1/9ページ

ダウンロード(3.7Mb)

このカタログについて

| ドキュメント名 | ACCUPYC II |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 3.7Mb |

| 取り扱い企業 | 島津サイエンス東日本株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

Accupyc II

gas displacement pycnometry system

Page2

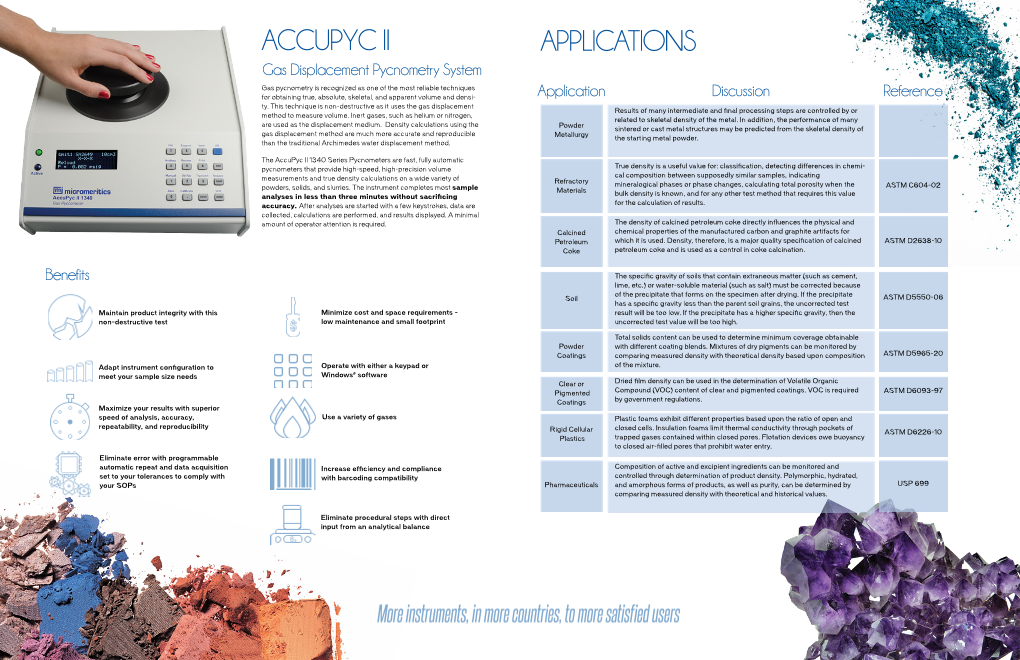

Accupyc II AppLIcATIONS

Gas Displacement pycnometry System

Gas pycnometry is recognized as one of the most reliable techniques

for obtaining true, absolute, skeletal, and apparent volume and densi- Application Discussion Reference

ty. This technique is non-destructive as it uses the gas displacement

Results of many intermediate and final processing steps are controlled by or

method to measure volume. Inert gases, such as helium or nitrogen,

related to skeletal density of the metal. In addition, the performance of many

are used as the displacement medium. Density calculations using the Powder sintered or cast metal structures may be predicted from the skeletal density of

gas displacement method are much more accurate and reproducible Metallurgy the starting metal powder.

than the traditional Archimedes water displacement method.

The AccuPyc II 1340 Series Pycnometers are fast, fully automatic

pycnometers that provide high-speed, high-precision volume True density is a useful value for: classification, detecting differences in chemi-

measurements and true density calculations on a wide variety of cal composition between supposedly similar samples, indicating Refractory

powders, solids, and slurries. The instrument completes most sample mineralogical phases or phase changes, calculating total porosity when the ASTM C604-02Materials

analyses in less than three minutes without sacrificing bulk density is known, and for any other test method that requires this value

accuracy. After analyses are started with a few keystrokes, data are for the calculation of results.

collected, calculations are performed, and results displayed. A minimal

amount of operator attention is required. The density of calcined petroleum coke directly influences the physical and

Calcined chemical properties of the manufactured carbon and graphite artifacts for

Petroleum which it is used. Density, therefore, is a major quality specification of calcined ASTM D2638-10

Coke petroleum coke and is used as a control in coke calcination.

Benefits The specific gravity of soils that contain extraneous matter (such as cement,

lime, etc.) or water-soluble material (such as salt) must be corrected because

of the precipitate that forms on the specimen after drying. If the precipitate

Soil ASTM D5550-06

has a specific gravity less than the parent soil grains, the uncorrected test

Maintain product integrity with this Minimize cost and space requirements - result will be too low. If the precipitate has a higher specific gravity, then the

non-destructive test low maintenance and small footprint uncorrected test value will be too high.

