1/12ページ

ダウンロード(1.4Mb)

EtherCAT通信対応のサーボシステム

高精度位置決め:分解能=16,777,216パルス/1回転(24Bit、INC/ABS)

最大3kHzの応答周波数。

ワンクリックチューニング、システム分析機能、他。

ノッチフィルタ5セット、制振制御アルゴリズムの機能を追加。

CiA402に対応。 同期周期は最高125μs。

安全機能 STO に対応(IEC61508 (SIL2)、IEC62061 (SILCL2)、ISO13849-1、カテゴリ3 PL=dに準拠)

専用ソフトウェアASDA-Soft無償提供(サーボ調整、オシロスコープ、パラメータ編集、他)

関連メディア

このカタログについて

| ドキュメント名 | デルタ電子 EtherCAT通信対応サーボシステム A3-Eシリーズ |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 1.4Mb |

| 登録カテゴリ | |

| 取り扱い企業 | デルタ電子株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

Automation for a Changing World

Delta AC Servo Drive & Motor

ASDA-A3 Series

www.del taww.com

Page2

Cutting-edge Specifications

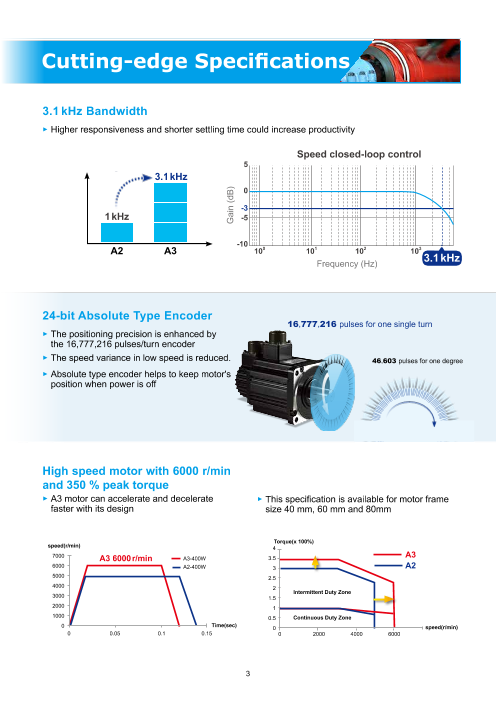

3.1 kHz Bandwidth

► Higher responsiveness and shorter settling time could increase productivity

Speed closed-loop control

5

3.1 kHz

0

-3

1 kHz -5

-10

A2 A3 100 101 102 103

Frequency (Hz) 3.1 kHz

24-bit Absolute Type Encoder

16,777,216 pulses for one single turn

► The positioning precision is enhanced by

the 16,777,216 pulses/turn encoder

► The speed variance in low speed is reduced. 46,603 pulses for one degree

► Absolute type encoder helps to keep motor's

position when power is off

High speed motor with 6000 r/min

and 350 % peak torque

► A3 motor can accelerate and decelerate ► This specification is available for motor frame

faster with its design size 40 mm, 60 mm and 80mm

Torque(x 100%)

speed(r/min) 4

7000 A3 6000 r/min A3-400W 3.5 A3

6000 A2-400W 3 A2

5000 2.5

4000 2

Intermittent Duty Zone

3000 1.5

2000 1

1000 0.5 Continuous Duty Zone

0 Time(sec) 0 speed(r/min)

0 0.05 0.1 0.15 0 2000 4000 6000

3

Gain (dB)

