1/14ページ

Download(4.3Mb)

TAKAMAZ GENERAL CATALOG

Product Catalog

Document Information

| Document Title | TAKAMAZ GENERAL CATALOG |

|---|---|

| Document Type | Product Catalog |

| File size | 4.3Mb |

| Category | |

| Company | TAKAMAZ (TAKAMATSU MACHINERY Co.,ltd) (Documents List) |

Documents related to this company

Document Contents

Page1

OPERATING SYSTEM PRODUCTS

OF PARTNERS

Head Office and Plant TAKAMAZ

■TAKAMATSU MACHINERY CO., LTD.

・ HEAD OFFICE GENERAL CATALOG

1-8 ASAHIGAOKA HAKUSAN-CITY ISHIKAWA JAPAN. 924-8558 De

TEL +81-(0)76-207-6155 FAX +81-(0)76-274-1418

TAKAMAZ-EMAG Co., Ltd., is a joint venture between ENGLISH

Takamatsu Machinery Co., Ltd., (Japan) and EMAG ・ ASAHI PLANT

GmbH & Co. KG (Germany). A whole range of 4-13 ASAHIGAOKA HAKUSAN-CITY ISHIKAWA JAPAN. 924-0004

high-quality EMAG products from hard turning TEL +81-(0)76-274-0123 FAX +81-(0)76-274-8530

machines to grinding machines, laser processing, and Overseas Bases Sign

Featuring Functions Unique to TAKAMAZ! TAKAMAZ-EMAG gear hobbing machines are available. ■TAKAMATSU MACHINERY U.S.A., INC.

Its mission is to offer customized equipment tailored ・ CHICAGO HEAD OFFICE

to customers’ needs at low prices with short delivery 1280 LANDMEIER ROAD ELK GROVE VILLAGE, IL 60007 USA

times, and as turnkey projects. TEL +1-(0)847-981-8577 FAX +1-(0)847-981-8599

■Realizes High Productivity through Increased Loader Speed ■TAKAMAZ MACHINERY EUROPE GmbH

and Shorter Machine Stoppage Times ■VT2-4 Vertical Lathe with One Spindle and Two Turrets IM HÜLSENFELD 19, 40721 HILDEN, GERMANY

TEL +49-(0)2103-789-4882 FAX +49-(0)2103-789-4883

Productivity improvement ●Traverse axis: 120m/min Ultimate Shaft Work Machine ■TAKAMAZ MACHINERY( HANGZHOU) CO.,LTD.

(43% up compared with existing systems) High speed loading time with a 2-turret ・ HANGZHOU HEAD OFFICE

simultaneous 4-axis control capability.

●Vertical axis: 120 m/min NO.6800, JIANGDONG 3RD ROAD, JIANGDONG INDUSTRIAL PARK,

“VT series” machines are characterized

XIAOSHAN, HANGZHOU, ZHEJIANG, CHINA

(69% up compared with existing systems) by a construction that gives good EASY WAYS

Loader Size Display Function Y-Axis Automatic Adjustment Function TEL +86(- 0)571-8287-9709 FAX +86(- 0)571-8215-3732

■Shorter Setup Times by Functions Unique to TAKAMAZ access to the machining area and TO REDUCE WASTE

high-power spindles. ■TAKAMATSU MACHINERY( THAILAND) CO., LTD.

・ BANGKOK HEAD OFFICE

Ease-of-setup improvement ●Loader system operation can be checked 888/59 MOO 9, TAMBOL BANGPLA, AMPHUR BANGPLEE,

safely using handle operation. SAMUTPRAKARN PROVINCE, THAILAND

●Two types of teaching methods are TEL +66(- 0)2-136-7831 FAX +66(- 0)2-136-7834

available to suit various situations. ■PT. TAKAMAZ INDONESIA

■Loader Speed Optimization Function for JL. FESTIVAL BOULEVARD BLOK AA 11 NO.30,31 GRAND WISATA TAMBUN, BEKASI 17510

TEL +62-(0)21-8261-6431 FAX +62-(0)21-8261-6430 NO! CO2 NO MORE

Energy Savings and Longer Service Life ■TAKAMAZ MACHINERY MEXICO, S.A.DE C.V. OVERTIME

When setting up after changing the workpiece, When teaching the loader, the Y-axis position

Energy saving functions ●By automatically optimizing the speed of the

AVENIDA DE LOS INDUSTRIALES 522, LOCAL 4, INDUSTRIAL JULIAN DE OBREGON,

teaching can be completed by simply setting the can be automatically adjusted just by

loader, loader energy savings and a longer workpiece size. repeatedly opening and closing the fingers. 37290 LEON, GUANAJUATO MEXICO

F.T. Japan Inc. imports machines manufactured by TEL +52-477-784-0468

loader service life are achieved. Teaching time for a workpiece size change Loading position fine-adjustment time FEELER, ECOCA, and LEADWELL from our affiliate ■TAKAMATSU MACHINERY VIETNAM CO., LTD

Loader power consumption Reduced 17% 80% shorter 53% shorter FFG Group (Taiwan), the world’s third-largest NO.76 M HOANG QUOC VIET, PHU MY WARD, DISTRICT 7, HO CHI MINH CITY, VIETNAM

TEL +84-(0)28-3620-5671 FAX +84-(0)28-3620-5673

■In Addition to a Touch Panel Giving Exceptional Loader Operability, a Servo System Made by FANUC Is Adopted. general machine tool manufacturer, and sells them.

F.T. Japan Affiliated Companies

■General-Purpose Lathe SJ460 × 1000G ■HANGZHOU FEELER TAKAMATSU MACHINERY CO., LTD.

NO.6800, JIANGDONG 3RD ROAD, JIANGDONG INDUSTRIAL PARK,

This is a general-purpose

lathe manufactured by XIAOSHAN, HANGZHOU, ZHEJIANG, CHINA

ECOCA. It has excellent TEL +86(- 0)571-8215-3760 FAX +86(- 0)571-8286-5311

cost performance and is

available in a wide range

TAKAMAZ Technology Aids Productivity ■Functions for Better Working Efficiency in Addition to Conventional NC Screens of sizes. The apron

■Work Simplified by Automation of Operations and Network Function handle position can be

selected from either the

Better Working Efficiency Quality Control IT & IoT left or right sides. Slides are hardened/polished. Equipped

Operator working efficiency improved, Storing of traceability information per Programs can easily be input and output with an auto-feed stopper ring, machining that meets your

reducing production stoppage time workpiece to assist quality control between machines via the network. needs can be accomplished.

Equipment sold by the TAKAMAZ Group will be fully

supported by the TAKAMAZ service network.

Keeping Track of Production Progress The status of the machine during Simple On-Screen Input/Output

Production count and tool usage count can be determined at a glance. machining and can be checked and the

Display of Start Conditions No need to move between machines

information can be used for quality

Operations to prepare for starting can be performed quickly. control and preventive maintenance. No need for USB flash drives

Machine Stoppage Warning No need for an external computer

Advance warning of the next machine stoppage is displayed Examples of Traceability Data

based on the workpiece count, etc. Times, motor temperatures, cycle times,

Camera Image Display (Option) program numbers, tool wear offsets, etc. https://www.takamaz.co.jp

Makes it possible to check areas that are difficult to see, like the

rear section of the machine. Scan this QR Code

for more details.

12

23.07.3B(O)

Page2

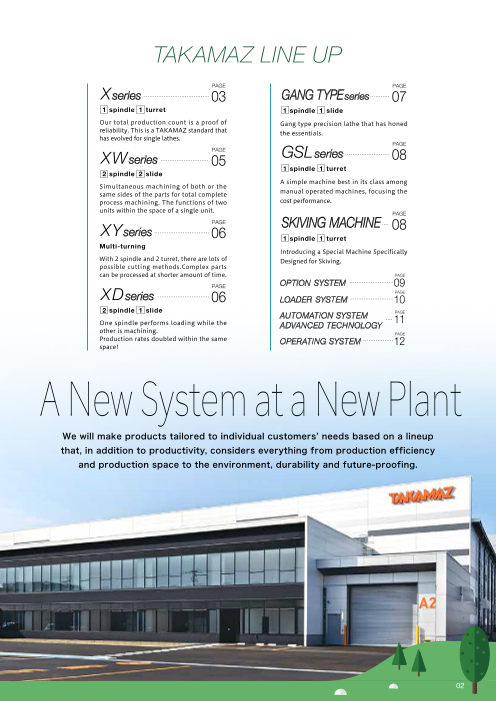

Aiming for Carbon-neutral TAKAMAZ LINE UP

Production PAGE

X PAGE

series 03 GANG TYPEseries 07

1 spindle 1 turret 1 spindle 1 slide

The new TAKAMAZ plant (Asahi plant) is contributing to global environmental Our total production count is a proof of Gang type precision lathe that has honed

reliability. This is a TAKAMAZ standard that the essentials.

conservation by introducing energy-saving equipment including air conditioning has evolved for single lathes.

