1/8ページ

ダウンロード(1.3Mb)

このカタログについて

| ドキュメント名 | AUTOPORE V |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 1.3Mb |

| 取り扱い企業 | 島津サイエンス東日本株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

AUTOPORE V

Mercury Intrusion Porosimetry

Page2

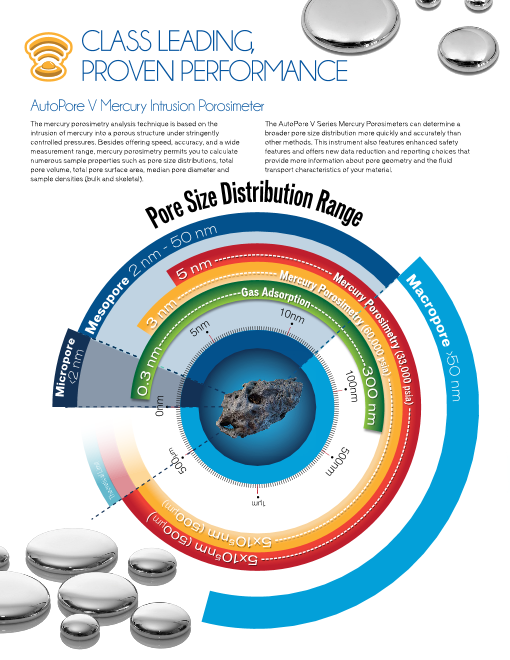

CLASS LEADING,

PROVEN PERFORMANCE

AutoPore V Mercury Intrusion Porosimeter

The mercury porosimetry analysis technique is based on the The AutoPore V Series Mercury Porosimeters can determine a

intrusion of mercury into a porous structure under stringently broader pore size distribution more quickly and accurately than

controlled pressures. Besides offering speed, accuracy, and a wide other methods. This instrument also features enhanced safety

measurement range, mercury porosimetry permits you to calculate features and offers new data reduction and reporting choices that

numerous sample properties such as pore size distributions, total provide more information about pore geometry and the fluid

pore volume, total pore surface area, median pore diameter and transport characteristics of your material.

sample densities (bulk and skeletal).

e Size Distributr iono RP ange

0 n

m

- 5

m ----------------n --- m -------

2 5 n ------------- M -e --

-----

- rcu Mr e

----

- y P rcu

- ------

-Gas Adsorp oti ro os

ry

m ----

-- i

-

n m

- 1

-

0 -n -m - -

e

-- m -

-

• -

n

-

5 •

Microp

<2 o rn em

M

Limit es

oret

ical o

The

pore

0.3 nm 3

0nm -- n

m •

--

μ - -

50

0

•

------

------- 5x105

- n-- m

---- 5x10

5 (5

--- -----

------ nm 0( 0

---

- 5 μ

---- 00 m- -- μ )

---

- m

1μm

)

•

0 nm

por

e >5

ac

ro

M psia) ------

(33,0

00 ---------

me

try

a) -----------

----

osi

---- -

00 p

si ------ -- -- --or ,0 0 nm --- --- P -

ry

(60 --30 -- -- -t -- m - --

---

-- 100n •

5

- 0

0

n

• m

Page3

CLASS LEADING, A NEW BENCHMARK FOR

PROVEN PERFORMANCE OPERATIONAL SAFETY

Triple Fail Safe - 1 Triple Fail Safe - 2

Penetrometer Safety Cap Interlock on Locking Cap

In case of operator error, this device Verifies that capacitance detector is

prevents the penetrometer or rod being installed on low-pressure port, automatical-

released from port unintentionally ly suspends run, and permits user to check

filling of the penetrometer prior to run

Triple Fail Safe - 3 Mercury Collection Trays

System Pressure Vent Safe collection of mercury for disposal in the case of compromised penetrometer