Page3

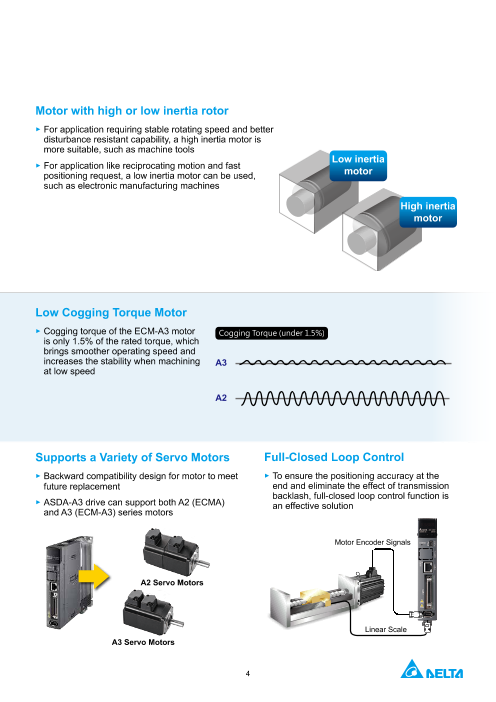

Motor with high or low inertia rotor

► For application requiring stable rotating speed and better

disturbance resistant capability, a high inertia motor is

more suitable, such as machine tools

Low inertia

► For application like reciprocating motion and fast

positioning request, a low inertia motor can be used, motor

such as electronic manufacturing machines

High inertia

motor

Low Cogging Torque Motor

► Cogging torque of the ECM-A3 motor Cogging Torque (under 1.5%)

is only 1.5% of the rated torque, which

brings smoother operating speed and

increases the stability when machining A3

at low speed

A2

Supports a Variety of Servo Motors Full-Closed Loop Control

► Backward compatibility design for motor to meet ► To ensure the positioning accuracy at the

future replacement end and eliminate the effect of transmission

backlash, full-closed loop control function is

► ASDA-A3 drive can support both A2 (ECMA) an effective solution

and A3 (ECM-A3) series motors

Motor Encoder Signals

A2 Servo Motors

Linear Scale

A3 Servo Motors

4

Page4

System Tuning and Safety

Functions

System Diagnosis Function

► The rigidity of a machine is known through a

mathematical model

► The consistency of the machine's batch installation

can be checked

► By comparing the data from different time span, the

wear condition of a machine can be acquired

Low Frequency Vibration Suppression Function

► Vibration elimination algorithm is different from command filter and used as a creative algorithm on

ASDA-A3

► The vibration can be eliminated without slowing down its response

► In addition to vibration elimination algorithm, the two command filters for low frequency vibration are

included

Without Vibration Suppression Delta Vibration Suppression

Unstable Stable

Auto-Tuning Function Motor Load (inertia ratio=68)

2500

Position Command

► Lower the barrier for users to use Before Auto-Tuning

servo systems 2000 After Auto-Tuning

► This function will optimize the machine

performance with less tuning effort 1500

► It can be done via panel keypad or 1000

software

500

0

-500

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45 0.5

Time (sec)

5

Pulse of User Unit (PUU)

Page5

Advanced Notch Filter Test Machine Layout

► There are 5 sets of notch filters with tunable

bandwidth and up to 5000 Hz band for ASDA-A3

► Those filters can search resonance and set the

attenuation level automatically

► With shorter search time for resonance, the

machine is less likely to be damaged

Speed (r/min)

Less than 0.5 sec

Time (ms)

Safe Torque Off (STO) Function *note : will be certified

► Built-in STO (Safe Torque Off) function

► The motor power will be cut-off when STO is activated

! Motor Speed

! Trigger STO

Grating Time

6

Page6

Motion Inside

Motion Inside

► 99 sophisticated motion commands and segments

allowed

► Arithmetic operation and condition jump commands

are added

► Graphical user interface offers simple setup and

programming

► General motion functions like homing, position and

speed commands are available

► Superimposition, blending and on-the-fly change

motion commands are provided

Built-in Camming Functions

► E-CAM functions for flying shear and rotary

cut are well configured

► There are maximum 720 points in one cam

profile or contour with interpolation smooth

algorithm

► Useful E-CAM phase secure and adjustment

functions are easy to apply

► Many successful applications from ASDA-A2

are available for reference

Capture and Compare Functions

► It is only 5 µs response time to latch the position or pulse count after receiving the activated DI single.

► The high-speed DO will response when assigned position or count value is reached after 5 µs

response time

DI7

383838 Position

383838 Position==

383838

383838 True

D O4

When DI7 is triggered, the latched position is When the data recorded in Data Array is identical to the

recorded in Data Array. detected position, DO4 will be on.

