40°C to 125°C 10-LEAD PLASTIC MSOP

T = 125°C, θ = 40°C/W

LT3960J............................................. –40°C to 150°C JMAX JA

EXPOSED PAD (PIN 11) IS GND, MUST BE SOLDERED TO PCB

Storage Temperature Range .................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec) ................... 300°C

ORDER INFORMATION

LEAD FREE FINISH TAPE AND REEL PART MARKING* PACKAGE DESCRIPTION TEMPERATURE RANGE

LT3960EMSE#PBF LT3960EMSE#TRPBF LHJP 10-Lead Plastic MSOP –40°C to 125°C

LT3960JMSE#PBF LT3960JMSE#TRPBF LHJP 10-Lead Plastic MSOP –40°C to 150°C

AUTOMOTIVE PRODUCTS**

LT3960EMSE#WPBF LT3960EMSE#WTRPBF LHJP 10-Lead Plastic MSOP –40°C to 125°C

LT3960JMSE#WPBF LT3960JMSE#WTRPBF LHJP 10-Lead Plastic MSOP –40°C to 150°C

Contact the factory for parts specified with wider operating temperature ranges. *The temperature grade is identified by a label on the shipping container.

Tape and reel specifications. Some packages are available in 500 unit reels through designated sales channels with #TRMPBF suffix.

**Versions of this part are available with controlled manufacturing to support the quality and reliability requirements of automotive applications. These

models are designated with a #W suffix. Only the automotive grade products shown are available for use in automotive applications. Contact your

local Analog Devices account representative for specific product ordering information and to obtain the specific Automotive Reliability reports for

these models.

Rev. 0

2 For more information www.analog.com

Page3

Electrical Characteristics

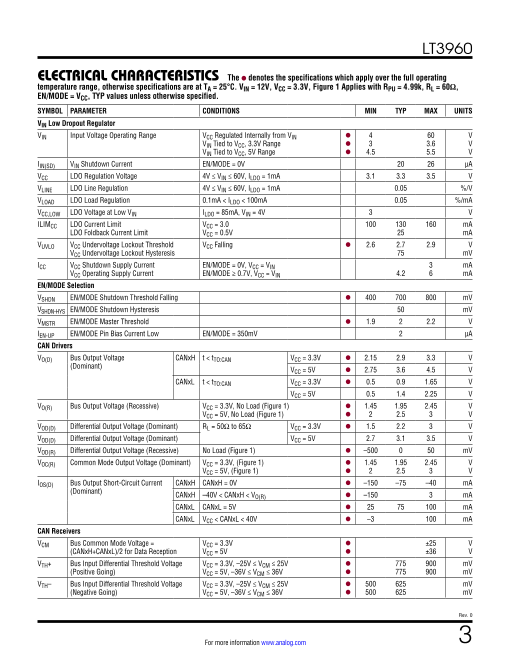

LT3960

E LECTRICAL CHARACTERISTICS The l denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VIN = 12V, VCC = 3.3V, Figure 1 Applies with RPU = 4.99k, RL = 60Ω,

EN/MODE = VCC, TYP values unless otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

VIN Low Dropout Regulator

VIN Input Voltage Operating Range VCC Regulated Internally from VIN l 4 60 V

VIN Tied to VCC, 3.3V Range l 3 3.6 V

VIN Tied to VCC, 5V Range l 4.5 5.5 V

IIN(SD) VIN Shutdown Current EN/MODE = 0V 20 26 µA

VCC LDO Regulation Voltage 4V ≤ VIN ≤ 60V, ILDO = 1mA 3.1 3.3 3.5 V

VLINE LDO Line Regulation 4V ≤ VIN ≤ 60V, ILDO = 1mA 0.05 %/V

VLOAD LDO Load Regulation 0.1mA < ILDO < 100mA 0.05 %/mA

VCC,LOW LDO Voltage at Low VIN ILDO = 85mA, VIN = 4V 3 V

ILIMCC LDO Current Limit VCC = 3.0 100 130 160 mA

LDO Foldback Current Limit VCC = 0.5V 25 mA

VUVLO VCC Undervoltage Lockout Threshold VCC Falling l 2.6 2.7 2.9 V

VCC Undervoltage Lockout Hysteresis 75 mV

ICC VCC Shutdown Supply Current EN/MODE = 0V, VCC = VIN 3 mA

VCC Operating Supply Current EN/MODE ≥ 0.7V, VCC = VIN 4.2 6 mA

EN/MODE Selection

VSHDN EN/MODE Shutdown Threshold Falling l 400 700 800 mV

VSHDN-HYS EN/MODE Shutdown Hysteresis 50 mV

VMSTR EN/MODE Master Threshold l 1.9 2 2.2 V

IEN-UP EN/MODE Pin Bias Current Low EN/MODE = 350mV 2 µA

CAN Drivers

VO(D) Bus Output Voltage CANxH t < tTO:CAN VCC = 3.3V l 2.15 2.9 3.3 V

(Dominant) VCC = 5V l 2.75 3.6 4.5 V

CANxL t < tTO:CAN VCC = 3.3V l 0.5 0.9 1.65 V

VCC = 5V 0.5 1.4 2.25 V

VO(R) Bus Output Voltage (Recessive) VCC = 3.3V, No Load (Figure 1) l 1.45 1.95 2.45 V

VCC = 5V, No Load (Figure 1) l 2 2.5 3 V

VOD(D) Differential Output Voltage (Dominant) RL = 50Ω to 65Ω VCC = 3.3V l 1.5 2.2 3 V

VOD(D) Differential Output Voltage (Dominant) VCC = 5V 2.7 3.1 3.5 V

VOD(R) Differential Output Voltage (Recessive) No Load (Figure 1) l –500 0 50 mV

VOC(R) Common Mode Output Voltage (Dominant) VCC = 3.3V, (Figure 1) l 1.45 1.95 2.45 V

VCC = 5V, (Figure 1) l 2 2.5 3 V

IOS(D) Bus Output Short-Circuit Current CANxH CANxH = 0V l –150 –75 –40 mA

(Dominant) CANxH –40V < CANxH < VO(R) l –150 3 mA

CANxL CANxL = 5V l 25 75 100 mA

CANxL VCC < CANxL < 40V l –3 100 mA

CAN Receivers

VCM Bus Common Mode Voltage = VCC = 3.3V l ±25 V

(CANxH+CANxL)/2 for Data Reception VCC = 5V l ±36 V

VTH+ Bus Input Differential Threshold Voltage VCC = 3.3V, –25V ≤ VCM ≤ 25V l 775 900 mV

