1/8ページ

ダウンロード(784.6Kb)

このカタログについて

| ドキュメント名 | BioFlo 120 bioprocess control station |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 784.6Kb |

| 登録カテゴリ | |

| 取り扱い企業 | エッペンドルフ株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

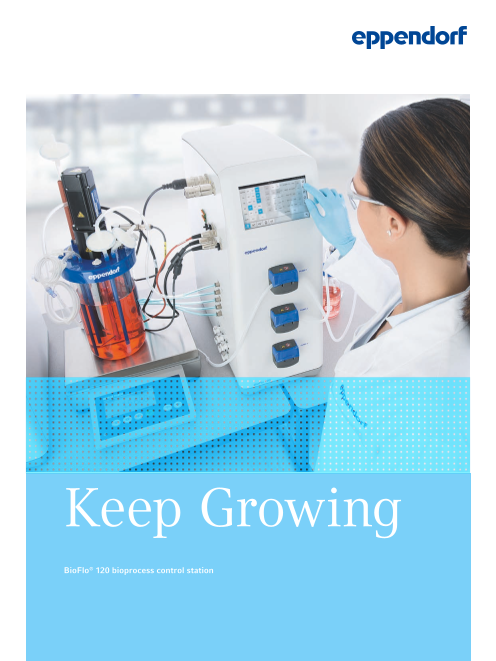

Page1

Keep Growing

BioFlo® 120 bioprocess control station

Page2

2 BioFlo® 120

Page3

BioFlo® 120 3

»Performance meets value.«

The Eppendorf BioFlo 120 offers simplicity and ease of use, without sacrificing capability. No

matter if you are in an academic, governmental or industrial research setting, or working with

bacteria, yeast, fungi, mammalian, insect or plant cells, the BioFlo 120 is an attractive solution to

meet your needs–all at an affordable price.

Feature-packed and future-proof

> Scale-up from 250 mL to 40 L on a wide variety of > Universal connections for digital Mettler Toledo® ISM®

autoclavable and Eppendorf BioBLU® Single-Use sensors or analog sensors offer unsurpassed flexibility

Bioreactors > User-defined DO cascades offer process flexibility

> New Auto Culture modes offer process control for > Automatic gas mixing algorithms for simplified control

microbial and cell culture applications at the touch of a > View your entire process with expanded trend screen

button > Access your data from anywhere with Eppendorf SCADA

> Ready for process. Unbox and install in minutes platforms, IP network, and remote monitoring capabilities

> Save critical lab space with a minimal footprint

Page4

4 BioFlo® 120

Connection for interchangeable

direct- and magnetic-drive motors; Easy-to-read 7” integrated

magnetic drive capable of clockwise and touchscreen monitor

counterclockwise rotation for simplified

impeller selection

Three user-defined

analog input /output All vessel

connections. Select connections

between 0-5V, 0-10V, located on the

and 4-20 mA depending side–set up and

on the device ready to go in

minutes

High-precision thermal

mass flow controller

(TMFC) or rotameter

for gas flow control.

Standard automatic IP21 rated enclosure

mixing of four for protection of

independent sparge gas sensitive electronics

supplies and cleanability

Water recirculation module Three front-mounted fixed-speed pumps

provides precise temperature with industry-standard easy load pump

control and exhaust heads for convenient liquid addition/

condensing removal

Page5

BioFlo® 120 5

BioBLU® single-use advantage Sophisticated software

> The rigid-walled design advantage: > Eppendorf Bioprocess Control Software offers real time,

> Sets up in minutes, no inflation necessary local process control with integrated touchscreen

> No more tears, pits, or folds as seen in bag installations > Optional Eppendorf SCADA platforms (BioCommand®,

> Consistent leachables and extractables profile with DASware®) provide high level process control capabilities,

single-layer molded polymer vs. multi-layer bag design and secure database management

> Scale from 250 mL to 40 L with BioBLU Single-Use > IP networking provides remote access through PC or

Bioreactors mobile device

> BioBLU f Single-Use Bioreactors designed for high density

fermentation

> Eppendorf exclusive BioBLU 5p with Fibra-Cel® Disks for

continuous and perfusion processes

Scalable solutions Unlimited applications

> Perfectly suited for research and development > Grow any cell type you can think of: Microbial, insect,

> Scale-up and scale-down modeling plant, fungal, mammalian, and stem cells

> Growth of seed to pilot-scale cultures in a working volume > Unlimited process flexibility: Batch, fed-batch, continuous,

range of 250 mL to 40 L or perfusion; supports high-density, micro-aerobic, and

> Blends into the Eppendorf bioreactor and fermentor anaerobic fermentation, secreted products production, and

portfolio covering working volumes of 65 mL to 2,400 L, process development for cell and gene therapies

for comprehensive scalability

Find more detailed information, including video presentations, an online configurator and a 360°

product show on our website. Visit www.eppendorf.group/BioFlo-120 or easily scan the QR code

beside.

