1/8ページ

ダウンロード(2.1Mb)

LIQUID PHASE ORGANIC SYNTHESIZER, “CHEMIST PLAZA” Large Capacity CPG-2000

製品カタログ

このカタログについて

| ドキュメント名 | LIQUID PHASE ORGANIC SYNTHESIZER, “CHEMIST PLAZA” Large Capacity CPG-2000 |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 2.1Mb |

| 取り扱い企業 | 柴田科学株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

CP-1

manufacturered by

LIQUID PHASE ORGANIC SYNTHESIZER, “CHEMIST PLAZA”

Large Capacity

CPG-2000

Small Capacity

CP-1000

Page2

CP-2

Introduction

To bond organic compounds with other substances or organic compounds with organic compounds

Examples of organic compounds

→ Organic solvents, plastics, rubbers, drugs, dyes, perfumes, etc

What are organic compounds?

→ Compounds that are mainly carbon, with most compounds consisting of carbon and hydrogen

Goals of Organic Synthesis

①To create a new substance

To develop a new material → Resin, fibers, dyes, etc

To develop new chemical substances → New drugs, perfumes, high performance substances

②To make existing substances at low cost

Synthesis of natural products → Manufacture expensive natural products industrially

→ Uniform quality

③Other research goals

Specific Example

Mass production of active ingredients of natural substances

An active ingredient that has pain relieving effects was found to exist in willow branches.

↓

It can not be mass produced from natural products

(Mass amounts of willow braches would be necessary.)

↓

The main substances are synthetically arranged by chemical synthesis (organic synthesis)

↓

Enables the mass production/manufacturing of aspirin

(acetylsalicylic acid: pain reliever/fever reducer)

↓

Enables sales as medication

Research procedures of organic synthesis

Determine the new substance according to goals.

(Determine the structures of substances that have the characteristics

that are in accordance to goals from documents.)

↓

Determine how to synthesize.

(Determine the synthesizing method for production and start development.)

↓ Heat, cool, stirring, etc.

Evaluate product.

(Determine if product coincides with original goal if it does not, re-determine synthesis methods.)

↓

Determine the manufacturing method, determination of (scaling up)

(Determination of methods and conditions where the compounds

can be mass produced in the most cost effective way.)

↓

Goes to market as a product...

Page3

CP-3

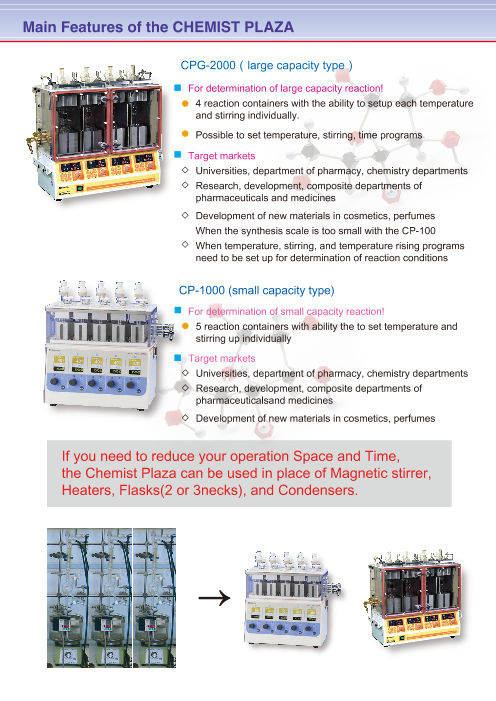

Main Features of the CHEMIST PLAZA

CPG-2000(large capacity type)

■ For determination of large capacity reaction!

● 4 reaction containers with the ability to setup each temperature

and stirring individually.

● Possible to set temperature, stirring, time programs

■ Target markets

◇ Universities, department of pharmacy, chemistry departments

◇ Research, development, composite departments of

pharmaceuticals and medicines

◇ Development of new materials in cosmetics, perfumes

When the synthesis scale is too small with the CP-100

◇ When temperature, stirring, and temperature rising programs

need to be set up for determination of reaction conditions

CP-1000 (small capacity type)

■ For determination of small capacity reaction!