(Positive Going) VCC = 5V, –36V ≤ VCM ≤ 36V l 775 900 mV

VTH– Bus Input Differential Threshold Voltage VCC = 3.3V, –25V ≤ VCM ≤ 25V l 500 625 mV

(Negative Going) VCC = 5V, –36V ≤ VCM ≤ 36V l 500 625 mV

Rev. 0

For more information www.analog.com 3

Page4

LT3960

ELECTRICAL CHARACTERISTICS The l denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VIN = 12V, VCC = 3.3V, Figure 1 applies with RPU = 4.99k, RL = 60Ω,

EN/MODE = VCC, TYP values unless otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

∆VTH Bus Input Differential Hysteresis Voltage VCC = 3.3V, –25V ≤ VCM ≤ 25V 150 mV

VCC = 5V, –36V ≤ VCM ≤ 36V 150 mV

RIN Input Resistance (CANxH and CANxL) SCL = SDA = VCC; RIN = ∆V/∆I; ∆I = ±20 µA l 25 35.7 50 kΩ

RID Differential Input Resistance SCL = SDA = VCC; RIN = ∆V/∆I; ∆I = ±20 µA l 50 71.4 100 kΩ

∆RIN Input Resistance Matching RIN (CANxH) to RIN (CANxL) l ±3 %

CIH Input Capacitance to GND (CANxH) (Note 4) 32 pF

CIL Input Capacitance to GND (CANxL) (Note 4) 8 pF

CID Differential Input Capacitance (Note 4) 8.4 pF

IL Bus Leakage Current (Power Off) VCC = 0V, CANxH = CANxL = 5V ±10 µA

VCC = 0V, CANxH = CANxL = 5V, t < 150°C l ±50 µA

I2C Port

VIL SDA, SCL Input Low Voltage l 0.4 V

VIH SDA, SCL Input High Voltage l 1.5 V

Ii SDA, SCL Input Leakage Current SDA = SCL = 0V to 5.5V –50 50 nA

Vhys SDA, SCL Input Hysteresis l 0.05 • VCC V

VOL1 SDA, SCL Output Low Voltage ISDA = 3mA l 0.4 V

tr Clock/Data Rise Time CB = Capacitance of One Bus Line (pF) (Note 5) 20 + 0.1CB 300 ns

tf Clock/Data Fall Time CB = Capacitance of One Bus Line (pF) (Note 5) 20 + 0.1CB 300 ns

Rev. 0

4 For more information www.analog.com

Page5

Switching Characteristics

LT3960

S WITCHING CHARACTERISTICS The l denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VIN = 12V, VCC = 3.3V, Figure 2 applies with RPU = 4.99k, RL = 60Ω,

EN/MODE = VCC, TYP values unless otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Transceiver Timing

fSCL SCL Clock Frequency (Notes 5,6) l 0 400 kHz

t I2C to I2PI2CBD CAN Dominant Propagation Delay (Figure 2, Figure 3) VCC = 3.3V l 45 80 130 ns

VCC = 5V l 45 75 115 ns

t I2C to I2PI2CBR CAN Recessive Propagation Delay (Figure 2, Figure 3) VCC = 3.3V l 80 120 170 ns

VCC = 5V l 60 90 120 ns

t 2

PBI2CD I CAN Dominant to I2C Propagation Delay (Figure 2, Figure 3) VCC = 3.3V l 25 40 65 ns

VCC = 5V l 25 40 65 ns

t 2

PBI2CR I CAN Recessive to I2C Propagation Delay (Figure 2, Figure 3) VCC = 3.3V l 25 45 80 ns

VCC = 5V l 20 35 60 ns

t 2

TO;CAN I CAN Dominant Timeout Time (Figure 2, Figure 4) l 0.5 1.5 2 ms

t 2

EN;I2C I C Driver Enable from Shutdown VCC = 3.3V or 5V (Figure 2, Figure 5) l 40 µs

t 2

EN;CAN I CAN Driver Enable from Shutdown VCC = 3.3V or 5V (Figure 2, Figure 6) l 40 µs

t 2

SHDN;I2C Time to Shutdown, I C (Figure 2, Figure 5) l 500 ns

tSHDN;CAN Time to Shutdown, I2CAN (Figure 2, Figure 6) l 500 ns

Note 1: Stresses beyond those listed under Absolute Maximum Ratings Note 3: The LT3960 includes overtemperature protection that is intended

may cause permanent damage to the device. Exposure to any Absolute to protect the device during momentary overload conditions. Junction

Maximum Rating condition for extended periods may affect device temperature will exceed the maximum operating junction temperature

reliability and lifetime. when overtemperature is active. Continuous operating above the specified

Note 2: The LT3960E is guaranteed to meet specified performance maximum operating junction temperature may impair device reliability.

from 0°C to 125°C. Specifications over the –40°C to 125°C operating Note 4: Pin capacitance given for reference only and is not tested in

temperature range are assured by design, characterization and correlation production.

with statistical process controls. The LT3960J is guaranteed to meet Note 5: Rise and fall times are measured at 30% and 70% levels.

performance specifications over the full –40°C to 150°C operating Note 6: Maximum SCL clock frequency will be affected by delays through

junction temperature range. High junction temperatures degrade operating the twisted-pair interface and I/O circuitry of other devices on the bus.

lifetimes. Operating lifetime is derated at junction temperatures greater These delays may limit the operation frequency to below the LT3960

than 125°C. maximum specification.

Note 7: The LT3960 does not support clock stretching. SCL should not be

pulled low by slave devices.

Rev. 0

For more information www.analog.com 5

Page6

Typical Performance Characteristics

LT3960

TYPICAL PERFORMANCE CHARACTERISTICS

TA = 25°C, VCC = 3.3V, RPU = 60Ω unless otherwise noted.