7

Page7

Energy-Saving and

Compact Size Design

DC-bus Sharing Feature Without Sharing DC Bus With Sharing DC Bus

► The regenerative energy will be collected

to DC-bus for other axes to increase

energy efficiency

► Smaller resistor installed is possible for

the system, which can save cost and

installation space

Regenerative energy Regenerative energy

Generator effect Generator effect

A3 A2

200 W 200 W

Thinner Size Servo Drive

► ASDA-A3 is 20% smaller than A2 on dimensions,

which requires less installation space

20%

Smaller Size Servo Motor Shorter in length

► ASDA-A3 series servo motor is 20% shorter than A2's A2

A3

20%

8

Page8

User-Friendly Software

Tree-View Index Window Graphical Interface for Parameter

► Well organized list and collapsible menu help Settings

to access functions easily ► Intuitive user interface provides set up

functions and parameters without manual

findings

Auto-Tuning Wizard for Gains

► Provides step by step guiding wizard for users to tune a servo

Advanced Gain Tuning Interface

► The servo gains can be easily fine-tuned for

better performance with its well-designed

tuning modes

9

Page9

System Analysis in Bode Plot

■ Speed Open-Loop Mode ■ System Module Mode

Checks the bode plot to know the margin for The machine rigidity can be judged from the

stability for properly tuned system bode plot in this mode

Oscilloscope Function

► The channel configurations for applying the ► Offers FFT (Fast Fourier Transform) function

PC scope include: for checking its signal spectrum

‐ 8 channels with 16-bit data size and 10 kHz ► The RMS value can be calculated by selecting

sampling rate the period of a signal

‐ 4 channels with 32-bit data size and 10 kHz ► The conditions of start-to-record and stop-

sampling rate recording can be configured

‐ 4 channels with 16 bit data size and 20 kHz

sampling rate

Graphical Programing Interface of

PR mode

► This tool easily allow users to write and trace

programs including Jump instructions

10

Page10

Model Explanation

ASDA-A3 Series Servo Drives

ASD - A3 - 04 21 - L

Product Name: Model Type

AC Servo Drive (see the table below)

Series: Input Voltage and Phase

A3 Series 21: 220V 1-phase / 3-phase

23: 220V 3-phase

Rated Output Power

01: 100 W 10: 1 kW

02: 200 W 15: 1.5 kW

04: 400 W 20: 2 kW

07: 750 W 30: 3 kW

PT Mode Full-closed Analog Type Pulse PR Mode RS-485 CANopen DMCNET EtherCAT

Train Loop

Voltage E-CAM STO

Control Control

L ○ ○ ○ X X X ○ ○ X X

M ○ ○ ○ ○ X X ○ ○ ○ ○

F X ○ X X ○ X ○ X ○ X

E* X ○ X X X ○ ○ X ○ ○

Note: Models with a * mark are the ones to be launched.

12

Page11

Model Explanation

ECM-A3 Series Servo Motors

ECM - A 3 H - C Y 06 04 R S 1

Product Name

ECM: Electrical Special digit

Commutation Motor 1: standard product

Driving Type Shaft size

A: AC Servo Motor S: Standard

7: special (14 mm)

Generation

3: A3 Series W/O With W/O With Shaft and Brake Brake Brake Brake

Oil Seal W/O Oil W/O Oil With With

Seal Seal Oil Seal Oil Seal

Inertia Round Shaft

H: High inertia (with screw hole) - - C* D*

L: Low inertia Keyway

P* Q* R S

(with screw hole)

Series Rated Voltage / Rated Speed Note: Note: Models with a * mark are the ones to be launched

C: Rated Voltage 220 V, Rated Output Power

Rated Speed 3,000 r/min 0F: 50 W

01: 100 W

02: 200 W

Encoder Type 04: 400 W

Y: 24-bit Absolute Optical Encoder 07: 750 W

Single-turn: 24-bit

Multi-turn: 16-bit

1: 24-bit Single-turn Absolute Optical Encoder Motor Frame Size

G: 16-bit Single-turn Absolute Magnetic Encoder 04: 40 mm

2*: 24-bit Single-turn Absolute Magnetic 06: 60 mm

Optical Encoder 08: 80 mm

A*: 24-bit Absolute Magnetic Optical Encoder

Single-turn: 24-bit

Multi-turn: 16-bit

*To be launched

13

Page12

Industrial Automation Headquarters

Delta Electronics, Inc.