Total solids content can be used to determine minimum coverage obtainable

Powder with different coating blends. Mixtures of dry pigments can be monitored by

Coatings comparing measured density with theoretical density based upon composition ASTM D5965-20

Adapt instrument configuration to Operate with either a keypad or of the mixture.

®

meet your sample size needs Windows software

Clear or Dried film density can be used in the determination of Volatile Organic

Pigmented Compound (VOC) content of clear and pigmented coatings. VOC is required ASTM D6093-97

Coatings by government regulations.

Maximize your results with superior

speed of analysis, accuracy, Use a variety of gases Plastic foams exhibit different properties based upon the ratio of open and

repeatability, and reproducibility Rigid Cellular closed cells. Insulation foams limit thermal conductivity through pockets of ASTM D6226-10

Plastics trapped gases contained within closed pores. Flotation devices owe buoyancy

to closed air-filled pores that prohibit water entry.

Eliminate error with programmable

automatic repeat and data acquisition Increase efficiency and compliance Composition of active and excipient ingredients can be monitored and

set to your tolerances to comply with with barcoding compatibility controlled through determination of product density. Polymorphic, hydrated,

your SOPs Pharmaceuticals and amorphous forms of products, as well as purity, can be determined by USP 699

comparing measured density with theoretical and historical values.

Eliminate procedural steps with direct

input from an analytical balance

8g

More instruments, in more countries, to more satisfied users

Page3

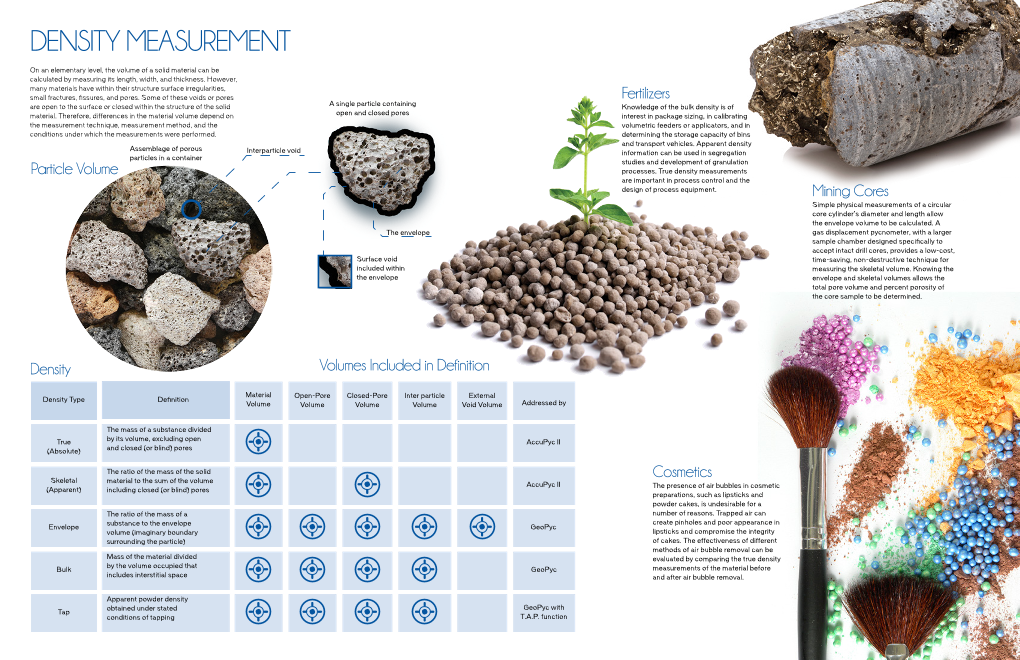

DENSITy MEASuREMENT

On an elementary level, the volume of a solid material can be

calculated by measuring its length, width, and thickness. However,

many materials have within their structure surface irregularities,

small fractures, fissures, and pores. Some of these voids or pores Fertilizers

are open to the surface or closed within the structure of the solid A single particle containing Knowledge of the bulk density is of

material. Therefore, differences in the material volume depend on open and closed pores interest in package sizing, in calibrating

the measurement technique, measurement method, and the volumetric feeders or applicators, and in