Page6

Liquid Handling

Cell Handling

Sample Handling

To make your job in the lab easier and more efficient – with this goal in mind

we are developing products and solutions in the areas of Liquid Handling,

Cell Handling, and Sample Handling. Visit the Eppendorf Handling Solutions

online sphere and dive into the area of your choice, learn new things, and have

fun as well: www.eppendorf.com/handling-solutions

Liquid Handling Cell Handling Sample Handling

In 1961, Eppendorf launched For handling cells, in addition Sample Handling encompasses

the first piston-stroke pipette. to manipulators and injectors, many different work processes

Today, our broad product incubators and consumables for and steps: centrifugation,

offerings in Liquid Handling cultivation as well as complete heating, freezing, mixing,

range from manual pipettes to bioreactor systems for cell amplification, and analysis of

electronic pipettes, dispensers culture applications are available. samples. Eppendorf offers the

and burettes to automated Corresponding detection systems devices and consumables needed

pipetting systems. are offered for subsequent analysis. for each of these steps.

Eppendorf Easypet® 3 New Brunswick S41i Centrifuge 5920 R

Experience a new dimension of electronic The only CO2 incubator with an Eppendorf Experience extraordinary high capacity

pipetting with complete speed control and shaker inside. in a very compact and ergonomic product

the utmost precision. design.

> Precise control of temperature, shaking

> Intuitive and convenient speed adjustment speed and CO2 for stable culture conditions > S wing-bucket rotors and adapters

simply done with the tips of your fingers > E asy-to-clean chamber design and accomodate tubes and bottles from 0.2 mL

> Lightweight, well-balanced and ergonomic 120°C disinfection cycle saves time and to 1,000 mL

design that allows for fatigue-free pipetting effectively eliminates contamination > F ixed-angle rotors and plate rotor options

epMotion® 5075m Concerned about

Bacteria in

The most flexible member of our family of

automated liquid handling systems. Cell Culture?

> Mixing, temperature control and magnetic

Find useful tips on

bead separation abilities

> O ptical sensor verifies labware, tips and www.eppendorf.com/cellexperts

volumes before the run

Page7

BioFlo® 120 7

Bioreactor Specifications

Autoclavable bioreactors

Bioreactor 1 L 2 L 5 L 10 L

Total volume 1.3 L 3.0 L 7.5 L 14.0 L

Working volume 0.4 – 1.0 L 0.8 – 2.2 L 2.0 – 5.6 L 4.0 – 10.5 L

Vessel type Water-jacketed or heat-blanketed

Material Borosilicate glass, 316L stainless steel

Impellers

Direct drive or magnetic drive Rushton-type, pitched blade, marine or spin filter

Autoclave dimensions

Heat-blanketed

Outer diameter (OD) 20.3 cm 20.3 cm 29.8 cm 29.8 cm

8.0 in 8.0 in 11.7 in 11.7 in

Height (without exhaust filter) 54.0 cm 54.0 cm 61.0 cm 68.0 cm

21.3 in 21.3 in 24.0 in 26.9 in

Water-jacketed

Outer diameter (OD) 24.1 cm 24.1 cm 29.8 cm 29.8 cm

9.5 in 9.5 in 11.7 in 11.7 in

Height (without exhaust filter) 48.9 cm 56.5 cm 64.8 cm 76.8 cm

19.3 in 22.3 in 25.5 in 30.3 in

Number of head plate ports

6 mm 1 6 7 7

12 mm 9 7 8 8

19 mm 0 0 1 1

Total 10 13 16 16

Recommended sensor lengths (mm)

Sensor

pH (analog)1 200 225 325 425

pH/redox (digital)1 225 325 425

DO (analog)1 160 220 320 420

DO (digital/optical)1 220 320 420

Redox (analog)1 200 325 325 425

CO2 (digital)1 320 320 320

Single-use bioreactors

Bioreactor BioBLU 1c/f BioBLU 3c/f BioBLU 5c BioBLU 5p BioBLU 14c BioBLU 50c

Total volume 1.8 L 5 L 5 L 5 L 14 L 50 L

Working volume 0.25 – 1.25 L2 1.25 – 3.75 L 1.25 – 3.75 L 3.75 L 3.5 – 10.5 L 18 – 40 L

Vessel type Rigid-walled, stirred-tank

Impellers

Magnetic drive BioBLU c: pitched blade/BioBLU p: packed-bed/BioBLU f: Rushton-type

Recommended sensor lengths (mm)

pH (EC)3 220 225 225 120 425 625

DO3 220 225 225 120 355 526

Redox3 220 225 225 120 425 625

CO 3

2 220 220 220 120 320 N/A

1 Installation may require compression fitting for optimal fit and depth (M1273-5040), 2 x included with Vessel Connection Kit.