● 5 reaction containers with ability the to set temperature and

stirring up individually

■ Target markets

◇ Universities, department of pharmacy, chemistry departments

◇ Research, development, composite departments of

pharmaceuticalsand medicines

◇ Development of new materials in cosmetics, perfumes

If you need to reduce your operation Space and Time,

the Chemist Plaza can be used in place of Magnetic stirrer,

Heaters, Flasks(2 or 3necks), and Condensers.

→

Page4

CP-4

CPG-2000 For Determination of Conditions for Large Capacity Reactions!!

The Chemist Plaza CPG-2000 series are devices

well suited for large capacity organic synthesis such

as development of new reaction,and new catalysts,

synthesis of intermediate products, and when

scaling-up small capacity samples to large capacity

samples.

To efficiently determine reaction conditions,

temperature, stirring (number of rotations), and

program (temperature, stirring, time) of the 4 blocks

on the main body can be set individually.

Individual Manual, Program Operation for

4 Specimen

(Possible to setup temperature, stirring speed, time)

Individual Program Functions, Link Functions

(Possible to setup temperature, stirring speed, time) 4 Varieties of Reaction Containers

9 varieties of program setups possible per block. 2 varieties of standard reaction containers; the 100mL

Loaded with a link function that connects each type (CPG-2110) and 200mL type (CPG-2120).

program. Optionally, two mouth types are available.

Maximum 81 steps are programmable per program. Please contact us for other special order support.

Example: 1 Program (3step)

Step1 Step2 Step3

Temp. Stop

30min.

10min.

Start Time

Individual Temperature Adjustment from -30~200℃ (two mouth) (two mouth)

Each of the 4 heating blocks have auto-tuning

function loaded in the so that temperatures can be Container Units, Container Holders

individually set (-30~200℃), enabling highly precise Exchanging just the container holder or reaction

heating and cooling. container enables different reaction experiments

* 1 A cooling water circulation device is necessary to be performed on each of the heating blocks.

if the temperature is to be adjusted below room Aluminum block holder, Return current unit,

temperature. Container holder

Strong Individual Agitation of 50 to 2000rpm

Cooling Catridge

When a low temperature circulation tank is

connected, return current and low temperature

reaction can be preformed.

The cooling cartridge can be inserted from Aluminum Reflux unit Container

both the right and left side of the main body block holder holder

and the connection nozzle will turn 360

degrees. Reagent Adder

The hose will not The reagent adder is a

bend and can be SPC15 joint. Mounting

arranged in any the included silicon

direction. septum and the reagentscan also be added with

a syringe. Septum SPC15 jointControl Panel

Display TIMER key

Current temperature of the heating Use to set the time in manual mode and

block, number of rotations, program, program mode.

and step number is displayed

according to the conditions. START/STOP keyThis is the ON/OFF switch for the heating

MODE key program of each of the heating blocks.

Use to convert to and from manual

mode and program mode. Revolution Adjustment Volume

SET key Use to set the number of rotations of the stirrer.

Use to edit the program in program

mode

Page5

CP-5

Specifications

Models in sets

Synthesizer Main Body

Synthesize Scale

Reaction Type, No. of Units Atmospheric pressure: glass containers x 4

Vessel Dimensions (mm)

Dimension of Stirring Bar (mm) Max. dia. approx. 13mm x total length 25mm, Oval edge type

Stirrer Dimensions (mm) pcs

Setting Range 4 individual temperature adjustment

Temperature Setting Accuracy

Setup/Display Sheet key entry/Digital LED Display

Setting Range 50~2000rpm, 4 individual stirrers

Revolutions Stirring Method Ferromagnetic Stirrer Method

Setup/Display Volume entry (During program control: digital up down setup) Digital LED Display

Program Program Number 9 programs (individually separate blocks: 4locations)/9 steps (per program)

Functions Program Link Func. 9 step/1 program x 9 programs (maximum program links of 81 steps possible:4 locations)Setup Contents Temperature, number of revolutions, time (constant temperature, rising temperature program possible), ON/OFF timer