on Manifold seals or operator error resulting in broken

penetrometers

Works in concert with Cap Interlock to

automatically vent system pressure if above

ambient pressure and error condition is

detected Improved Mercury

Funnel Design

Attached screw cap and funnel-shaped

opening eliminates mercury contamination

and possible drip-spillage associated with

separate detached filling funnel. Attached

screw cap prevents loose cap and possible

vapor release

Mercury Vapor

Detection Device

Handheld device to check localized Software Control for

mercury vapor levels that exceed defined

safety limits. Portable device allows point Fine Powder Samples

checks at the instrument or any location

Prevents fine powder from accidental

within the lab exposed to mercury

aspiration into low-pressure ports during

analysis by using intelligent evacuation

controlled by sample type

Mercury Vapor

Capture Filter Mercury Temperature Sensor

Affixed to vacuum pump, this filter prevents release of The ability to set a temperature limit in the software allows

mercury vapors. This is a superior and safer the display of a warning message if the temperature is

solution to cold trap dewars used in competitive exceeded

instruments, particularly if the constantly evaporating

cryogen level is insufficiently maintained

Page4

OPERATIONAL DESIGN

ADVANTAGES ADVANTAGES

• Ability to measure pore diameters from 0.003 to 1100* µm

*Calculated with an initial filling pressure of 0.2psia (0.00128MPa) • Improved safety features reduce the risk of mercury spills

and operator exposure

• Controlled pressure can increase in increments as fine as 0.05 psia

from 0.2 to 50 psia. This allows detailed data to be collected in the • Available with four low- and two high-pressure ports for

macropore region increased sample throughput

• High-resolution (sub-microliter) measurement of intrusion/extrusion • Available in 33,000 psia or 60,000 psia models

volumes produces extraordinary precision allowing the development

of tighter sample specifications, improved production processes, • Low-noise, high-pressure generating system

and high-quality research data

• A quick-scan mode allows a continuous pressure increase

• Operates in scanning and time- or rate-of-intrusion equilibrated approximating equilibrium and providing faster screening

modes

• A choice of correction routine for baseline (automatic,

• Real-time diagnostics provide knowledge of an issue before it differential, or manual) produces greater accuracy by

becomes critical or impairs your analytical results correcting for compressibility and thermal effects caused

by high pressure

• Collects extremely high-resolution data; better than 0.1 µL for

mercury intrusion and extrusion volume • Choice of pressure ramping methods lets you choose the

scanning mode for high-speed or on-demand results, or

• Improved linear motion for high-pressure chamber closure equilibration mode for more accurate results with greater

detail

• Mercury temperature sensor allows automatic calculation of

mercury density used for penetrometer calibrations

• MicroActive software allows you to interactively manipulate

data, define custom reports, and quickly achieve

analytical results

• Compensation for material compression under

high-pressure analysis

FOUR MODELS

The AutoPore V is available in four models to best match the needs

of individual quality assurance and research labs.

9605 9620

Low Pressure 4 ports 4 ports

High Pressure 2 ports @ 33,000 psia 2 ports @ 60,000 psia

9600 9610

Low Pressure 2 ports 2 ports

High Pressure 1 port @ 33,000 psia 1 port @ 60,000 psia

Page5

MICROACTIVE

FOR AUTOPORE

Intelligent, Intuitive, Interactive

MicroActive software greatly improves the functionality, convenience,

diagnostics, and data interpretation that establish the new standard

for high-performance results in mercury porosimetry.

Method Wizard

Build a method through an interactive step-by-step script. Eases method

creation and new user introduction to the operation of the AutoPore V.

Mercury Density Calculation

Unlike competitive systems that use mercury density at ambient

temperature only, the AutoPore V automatically measures the actual

mercury temperature for accurate density calculations under

operation conditions.

User-Defined Reports

and Report Options

You can quickly create custom advanced reports to meet your

specific needs using Python scripting. New report options

permit automatic report conversion to PDF or spreadsheet

formats.

Post-Analysis Parameter Change

Allows analysis parameters (stem volume, maximum head

pressure, pen constant) to be changed or corrected post anal-

ysis, eliminating re-running samples due to error.