PAGE

PAGE

systems that utilize solar power generation※ and well water. ※Scheduled to be installed sequentially from 2023 XWseries 05 GSLseries 08

1 spindle 1 turret

2 spindle 2 slide

Environmental Technology Supporting Customers’ Push Toward Carbon Neutrality A simple machine best in its class among

Simultaneous machining of both or the

same sides of the parts for total complete manual operated machines, focusing the

process machining. The functions of two cost performance.

■Increased energy conservation units within the space of a single unit. PAGE

(adoption of regenerative energy, high-efficiency motors) PAGE

■More compact, increased space savings XY SKIVING MACHINE

series 06 08

1 spindle 1 turret

Successful integration of loading units, oil mist collectors, Multi-turning

Introducing a Special Machine Specifically

chip conveyors, coolant temperature regulators, etc. With 2 spindle and 2 turret, there are lots of Designed for Skiving.

possible cutting methods.Complex parts

■Defectives reduced by stable precision machining can be processed at shorter amount of time. PAGE

■Cycle times shortened by speed increases PAGE OPTION SYSTEM 09

XDseries 06 PAGE

■Improved operability and maintainability LOADER SYSTEM 10

2 spindle 1 slide

■Reduced number of structural components AUTOMATION SYSTEM PAGE

One spindle performs loading while the ADVANCED TECHNOLOGY 11

other is machining. PAGE

Production rates doubled within the same

Lineup Realizing Process Integration and Productivity Improvements OPERATING SYSTEM

space! 12

Turning + grinding Compound machining Turning + hobbing Ultrasonic vibration cutting Operating system

®

A New System at a New Plant

SKV-� XYseries XT-�MY Chip breaking machining method ® ® We will make products tailored to individual customers’ needs based on a lineup

Skiving machining Compound machining Compound machining that, in addition to productivity, considers everything from production efficiency

and production space to the environment, durability and future-proofing.

EASY WAYS

TO REDUCE WASTE

NO MORE

OVERTIME

NO! CO2

01 02

Page3

Aiming for Carbon-neutral TAKAMAZ LINE UP

Production PAGE

X PAGE

series 03 GANG TYPEseries 07

1 spindle 1 turret 1 spindle 1 slide

The new TAKAMAZ plant (Asahi plant) is contributing to global environmental Our total production count is a proof of Gang type precision lathe that has honed

reliability. This is a TAKAMAZ standard that the essentials.

conservation by introducing energy-saving equipment including air conditioning has evolved for single lathes.

PAGE

PAGE

systems that utilize solar power generation※ and well water. ※Scheduled to be installed sequentially from 2023 XWseries 05 GSLseries 08

1 spindle 1 turret

2 spindle 2 slide

Environmental Technology Supporting Customers’ Push Toward Carbon Neutrality A simple machine best in its class among

Simultaneous machining of both or the

same sides of the parts for total complete manual operated machines, focusing the

process machining. The functions of two cost performance.

■Increased energy conservation units within the space of a single unit. PAGE

(adoption of regenerative energy, high-efficiency motors) PAGE

■More compact, increased space savings XY SKIVING MACHINE

series 06 08

1 spindle 1 turret

Successful integration of loading units, oil mist collectors, Multi-turning

Introducing a Special Machine Specifically

chip conveyors, coolant temperature regulators, etc. With 2 spindle and 2 turret, there are lots of Designed for Skiving.

possible cutting methods.Complex parts

■Defectives reduced by stable precision machining can be processed at shorter amount of time. PAGE

■Cycle times shortened by speed increases PAGE OPTION SYSTEM 09

XDseries 06 PAGE

■Improved operability and maintainability LOADER SYSTEM 10

2 spindle 1 slide

■Reduced number of structural components AUTOMATION SYSTEM PAGE

One spindle performs loading while the ADVANCED TECHNOLOGY 11

other is machining. PAGE

Production rates doubled within the same

Lineup Realizing Process Integration and Productivity Improvements OPERATING SYSTEM

space! 12

Turning + grinding Compound machining Turning + hobbing Ultrasonic vibration cutting Operating system

®

A New System at a New Plant

SKV-� XYseries XT-�MY Chip breaking machining method ® ® We will make products tailored to individual customers’ needs based on a lineup

Skiving machining Compound machining Compound machining that, in addition to productivity, considers everything from production efficiency

and production space to the environment, durability and future-proofing.

EASY WAYS

TO REDUCE WASTE

NO MORE

OVERTIME

NO! CO2

01 02

Page4

“Starting Point of TAKAMAZ”

Integration of the Power of Technology. Suited for Compound Machining

X Standard of Single Lathes and Complete Part Machining

Ideal for small part processing Ideal for Compound Machine

and Machining Products to Completion

XTS-6

series 6inch Chuck

NEW Long Shaft

Workpiece

XL-200

Suited for Powerful Heavy Cutting 8(10) inch Chuck

1-spindle 1-turret XC-150 XT-8MY

Our total production count is

proof of reliability. 8inch Chuck 8(10) inch Chuck

This is a TAKAMAZ standard that has

evolved for single lathes.

Suited for Various Shaft Processing

High Rigidity/High Output/Space Saving

XT-6 XT-6M X-S700

6(8) inch Chuck 8(10) inch Chuck

XT-8 XT-8M XTT-500 XTT-500M

8(10) inch Chuck 8(10) inch Chuck

Xseries Machine Specifications

I t em Un i t XTS-6 XC-150 XT-6 XT-6M XT-8 XT-8M XL-200 XTT-500 XTT-500M

NEW Standard Power tool type Standard Power tool type XT-8MY Standard Power tool type X-S700 Standard Power tool type

Chuck size inch 6 8 6(8) 8(10) 8 8(10) 8(10) 8(10) 8

Spindle bearing I.D. mm φ75 φ100 φ75(φ85) φ100(φ120) φ100 φ100(φ120) φ100(φ120) φ100(φ120) φ100 Number of Gang type Y-axis control Power tool

Spindle speed minー1 Max.5,000 Max.3,500 Max.4,500(6,000)(3,500) Max.3,500(5,000)(3,000) Max.4,000 Max.3,500(5,000・4,000) Max.3,500(3,000) Max.4,000(3,500) Max.4,000 turret stations

Tool post type 8-station turret 8-station turret 8-station(12-station)turret 12-station turret 8-station(12-station)turret 12-station turret 12-station turret 12-station turret 10-station turret × 2 8-station turret × 2

Max. stroke mm X:120 Z:230 X:175 Z:250 X:120 Z:280 X:190 Z:400 X:190 Z:420 X:175 Z:420 Y:+35、-40 X:225 Z:800 X:115 Z:650 X:105 Z:450

Rapid traverse m/min C CS

X:18 Z:24 X:18 Z:24 X:18 Z:24 X:18 Z:24 X:18 Z:24 Y:10 X:18 Z:24 X:16 Z:30 X:18 Z:24

AC11/7.5:φ100 3,500min-1 Built-in Spindle C-axis Spindle CS-axis Spindle indexing

Spindle motor kW AC7.5/5.5 AC11/7.5 AC7.5/5.5(AC11/7.5) (AC15/11:φ100 5,000min-1) AC11/7.5(18.5/15) AC15/11(18.5/15) AC15/11(18.5/15) AC15/11 spindle motor indexing indexing (electrical/mechanical)

(AC15/11:φ120 3,000min-

AC15/11

1)

Power tool Milling mm ー ー ー φ10 ー φ20 φ16 ー φ20 ー ー φ10

capability Tap mm ー ー ー M6 ー M16 M16 ー M4~M16 ー ー M4~M8

Dimensions (L×W) mm S

1,105 × 1,380 1,250 × 1,480 1,360 × 1,370 1,600 × 1,535 1,750 × 1,535 1,780 × 1,685 2,900(3,100※) × 1,845 1,960 × 1,720 1,695 × 1,830

Controller TAKAMAZ & FANUC 0i-TF Plus TAKAMAZ & FANUC 0i-TD TAKAMAZ & FANUC 0i-TF TAKAMAZ & FANUC 0i-TF Plus TAKAMAZ & FANUC 0i-TF Plus TAKAMAZ & FANUC 0i-TD TAKAMAZ & FANUC 0i-TD TAKAMAZ & FANUC 0i-TF Sub-spindle Tailstock CE type Environmentally

friendly design

※When sub spindle mounted ( ) :Options.

03 04

Page5

“Starting Point of TAKAMAZ”

Integration of the Power of Technology. Suited for Compound Machining

X Standard of Single Lathes and Complete Part Machining

Ideal for small part processing Ideal for Compound Machine

and Machining Products to Completion

XTS-6

series 6inch Chuck

NEW Long Shaft

Workpiece

XL-200

Suited for Powerful Heavy Cutting 8(10) inch Chuck

1-spindle 1-turret XC-150 XT-8MY

Our total production count is

proof of reliability. 8inch Chuck 8(10) inch Chuck

This is a TAKAMAZ standard that has

evolved for single lathes.