conditions under which the measurements were performed. determining the storage capacity of bins

and transport vehicles. Apparent density

Assemblage of porous Interparticle void information can be used in segregation

particles in a container

studies and development of granulation

particle Volume processes. True density measurements

are important in process control and the

design of process equipment. Mining cores

Simple physical measurements of a circular

core cylinder’s diameter and length allow

the envelope volume to be calculated. A

The envelope gas displacement pycnometer, with a larger

sample chamber designed specifically to

accept intact drill cores, provides a low-cost,

Surface void time-saving, non-destructive technique for

included within measuring the skeletal volume. Knowing the

the envelope envelope and skeletal volumes allows the

total pore volume and percent porosity of

the core sample to be determined.

Density Volumes Included in Definition

Material Open-Pore Closed-Pore Inter particle External

Density Type Definition

Volume Volume Volume Volume Void Volume Addressed by

The mass of a substance divided

True by its volume, excluding open AccuPyc II

(Absolute) and closed (or blind) pores

The ratio of the mass of the solid cosmetics

Skeletal material to the sum of the volume AccuPyc II The presence of air bubbles in cosmetic

(Apparent) including closed (or blind) pores

preparations, such as lipsticks and

powder cakes, is undesirable for a

The ratio of the mass of a number of reasons. Trapped air can

substance to the envelope create pinholes and poor appearance in Envelope GeoPyc

volume (imaginary boundary lipsticks and compromise the integrity

surrounding the particle) of cakes. The effectiveness of different

methods of air bubble removal can be

Mass of the material divided evaluated by comparing the true density

Bulk by the volume occupied that GeoPyc measurements of the material before

includes interstitial space and after air bubble removal.

Apparent powder density

Tap obtained under stated

GeoPyc with

conditions of tapping T.A.P. function

Page4

GAS DISpLAcEMENT pycNOMETRy

principle of Operation

This technique uses the gas displacement method to Inert gas flows Equilibrium is reached

measure volume accurately. Inert gases, such as helium or

nitrogen, are used as the displacement medium. The sample 1 Into sample chamber 4 yet again

is sealed in the instrument compartment of known volume, valve a opens then closes

the appropriate inert gas is admitted, and then expanded into Volume divided into

another precision internal volume. The pressures observed

upon filling the sample chamber and then discharging it into Equilibrium is sample weight

a second empty chamber allow computation of the sample 2 reached 5

solid phase volume. Helium molecules rapidly fill pores as determines density

small as one angstrom in diameter; only the solid phase of

the sample displaces the gas. Dividing this volume into the Gas flows into

sample weight gives the gas displacement density. 3 second chamber Pressure ventedfor volume measurement 6 off to atmosphere

valve b opens valve c opens

2 4 3 5

Density

1

sample

6

Every Eight Hours – A Technical Paper Citing a Micromeritics instrument is Accepted for Publication in a Scientific Journal

Page5

HIGHLy ADApTIVE SySTEM Direct sample mass input

The AccuPyc II Pycnometer consists of an integrated control and Sample mass may be directly input from corepyc***

analysis module. For those who require high throughput, analysis an analytical balance

modules are also available in a single configuration, allowing you to Specialized unit with

attach up to five additional analysis modules to a single controlling 2000-cm3 sample chamber size

unit. Each module has its own gas connection. A variety of sample

chamber sizes can be selected to provide the best fit with your

samples. The run precision mode allows you to achieve high repeat-

ability. The instrument automatically purges water and volatiles from

the sample and then repeats the analysis until successive measure-

ments converge upon a consistent result. Integrated control and

analysis module

unique run Can control up to five additional external

analysis modules

precision

Increases the precision of analysis results

by reporting data from five consecutive

measurements that are within a user-specified

tolerance. This feature allows early termination

of analysis, thereby decreasing the number of

cycles needed for accurate results.