Taoyuan Technology Center

No.18, Xinglong Rd., Taoyuan District,

Taoyuan City 33068, Taiwan

TEL: 886-3-362-6301 / FAX: 886-3-371-6301

Asia EMEA

Delta Electronics (Shanghai) Co., Ltd. Delta Electronics (Netherlands) BV

No.182 Minyu Rd., Pudong Shanghai, P.R.C. Eindhoven Office

Post code : 201209 De Witbogt 20, 5652 AG Eindhoven, The Netherlands

TEL: 86-21-6872-3988 / FAX: 86-21-6872-3996 MAIL: Sales.IA.EMEA@deltaww.com

Customer Service: 400-820-9595 MAIL: Sales.IA.Benelux@deltaww.com

Delta Electronics (Japan), Inc. Delta Electronics (France) S.A.

Tokyo Office ZI du bois Chaland 2 15 rue des Pyrénées,

Industrial Automation Sales Department Lisses 91056 Evry Cedex, France

2-1-14 Shibadaimon, Minato-ku MAIL: Sales.IA.FR@deltaww.com

Tokyo, Japan 105-0012

TEL: 81-3-5733-1155 / FAX: 81-3-5733-1255 Delta Electronics Solutions (Spain) S.L.U

Ctra. De Villaverde a Vallecas, 265 1˚ Dcha Ed.

Delta Electronics (Korea), Inc. Hormigueras – P.I. de Vallecas 28031 Madrid

Seoul Office C/Llull, 321-329 (Edifici CINC) | 22@Barcrelona, 08019 Barcelona

1511, 219, Gasan Digital 1-Ro., Geumcheon-gu, MAIL: Sales.IA.Iberia@deltaww.com

Seoul, 08501 South Korea

TEL: 82-2-515-5305 / FAX: 82-2-515-5302 Delta Electronics (Italy) Srl

Ufficio di Milano Via Senigallia 18/2 20161 Milano (MI)

Delta Energy Systems (Singapore) Pte Ltd. Piazza Grazioli 18 00186 Roma, Italy

4 Kaki Bukit Avenue 1, #05-04, Singapore 417939 MAIL: Sales.IA.Italy@deltaww.com

TEL: 65-6747-5155 / FAX: 65-6744-9228

Delta Electronics (Germany) GmbH

Delta Electronics (India) Pvt. Ltd. Coesterweg 45, D-59494 Soest, Germany

Plot No.43, Sector 35, HSIIDC Gurgaon, MAIL: Sales.IA.DACH@deltaww.com

PIN 122001, Haryana, India

TEL: 91-124-4874900 / FAX : 91-124-4874945 Delta Energy Systems LLC (CIS)

Vereyskaya Plaza II, office 112 Vereyskaya str.

Delta Electronics (Thailand) PCL. 17 121357 Moscow, Russia

909 Soi 9, Moo 4, Bangpoo Industrial Estate (E.P.Z), MAIL: Sales.IA.RU@deltaww.com

Pattana 1 Rd., T.Phraksa, A.Muang,

Samutprakarn 10280, Thailand Delta Greentech Ltd. (Turkiye)

TEL: 66-2709-2800 / FAX : 662-709-2827 Serifali Mevkii Barboros Bulvari Soylesi Sok

No 19 34775, Y.Dudullu-Umraniye/Istanbul

Delta Energy Systems (Australia) Pty Ltd. MAIL: Sales.IA.Turkey@delta-emea.com

Unit 20-21/45 Normanby Rd., Notting Hill Vic 3168, Australia

TEL: 61-3-9543-3720 Delta Energy Systems AG (Dubai BR)

P.O. Box 185668, Gate 7, 3rd Floor, Hamarain Centre,

Americas Dubai, United Arab Emirates

Delta Electronics (Americas) Ltd MAIL: Sales.IA.MEA@deltaww.com.

Raleigh Office

P.O. Box 12173, 5101 Davis Drive,

Research Triangle Park, NC 27709, U.S.A.

TEL: 1-919-767-3813 / FAX: 1-919-767-3969

Delta Greentech (Brasil) S/A

São Paulo Office

Rua Itapeva, 26 – 3˚ Andar - Bela Vista

CEP: 01332-000 – São Paulo – SP - Brasil

TEL: 55-11-3530-8642 / 55-11-3530-8640

Delta Electronics International Mexico S.A. de C.V.

Mexico Office

Vía Dr. Gustavo Baz No. 2160, Colonia La Loma,

54060 Tlalnepantla Estado de Mexico

TEL: 52-55-2628-3015 #3050/3052

*We reserve the right to change the information in this catalogue without prior notice. DELTA_IA-ASDA_ASDA-A3_C_EN_20180419