Supply Current (I2CAN Dominant) Supply Current (I2CAN Recessive) Supply Current (I2CAN Dominant)

vs VCC vs VCC vs Temperature

70 6.0 70

5.8

65 65

5.6

60 V = 5V

5.4 60 CC

55 5.2 55

5.0

50 4.8 50

V = 3.3V

45 4.6 CC

45

4.4

40 40

4.2

35 4.0 35

3 3.5 4 4.5 5 5.5 3 3.5 4 4.5 5 5.5 –50 –25 0 25 50 75 100 125 150

VCC (V) VCC (V) TEMPERATURE (˚C)

3960 G01 3960 G02 3960 G03

Supply Current (I2CAN Recessive) I2CAN Differential Output Voltage I2CAN Common Mode Voltage

vs Temperature (Dominant) vs Temperature (Dominant) vs Temperature

5.5 3.4 2.7

5.4 2.6

3.2 VCC = 5V

5.3 VCC = 5V 2.5

5.2 3.0 2.4

5.1 2.8 2.3

5.0

VCC = 3.3V 2.2

4.9 2.6 2.1

4.8 2.4 2.0

4.7 VCC = 3.3V 1.9

2.2 VCC = 3.3V

4.6 1.8

4.5 2.0 1.7

–50 –30 –10 10 30 50 70 90 110 130 150 –50 –25 0 25 50 75 100 125 150 –50 –25 0 25 50 75 100 125 150

TEMPERATURE (˚C) TEMPERATURE (˚C) TEMPERATURE (˚C)

3960 G04 3960 G05 3960 G06

CANxH Short-Circuit Current CANxH Short-Circuit Current I2C to CAN Propagation Delay

(Dominant) vs CANxH Voltage (Dominant) vs CANxH Voltage vs Temperature

0 100 70

–10 90

60

–20 80 DOMINANT

–30 70 50

–40 VCC = 5V 60 VCC = 3.3V

40

–50 50

–60 V 30

CC = 3.3V 40 VCC = 5V

–70 30 20

–80 20

10 RECESSIVE

–90 10

–100 0 0

–40 –35 –30 –25 –20 –15 –10 –5 0 5 0 5 10 15 20 25 30 35 40 –50 –25 0 25 50 75 100 125 150

CANXH (V) CANXL (V) TEMPERATURE (˚C)

3960 G07 3960 G08 3960 G09

Rev. 0

6 For more information www.analog.com

ICANXH(D) (mA)

ICC (mA) ICC(D) (mA)

ICANXL(D) (mA) VOD(D) (V) ICC(R) (mA)

TPI2CB (ns) VOC(D) (V) ICC(D) (mA)

Page7

LT3960

TYPICAL PERFORMANCE CHARACTERISTICS

TA = 25°C, VCC = 3.3V, RPU = 60Ω unless otherwise noted.

CAN to I2C Recessive Propagation EN/MODE Shutdown Thresholds EN/MODE Current vs Temperature

vs Temperature vs Temperature (VCC = 3.3V, 5V) (VEN/MODE = 0.35V)

120 900 2.6

850

2.5

110 800

DOMINANT

750 RISING 2.4

100 700 2.3

650 FALLING

90 2.2

600

80 RECESSIVE 550 2.1

500 2.0

70 450

1.9

400

60 350 1.8

–50 –25 0 25 50 75 100 125 150 –50 –25 0 25 50 75 100 125 150 –50 –25 0 25 50 75 100 125 150

TEMPERATURE (˚C) TEMPERATURE (˚C) TEMPERATURE (˚C)

3960 G10 3960 G11 3960 G12

VIN Shutdown Current VIN Quiescent Current

vs Temperature vs Temperature VCC vs Temperature (Various VIN)

24 220 3.6

VIN = 12V I = 1mA

210 CC

VCC = EN = 5V

22 200 3.5

190

20 180 3.4

170

18 160 3.3

150

16 140 3.2

130

14 120 3.1 VIN = 12V

110 VIN = 24V

VIN = 48V

12 100 3.0

–50 –25 0 25 50 75 100 125 150 –50 –25 0 25 50 75 100 125 150 –50 –25 0 25 50 75 100 125 150

TEMPERATURE (˚C) TEMPERATURE (˚C) TEMPERATURE (°C)

3960 G13 3960 G14 3960 G15

VCC vs Current (Various VIN) VCC UVLO vs Temperature VCC Current Limit vs VIN

3.40 2.80 160

VIN = 5V

3.35 VIN = 12V

V 2.78 140

IN = 24V

3.30 VIN = 48V RISING 120

2.76

3.25 100

2.74

3.20 80

2.72

3.15 60

FALLING

2.70

3.10 40

3.05 2.68 20

3.00 2.66 0

0 15 30 45 60 75 90 105 120 135 150 –50 –25 0 25 50 75 100 125 150 0 5 10 15 20 25 30 35 40 45 50 55 60

VCC CURRENT (mA) TEMPERATURE (°C) VIN (V)

3960 G16 3960 G17 3960 G18

Rev. 0

For more information www.analog.com 7

VCC (V) IIN(SD) (μA) TPBI2C (ns)

VCC UVLO (V) IIN(Q) (μA) VSHDN (V)

ILIMCC (mA) VCC (V) IEN–UP (μA)

Page8

Pin Functions、Block Diagram

LT3960

PIN FUNCTIONS

CANSDAL (Pin 1): Low Level CAN Bus Line. Carries the EN/MODE (Pin 7): MODE/Shutdown pin. Tie above 2.5V

I2C data bus. to select master mode, float pin to select slave mode, or

CANSDAH (Pin 2): High Level CAN Bus Line. Carries the pull this pin to ground for low-power shutdown mode.

I2C data bus. VCC (Pin 8): Low Dropout Regulator Output and Device

CANSCLH (Pin 4): High Level CAN Bus Line. Carries the Power Supply Input. Bypass this pin with a 2.2µF or

I2C clock bus. greater capacitor to ground. Any bypass capacitors must

be located as close to the pin as possible.

CANSCLL (Pin 5): Low Level CAN Bus Line. Carries the

I2C clock bus. SCL (Pin 9): Clock Input or Output Pin for the I2C Serial

Port. When EN/MODE is 2.5V or above, the SCL pin is

GND (Pin 3 and Exposed Pad): Ground. Solder the an input for the master clock. When EN/MODE is float-

exposed pad and pin directly to the ground plane. ing, the SCL pin is an output for data received on the

V (Pin 6): Input Voltage Supply. This pin is the power CANSCLH/L pins.