Multilingual

The AccuPyc may be operated in five

languages: English, French, German,

Italian, or Spanish

Five standard

Ethernet port sample chamber

An Ethernet port on the rear panel of sizes

the control module enables you to email

3 3 3 3

reports, send data to a web browser for 1 cm , 10 cm , 100 cm , 350 cm , and

3

archiving, or interface with the AccuPyc 2000 cm ***

Windows application

uSB ports Simple calibration Bayonet cap fitting

Provides superior repeatable seal compared

USB ports on the rear panel of the process

to screw-type fitting

control module allow for connection

to a printer (output of analysis and Allows you to easily determine the volume of the

calibration results in either ascii or excel instrument sample cell and expansion chambers

formats) and keyboard (alphanumeric using a traceable standard volume. After

character input). The USB port is also calibration, the cell and expansion chamber

used for installing software upgrades volumes are stored automatically

2000 cm3 350 cm3 100 cm3 10 cm3 1 cm3

Page6

MODEL SELEcTION HARDWARE

Sample Sample Available Temp

Catalog

Chamber Chamber MultiVolume Control

Number

Capacity Dimensions Insert Kits Type VERSATILITy

AccuPyc II

1 cm3 1-cm ID x 1.1-cm D 0.1 cm3 134/00001/00 MultiVolume Kits

10 cm3 1.80-cm ID x 3.93-cm D 1.0 and 3.5 cm3 N/A 134/00000/00 A MultiVolume option allowing you to analyze smaller-sized

samples with your current AccuPyc model is available for

100 cm3 4.62-cm ID x 6.17-cm D 10 and 35 cm3 134/00002/00 configurations listed below;

Each kit includes appropriate insert(s), reference standard(s), and

AccuPyc II 1340 Remote Analysis Instruments sample cup(s).

Bundle includes Control module and 2-ft cable connected to Analysis modules. 2000-cm3 nominal cell volume

650- and 1300-cm3 cups

1 cm3 1-cm ID x 1.1-cm D 0.1 cm3 134/00031/00

AccuPyc II Bundle

10 cm3 1.80-cm ID x 3.93-cm D 1.0 and 3.5 cm3 134/00030/00 100-cm3 nominal cell volume

3

100 cm3 4.62-cm ID x 6.17-cm D 10 and 35 cm3 N/A 134/00032/00 10- and 35-cm cups

350 cm3 5.84-cm ID x 13.94-cm D NA 134/00033/00

10-cm3 nominal cell volume

2000 cm3 9.7-cm ID x 26.00-cm D 650 and 1300 cm3 134/00034/00 1- and 3.5-cm3 cups

Remote analysis modules only. Remote analysis units require connection to a control module 1-cm3 nominal cell volume

or AccuPyc II 1340 0.1-cm3 cup

Remote Analysis

Module Only 1 cm3 1-cm ID x 1.1-cm D 0.1 cm3 134/00041/00

10 cm3 1.80-cm ID x 3.93-cm D 1.0 and 3.5 cm3 134/00040/00

100 cm3 4.62-cm ID x 6.17-cm D 10 and 35 cm3 N/A 134/00042/00 SOFTWARE VERSATILITy

350 cm3 5.84-cm ID x 13.94-cm D NA 134/00043/00 Data presentation

2000 cm3 9.7-cm ID x 26.00-cm D 650 and 1300 cm3 134/00046/00 Density vs Cycle #

The AccuPyc II can be operated with a keypad or an optional Average: 3.8691 g/cm³ Standard Deviation: 0.0123 g/cm³Density vs Cycle #

Windows® interface that provides exceptional reporting and 3.895

Control Module Only

archiving capability. Both versions include direct sample mass input

Control module only. Up to 5 analysis modules can be connected to a single control module. 3.890from a balance and cycle-based displacement volume reporting.

With the Windows interface, features such as time-based pressure 3.885

N/A N/A N/A N/A 134/00005/00 equilibration reporting and additional calculations such as percent

3.880

solids content and total pore volume are included. Operational

status can also be continually monitored in a status window on the 3.875

AccuPyc II 1340 Temperature - Controlled Instruments monitor screen.

Equilibration Repo3.8r7t0

10 cm3 1.80-cm ID x 3.93-cm D 3

• Combined Report P2 (Expansion Pressure) shown every 1 second(s)

1.0 and 3.5 cm Use with External 134/00010/00 Cycle #1 Cycle #2 Cycle #3 Cycle #4 3.865 Cycle #5 Cycle #6AccuPyc II TC Cycle #7 Cycle #8

3 Recirculating Bath100 cm3 4.62-cm ID x 6.17-cm D 10 and 35 cm 134/00020/00

• Summary Report 18 3.860

AccuPyc II TEC 15-50 ˚C 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5V.0 o5.l5. v6.0s6 .C5 y7.0cl7.e5 #8.0 8.5 9.0 9.5 10.0

17 Cycle Number

• User-Defined Tabular Reports Average: 6.3725 cm³ Standard Deviation: 0.0004 cm³