Suited for Various Shaft Processing

High Rigidity/High Output/Space Saving

XT-6 XT-6M X-S700

6(8) inch Chuck 8(10) inch Chuck

XT-8 XT-8M XTT-500 XTT-500M

8(10) inch Chuck 8(10) inch Chuck

Xseries Machine Specifications

I t em Un i t XTS-6 XC-150 XT-6 XT-6M XT-8 XT-8M XL-200 XTT-500 XTT-500M

NEW Standard Power tool type Standard Power tool type XT-8MY Standard Power tool type X-S700 Standard Power tool type

Chuck size inch 6 8 6(8) 8(10) 8 8(10) 8(10) 8(10) 8

Spindle bearing I.D. mm φ75 φ100 φ75(φ85) φ100(φ120) φ100 φ100(φ120) φ100(φ120) φ100(φ120) φ100 Number of Gang type Y-axis control Power tool

Spindle speed minー1 Max.5,000 Max.3,500 Max.4,500(6,000)(3,500) Max.3,500(5,000)(3,000) Max.4,000 Max.3,500(5,000・4,000) Max.3,500(3,000) Max.4,000(3,500) Max.4,000 turret stations

Tool post type 8-station turret 8-station turret 8-station(12-station)turret 12-station turret 8-station(12-station)turret 12-station turret 12-station turret 12-station turret 10-station turret × 2 8-station turret × 2

Max. stroke mm X:120 Z:230 X:175 Z:250 X:120 Z:280 X:190 Z:400 X:190 Z:420 X:175 Z:420 Y:+35、-40 X:225 Z:800 X:115 Z:650 X:105 Z:450

Rapid traverse m/min C CS

X:18 Z:24 X:18 Z:24 X:18 Z:24 X:18 Z:24 X:18 Z:24 Y:10 X:18 Z:24 X:16 Z:30 X:18 Z:24

AC11/7.5:φ100 3,500min-1 Built-in Spindle C-axis Spindle CS-axis Spindle indexing

Spindle motor kW AC7.5/5.5 AC11/7.5 AC7.5/5.5(AC11/7.5) (AC15/11:φ100 5,000min-1) AC11/7.5(18.5/15) AC15/11(18.5/15) AC15/11(18.5/15) AC15/11 spindle motor indexing indexing (electrical/mechanical)

(AC15/11:φ120 3,000min-

AC15/11

1)

Power tool Milling mm ー ー ー φ10 ー φ20 φ16 ー φ20 ー ー φ10

capability Tap mm ー ー ー M6 ー M16 M16 ー M4~M16 ー ー M4~M8

Dimensions (L×W) mm S

1,105 × 1,380 1,250 × 1,480 1,360 × 1,370 1,600 × 1,535 1,750 × 1,535 1,780 × 1,685 2,900(3,100※) × 1,845 1,960 × 1,720 1,695 × 1,830

Controller TAKAMAZ & FANUC 0i-TF Plus TAKAMAZ & FANUC 0i-TD TAKAMAZ & FANUC 0i-TF TAKAMAZ & FANUC 0i-TF Plus TAKAMAZ & FANUC 0i-TF Plus TAKAMAZ & FANUC 0i-TD TAKAMAZ & FANUC 0i-TD TAKAMAZ & FANUC 0i-TF Sub-spindle Tailstock CE type Environmentally

friendly design

※When sub spindle mounted ( ) :Options.

03 04

Page6

From High Volume Machining to Heavy Cutting. TAKAMAZ Compact Machines

Revolutionary Machine with 2-Spindle and 2-Slide Ideal for Small Part Processing Suitable for Compound Machining Sub-Spindle + Power Tools

XW XWG-3

3inch /4inch Chuck

NEW XY XY-120 PLUS

6inch Chuck

series series

Integrating Various Process

XW-60 XW-60M

Sub-Spindle + Power Tools

6inch Chuck

2-spindle 2-slide Multi- Turning XYT-51

With 2 spindle and 2 turret, there are

Simultaneous machining of both or the same sides of lots of possible cutting methods. 6inch Chuck

the parts for total complete process machining. Complex parts can be processed at

The functions of two units within the space of a single unit. Fastest Loading Cycle in its Class shorter amount of time.

XW-130 XW-130M

8inch Chuck

Flexible Usability Depending

on Production Needs

2-Spindle and 1-Slide TAKAMAZ

Large Flange-Like Workpiece Specialized Structure. XD-8 PLUS XD-8T PLUS

XW-200

10 inch Chuck XD 5inch Chuck

XD-8 PLUS XD-8T PLUS

series

Large Flange-Like Workpiece, Fastest Loading Cycle Power Tools Option

XWT-10 XD-10i

2-spindle 1-slide

10 inch Chuck One spindle performs loading while 6inch Chuck

the other is machining. Production

rates doubled within the same space!

XWseries Machine Specifications XYseries Machine Specifications XDseries Machine Specifications

I t em Un i t XWG-3 NEW XW-60 XW-60M XW-130 XW-130M

Standard Power tool type Standard Power tool type XW-200 XWT-10 I t em Un i t XY-120 XYT-51

PLUS I t em Un i t XD-8 PLUS XD-8T PLUS XD-10 i

φ51 THRU,BMT45 specification φ65 THRU,BMT55 specification(OP)

Chuck size inch Collet,3,4 Collet,6(5)×2 Collet,8 × 2 10 × 2 10 × 2 Main-spindle Sub-spindle Main-spindle Sub-spindle Main-spindle Sub-spindle Chuck size inch Collet(, 5) × 2 Collet,6 × 2

Spindle bearing I.D. mm φ60 φ75(φ65) φ100 φ120 φ120 Chuck size inch Collet,6 Collet,5 Collet,6 8 Spindle bearing I.D. mm φ65 φ75

Spindle speed minー1 Max.8,000(6,000※1) Max.4,500(6,000) Max.4,000 Max.2,800 Max.2,800(4,000) Spindle bearing I.D. mm φ85(φ100) φ65 φ100 φ85 φ120 φ100 Spindle speed minー1 Max.4,500(8,000) Max.4,500(6,000)

Tool post type Gang type( Max.4 pcs.) 8-station turret×2 10-station turret×2 8-station turret × 2 10-station turret × 2 8-station turret × 2 10-station turret× 2 Spindle speed minー1 Max.5,000(4,000) Max.5,000 Max.5,000 Max.4,000 Tool post type Gang type 6-station turret 10-station turret

Max. stroke mm X:160 Z:230 X:125 Z:140 X:150 Z:160 X:170 Z:220 X:170 Z:220 X:170 Z:270 Tool post type 12-station turret,24ST 12-station turret,24ST,BMT45 12-station turret,24ST,BMT55 Max. stroke mm X:200 Z:380( ±190) X:140 Z:380( ±190) X:120 Z:520

Rapid traverse m/min X:16 Z:20 X:21 Z:18 X:24 Z:24 X:24 Z:24 X:24 Z:24 Max. stroke mm X1:150 Z1:330 Y:±35 X2:150 Z2:440 X1:162.5 Z1:500 Y:±35 X2:170 Z2:500 A:550 X1:162.5 Z1:500 Y:+40-35 X2:170 Z2:500 A:550 Rapid traverse m/min X:18 Z:24 X:18 Z:24

Spindle motor kW AC5.5/3.7 AC 7.5/5.5×2 AC11/7.5 × 2 AC18.5/15 × 2 AC18.5/15 × 2 Rapid traverse m/min X1:18 Z1:24 Y:±12 X2:18 Z2:18 X:18 Z:30 Y:12 A:30 X:18 Z:30 Y:12 A:30 Spindle motor kW AC3.7/2.2(5.5/3.7※4) × 2 AC5.5/3.7(7.5/5.5) × 2

Power tool Milling mm ー ー φ13 ー φ16 ー ー Spindle motor kW AC7.5/5.5(AC11/7.5) AC5.5/3.7 AC18.5/15/11 AC9/7.5/5.5 AC18.5/15/11 AC9/7.5/5.5 Dimensions (L×W) mm 1,580 × 1,550 2,310 × 1,695

capability Tap mm ー Power tool Millingー M4~M10 ー M4~M10 ー ー mm φ13 φ13 φ20 Controller TAKAMAZ & FANUC 0i-TD TAKAMAZ & FANUC 0i-TD

Dimensions (L×W) mm 1,340 × 2,130 1,595(1,950)×2,005 1,695(1,950)×2,005 1,890(2,250※2) × 2,140 1,990(2,350※2) × 2,330 1,990(2,350※2) × 2,330 2,030(2,350※2) × 2,370 capability Tap mm M8 M12 M16 ※4.XD-8PLUS : 5.5/3.7kW is exclusive to the specifications for spindle rotations speed of 8,000minー1

Controller TAKAMAZ & MITSUBISHI M830VW TAKAMAZ & FANUC 0i-TF TAKAMAZ & FANUC 0i-TD(0i-TF※3) TAKAMAZ & FANUC Oi-TF TAKAMAZ & FANUC 0i-TF Dimensions (L×W) mm 2,630 × 1,950 2,988 × 2,163 3,000 × 2,163 ( ) :Options.