IN

supply input to the LDO. It must be locally bypassed with SDA (Pin 10): Data Input and Output Pin for the I2C

a 1µF filter capacitor to GND as close to the pin as possi- Serial Port.

ble. If the LDO function is unused, tie VIN to VCC.

BLOCK DIAGRAM

VIN

4V TO 60V

6

VIN

–

0.5V 3.3V

+ SHUTDOWN

VCC VCC

V 2 8

CC EN/MODE I C MASTER V

7 CC 2.2μF

RPU TX TIMEOUT PREDRIVE

SCL

9 MODE

SELECT

35.7k

+ CANSCLH

4

35.7k CANSCLL

– 5

VCC 1.1k 1.1k

1.95V FOR VCC = 3.3V

+ 2.5V FOR VCC = 5V

SHUTDOWN

–

VCC VCC

1.1k 1.1k

RPU TX TIMEOUT PREDRIVE

10 SDA

READ/WRITE 35.7k

ARBITRATION + CANSDAH

2

35.7k CANSDAL

11 – 1

3 GND

3960 BD

Rev. 0

8 For more information www.analog.com

+

–

Page9

Test Circuits

LT3960

TEST CIRCUITS

VCC

5V

1µF VIN CANSDAH

RL/2

CANSDAH 30.1Ω

EN/MODE 1%

VCC VCC CM

R SDA

RPU RPU 2.2µF CANSDAL L/2

30.1Ω

4.99k 4.99k 1%

SDA SDA CANSDAL

LT3960

CANSCLH

RL/2

CANSCLH 30.1Ω

SCL SCL 1%

CM

R SCL

CANSCLL L/2

30.1Ω

1%

GND CANSCLL

3960 F01

Figure 1. All Electrical Characteristic Measurements

VCC

5V

1µF VIN CANSDAH

RL/2

EN/MODE CANSDAH 30.1Ω

1% C

V L

CC VCC CM

R SDA 100pF

RPU RPU 2.2µF CANSDAL L/2

30.1Ω 4.7nF

1k 1k 1%

SDA SDA CANSDAL

LT3960

15pF CANSCLH

RL/2

CANSCLH 30.1Ω

SCL SCL 1%

CM CL

R SCL

15pF 100pF

CANSCLL L/2

30.1Ω 4.7nF

1%

GND CANSCLL

3960 F02

Figure 2. All Switching Characteristic Measurements

Rev. 0

For more information www.analog.com 9

Page10

Timing Diagrams

LT3960

TIMING DIAGRAMS

HIGH

SCL (MASTER) 0.7VDD

0.3VDD LOW

CANSCLH HIGH

SCL (MASTER) 0.3VDD LOW

CANSCLL

CANSCLH

DOMINANT

V CANSCLL

OD 0.9V

0.5V

RECESSIVE DOMINANT

HIGH V 0.9V

SCL (SLAVE) 0.7V OD

0.3V DD

DD 0.5V

LOW RECESSIVE

tPI2CBD tPI2CBR tTO;CAN

t 3960 F04

PBI2CD tPBI2CR 3960 F03

Figure 3. Transceiver Data Propagation Timing Diagram Figure 4. I2CAN Dominant Timeout

1.2V (SLAVE MODE) 2.5V (MASTER MODE)

EN 0.75V 0.7V EN 0.75V 0.7V

SCL OR SDA 0.7VCC

0.3V SCL OR SDA

DD 0.3VDD

tEN;I2C tSHDN;I2C tEN;CAN tSHDN;CAN

CANxH CANxH CAN

CANxL CANxL

V 0.9V V 0.9V

OD OD

0.5V 0.5V

3960 F05 3960 F06

Figure 5. I2CAN Enable and Disable Times Figure 6. I2CAN Enable and Disable Times

Rev. 0

10 For more information www.analog.com

Page11

Operation

LT3960

OPERATION

The LT3960 is a high-speed transceiver which creates the the VCC pin from which the transceivers and bus lines are

functional equivalent of a single-master I2C bus in the CAN powered. Alternatively, the LT3960 can by powered from

physical layer and is powered from a single wide-ranging a supply voltage of 3.3V or 5V on VIN, bypassing the LDO

input voltage. Using two integrated CAN transceivers, the by shorting VCC to VIN.

LT3960 creates a differential proxy for each of the sin-

2 The EN/MODE pin is used to put the LT3960 in low power

gle-ended I C clock and data signals which is capable shutdown mode and selects between Master and Slave

of traversing harsh or noisy environments across two modes of operation when enabled. When the EN/MODE

twisted pairs. pin is below 0.7V, (typical) the LT3960 is in shutdown

Each transceiver consists of a transmitter and receiver, mode, disabling both the LDO and transceivers. When

capable of quickly converting a single-ended I2C domi- VIN is powered, floating the EN/MODE pin or driving it

nant signal into a differential dominant signal, and vice between 0.7V and 2.0V (typical) enables the LDO and

versa. The transmitter is a current-regulated differential sets the transceiver in Slave Mode. An EN/MODE voltage

driver that generates a differential voltage between the above 2.0V (typical) with VIN is powered sets the LT3960

CANxH and CANxL pins determined by drive current and in Master Mode.

the equivalent resistive load on the CANx bus. Common- Bidirectional communication is supported on the data

mode voltage of the CANx bus is regulated by the trans- channel (SDA and CANSDA) regardless of the mode of

mitter when driving dominant as described in the applica- operation. Communication on the clock channel (SCL

tions section. The receiver is a CAN compatible differential and CANSCL) is unidirectional, with the direction deter-

receiver with a wide common-mode range of ±25V or mined by the selected mode of operation. In Slave Mode,

±36V, depending on VCC voltage. an LT3960 only communicates clock signals from the

In the simplest setup, two LT3960 devices are used CANSCL bus to the SCL bus. Any LT3960 connected to

(Figure 7). The first is connected to the I2C master (micro- slave I2C devices should be operated in Slave Mode. In

controller or otherwise). The second LT3960 is connected Master Mode, an LT3960 only communicates clock sig-

to the first by two twisted pairs and regenerates the I2C nals from the SCL bus to the CANSCL bus. The LT3960

bus locally for one or more I2C slave devices. The LT3960 connected to the I2C master device should always be

devices transmit the clock signal in only one direction, operated in Master Mode. Regardless of the number of

from master to slave. Bidirectional communication of the LT3960 devices tied to a I2CAN bus in a given applica-

data signal is always permitted. tion, exactly one will operate in Master Mode, driving the

The LT3960 contains an integrated LDO which regulates clock signal to the I2CAN bus and, ultimately, to all I2C

an input from the V pin between 4V and 60V to 3.3V on slave devices. The LT3960 does not support multi-master

IN I2C systems.