Reverberi Method Data Reduction

Receive information on the distribution of pore shape. The

method yields a three-dimensional array of cavity size and

throat size vs. volume.

Page6

Diagnostic Dashboard Intelligent Data Reporting

Real-time monitoring of critical system components for Warnings are supplied automatically when suspect data

preventative maintenance and trouble shooting are collected

Variety of Available Plots

Pore volume, pore area, and pore size plots are available as well as

the ability to calculate total intrusion volume, total pore (surface) area,

median pore diameters, average pore diameters, bulk or envelope

density, and apparent (skeletal) density

Enhanced Penetrometer

Calibration

Simplifies penetrometer calibration through automated calculations

either volumetrically or gravimetrically

Reports Include

• Summary

• Tabular Report

• Cumulative Volume vs Size

• Incremental Volume vs Size

• Cumulative Area vs Size

• Cumulative Volume vs Pressure

• Incremental Volume vs Pressure

• Differential Volume vs Size 1

• Log Difference Volume vs Size

• Differential Reference % Volume vs Size

• Out Spec. % Volume vs Pressure

• Differential Volume vs Size 2

Overlay Multiple Runs and • Material Compressibility

Gas Adsorption Data • Cavity to Throat Size Ratio

• Fractal Dimension

MicroActive for Autopore V provides the ability to overlay up

to 20 runs. Included is the option to import pore size distribu- • Mayer-Stowe Particle Size

tions from gas adsorption isotherms to provide analysis data • Tortuousity

in the micro to macropore range in a single report • Permeability

• Reverberi

• Advanced Report System

Page7

PENETROMETERS

Partial List

Stem

Model# Size Volume Medium Typical Use

refractories, low-porosity solid rocks/cores,

01 15 cc 0.392 Solid low porosity solid polymers

02 15 cc 0.392 Powder low-porosity powders, gravel, irregular rock shapes

03 15 cc 1.131 Solid medium-porosity rocks/cores, solid materials

04 15 cc 1.131 Powder medium-porosity rocks, solid materials, fumed silica

paper, flexible polymer/membrane sheets, pharma

07 5 cc 0.392 Solid tablets

silicates, catalysts, powders (general use), pharma

08 5 cc 0.392 Powder powders

medium/high-porosity sheet-form materials (paper,

09 5 cc 1.131 Solid polymer, etc.), pharma tablets

silica-alumina, silicates, zeolites, catalysts, powders

10 5 cc 1.131 Powder (general use), pharma powders

powders (general use), materials with low quantity

14 3 cc 0.412 Powder available

high-porosity rock/cores, low-density/high-porosity

24 15 cc 3.263 Solid foams

25 15 cc 4.185 Solid high-porosity material with large volume

ACCESSORIES

Penetrometer Rack Mercury QuikVac

Safely store and transport penetrometers to prevent breakage and Mercury QuikVac is an excellent low-cost method for quickly

unnecessary replacement. containing mercury spills. The device is designed to be

specifically useful in collecting those elusive mercury droplets

and small mercury-contaminated particulate matter. Mercury

is collected in a 250-mL recovery vessel and a replaceable

0.3 – 0.5 micron activated carbon filter assures that the device

exhausts clean, safe air.

Page8

Height:

143 cm (56.25 in.)

Width:

54.3 cm (21.38 in.)

Depth:

78 cm (30.75 in.)

Weight:

250 kg (500 lb)

Micromeritics Instrument

Corporation

4356 Communications Drive

Norcross, GA 30093 U.S.A.

To request a quote or additional product information,

visit Micromeritics website at:

www.micromeritics.com

Contact your local Micromeritics sales representative, or

our Customer Service Department at:

770.662.3636

© All Rights Reserved 2014. Micromeritics Instrument Corporation.

Norcross GA 30093. 770.662.3636. Printed in U.S.A.

960/42700/00