Gas Displacement Vacuuming/Inert gas induction possible, Connection port outside diameter φ8mm

Reflux Reflux via cleaning cartridge (cooling plate can be attached and removed from both left and right sides) *1

Low Temperature Reaction Reflux via cleaning cartridge (cooling plate can be attached and removed from both left and right sides) *1

Reagent Addition Method Pipit, syringe, dropping funnel (SPC15) possible to add either under inert conditions

Reaction Observation Observation possible from slit in aluminum block

Safety Measures Polycarbonate cover, drip receiving tray, over heating/over cooling warnings (able to set individually)

Wetted Material Glass

Cooling Water Connection Port Outside diameter φ10mm, φ12.7mm 2stange hose port

Analog Output

Operational Ambient Temperaure

Dimensions

Weight

Power Supply

Ordering Code No.

It is necessary to connect a cooling water circulation device if the temperature is adjusted below room temperature or return current is to be performed

CPG Series Standard Component

Order No. Description Q'ty Necessary number Necessary number

Synthesizer Main Body

Cooling cartridge 4pcs

Heating block adapter

Reaction container stand

Stirrer, oval edge model

Refrux unit

Container holder stand

Reagent addition part

Reaction container

Reaction container

Two way valve set

Joint clamp for taper

Septum

Optional Parts

Order No. Description Q'ty

Cooling cartridge 2pcs

SPC two mouth reaction container

SPC two mouth reaction container

SPC flat plug for SPC15

SPC flat plug for SPC29

Test tube adapter set

Test tube adapter set

Test tube adapter set

Page6

CP-6

CP-1000 For Determination of Conditions for Small Capacity Reactions!!

Temperatures and stiiring of the 5 reaction containers of

the CP-1000 series can be set individually, which enables

an efficient determination of 5 types of reaction conditions

simultaneously. It is equipped with heating, cooling,

return current, and gas flow functions andcan also

speedily perform concentrations after reaction.

Individual Temperature Adjustment from -20~160℃

The built in auto-tuning function enables high precision

heating and cooling.

6 varieties of Reaction Containers!

A total varieties; the test tube type (2 varieties),

vial type (variety), and the SPC test tube type (2 varieties) 222mm

to choose from. 330mm

An Ultra Compact Body needs less than the

Surface Area of A3 Size Paper for Installation!!

Width 330mm X Depth 222mm

Strong Indivisdual Agitation of 100 to 2000rpm

A Ferromagnetic stirrer is used for strong agitation.

Complete Safety Functions

Container Unit, Container Holder The safety cover prevents casualties from accidental

The entire rack of the container unit can be removed dispersion of glass test tubes.

from the main body. Constructed so that the power is not supplied if the

Each of the container blocks are independent of one safety cover is not on.

another, enabling the use of different containers.

Over Heating/Over Cooling Warnings

When the heating block reaches a certain temperature

in relation to the set temperature, a warning buzzer will

sound and the individual displays will show an error

message. Further, each heating block can be set

to its own high-low limit.

Cooling Cartridge

When a low temperature Prevent Condensation

circulation tank is connected, Send dry air without using nitrogen gas and prevent

return current and low condensation within the device.

temperature reaction can be

preformed.

The connection nozzle will t

urn 360 degrees, and can be

installed in any location.

Gas inlet port

* The silica gel is sold separately.

Page7

CP-7

Line-Up

Name in Setting φ15x105H Test Tube set φ15x150H Test Tube set φ30x200H Test Tube set

Type of Vessel Test Tube with Lip Test Tube with Lip Test Tube with Lip

Size of Vessel φ15x105Hmm φ15x150Hmm φ30x200Hmm

Synthesize Capacity 7mL (Max.) 7mL (Max.) 30mL (Max.)