CIRCUIT BOARD 1 CIRCUIT BOARD 2

3.3V OR 5V 4V TO 60V

VIN VIN

VCC CANSDAH CANSDAH EN/MODE

µCONTROLLER LT3960 LT3960 VCC

CANSDAL CANSDAL I2C

SDA SDA CANSCLH CANSCLH SLAVE

SCL SCL SDA SDA

DIG I/O EN/MODE CANSCLL CANSCLL SCL SCL

GND GND

3960 F07

Figure 7. Simple Single-Slave Application

Rev. 0

For more information www.analog.com 11

Page12

LT3960

OPERATION

Data Transmission Detail CANSDA bus. The primary factor determining the direction

The timing diagram in Figure 8 shows how a byte of data of communication is the time of arrival of dominant sig-

is sent by the I2C master and acknowledged by the I2C nals on SDA and CANSDA. The first of SDA and CANSDA

slave in the single-master single-slave system described to be asserted dominant by an external device will cause

in Figure 7. The I2C master issues a start command to the LT3960 to drive the other dominant, establishing the

initiate a communication frame. The LT3960 connected to direction of communication until it is released and returns

the master drives the CANSCL and CANSDA buses dom- to a recessive state. The transmitter which opposes the

inant in response to the change in state on the SCL and established direction of communication will be blocked

SDA pins without interpretation or delay. The LT3960 con- until it can be safely re-enabled without locking up a bus

nected to the I2C slave receives the dominant signals on or misinterpreting the direction of communication. To

the CANSCL and CANSDA buses and drives the slave SCL fully describe the method of arbitration, communication

and SDA pins dominant without interpretation or delay. in each direction is described in detail below.

The result on the slave I2C bus is an I2C Start command In the default state, SDA and CANSDA are in a recessive

nearly identical to that generated by the master, delayed by state and no direction of communication is set. If SDA is

propagation delays of the master LT3960, twisted pairs, asserted dominant (low) by an external I2C device from

and slave LT3960. a default state, the LT3960 will drive CANSDA dominant

As additional clock and data edges are written by the I2C and the LT3960’s receiver on CANSDA is blocked from

master, they too are recreated, first on the CANSCL and driving SDA. When the SDA line is eventually released by

CANSDA buses and then on the slave I2C bus. Once the the external I2C device and returns to a recessive state,

entire byte of data is written on the slave I2C bus, the I2C the LT3960 stops driving the CANSDA bus dominant.

slave device issues an ACK, pulling down SDA to acknowl- After allowing the CANSDA bus sufficient time to return

edge receipt of a valid byte. The slave LT3960 recognizes to a passive state as required by the CAN physical layer

that a slave I2C device is driving the SDA line dominant specifications, the LT3960 reopens the possibility of bidi-

and switches from receiving to transmitting to drive the rectional traffic and waits for a dominant signal on SDA or

CANSDA bus dominant. The master LT3960 then receives CANSDA to once again set a direction for communication.

the ACK on the CANSDA bus and pulls the master SDA If, from the default state, CANSDA is asserted dominant

low, communicating the ACK to the master. by another LT3960 on the bus while SDA remains reces-

Note that clock data is always transmitted from master to sive (high), the LT3960 will drive SDA dominant (low)

slave, but the LT3960 dynamically switches the direction and the CAN transmitter is blocked from driving CANSDA

of SDA communication based primarily on the time of based on its input while CANSDA is held dominant. When

arrival of dominant signals on its inputs. the CANSDA bus returns to a recessive state, the LT3960

stops driving the other dominant. When it is safe to do so

Bidirectional Arbitration of SDA without causing glitches or latch up, the LT3960 reopens

The LT3960 facilitates bidirectional SDA communication the possibility of bidirectional traffic and waits for a dom-

between master and slave I2C devices by dynamically inant signal on SDA or CANSDA to once again set a direc-

controlling the direction of traffic between SDA and the tion for communication.

Rev. 0

12 For more information www.analog.com

Page13

LT3960

OPERATION

I2C START I2C STOP

SCL (MASTER)

SDA (MASTER) 1 1 0 0 1 1 0 0 ACK

MASTER

LT3960

CANSCL

CANSDA ACK

TWISTED PAIRS

CANSDA ACK

CANSCL

SLAVE

LT3960

I2C START I2C STOP

SCL (SLAVE)

SDA (SLAVE) 1 1 0 0 1 1 0 0

3960 F08

ACK FROM I2C SLAVE

Figure 8. Simple Single-Slave Application

Rev. 0

For more information www.analog.com 13

Page14

Applications Information

LT3960

APPLICATIONS INFORMATION

Supply Voltage Ranges 3.3V OR 5V

BUS VOLTAGE

The LT3960 can be operated with or without using its VCC VIN

2.2µF V

internal LDO. Tying VIN to VCC and powering directly from 30k CC

LT3960

µCONTROLLER

a 3.3V or 5V supply will bypass the LDO. With a 5V supply EN/MODE

on VCC, transmitter common-mode voltage and receiver I/O EN

common-mode input range are increased from their 3.3V 3960 F09

values. In this configuration, an internal comparator mon-

itors the supply voltage and switches internal reference Figure 9. Recommended Master Mode Power Setup

voltages and output drive strengths at approximately An LT3960 connected to slave I2C devices must be oper-

4.1V. Operation with a supply between 3.6V and 4.5V is ated in Slave Mode, with the EN/MODE pin between 0.7V

not recommended, because of the discontinuity in the and 2V. When left floating, the EN/MODE pin will pull

internal voltages at this switch point. up to approximately 1.2V, enabling the LT3960 and set-