※1.Hydraulic specification ※2.Machine width with loader spec. ※3.Optional with power tools. ( ) :Options. Controller TAKAMAZ & FANUC 0i-TD TAKAMAZ & FANUC 0i-TD Customizable for

( ) :Options.

unique specifications

05 06

Page7

From High Volume Machining to Heavy Cutting. TAKAMAZ Compact Machines

Revolutionary Machine with 2-Spindle and 2-Slide Ideal for Small Part Processing Suitable for Compound Machining Sub-Spindle + Power Tools

XW XWG-3

3inch /4inch Chuck

NEW XY XY-120 PLUS

6inch Chuck

series series

Integrating Various Process

XW-60 XW-60M

Sub-Spindle + Power Tools

6inch Chuck

2-spindle 2-slide Multi- Turning XYT-51

With 2 spindle and 2 turret, there are

Simultaneous machining of both or the same sides of lots of possible cutting methods. 6inch Chuck

the parts for total complete process machining. Complex parts can be processed at

The functions of two units within the space of a single unit. Fastest Loading Cycle in its Class shorter amount of time.

XW-130 XW-130M

8inch Chuck

Flexible Usability Depending

on Production Needs

2-Spindle and 1-Slide TAKAMAZ

Large Flange-Like Workpiece Specialized Structure. XD-8 PLUS XD-8T PLUS

XW-200

10 inch Chuck XD 5inch Chuck

XD-8 PLUS XD-8T PLUS

series

Large Flange-Like Workpiece, Fastest Loading Cycle Power Tools Option

XWT-10 XD-10i

2-spindle 1-slide

10 inch Chuck One spindle performs loading while 6inch Chuck

the other is machining. Production

rates doubled within the same space!

XWseries Machine Specifications XYseries Machine Specifications XDseries Machine Specifications

I t em Un i t XWG-3 NEW XW-60 XW-60M XW-130 XW-130M

Standard Power tool type Standard Power tool type XW-200 XWT-10 I t em Un i t XY-120 XYT-51

PLUS I t em Un i t XD-8 PLUS XD-8T PLUS XD-10 i

φ51 THRU,BMT45 specification φ65 THRU,BMT55 specification(OP)

Chuck size inch Collet,3,4 Collet,6(5)×2 Collet,8 × 2 10 × 2 10 × 2 Main-spindle Sub-spindle Main-spindle Sub-spindle Main-spindle Sub-spindle Chuck size inch Collet(, 5) × 2 Collet,6 × 2

Spindle bearing I.D. mm φ60 φ75(φ65) φ100 φ120 φ120 Chuck size inch Collet,6 Collet,5 Collet,6 8 Spindle bearing I.D. mm φ65 φ75

Spindle speed minー1 Max.8,000(6,000※1) Max.4,500(6,000) Max.4,000 Max.2,800 Max.2,800(4,000) Spindle bearing I.D. mm φ85(φ100) φ65 φ100 φ85 φ120 φ100 Spindle speed minー1 Max.4,500(8,000) Max.4,500(6,000)

Tool post type Gang type( Max.4 pcs.) 8-station turret×2 10-station turret×2 8-station turret × 2 10-station turret × 2 8-station turret × 2 10-station turret× 2 Spindle speed minー1 Max.5,000(4,000) Max.5,000 Max.5,000 Max.4,000 Tool post type Gang type 6-station turret 10-station turret

Max. stroke mm X:160 Z:230 X:125 Z:140 X:150 Z:160 X:170 Z:220 X:170 Z:220 X:170 Z:270 Tool post type 12-station turret,24ST 12-station turret,24ST,BMT45 12-station turret,24ST,BMT55 Max. stroke mm X:200 Z:380( ±190) X:140 Z:380( ±190) X:120 Z:520

Rapid traverse m/min X:16 Z:20 X:21 Z:18 X:24 Z:24 X:24 Z:24 X:24 Z:24 Max. stroke mm X1:150 Z1:330 Y:±35 X2:150 Z2:440 X1:162.5 Z1:500 Y:±35 X2:170 Z2:500 A:550 X1:162.5 Z1:500 Y:+40-35 X2:170 Z2:500 A:550 Rapid traverse m/min X:18 Z:24 X:18 Z:24

Spindle motor kW AC5.5/3.7 AC 7.5/5.5×2 AC11/7.5 × 2 AC18.5/15 × 2 AC18.5/15 × 2 Rapid traverse m/min X1:18 Z1:24 Y:±12 X2:18 Z2:18 X:18 Z:30 Y:12 A:30 X:18 Z:30 Y:12 A:30 Spindle motor kW AC3.7/2.2(5.5/3.7※4) × 2 AC5.5/3.7(7.5/5.5) × 2

Power tool Milling mm ー ー φ13 ー φ16 ー ー Spindle motor kW AC7.5/5.5(AC11/7.5) AC5.5/3.7 AC18.5/15/11 AC9/7.5/5.5 AC18.5/15/11 AC9/7.5/5.5 Dimensions (L×W) mm 1,580 × 1,550 2,310 × 1,695

capability Tap mm ー Power tool Millingー M4~M10 ー M4~M10 ー ー mm φ13 φ13 φ20 Controller TAKAMAZ & FANUC 0i-TD TAKAMAZ & FANUC 0i-TD

Dimensions (L×W) mm 1,340 × 2,130 1,595(1,950)×2,005 1,695(1,950)×2,005 1,890(2,250※2) × 2,140 1,990(2,350※2) × 2,330 1,990(2,350※2) × 2,330 2,030(2,350※2) × 2,370 capability Tap mm M8 M12 M16 ※4.XD-8PLUS : 5.5/3.7kW is exclusive to the specifications for spindle rotations speed of 8,000minー1

Controller TAKAMAZ & MITSUBISHI M830VW TAKAMAZ & FANUC 0i-TF TAKAMAZ & FANUC 0i-TD(0i-TF※3) TAKAMAZ & FANUC Oi-TF TAKAMAZ & FANUC 0i-TF Dimensions (L×W) mm 2,630 × 1,950 2,988 × 2,163 3,000 × 2,163 ( ) :Options.

※1.Hydraulic specification ※2.Machine width with loader spec. ※3.Optional with power tools. ( ) :Options. Controller TAKAMAZ & FANUC 0i-TD TAKAMAZ & FANUC 0i-TD Customizable for

( ) :Options.

unique specifications

05 06

Page8

Gang Type Precision Lathe A Simple Machine Best in Its Class

That Has Honed the Essentials. Super Compact Machine Body among Manual Operated Machines, Excellent Cost Performance

GANG USL-480 Focusing the Cost Performance.

Global Startegy Lathe

3inch Chuck

TYPE GSL GSL-10H

series High-Accuracy Turning with Built-In Motors series 6inch Chuck

XG-4

4inch Chuck

1-spindle 1-slide 1-spindle 1-turret

Fastest Loading Cycle in its Class

J-WAVE PLUS GSL-15 PLUS

4inch 8inch Chuck

USL-480 Chuck

Suited for Powerful Heavy Cutting

XG-4 TOP-TURN Ⅱ A Machine Specialized for Skiving

Turning + Grinding on This One Machine

6(8) inch Chuck SKIVING

TOP-TURN Ⅱ MACHINE SKV-8

Integration of Diverse Processes 8inch Chuck

XV-3

3inch /4inch Chuck Limited exclusively to domestic sales in Japan

XV-3 1-spindle 1-turret

GANG TYPE series Machine Specifications GSLseries Machine Specifications SKV-8 Machine Specifications

I t em Un i t USL-480 XG-4 J-WAVE PLUS TOP-TURN Ⅱ

type A type B XV-3 I t em Un i t GSL-10 H GSL-15 PLUS I t em Un i t SKV-8

Chuck size inch Collet,3 Collet,4 6 8 Collet,3,4 Chuck size inch Collet,6 Collet,8 Chuck size inch 8

Spindle bearing I.D. mm φ50 φ65 φ75 φ85 φ60 Spindle bearing I.D. mm φ75 φ100 Spindle bearing I.D. mm φ100

Spindle speed minー1 Max.10,000 Max.8,000 Max.4,500 Max.6,000 Max.4,500 Max.10,000 Spindle speed minー1 Max.4,500 Max.3,500 Spindle speed minー1 Max.5,000

Tool post type Gang type Gang type Gang type Gang type Tool post type 8-station turret 8-station turret Tool post type 12-station turret

Max. stroke mm X:160 Z:200 X:200 Z:250 X:300 Z:300 X:160 Z:200 Y:265 Max. stroke mm X:120 Z:230 X:175 Z:330 Max. stroke mm X:150 Y:±35 Z:400