2 BioBLU 1c: 425 mL minimal working volume when used with vessel stand and heat blanket

3 Installation may require compression fitting for optimal fit and depth (1386010200).

Specifications subject to change.

Page8

BioFlo 120 Specifications

Control Station

Dimensions (W x D x H) 24.7 x 55.9 x 62.9 cm (9.7 x 22 x 24.8 in)

Net weight 14.8 kg (32.7 lb)

Touchscreen 7 in projected capacitive touchscreen

Communication 2 x USB (software updates, serial communication)

Ethernet (SCADA, IP Network)

Utility Connection Requirement

Electrical IEC-C14 (with regional plug types) 100 – 120/208 – 240 (± 10 %) V, 50/60 Hz, 10 A, Single Phase

Water Quick-connect 10 psig (0.69 barg)

Gas supply (air, O2, N2, CO2) Push-connect fittings accept 1/4 in Autoclavable Single-use

tubing or hose barb fitting 10 psig (0.69 barg) 6 psig (0.44 barg)

Exhaust 0.5 psig (0.035 barg)

Operating conditions 10 – 30°C, up to 80 % RH, non-condensing

Agitation

Direct drive 1 L: 25 – 1,500 rpm

3 L, 5 L, 10 L: 25 – 1,200 rpm

Magnetic drive (autoclavable vessels) 1 L, 3 L, or 5 L: 5 – 500 rpm

10 L: 5 – 150 rpm

Magnetic drive (single-use vessels) BioBLU 1f & 3f: 5 – 1,200 rpm

BioBLU 1c: 5 – 500 rpm

BioBLU 3c, 5c, 5p & 14c: 5 – 200 rpm

BioBLU 50c: 5 – 150 rpm

Temperature

Autoclavable 1, 2, 5 L: 8°C above coolant to 45°C above ambient (0°C – 70°C absolute)*

10 L: 8°C above coolant to 40°C above ambient (0°C – 65°C absolute)*

BioBLU Single-Use Vessels BioBLU c vessels: 5°C above ambient to 40°C*

BioBLU f vessels: 5°C above coolant to 45°C*

Sensor type Pt100

Gas supply

Sparge 1 TMFC (0.002 – 1 SLPM or 0.01 – 5 SLPM or 0.04 – 20 SLPM)

or 1 rotameter (multiple options available); ring or microsparger

Sensors Communication Control range

pH Analog or digital Mettler Toledo ISM 2 – 12

DO Analog or digital Mettler Toledo ISM 0 – 200 % (air saturation)

Optical DO Digital Mettler Toledo ISM 0 – 200 % (air saturation)

Redox Analog or digital Mettler Toledo ISM (-)2000 mV – (+)2000 mV

CO2 Digital Mettler Toledo ISM 0 – 100 %

Pumps Pump head Fixed speed

Pumps 1, 2, & 3 Watson-Marlow 114DV 30 rpm (0 – 100 % duty cycle)

* Requires 115/230 V line voltage. Specifications cannot be guaranteed with operation at alternative line voltages.

Specifications subject to change.

Your local distributor: www.eppendorf.com/contact

Eppendorf SE · Barkhausenweg 1 · 22339 Hamburg · Germany

eppendorf@eppendorf.com · www.eppendorf.com

www.eppendorf.com

Mettler Toledo® and ISM® are registered trademarks of Mettler Toledo AG, Switzerland. Watson-Marlow® is a registered trademark of Watson-Marlow Limited, UK. Eppendorf®, the

Eppendorf Brand Design, BioBLU®, Easypet®, and epMotion® are registered trademarks of Eppendorf SE, Germany. DASware® is a registered trademark of DASGIP Information and

Process Technology GmbH, Germany. BioFlo® and BioCommand® are registered trademarks of Eppendorf, Inc., USA.

All rights reserved, including graphics and images. Copyright © 2022 by Eppendorf SE.

Order No.: AN01 311 020/GB7/0.5T/0422/EBC/STEFF · Carbon neutrally printed in Germany