When using the internal LDO to generate the 3.3V bus ting it in Slave Mode, whenever the VIN pin is powered

supply on VCC, any VIN supply voltage between 4V and above approximately 2V. It is recommended that the EN/

60V is allowed. In this configuration, the switch point MODE pin be left floating for Slave Mode LT3960 devices,

mentioned above is avoided since VCC is regulated to a regardless of whether the internal LDO is employed.

fixed 3.3V. LT3960 and Standard CAN Transceivers

An LT3960 operating with a VCC at 5V may share an I2CAN

bus with an LT3960 operating with V at 3.3V. However, It should be noted that while the LT3960 uses the CAN

CC 2

the fluctuation in common mode voltage between 1.95V physical layer to conduct bidirectional I C data, the

(when an LT3960 with VCC = 3.3V is dominant) and CANSCL and CANSDA buses created by the LT3960 are

2.5V (when an LT3960 with V = 5V is dominant) may not traditional CAN buses carrying traditional CAN data. As

CC

increase electromagnetic emissions. such, the CANSCL and CANSDA buses between LT3960

devices cannot be shared with standard CAN transceivers

Master and Slave Mode Configurations in a multidrop configuration.

The LT3960 connected to the I2C master must be oper- ±40V Fault Protection

ated in Master Mode, with the EN/MODE pin driven greater

than 2.5V. When operating in Master Mode, it is recom- The LT3960 provides ±40V fault protection on the

2

mended that VCC be tied to V and driven from a bus I CAN interface pins (CANSCLH, CANSCLL, CANSDAH,

IN 2

voltage of 3.3V or 5V. Additionally, EN/MODE should be CANSDAL), allowing I C communication in applications

driven from a digital output pin from the I2C Master as where it was previously impractical. Addressing the need

shown below. In this configuration, EN/MODE can be held the overvoltage tolerance in many industrial and auto-

low until the V cap is fully charged. motive applications, the driver outputs use a progressive

CC foldback current limit to protect against overvoltage faults

Do not tie the EN/MODE pin directly to VCC when oper- while still allowing high current output drive. The LT3960

ating in Master Mode. With EN/MODE and VCC shorted, is protected from ±40V faults powered or unpowered,

every power-up sequence will set the LT3960 into slave even in the case of VCC open or shorted to ground. When

mode for many microseconds while the VCC capacitor VCC is open or shorted to GND, the transceivers are off and

charges between the enable threshold and the Master the I2CAN bus pins remain in the high impedance state.

Mode threshold.

Rev. 0

14 For more information www.analog.com

Page15

LT3960

APPLICATIONS INFORMATION

±8kV ESD Protection in the dominant state. For example, if the SCL line is held

The LT3960 features robust ESD protection. All I2CAN low in Master Mode, a dominant state is asserted on the

interface pins (CANSCLH, CANSCLL, CANSDAH, CANSCL bus until the timer expires, after which the driver

CANSDAL) are protected to ±8kV HBM with respect to releases the bus to a recessive state. The timer is reset

GND, powered or unpowered and all other pins are pro- when SCL is brought high.

tected to 2kV HBM to ensure reliable operation in severe I2CAN Driver Overvoltage, Overcurrent, and

environmental conditions. For applications where greater Overtemperature Protection

ESD protection of interface pins is needed, a simple net-

work providing IEC 61000-4-2 Level 4 ESD protection is The I2CAN driver outputs are protected from short cir-

shown in the Typical Application section. cuits to any voltage within the absolute maximum range

of -40V to 40V. The maximum current on I2CAN interface

±36V Extended Common-Mode Range pins in a fault condition is ±150mA. The drivers include a

The LT3960 receiver features an extended common progressive foldback current limiting circuit that contin-

mode range of -36V to 36V when operating from a 5V uously reduces the driver current with increasing output

V and -25V to 25V when operating from a 3.3V V . fault voltage. The fault current is typically ±2mA for faults

CC CC

The wide common mode increases the reliability of oper- at the absolute maximum voltages of ±40V.

ation in environments with electrical noise or local ground The LT3960 also features thermal shutdown protection

potential differences due to ground loops. This extended that disables the chip in the case of excessive power

common mode range allows the LT3960 to conduct I2C dissipation from the drivers. When the die temperature

communication in environments inhospitable to standard exceeds 168 ˚ C (typical), the LT3960 is forced into shut-

I2C, such as between two distant PCBs in an automobile. down mode and the I2CAN drivers enter a high impedance

state.

I2CAN Driver

When the SCL or SDA pin is asserted low by external Power-Up/Down Glitch-Free Outputs

I2C device and the conditions are met (whether by mode The LT3960 employs an undervoltage monitoring circuit

selection or bidirectional arbitration) to propagate this on the VCC supply to control the activation of the trans-

data from I2C to CAN, the I2CAN driver asserts the dom- ceiver circuitry. During start-up SDA, SCL, and all I2CAN

inant state on the corresponding bus lines; the CANxH outputs are in a high impedance state until VCC reaches a

driver pulls high and the CANxL driver pulls low. When the voltage sufficient to reliably operate the chip. At this point,

SCL or SDA pin is high under these same conditions, the if EN/MODE is out of its shutdown region, the chip acti-

I2CAN driver is in the recessive state; both the CANxH and vates. The CANSCL and CANSDA receivers activate after

CANxL drivers are in the high impedance state and the bus a short delay tEN;I2C allowing SCL or SDA to follow the

termination resistor equalizes the voltage on CANxH and state of CANSCL or CANSDA. The CANSCL and CANSDA

CANxL. In the recessive state, the impedance on CANxH drivers power up in the transmit dominant timeout state

and CANxL is determined by the receiver input resistance, regardless of the state of SCL or SDA and remain in the

RIN. When EN/MODE is low or the VCC is in UVLO, the recessive state until the first high to low transition of SCL

LT3960 is in shutdown; all I2CAN drivers are in the high or SDA, respectively. This assures that the LT3960 does

impedance state, and the receiver input resistance RIN is not disturb the I2CAN bus by glitching to the dominant

disconnected from the bus by a FET switch. state during start-up.