Rapid traverse m/min X:12 Z:15 X:18 Z:18 X:12 Z:18 X:12 Z:24 Y:24 Rapid traverse m/min X:12 Z:18 X:18 Z:24 Rapid traverse m/min X:18 Y:12 Z:24

Spindle motor kW AC5.5/3.7 AC7.5/5.5/3.7 AC5.5/3.7 AC7.5/5.5 AC5.5/3.7 Spindle motor kW AC5.5/3.7 AC7.5/5.5 Spindle motor kW AC 15/11

Dimensions (L×W) mm 480 × 1,941 1,506 × 1,250(780 × 1,735※) 1,820 × 1,510 1,600(2.075) × 2,130 × 2,230 Dimensions (L×W) mm 1,610 × 1,390 1,875(With tailstock:1,990) × 1,680 Dimensions (L×W) mm 2,270 × 1,690

TAKAMAZ & FANUC 0i-TD/ TAKAMAZ & Controller TAKAMAZ & FANUC 0i-TF

Controller TAKAMAZ & MITSUBISHI M80 TAKAMAZ & FANUC 0i-TD TAKAMAZ & MITSUBISHI M80 Controller TAKAMAZ & FANUC 0i-TF

TAKAMAZ & MITSUBISHI M64 FANUC 0i Mate-TD

※When the loader is mounted. ( ) :Options.

Customizable for

unique specifications

07 08

Page9

Gang Type Precision Lathe A Simple Machine Best in Its Class

That Has Honed the Essentials. Super Compact Machine Body among Manual Operated Machines, Excellent Cost Performance

GANG USL-480 Focusing the Cost Performance.

Global Startegy Lathe

3inch Chuck

TYPE GSL GSL-10H

series High-Accuracy Turning with Built-In Motors series 6inch Chuck

XG-4

4inch Chuck

1-spindle 1-slide 1-spindle 1-turret

Fastest Loading Cycle in its Class

J-WAVE PLUS GSL-15 PLUS

4inch 8inch Chuck

USL-480 Chuck

Suited for Powerful Heavy Cutting

XG-4 TOP-TURN Ⅱ A Machine Specialized for Skiving

Turning + Grinding on This One Machine

6(8) inch Chuck SKIVING

TOP-TURN Ⅱ MACHINE SKV-8

Integration of Diverse Processes 8inch Chuck

XV-3

3inch /4inch Chuck Limited exclusively to domestic sales in Japan

XV-3 1-spindle 1-turret

GANG TYPE series Machine Specifications GSLseries Machine Specifications SKV-8 Machine Specifications

I t em Un i t USL-480 XG-4 J-WAVE PLUS TOP-TURN Ⅱ

type A type B XV-3 I t em Un i t GSL-10 H GSL-15 PLUS I t em Un i t SKV-8

Chuck size inch Collet,3 Collet,4 6 8 Collet,3,4 Chuck size inch Collet,6 Collet,8 Chuck size inch 8

Spindle bearing I.D. mm φ50 φ65 φ75 φ85 φ60 Spindle bearing I.D. mm φ75 φ100 Spindle bearing I.D. mm φ100

Spindle speed minー1 Max.10,000 Max.8,000 Max.4,500 Max.6,000 Max.4,500 Max.10,000 Spindle speed minー1 Max.4,500 Max.3,500 Spindle speed minー1 Max.5,000

Tool post type Gang type Gang type Gang type Gang type Tool post type 8-station turret 8-station turret Tool post type 12-station turret

Max. stroke mm X:160 Z:200 X:200 Z:250 X:300 Z:300 X:160 Z:200 Y:265 Max. stroke mm X:120 Z:230 X:175 Z:330 Max. stroke mm X:150 Y:±35 Z:400

Rapid traverse m/min X:12 Z:15 X:18 Z:18 X:12 Z:18 X:12 Z:24 Y:24 Rapid traverse m/min X:12 Z:18 X:18 Z:24 Rapid traverse m/min X:18 Y:12 Z:24

Spindle motor kW AC5.5/3.7 AC7.5/5.5/3.7 AC5.5/3.7 AC7.5/5.5 AC5.5/3.7 Spindle motor kW AC5.5/3.7 AC7.5/5.5 Spindle motor kW AC 15/11

Dimensions (L×W) mm 480 × 1,941 1,506 × 1,250(780 × 1,735※) 1,820 × 1,510 1,600(2.075) × 2,130 × 2,230 Dimensions (L×W) mm 1,610 × 1,390 1,875(With tailstock:1,990) × 1,680 Dimensions (L×W) mm 2,270 × 1,690

TAKAMAZ & FANUC 0i-TD/ TAKAMAZ & Controller TAKAMAZ & FANUC 0i-TF

Controller TAKAMAZ & MITSUBISHI M80 TAKAMAZ & FANUC 0i-TD TAKAMAZ & MITSUBISHI M80 Controller TAKAMAZ & FANUC 0i-TF

TAKAMAZ & MITSUBISHI M64 FANUC 0i Mate-TD

※When the loader is mounted. ( ) :Options.

Customizable for

unique specifications

07 08

Page10

OPTION SYSTEM LOADER SYSTEM AUTOMATION SYSTEM

By applying our experiences in manufacturing Encouraged from sales of more than 65 years, with "Integral loader" design philosophy in mind, ®

Transfer Device

(Loader) TAKAMAZ will lead the consistent support service follow up and support system built on trust,

of peripheral devices and our wealth of design leading to increased productivity.

achievements, we will continue to meet the Compact Loader Gantry Loader A Highly-Productive Robot System That Solves Your Problems!

needs of our customers.

Parts Supply Device Parts Supply Device ●Hi Speed Loader mounted on the machine ●Gantry-type servo loader with high rigidity. ■Reduces Personnel Costs

(Stocker, Pallet Changer, etc.) (Stocker, Pallet Changer, etc.) to save space. ●The traverse distance can be extended, ensuring extremely

A production line with different ●A dedicated servo controller allows speedy setup. flexible line configuration and systemization of peripheral This system loads/unloads workpieces with a robot that is integrated

equipment. with a tray changer. It realizes unmanned operation day and night, and

varieties of peripheral devices and improves production efficiency by maintaining machining quality,

loading variations can be designed. ensuring stable loading, and allowing multi-machine control.

Space Saving Accessory Devices ■Wide Range of Variations

Improving Durability Based on this robot + tray changer system, we can meet various needs

including washing units and gauging systems.

Pursuing of the Low Cost ■Simple Setup

Short Loading Time With the integrated robot + tray changer construction, setup can be

Flexible System Line Configuration completed just by teaching on site. The system can be retrofitted to an

When setting up the lathe,

existing machine provided there is a space of 1.8 x 0.9 meters in front of the robot can be slid

Improving Operability it. Consultations are welcome. together with its base.

■Retrofitting Even to Previous Models

Automation Peripheral Devices Quality/Environment Control Unit Cutting Efficiency/Chip Disposal For Small and Short Workpiece For Flange Workpiece Workpiece Delivery from Transport Unit Using a Conveyor ADVANCED TECHNOLOGY

Vertically-Oriented Workpiece

■Station Stocker ■Cleaning Unit ■Alloyed Clamp Holder (For Machining the Bottom Face) ®

Flexible Multi-layer Without operator for Vibration Suppression

stocker to intervention, Inhibiting the progression of E Turn Device

accommodate cleaning is wear boundary is expected Processing Region

different part performed to extend cutting tool life in

diameter sizes. automatically. high speed machining.

Constantly Monitors Machines and Automatically Corrects to the Appropriate Status!

Parallel Hand L Hand Standing Workpiece

■Flat Stocker ■Measuring Devices ■Chip Conveyor (For Cutting the Top Surface) ® ®

For Front and Back Cutting Workpiece For Shaft Workpiece Patented Patented

Feeds dimensional

errors back to the (Spiral Type) Processing Region

machine to maintain Mounted on the rear side ■Thermal Displacement Compensation System ■Spindle Condition Monitoring System

high-quality Chip disposal is done Y Turn Device The machined dimension values change as the machine temperature changes due to the The application of machine fault diagnosis methods is difficult in many cases where

dimensional semi-automatically in

accuracy. minimal space. customer’s conditions of use (machining conditions) and the environmental conditions existing threshold values are provided, because the threshold values differ for each

(factory temperature, etc.). This system predicts the amount of thermal displacement based machine. We have addressed this issue by providing a new method of diagnosis

(Floor Type) Horizontally Placed on the temperature changes at each part of the machine and provides compensation values to with a spindle status monitoring system based on the "characteristic space common

■Stocker for Mounted on the rear side Small Diameter Workpiece the CNC controller In order to minimize these changes in the machining dimension values. among machines", which is determined using characteristic quantities.