Ordering Code 054300-1010 054300-1020 084300-1030

φ15×105H Test Tube set φ15×150H Test Tube set φ30×200H Test Tube set

Name in Setting SPC15 Test Tube set SPC29 Test Tube set Vial Tube set

Type of Vessel SPC Test Tube SPC Test Tube Vial Tube

Size of Vessel φ15x170Hmm φ30x190Hmm φ30x65Hmm

Synthesize Capacity 7mL (Max.) 30mL (Max.) 28mL (Max.)

Ordering Code 054300-1040 054300-1050 084300-1060

SPC15 Test Tube set SPC29 Test Tube set Vial Tube set

Specifications

Model CP-1000

Installed Reaction Vessel 1 to 5 Tubes

Temperature Setting Range -20 to 160℃, Individual setting

Setting / Display Sheet key entry/ Digital LED display with back-lit

Setting Range 100 to 2000rpm, Individual setting

Agitation Setting / Display Volume entry / Digital LED display with back-lit

Stirring Type Ferromagnetic stirrer

Reflux Method Reflux by cooling cartridge *1

Overall Dimensions 330W x 222D x 325Hmm

Weight Approx. 15kg

Ordering Code No. 054300-1000

Temperature of 5 heating blocks can setup individualy.

Page8

CP-8

Parts for CP-1000 (Includes optional items)

Ordering Code No. Description Q’ty

① 054310-1601A Test tube φ15 x 105mm 100 Test tube

② 054310-1602A Test tube φ15 x 150mm 50 ③φ30×200mm

③ 054310-1603A Test tube φ30 x 200mm 25

④ 054310-1606A Vial tube 28mL 50 ①φ15 x 105mm

⑤ 054310-1608A SPC Test tube φ15 x 170mm 10

⑥ 054310-1609A SPC Test tube φ30 x 190mm 10

⑦ 054310-4410 PTFE adapter (with taper) for φ15 test tube 1

⑧ 054310-4420 PTFE adapter (with taper) for φ30 test tube 1

⑨ 054310-4430 PTFE adapter (with taper) for vial tube 1

⑩ 054310-1201A Stirrer cross shape forφ15 test tube 10

054310-1202A Stirrer cross shape forφ30 test tube 10

054310-1204A Stirrer triangle shape for vial tube 28mL 10 ④Vial tube

⑪ 054310-1207A Stirrer cross shape forφ30 test tube L25 10 ②φ15×150mm

⑫ 054310-4210 Reflux unit for φ15 x 105mm test tube 1

⑬ 054310-4220 Reflux unit for φ15 x150mm, SPC φ15 test tube 1 SPC Test tube

⑭ 054310-4230 Reflux unit for φ30 test tube, Vial tube 1

⑮ 054310-4310 Heat block adaptor for φ15 tube 1 ⑤φ15×170H

⑯ 054310-4110 Cooling cartridge 1

⑰ 030300-1529 SPC adaptor SPC15 - SPC29 1

⑱ 054310-4510 Three-way cock SPC15 1

054310-1804A Septum 10

⑲ 030300-2915 SPC adaptor SPC29 - SPC15 1

007020-2915 T S joint adaptor 29/40 - 15/25 1

030730-15150 Dimroth condenser SPC15 1

030230-1525 Separatory funnel, SOC joint 1

054330-5100 Liebig condenser SPC15, GL14 1 ⑥φ30×190H

054330-5200 Half-moon shaped funnel SPC15 1

054330-5300 Funnel with stop cock, 50mL 1

Stirrer cross shape PTFE adapter (with taper)

⑧for φ30 test tube

⑩forφ15 ⑪forφ30

⑦for φ15 test tube

Reflux unit ⑨for vial tube

⑫for φ15 x 105mm ⑬φ15 x150mm, SPC φ15 ⑭for φ30 test tube, Vial tube ⑰SPC adaptor ⑲SPC adaptor

SPC15 - SPC29

⑮Heat block adaptor ⑯Cooling cartridge

⑱Three-way cock SPC15

1-1-62, Nakane Soka-City, Saitama, Japan

TEL:+81-48-933-1574 FAX:+81-48-933-1591

E-mail:overseas@sibata.co.jp

http://www.sibata.co.jp/english/

201405K