Transmit Dominant Timeout Function During power-down, similar protection exists. When the

undervoltage detection circuit senses low supply voltage

Both transceivers in the LT3960 include a 1.5ms (typical) on VCC, it immediately puts the chip into shutdown. All

timer to limit the time that driver can hold the I2CAN bus I2C and I2CAN pin outputs go the high impedance state.

Rev. 0

For more information www.analog.com 15

Page16

LT3960

APPLICATIONS INFORMATION

Passive Leakage on I2CAN Bus Pins RESISTOR TERMINATION

When the power supply is removed or the chip is in shut- CANxH CANxH BUS

down, the I2CAN pins are in a high impedance state. The LT3960 120Ω

I2CAN receiver inputs are isolated from the CANxH and

CANxL pins by FET switches which open in the absence CANxL CANxL BUS

of power, preventing the resistor dividers on the receiver

inputs from loading the bus. The high impedance state SPLIT TERMINATION

of I2CAN pins is maintained over a range determined by CANxH CANxH BUS

the ESD protection of the pins, typically -0.3V to 7V. For 60Ω

LT3960

bus voltages outside this range, the current flowing into 60Ω 4.7nF

the receiver is governed by the conduction voltages of CANxL CANxL BUS

3960 F10

the ESD device and the 35.7k nominal I2CAN receiver

input resistance. Figure 10. Split Termination for Improved

Common Mode Behavior

I2CAN Bus Termination

VCC = 3.3V

I2

SDA

CAN buses must be terminated at the ends of each 5V/DIV

twisted pair with a 120Ω resistor. Split termination is an CANSDAH

optional termination technique to reduce common mode 1V/DIV

voltage perturbations that can produce EME. A split ter- CANSDAL

1V/DIV

minator divides the single line-end termination resistor CANSDA CM

(nominally 120Ω) into two series resistors of half the 50mV/DIV

value of the single termination resistor (Figure 10). 3960 F11

200ns/DIV

The center point of the two resistors is connected to a Figure 11. I2CAN Common Mode Noise (4.7nF Split Cap)

4.7nF capacitor. Split termination suppresses common

mode voltage perturbations by providing a low impedance VCC = 3.3V

SDA

load to common mode noise sources such as transmitter 5V/DIV

noise or coupling to external noise sources. In the case CANSDAH

1V/DIV

of single resistor termination, the only load on a com-

mon mode noise source is the parallel impedance of the CANSDAL

1V/DIV

input resistors of the I2CAN transceivers on the bus. This CANSDA CM

results in a common mode impedance of several kΩ for a 500mV/DIV

3960 F12

small network. The split termination, on the other hand, 200ns/DIV

provides a common mode load equal to the parallel resis- Figure 12. I2CAN Common Mode Noise (No Split Cap)

tance of the two split termination resistors (30Ω). This

low common mode impedance results in a reduction of

the common mode noise voltage compared to the much

higher common mode impedance of the single resistor

termination. Figure 11 and Figure 12 compare the com-

mon mode noise of an application with and without split

cap termination.

Rev. 0

16 For more information www.analog.com

Page17

LT3960

APPLICATIONS INFORMATION

Multidrop Applications of the propagation delays (tPI2CBD and tPBI2CD), slave ACK

The LT3960 can be used in a multidrop setup, employ- time (tVD;ACK), and master data setup time (tSU;ACK). This

ing multiple slave-mode LT3960’s to generate multiple requirement is shown explicitly in Equation 1.

local I2C buses on multiple PCBs along the length of the tLOW >2(tPI2CBD,max + tCABLE + tPBI2CD,max )

I2CAN bus lines. No additional termination is required in +t (1)

VD;ACK,max + tSU;ACK

a multidrop system, but some care must be taken in the

design of such systems. The stub length, or the distance A conservative estimate of propagation delay

from twisted pairs to any additional LT3960, should be through a twisted pair based on cable length is shown in

less than 0.3m. Stub lengths to the CANSDA and CANSCL Equation 2. Equation 2 is useful for rough estimates, but

buses should be as close as possible in length to avoid when designing applications always calculate propaga-

adding unequal transmission delays to the clock and tion delay based on the actual physical properties of the

data signals. cabling used for the I2CAN bus lines.

120Ω 120Ω

t = ICABLE

CABLE (2)

0.15m/ns

I2C SLAVE LT3960

Fast-mode (400kHz capable) I2C devices are allowed 0.9µs

to acknowledge a valid data byte, even while ACK times

(tVD;ACK) are often much shorter in practice. A tVD;ACK of

0.9µs would limit the data transmission rate of a LT3960

I2C SLAVE LT3960 application to under 400kHz for even one meter of twisted

pair. For this reason, it is recommended that all I2C slaves

be Fast-mode Plus (1MHz) devices instead of Fast-mode

(400kHz) devices when attempting to maximize trans-

I2C SLAVE

LT3960 mission rate. The shorter maximum tVD;ACK (450ns) of

I2C SLAVE Fast-mode plus devices allows for communication across

120Ω 120Ω

3960 F14 a greater distance at any given clock speed. Figure 14

consolidates the information above, plotting maximum

Figure 13. Multidrop Setup clock speeds for a given bus length for applications with

Maximum Data Transmission Rate fast-mode and fast-mode plus devices.

Successful communication in any I2C application is 450

dependent on slave I2C devices’ timely acknowledgment 425

(or ACK) upon receiving a byte of data. Specifically, I2C 400

slaves must assert the SDA line after the eighth clock 375

pulse leaving enough setup time before the ninth rising 350

edge of SCL to guarantee that the ACK will be received by 325

the I2C master. This requirement is straightforward when 300

275

all I2C devices share the same I2C bus, but in LT3960

250

applications where master and slave I2C buses are sepa-

225 FAST–MODE SLAVE DEVICES

rated by various propagation delays, extra care must be FAST–MODE PLUS SLAVE DEVICES

200

taken to ensure that ACKs from slave I2C devices will be 0 5 10 15 20 25 30 35 40 45 50

received by the I2C master at the desired transmission BUS LENGTH (m)

3960 F14

rate. In LT3960 applications, the SCL low period between

successive clock pulses (tLOW)must be less than the sum Figure 14. Maximum I2CAN Clock Speed

Rev. 0

For more information www.analog.com 17

MAX CLOCK SPEED (kHz)