Shaft Type Parts Chips are reliably

discharged outside the Characteristic space

Processing Region

machine. Temperature measurement

Spindle unit Scratches,

Pickup Device Measurement of

∑i GTH Hand Pendulum Hand Measured values input to CNC thermal displacement CNC controller foreign matter,

faults

Collected data Change in status Poor lubrication

Prediction of thermal displacement

■Oil Mist Collector ■High-Pressure Coolant

■Parts Feeder Normal

Offset values input to CNC

Oil mist collection Constantly cooled Feedback

Workpieces can be facilitates a clean coolant is discharged

stored together with production at high pressure so The collet chuck developed and marketed under the

the tray. Thermony applied - Amount of change = 6 μm

environment. that the tool life is 4.00 Occurrence of foreign matter and scratches Occurrence of

significantly TAKAMAZ TAKAMAZ brand is manufactured in the factory where an Improved by 60% 3.50 lubrication abnormalities

prolonged.

Collet Chuck integrated system is used to streamline every part of the 14 Red dot: Indicates the current status

12 3.00

10

production, from machining to heat treatment. 8 2.50

6 Change in status

■Automatic Fire Extinguisher ■Semi-Dry Machining

■Tray Changer Collet run-off accuracy conforms to TAKAMAZ standard, 4 2.00

If fire breaks out in the Ultratrace, 2 1.50 Good

Workpieces can be 0

machine during highly-lubricating organic which is even higher than Japanese

-2 1.00

stored in individual automatic operations, coolant is applied to the -4

trays. Industrial Standards (JIS), allowing us to

-6 0.50 Initial plot cluster

fire extinguishing correct point on the

agent is automatically cutting edge, realizing provide our customers with exceptionally Time 9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00 17:00 0.50 1.00 1.50 2.00 2.50 3.00

discharged. semi-dry machining. dependable products. Acceleration value

09 10 11

EASY WAYS TO REDUCE WASTE

Changeof diameter μm

Feature value

Page11

OPTION SYSTEM LOADER SYSTEM AUTOMATION SYSTEM

By applying our experiences in manufacturing Encouraged from sales of more than 65 years, with "Integral loader" design philosophy in mind, ®

Transfer Device

(Loader) TAKAMAZ will lead the consistent support service follow up and support system built on trust,

of peripheral devices and our wealth of design leading to increased productivity.

achievements, we will continue to meet the Compact Loader Gantry Loader A Highly-Productive Robot System That Solves Your Problems!

needs of our customers.

Parts Supply Device Parts Supply Device ●Hi Speed Loader mounted on the machine ●Gantry-type servo loader with high rigidity. ■Reduces Personnel Costs

(Stocker, Pallet Changer, etc.) (Stocker, Pallet Changer, etc.) to save space. ●The traverse distance can be extended, ensuring extremely

A production line with different ●A dedicated servo controller allows speedy setup. flexible line configuration and systemization of peripheral This system loads/unloads workpieces with a robot that is integrated

equipment. with a tray changer. It realizes unmanned operation day and night, and

varieties of peripheral devices and improves production efficiency by maintaining machining quality,

loading variations can be designed. ensuring stable loading, and allowing multi-machine control.

Space Saving Accessory Devices ■Wide Range of Variations

Improving Durability Based on this robot + tray changer system, we can meet various needs

including washing units and gauging systems.

Pursuing of the Low Cost ■Simple Setup

Short Loading Time With the integrated robot + tray changer construction, setup can be

Flexible System Line Configuration completed just by teaching on site. The system can be retrofitted to an

When setting up the lathe,

existing machine provided there is a space of 1.8 x 0.9 meters in front of the robot can be slid

Improving Operability it. Consultations are welcome. together with its base.

■Retrofitting Even to Previous Models

Automation Peripheral Devices Quality/Environment Control Unit Cutting Efficiency/Chip Disposal For Small and Short Workpiece For Flange Workpiece Workpiece Delivery from Transport Unit Using a Conveyor ADVANCED TECHNOLOGY

Vertically-Oriented Workpiece

■Station Stocker ■Cleaning Unit ■Alloyed Clamp Holder (For Machining the Bottom Face) ®

Flexible Multi-layer Without operator for Vibration Suppression

stocker to intervention, Inhibiting the progression of E Turn Device

accommodate cleaning is wear boundary is expected Processing Region

different part performed to extend cutting tool life in

diameter sizes. automatically. high speed machining.

Constantly Monitors Machines and Automatically Corrects to the Appropriate Status!

Parallel Hand L Hand Standing Workpiece

■Flat Stocker ■Measuring Devices ■Chip Conveyor (For Cutting the Top Surface) ® ®

For Front and Back Cutting Workpiece For Shaft Workpiece Patented Patented

Feeds dimensional

errors back to the (Spiral Type) Processing Region

machine to maintain Mounted on the rear side ■Thermal Displacement Compensation System ■Spindle Condition Monitoring System

high-quality Chip disposal is done Y Turn Device The machined dimension values change as the machine temperature changes due to the The application of machine fault diagnosis methods is difficult in many cases where

dimensional semi-automatically in

accuracy. minimal space. customer’s conditions of use (machining conditions) and the environmental conditions existing threshold values are provided, because the threshold values differ for each

(factory temperature, etc.). This system predicts the amount of thermal displacement based machine. We have addressed this issue by providing a new method of diagnosis

(Floor Type) Horizontally Placed on the temperature changes at each part of the machine and provides compensation values to with a spindle status monitoring system based on the "characteristic space common

■Stocker for Mounted on the rear side Small Diameter Workpiece the CNC controller In order to minimize these changes in the machining dimension values. among machines", which is determined using characteristic quantities.

Shaft Type Parts Chips are reliably

discharged outside the Characteristic space

Processing Region

machine. Temperature measurement

Spindle unit Scratches,

Pickup Device Measurement of

∑i GTH Hand Pendulum Hand Measured values input to CNC thermal displacement CNC controller foreign matter,

faults

Collected data Change in status Poor lubrication

Prediction of thermal displacement

■Oil Mist Collector ■High-Pressure Coolant

■Parts Feeder Normal

Offset values input to CNC

Oil mist collection Constantly cooled Feedback

Workpieces can be facilitates a clean coolant is discharged

stored together with production at high pressure so The collet chuck developed and marketed under the

the tray. Thermony applied - Amount of change = 6 μm

environment. that the tool life is 4.00 Occurrence of foreign matter and scratches Occurrence of

significantly TAKAMAZ TAKAMAZ brand is manufactured in the factory where an Improved by 60% 3.50 lubrication abnormalities

prolonged.

Collet Chuck integrated system is used to streamline every part of the 14 Red dot: Indicates the current status

12 3.00

10

production, from machining to heat treatment. 8 2.50

6 Change in status

■Automatic Fire Extinguisher ■Semi-Dry Machining

■Tray Changer Collet run-off accuracy conforms to TAKAMAZ standard, 4 2.00

If fire breaks out in the Ultratrace, 2 1.50 Good

Workpieces can be 0

machine during highly-lubricating organic which is even higher than Japanese

-2 1.00

stored in individual automatic operations, coolant is applied to the -4

trays. Industrial Standards (JIS), allowing us to

-6 0.50 Initial plot cluster

fire extinguishing correct point on the

agent is automatically cutting edge, realizing provide our customers with exceptionally Time 9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00 17:00 0.50 1.00 1.50 2.00 2.50 3.00

discharged. semi-dry machining. dependable products. Acceleration value

09 10 11

EASY WAYS TO REDUCE WASTE

Changeof diameter μm

Feature value

Page12

OPTION SYSTEM LOADER SYSTEM AUTOMATION SYSTEM

By applying our experiences in manufacturing Encouraged from sales of more than 65 years, with "Integral loader" design philosophy in mind, ®

Transfer Device

(Loader) TAKAMAZ will lead the consistent support service follow up and support system built on trust,

of peripheral devices and our wealth of design leading to increased productivity.

achievements, we will continue to meet the Compact Loader Gantry Loader A Highly-Productive Robot System That Solves Your Problems!

needs of our customers.

Parts Supply Device Parts Supply Device ●Hi Speed Loader mounted on the machine ●Gantry-type servo loader with high rigidity. ■Reduces Personnel Costs

(Stocker, Pallet Changer, etc.) (Stocker, Pallet Changer, etc.) to save space. ●The traverse distance can be extended, ensuring extremely

A production line with different ●A dedicated servo controller allows speedy setup. flexible line configuration and systemization of peripheral This system loads/unloads workpieces with a robot that is integrated

equipment. with a tray changer. It realizes unmanned operation day and night, and

varieties of peripheral devices and improves production efficiency by maintaining machining quality,

loading variations can be designed. ensuring stable loading, and allowing multi-machine control.

Space Saving Accessory Devices ■Wide Range of Variations

Improving Durability Based on this robot + tray changer system, we can meet various needs

including washing units and gauging systems.

Pursuing of the Low Cost ■Simple Setup

Short Loading Time With the integrated robot + tray changer construction, setup can be

Flexible System Line Configuration completed just by teaching on site. The system can be retrofitted to an

When setting up the lathe,

existing machine provided there is a space of 1.8 x 0.9 meters in front of the robot can be slid

Improving Operability it. Consultations are welcome. together with its base.