Vol. vs Cycle #

Reference

10 cm3 1.80-cm ID x 3.93-cm D 3

Sigma+/-

1.0 and 3.5 cm Integral Thermo- 134/00050/00 16 6.378 Min/Max• Volume vs. Cycle #

Electric Cooling,

15

100 cm3 4.62-cm ID x 6.17-cm D 10 and 35 cm3 15-36 ˚C, ± 0.1 ˚C* 134/00051/00 6.376• Density vs. Time

14

6.374

• Total Pore Volume vs. Temperature 13

6.372

• Density vs. Cycle # 12

10 cm3 1.80-cm ID x 3.93-cm D 1.0 and 3.5 cm3 Use with External 134/00044/00

11 6.370

4.62-cm ID x 6.17-cm D 3 Recirculating Bath 134/00045/00 • Options Report 0 2 4 6 8 10 12 14 16 18 20 22 24 26100 cm3 10 and 35 cm Time (seconds)15-50 ˚C 6.368

• Equilibration Report FPO

Research grade helium or nitrogen is strongly recommended. High purity Carbon dioxide, dry air, or 6.366

argon may be used. A multigas option for up to four gases on one analysis unit is available. 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5 10.0• Sample Log Cycle Number

*Subject to environmental operating conditions

P2 (Expansion Pressure) (psig)

Density (g/cm³)

Volume (cm³)

Page7

pOROSITy SOLuTION FOAM SOLuTION

Total pore Volume/percent porosity Bundle Foampyc Bundle – Density Measurements for

pharmaceutical Applications Open- and closed-cell Foams

While skeletal and envelope volume measurements are each The AccuPyc II unit can be ordered initially with the FoamPyc

important on their own merit, their combination also allows you to application installed. If you have a standard AccuPyc, you can

accurately calculate percent porosity and total pore volume of a upgrade with a software enhancement. A FoamPyc option for

body. measuring open- and closed-cell foam materials is available in the

following configurations for the standard and temperature-controlled

pycnometers:

• 10-cm3 nominal cell volume (for conformance

to ASTM and ISO methods)

• 100-cm3 nominal cell volume

WEIGHING

SOLuTION

Analytical Balance Bundle

The AccuPyc weighing solution bundle provides one-touch transfer

of mass data from the analytical balance directly to the AccuPyc’s

Tablet press pharmaceutical Ribbons Windows software. Direct transfer eliminates user error associated

Pharmaceutical scientists realize that many of the physical, me- With the skeletal density measured by the AccuPyc included in the with manual entry of mass data. Optional Peltier temperature con-

chanical, and pharmacokinetics properties of tablets are influenced setup parameters for the envelope density, the GeoPyc will calcu- trol eliminates environmental temperature variation and facilitates

by the basic settings of a tablet press. Using the AccuPyc coupled late and report the percent porosity and total pore volume of the the handling of “hot” samples.

with the GeoPyc, scientists are now able to determine quickly and ribbon. This information has proven to be useful in controlling the

• Optional Peltier thermoelectric control

easily the skeletal density, envelope density, total pore volume, mechanical properties of the material, compression force settings

(15 to 36 oC) provides ambient temperature

percent porosity, and closed-cell pore volume of tablets produced on the roller compactor, and subsequent tablet press settings.

stability

with varying press settings.

• Seamless device compatibility

Geopyc Accupyc/Geopyc* • One-touch mass data transfer to

Envelope Density Analyzer AccuPyc for automatic calculation of density

The GeoPyc utilizes a quasi-fluid displacement medium composed

of non-hazardous microspheres having a high degree of flowability • Includes 120 X 0.01 mg electronic

that do not wet the sample or fill its pores. analytical balance with calibration weight

• Determines envelope volume and

density of monolithic samples as well

as bulk volume and density of

powdered materials

• A variety of sample chambers is

available to accommodate a wide

range of sample sizes

• T.A.P. Density option – measures the

packing volume and calculates the *included in porosity bundle

bulk density of granular and powdered

samples

Superior Worldwide Support Assures You Consistent Instrument Performance for Years to Come

Page8

TEMpERATuRE-cONTROL SOLuTION HIGH-pRESSuRE SOLuTION

Accupyc II Hp – Density Determinations

in a High-pressure Environment

Accupyc II TEc - Density Testing for Semi-Solid Bituminous Materials This pycnometer can provide high-speed, high-precision volume measurements and density determinations in an elevated pressure

This AccuPyc solution can be closely correlated (< 0.15% difference) environment (i.e. intact or crushed shale core samples).

to results obtained with ASTM Test Method D70-09. The ASTM

method is burdensome and time consuming. Our approach offers an • Operates at a higher pressure of 500 psi to provide a better

expedited, more robust, operator-independent method, with results diffusion of the gas into the rock

in minutes.

