1/2ページ

ダウンロード(145.8Kb)

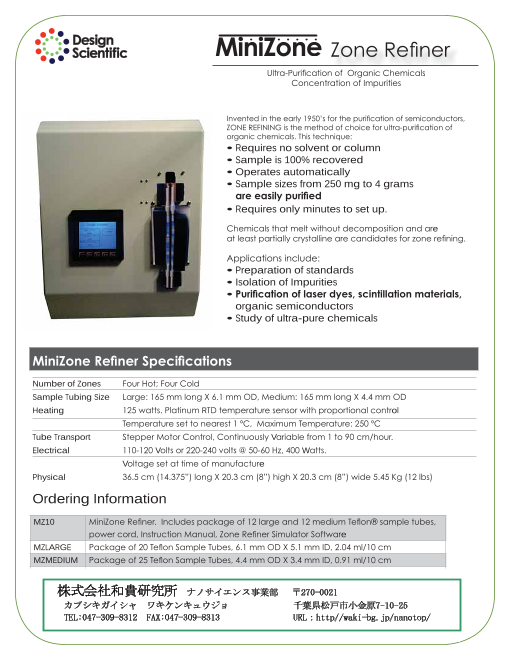

”有機化学超精製”装置です。

有機化学における不純物の超精製を可能にする非常にコンパクトなラボ用卓上型ゾーンメルト法試料精製装置です。

分解せず溶融する(少しでも部分的に結晶性のある)化学製品はゾーンメルト精製の対象となり得ます。

以下アプロケーションでご使用検討願います。

・不純物分離

・磁性材料の純良化

・分析物質の標準化

・単結晶成長、再結晶

・有機半導体の高純度化

・レーザー色素(ダイ)精製

・シンチレーション材料精製

このカタログについて

| ドキュメント名 | ゾーンメルト(帯溶融)精製装置 |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 145.8Kb |

| 登録カテゴリ | |

| 取り扱い企業 | 株式会社和貴研究所 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

• Requires no solvent or column

• Sample is 100% recovered

• Operates automatically

• S ample sizes from 250 mg to 4 grams

• Requires only minutes to set up.

e

• Preparation of standards

• Isolation of Impurities

•

organic semiconductors

• Study of ultra-pure chemicals

Number of Zones

Sample Tubing Size

Heating R ol

Tube Transport V

Electrical V W

V e

Physical

Ordering Information

MZ10 $5,980

e

MZLARGE $ 30

MZMEDIUM $ 30

Warranty

株式会社和貴研究所 ナノサイエンス事業部 〒270-0021

カブシキガイSCシIャE NCワEキ ケLAンBキOュRAウTジORョI E S 〒 2千70葉-0県02松1 千戸葉市県松小戸金市原小金7-原107-1205-25

( 80T0E)L 5:7024 7- -6360593株- •8 式3Fa1会x2: (社6F1Aサ6X): イ30946エ7 - ン37059ス20- 8ラ•3 51ボ930 ラ E aトs t リ3 2nーd ズS tr e et T, EHLUo:Rll0La4:n7d-h,3t 0Mt9pI- /489/34w121a3 k i•F-A Xbin:gf.o0j4@p7r/-e3ns0oa9nlu-ot8tio3o1np0s/ ys.com

次世代技術知識集団 www.resolutionsysht.tpc:/o/wmww.scilab.co.jp E-mail:support@scilab.co.jp

Page2

Zone Refiner

Ultra-Purification of Organic Chemicals

Concentration of Impurities

In Zone Refining, a short molten zone travels slowly The photo shows a

through an elongated sample of a crystalline mate- sample during the

rial. A molten zone traversing a solid sample has two refinement process

liquid-solid in the MiniZone re-

interfaces; finer. The sample is

a melting contained in one (or

interface and two) disposable, thin-

a freezing walled Teflon® sample

interface. tubes. These tubes are

At the melting filled with the sample

interface the and clamped on

composition each end in the tube

sample of a crystalline material. A molten zone tra- transport mechanism.

versing a solid sample has two liquid-solid interfaces; (The metal blocks at

a melting interface and a freezing interface. At the the top and bottom

melting interface the composition does not change of the photo.) The

but at the freezing interface, the impurities favor the transport mechanism

liquid phase because the crystal structure tends to slowly moves the tubes

exclude molecules that do not readily fit into the downward, passing

crystal lattice. Passing the molten zone(s) through the them through the

sample many times concentrates the impurities at one four heating and four

end leaving the opposite end highly purified. cooling zones of the

temperature regulated

metal blocks. After the

tubes move downward

Free Zone Refiner the distance of one hot

zone and one cold zone (two centimeters), the trans-

Simulator Software port mechanism is reversed and the tubes are quickly

Explains the theory of zone moved upward to the original position. The net result

refining and displays of this motion is that the molten and crystalline zones

how the sample is purified. migrate slowly and continuously upward with respect

to the tubing.

E-mail info@resolutionsys.com

to request your free copy. With a typical zone rate of 2 cm/hr and with four ac-

tive zones, each portion of the sample is subjected

to one purifying phase transitions per hour. Usually

within 18 hours of automatic operation (18 recrystal-

lizations), the sample is purified. After the sample tube

is cooled, it is removed from the MiniZone. The refined

sample is easily recovered by cutting the tube into

sections. The major portion of the impurities are con-

centrated at one end of the tube.

For more information on zone refining, please visit

our web site at www.resolutionsys.com.