■Retrofitting Even to Previous Models

Automation Peripheral Devices Quality/Environment Control Unit Cutting Efficiency/Chip Disposal For Small and Short Workpiece For Flange Workpiece Workpiece Delivery from Transport Unit Using a Conveyor ADVANCED TECHNOLOGY

Vertically-Oriented Workpiece

■Station Stocker ■Cleaning Unit ■Alloyed Clamp Holder (For Machining the Bottom Face) ®

Flexible Multi-layer Without operator for Vibration Suppression

stocker to intervention, Inhibiting the progression of E Turn Device

accommodate cleaning is wear boundary is expected Processing Region

different part performed to extend cutting tool life in

diameter sizes. automatically. high speed machining.

Constantly Monitors Machines and Automatically Corrects to the Appropriate Status!

Parallel Hand L Hand Standing Workpiece

■Flat Stocker ■Measuring Devices ■Chip Conveyor (For Cutting the Top Surface) ® ®

For Front and Back Cutting Workpiece For Shaft Workpiece Patented Patented

Feeds dimensional

errors back to the (Spiral Type) Processing Region

machine to maintain Mounted on the rear side ■Thermal Displacement Compensation System ■Spindle Condition Monitoring System

high-quality Chip disposal is done Y Turn Device The machined dimension values change as the machine temperature changes due to the The application of machine fault diagnosis methods is difficult in many cases where

dimensional semi-automatically in

accuracy. minimal space. customer’s conditions of use (machining conditions) and the environmental conditions existing threshold values are provided, because the threshold values differ for each

(factory temperature, etc.). This system predicts the amount of thermal displacement based machine. We have addressed this issue by providing a new method of diagnosis

(Floor Type) Horizontally Placed on the temperature changes at each part of the machine and provides compensation values to with a spindle status monitoring system based on the "characteristic space common

■Stocker for Mounted on the rear side Small Diameter Workpiece the CNC controller In order to minimize these changes in the machining dimension values. among machines", which is determined using characteristic quantities.

Shaft Type Parts Chips are reliably

discharged outside the Characteristic space

Processing Region

machine. Temperature measurement

Spindle unit Scratches,

Pickup Device Measurement of

∑i GTH Hand Pendulum Hand Measured values input to CNC thermal displacement CNC controller foreign matter,

faults

Collected data Change in status Poor lubrication

Prediction of thermal displacement

■Oil Mist Collector ■High-Pressure Coolant

■Parts Feeder Normal

Offset values input to CNC

Oil mist collection Constantly cooled Feedback

Workpieces can be facilitates a clean coolant is discharged

stored together with production at high pressure so The collet chuck developed and marketed under the

the tray. Thermony applied - Amount of change = 6 μm

environment. that the tool life is 4.00 Occurrence of foreign matter and scratches Occurrence of

significantly TAKAMAZ TAKAMAZ brand is manufactured in the factory where an Improved by 60% 3.50 lubrication abnormalities

prolonged.

Collet Chuck integrated system is used to streamline every part of the 14 Red dot: Indicates the current status

12 3.00

10

production, from machining to heat treatment. 8 2.50

6 Change in status

■Automatic Fire Extinguisher ■Semi-Dry Machining

■Tray Changer Collet run-off accuracy conforms to TAKAMAZ standard, 4 2.00

If fire breaks out in the Ultratrace, 2 1.50 Good

Workpieces can be 0

machine during highly-lubricating organic which is even higher than Japanese

-2 1.00

stored in individual automatic operations, coolant is applied to the -4

trays. Industrial Standards (JIS), allowing us to

-6 0.50 Initial plot cluster

fire extinguishing correct point on the

agent is automatically cutting edge, realizing provide our customers with exceptionally Time 9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00 17:00 0.50 1.00 1.50 2.00 2.50 3.00

discharged. semi-dry machining. dependable products. Acceleration value

09 10 11

EASY WAYS TO REDUCE WASTE

Changeof diameter μm

Feature value

Page13

OPERATING SYSTEM PRODUCTS

OF PARTNERS

Head Office and Plant TAKAMAZ

■TAKAMATSU MACHINERY CO., LTD.

・ HEAD OFFICE GENERAL CATALOG

1-8 ASAHIGAOKA HAKUSAN-CITY ISHIKAWA JAPAN. 924-8558 De

TEL +81-(0)76-207-6155 FAX +81-(0)76-274-1418

TAKAMAZ-EMAG Co., Ltd., is a joint venture between ENGLISH

Takamatsu Machinery Co., Ltd., (Japan) and EMAG ・ ASAHI PLANT

GmbH & Co. KG (Germany). A whole range of 4-13 ASAHIGAOKA HAKUSAN-CITY ISHIKAWA JAPAN. 924-0004

high-quality EMAG products from hard turning TEL +81-(0)76-274-0123 FAX +81-(0)76-274-8530

machines to grinding machines, laser processing, and Overseas Bases Sign

Featuring Functions Unique to TAKAMAZ! TAKAMAZ-EMAG gear hobbing machines are available. ■TAKAMATSU MACHINERY U.S.A., INC.

Its mission is to offer customized equipment tailored ・ CHICAGO HEAD OFFICE

to customers’ needs at low prices with short delivery 1280 LANDMEIER ROAD ELK GROVE VILLAGE, IL 60007 USA

times, and as turnkey projects. TEL +1-(0)847-981-8577 FAX +1-(0)847-981-8599

■Realizes High Productivity through Increased Loader Speed ■TAKAMAZ MACHINERY EUROPE GmbH

and Shorter Machine Stoppage Times ■VT2-4 Vertical Lathe with One Spindle and Two Turrets IM HÜLSENFELD 19, 40721 HILDEN, GERMANY

TEL +49-(0)2103-789-4882 FAX +49-(0)2103-789-4883

Productivity improvement ●Traverse axis: 120m/min Ultimate Shaft Work Machine ■TAKAMAZ MACHINERY( HANGZHOU) CO.,LTD.

(43% up compared with existing systems) High speed loading time with a 2-turret ・ HANGZHOU HEAD OFFICE

simultaneous 4-axis control capability.

●Vertical axis: 120 m/min NO.6800, JIANGDONG 3RD ROAD, JIANGDONG INDUSTRIAL PARK,

“VT series” machines are characterized

XIAOSHAN, HANGZHOU, ZHEJIANG, CHINA

(69% up compared with existing systems) by a construction that gives good EASY WAYS

Loader Size Display Function Y-Axis Automatic Adjustment Function TEL +86(- 0)571-8287-9709 FAX +86(- 0)571-8215-3732

■Shorter Setup Times by Functions Unique to TAKAMAZ access to the machining area and TO REDUCE WASTE

high-power spindles. ■TAKAMATSU MACHINERY( THAILAND) CO., LTD.

・ BANGKOK HEAD OFFICE

Ease-of-setup improvement ●Loader system operation can be checked 888/59 MOO 9, TAMBOL BANGPLA, AMPHUR BANGPLEE,

safely using handle operation. SAMUTPRAKARN PROVINCE, THAILAND

●Two types of teaching methods are TEL +66(- 0)2-136-7831 FAX +66(- 0)2-136-7834

available to suit various situations. ■PT. TAKAMAZ INDONESIA

■Loader Speed Optimization Function for JL. FESTIVAL BOULEVARD BLOK AA 11 NO.30,31 GRAND WISATA TAMBUN, BEKASI 17510

TEL +62-(0)21-8261-6431 FAX +62-(0)21-8261-6430 NO! CO2 NO MORE

Energy Savings and Longer Service Life ■TAKAMAZ MACHINERY MEXICO, S.A.DE C.V. OVERTIME

When setting up after changing the workpiece, When teaching the loader, the Y-axis position

Energy saving functions ●By automatically optimizing the speed of the

AVENIDA DE LOS INDUSTRIALES 522, LOCAL 4, INDUSTRIAL JULIAN DE OBREGON,

teaching can be completed by simply setting the can be automatically adjusted just by

loader, loader energy savings and a longer workpiece size. repeatedly opening and closing the fingers. 37290 LEON, GUANAJUATO MEXICO

F.T. Japan Inc. imports machines manufactured by TEL +52-477-784-0468

loader service life are achieved. Teaching time for a workpiece size change Loading position fine-adjustment time FEELER, ECOCA, and LEADWELL from our affiliate ■TAKAMATSU MACHINERY VIETNAM CO., LTD

Loader power consumption Reduced 17% 80% shorter 53% shorter FFG Group (Taiwan), the world’s third-largest NO.76 M HOANG QUOC VIET, PHU MY WARD, DISTRICT 7, HO CHI MINH CITY, VIETNAM

TEL +84-(0)28-3620-5671 FAX +84-(0)28-3620-5673

■In Addition to a Touch Panel Giving Exceptional Loader Operability, a Servo System Made by FANUC Is Adopted. general machine tool manufacturer, and sells them.