• Stainless-steel sample chamber with a volume of 100 cm3

• Reproducible results in minutes, virtually eliminates • Sample chamber can accommodate a 48-mm (1.85 in.)

operator error diameter core of up to 60 mm (2.40 in.) in length

• Integral solution with software for bituminous material

testing includes results for specific gravity, volume, and

density

• Peltier thermoelectric control (15 to 36 °C) provides excellent

temperature control/stability and sample handling

• Disposable sample cups limit cross-contamination and

minimize cleaning of sample chamber between analyses

LARGE VOLuME SOLuTION

Asphalt Analysis

core pyc – Density of Intact core Samples

Average Density %Relative Stan- ASTM Method %Difference With a large-volume sample chamber, this pycnometer has been

Asphalt Sample AccuPyc II TEC dard Deviation

Solution D70-9 Density

Between Methods designed to address the specific needs of operations that require

(n=11) (g/cc) pore volume knowledge of intact drilling cores. This instrument (n=11) (g/cc)

improves sampling statistics by eliminating the need to break a core

into many smaller pieces and run multiple analyses to obtain volume

Sample A 1.01906 0.03 1.01758 0.1453 results. The CorePyc eliminates the need to run multiple analyses

on large cores.

Sample B 1.02543 0.03 1.02536 0.0067

• Large sample chamber with a volume of

Sample C 1.01821 0.07 1.01848 0.0263

approximately 2000 cm3

Sample D 1.02563 0.09 1.02576 0.0125

• Sample chamber can accommodate a

95-mm (3.74 in.) diameter core of up to

Samples varied in composition and viscosity

278 mm (10.9 inches) in length

If your research work requires an analytical device, technique, or

CUSTOM configuration that is not commercially available, talk to us about modifications to our standard instrument designs. There are no

charges associated with the initial consultation and our research

ENGINEERED into the feasibility of your project.

PRODUCTS Call us here: 770.662.3698 Focused on your Solution

Page9

Height:

17.9 cm (7.0 in.), analysis modules for 1-, 10-, and 100-cm3

units, and control module

25.9 cm (10.2 in.), 350-cm3 analysis module

43.0 cm (17.0 in.), 2000-cm3 analysis module

Width:

27.3 cm (10.7 in.), control module

27.3 cm (10.7 in.), control module

27.0 cm (10.6 in.), 2000-cm3 analysis module

Depth:

36.2 cm (14.3 in.)

Weight:

9.3 kg (20.5 lbs), control/analysis unit (1-, 10-, and 100-cm3 units)

7.9 kg (17.4 lbs), analysis module (1-, 10-, and 100-cm3 units)

Micromeritics Instrument 10.5 kg (23.2 lbs), analysis module (350-cm3 unit)

corporation 3.6 kg (8.0 lbs), control module

26.0 kg (57.0 lbs), 2000-cm3 analysis module

4356 Communications Drive

Norcross, GA 30093 U.S.A. Electrical:

To request a quote or additional product information, Voltage - 90 to 264 VAC

Power - 30 VA

visit Micromeritics website at:

Frequency - 50 to 60 Hz

www.micromeritics.com

Contact your local Micromeritics sales representative, or Precision:

our Customer Service Department at: Reproducibility typically to within ± 0.01% of the nominal

770.662.3636 full-scale sample cell chamber volume. Reproducibility

guaranteed to within ± 0.02% of the nominal full-scale

volume on clean, dry, thermally equilibrated samples using

helium in the 15 to 35 ºC range.

The Micromeritics Accuracy:

Accurate to within 0.03% of reading, plus 0.03% of sample

customer Experience... capacity.

“ Micromeritics Instruments are easy to © All Rights Reserved 2014. Micromeritics Instrument Corporation. Norcross, GA 30093. 770.662.3636. Printed in U.S.A.

use and yield powerful results. The tech

and applications support professionals are

responsive and knowledgeable”

-Brenda Fisher, Lab Manager, Cornell University

TechValidate Research Study, Nov 2014 134/42701/00