Page18

Typical Applications

LT3960

TYPICAL APPLICATIONS

1A Matrix LED Dimmer with Remote I2C Control

31V TO 36V

(ENABLED AT 33V,

SHUTDOWN AT 31V) LED1+

VIN1 BST1

10µF 2.2µF 0.22µF

×2 50V 68µH 100mΩ LED1+

50V 100k GND SW1 DRN8 VIN 31V TO 36V

1MΩ 100nF 10k 1µF

50V 50V

EN/UVLO FB1 10µF SRC8 ENH

DRN7

3.92k 274k 31.6k 49.9k

LT3964

SRC7 LT3967

+

INTV DRN6 LED1

INTV CC INTV

CC VDD CC

INTVCC ISP1 SRC6 1µF

2.2µF PWM1 ISN1 DRN5 GND 100k

INTVCC

CTRL1 SRC5 ALERT ALERT

PWMTG1 DRN4

ADDR1 499k ADDR4 INTVCC

ADDR-1100011 ADDR3 ADDR-0101100

ADDR2 TSET SRC4 ADDR2

DRN3 ADDR1 POR-LED OFF

SYNC/CLKOUT CLOCK 165k UP TO 26V LED 22k

ALERT ALERT SRC3 RTCLK CLOCK

DRN2

SCL RT WDI 28k (FROM

178k SRC2 10nF LT3964)

SDA GND 360kHz DRN1

SCL

SRC1 SDA

2-WIRE I2C INTERFACE

1µF

3.3V

OR 5V 2.2µF VIN VIN

V CANSDAH CANSDAH V

μCONTROLLER CC CC

I2C MASTER LT3960 120Ω 120Ω LT3960 2.2µF

5k 5k 10k 10k

CANSDAL CANSDAL

SDA SDA CANSCLH CANSCLH SDA

SCL SCL 120Ω 120Ω SCL

DIG I/O EN/MODE CANSCLL CANSCLL EN/MODE

GND GND GND

3960 TA03

GND1 GND2

REMOTE I2C MASTER

Rev. 0

18 For more information www.analog.com

Page19

LT3960

PACKAGE DESCRIPTION

MSE Package

10-Lead Plastic MSOP, Exposed Die Pad

(Reference LTC DWG # 05-08-1664 Rev I)

BOTTOM VIEW OF

EXPOSED PAD OPTION

1.88 ±0.102 1.88

(.074 ±.004) 0.889 ±0.127 1 (.074) 0.29

(.035 ±.005) 1.68 REF

(.066)

5.10 0.05 REF

(.201) 1.68 ±0.102 3.20 – 3.45

MIN (.066 ±.004) (.126 – .136) DETAIL “B”

CORNER TAIL IS PART OF

DETAIL “B” THE LEADFRAME FEATURE.

10 FOR REFERENCE ONLY

0.50 NO MEASUREMENT PURPOSE

0.305 ± 0.038 (.0197) 3.00 ±0.102

(.0120 ±.0015) BSC (.118 ±.004)

TYP 0.497 ±0.076

(NOTE 3) (.0196 ±.003)

RECOMMENDED SOLDER PAD LAYOUT 10 9 8 7 6

REF

4.90 ±0.152 3.00 ±0.102

(.193 ±.006) (.118 ±.004)

DETAIL “A” (NOTE 4)

0.254

(.010) 0° – 6° TYP

GAUGE PLANE 1 2 3 4 5

0.53 ±0.152 1.10 0.86

(.021 ±.006) (.043) (.034)

MAX REF

DETAIL “A”

0.18

(.007) SEATING

PLANE 0.17 – 0.27 0.1016 ±0.0508

(.007 – .011)

0.50 (.004 ±.002)

TYP

(.0197) MSOP (MSE) 0213 REV I

NOTE:

1. DIMENSIONS IN MILLIMETER/(INCH) BSC

2. DRAWING NOT TO SCALE

3. DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH, PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

4. DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

5. LEAD COPLANARITY (BOTTOM OF LEADS AFTER FORMING) SHALL BE 0.102mm (.004") MAX

6. EXPOSED PAD DIMENSION DOES INCLUDE MOLD FLASH. MOLD FLASH ON E-PAD

SHALL NOT EXCEED 0.254mm (.010") PER SIDE.

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no responsibility is assumed by Analog

Devices for its use, nor for any infringements of patents or other rights of third parties that may result from its use. Specifications

subject to change without notice. No license Fiso gr rmanoterde biny fiomrpmlicaattiion owr wotwhe.arwniasleo ugn.cdeorm any patent or patent rights of Analog Devices. 19

Page20

Typical Application、Related Parts

LT3960

TYPICAL APPLICATION

Network for IEC 6100-4-2 Level 4 ESD Protection

CANSDAL CANSDAL

60.4Ω CANSDAH

4.7nF

60.4Ω TVS

CANSDAH

GND GND LT3960

CANSCLH

60.4Ω TVS

4.7nF

60.4Ω CANSCLH

CANSCLL CANSCLL

3960 TA02

TVS: ON SEMI NUP2105L, 350W DUAL BIDIRECTIONAL TVS DIODE, SOT-23

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT3965 8-Switch Matrix LED Dimmer I2C Multidrop Serial Interface, 16 Unique I2C Addresses, VDD Range: 2.7V to 5.5V,

VIN Range: 8V to 60V, Digital Programmable 256:1 PWM Dimming, 28-Lead TSSOP

LT3967 1.3A Eight-Switch Matrix LED Controls LED Dimming of Strings Up to 54V, I2C Serial Interface with Programmable

Dimmer with CRC-8 Address, 28-Lead TSSOP

LT3964 Dual 36V Synchronous 1.6A Buck Wide Input Voltage Range: 4V to 36V, Two Independent 1.6A/40V Synchronous Bucks,

LED Driver with I2C I2C Interface for Internal True Color PWM™ Dimming (8192:1), 36-Lead QFN

LTC4331 I2C Slave Device Extender Over Up to 1MHz Serial Clock, Fast-Mode Plus (FM+), Selectable Link Baud Rates Extend I2C

Rugged Differential Link Up to 1200m, 20-Lead QFN

Rev. 0

10/20

20 www.analog.com

For more information www.analog.com ANALOG DEVICES, INC. 2020