F.T. Japan Affiliated Companies

■General-Purpose Lathe SJ460 × 1000G ■HANGZHOU FEELER TAKAMATSU MACHINERY CO., LTD.

NO.6800, JIANGDONG 3RD ROAD, JIANGDONG INDUSTRIAL PARK,

This is a general-purpose

lathe manufactured by XIAOSHAN, HANGZHOU, ZHEJIANG, CHINA

ECOCA. It has excellent TEL +86(- 0)571-8215-3760 FAX +86(- 0)571-8286-5311

cost performance and is

available in a wide range

TAKAMAZ Technology Aids Productivity ■Functions for Better Working Efficiency in Addition to Conventional NC Screens of sizes. The apron

■Work Simplified by Automation of Operations and Network Function handle position can be

selected from either the

Better Working Efficiency Quality Control IT & IoT left or right sides. Slides are hardened/polished. Equipped

Operator working efficiency improved, Storing of traceability information per Programs can easily be input and output with an auto-feed stopper ring, machining that meets your

reducing production stoppage time workpiece to assist quality control between machines via the network. needs can be accomplished.

Equipment sold by the TAKAMAZ Group will be fully

supported by the TAKAMAZ service network.

Keeping Track of Production Progress The status of the machine during Simple On-Screen Input/Output

Production count and tool usage count can be determined at a glance. machining and can be checked and the

Display of Start Conditions No need to move between machines

information can be used for quality

Operations to prepare for starting can be performed quickly. control and preventive maintenance. No need for USB flash drives

Machine Stoppage Warning No need for an external computer

Advance warning of the next machine stoppage is displayed Examples of Traceability Data

based on the workpiece count, etc. Times, motor temperatures, cycle times,

Camera Image Display (Option) program numbers, tool wear offsets, etc. https://www.takamaz.co.jp

Makes it possible to check areas that are difficult to see, like the

rear section of the machine. Scan this QR Code

for more details.

12

23.07.3B(O)

Page14

OPERATING SYSTEM PRODUCTS

OF PARTNERS

Head Office and Plant TAKAMAZ

■TAKAMATSU MACHINERY CO., LTD.

・ HEAD OFFICE GENERAL CATALOG

1-8 ASAHIGAOKA HAKUSAN-CITY ISHIKAWA JAPAN. 924-8558 De

TEL +81-(0)76-207-6155 FAX +81-(0)76-274-1418

TAKAMAZ-EMAG Co., Ltd., is a joint venture between ENGLISH

Takamatsu Machinery Co., Ltd., (Japan) and EMAG ・ ASAHI PLANT

GmbH & Co. KG (Germany). A whole range of 4-13 ASAHIGAOKA HAKUSAN-CITY ISHIKAWA JAPAN. 924-0004

high-quality EMAG products from hard turning TEL +81-(0)76-274-0123 FAX +81-(0)76-274-8530

machines to grinding machines, laser processing, and Overseas Bases Sign

Featuring Functions Unique to TAKAMAZ! TAKAMAZ-EMAG gear hobbing machines are available. ■TAKAMATSU MACHINERY U.S.A., INC.

Its mission is to offer customized equipment tailored ・ CHICAGO HEAD OFFICE

to customers’ needs at low prices with short delivery 1280 LANDMEIER ROAD ELK GROVE VILLAGE, IL 60007 USA

times, and as turnkey projects. TEL +1-(0)847-981-8577 FAX +1-(0)847-981-8599

■Realizes High Productivity through Increased Loader Speed ■TAKAMAZ MACHINERY EUROPE GmbH

and Shorter Machine Stoppage Times ■VT2-4 Vertical Lathe with One Spindle and Two Turrets IM HÜLSENFELD 19, 40721 HILDEN, GERMANY

TEL +49-(0)2103-789-4882 FAX +49-(0)2103-789-4883

Productivity improvement ●Traverse axis: 120m/min Ultimate Shaft Work Machine ■TAKAMAZ MACHINERY( HANGZHOU) CO.,LTD.

(43% up compared with existing systems) High speed loading time with a 2-turret ・ HANGZHOU HEAD OFFICE

simultaneous 4-axis control capability.

●Vertical axis: 120 m/min NO.6800, JIANGDONG 3RD ROAD, JIANGDONG INDUSTRIAL PARK,

“VT series” machines are characterized

XIAOSHAN, HANGZHOU, ZHEJIANG, CHINA

(69% up compared with existing systems) by a construction that gives good EASY WAYS

Loader Size Display Function Y-Axis Automatic Adjustment Function TEL +86(- 0)571-8287-9709 FAX +86(- 0)571-8215-3732

■Shorter Setup Times by Functions Unique to TAKAMAZ access to the machining area and TO REDUCE WASTE

high-power spindles. ■TAKAMATSU MACHINERY( THAILAND) CO., LTD.

・ BANGKOK HEAD OFFICE

Ease-of-setup improvement ●Loader system operation can be checked 888/59 MOO 9, TAMBOL BANGPLA, AMPHUR BANGPLEE,

safely using handle operation. SAMUTPRAKARN PROVINCE, THAILAND

●Two types of teaching methods are TEL +66(- 0)2-136-7831 FAX +66(- 0)2-136-7834

available to suit various situations. ■PT. TAKAMAZ INDONESIA

■Loader Speed Optimization Function for JL. FESTIVAL BOULEVARD BLOK AA 11 NO.30,31 GRAND WISATA TAMBUN, BEKASI 17510

TEL +62-(0)21-8261-6431 FAX +62-(0)21-8261-6430 NO! CO2 NO MORE

Energy Savings and Longer Service Life ■TAKAMAZ MACHINERY MEXICO, S.A.DE C.V. OVERTIME

When setting up after changing the workpiece, When teaching the loader, the Y-axis position

Energy saving functions ●By automatically optimizing the speed of the

AVENIDA DE LOS INDUSTRIALES 522, LOCAL 4, INDUSTRIAL JULIAN DE OBREGON,

teaching can be completed by simply setting the can be automatically adjusted just by

loader, loader energy savings and a longer workpiece size. repeatedly opening and closing the fingers. 37290 LEON, GUANAJUATO MEXICO

F.T. Japan Inc. imports machines manufactured by TEL +52-477-784-0468

loader service life are achieved. Teaching time for a workpiece size change Loading position fine-adjustment time FEELER, ECOCA, and LEADWELL from our affiliate ■TAKAMATSU MACHINERY VIETNAM CO., LTD

Loader power consumption Reduced 17% 80% shorter 53% shorter FFG Group (Taiwan), the world’s third-largest NO.76 M HOANG QUOC VIET, PHU MY WARD, DISTRICT 7, HO CHI MINH CITY, VIETNAM

TEL +84-(0)28-3620-5671 FAX +84-(0)28-3620-5673

■In Addition to a Touch Panel Giving Exceptional Loader Operability, a Servo System Made by FANUC Is Adopted. general machine tool manufacturer, and sells them.

F.T. Japan Affiliated Companies

■General-Purpose Lathe SJ460 × 1000G ■HANGZHOU FEELER TAKAMATSU MACHINERY CO., LTD.

NO.6800, JIANGDONG 3RD ROAD, JIANGDONG INDUSTRIAL PARK,

This is a general-purpose

lathe manufactured by XIAOSHAN, HANGZHOU, ZHEJIANG, CHINA

ECOCA. It has excellent TEL +86(- 0)571-8215-3760 FAX +86(- 0)571-8286-5311

cost performance and is

available in a wide range

TAKAMAZ Technology Aids Productivity ■Functions for Better Working Efficiency in Addition to Conventional NC Screens of sizes. The apron

■Work Simplified by Automation of Operations and Network Function handle position can be

selected from either the

Better Working Efficiency Quality Control IT & IoT left or right sides. Slides are hardened/polished. Equipped

Operator working efficiency improved, Storing of traceability information per Programs can easily be input and output with an auto-feed stopper ring, machining that meets your

reducing production stoppage time workpiece to assist quality control between machines via the network. needs can be accomplished.

Equipment sold by the TAKAMAZ Group will be fully

supported by the TAKAMAZ service network.

Keeping Track of Production Progress The status of the machine during Simple On-Screen Input/Output

Production count and tool usage count can be determined at a glance. machining and can be checked and the

Display of Start Conditions No need to move between machines

information can be used for quality

Operations to prepare for starting can be performed quickly. control and preventive maintenance. No need for USB flash drives

Machine Stoppage Warning No need for an external computer

Advance warning of the next machine stoppage is displayed Examples of Traceability Data

based on the workpiece count, etc. Times, motor temperatures, cycle times,

Camera Image Display (Option) program numbers, tool wear offsets, etc. https://www.takamaz.co.jp

Makes it possible to check areas that are difficult to see, like the

rear section of the machine. Scan this QR Code

for more details.

12

23.07.3B(O)