1/76ページ

ダウンロード(5.5Mb)

独自設計による高精度・高剛性。工程集約により段替え時間の短縮可能

サポートがボールでなくローラーであり線であたる故にどちらの方向にも高い耐荷重を持ちます。線あたりは点あたりより磨耗耐久性があり寿命が長くなりえます。

ベースとプレートの接合部位にはシールが施されており、炭素加工時の炭素粉が入りにくく、精度・耐磨耗に優れています。

ワイヤー放電のクイックチェンジにも使用可能なタイプも御座います。

このカタログについて

| ドキュメント名 | 高精度リファレンス及び高速クランピングシステム 【ProGrit社】 |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 5.5Mb |

| 登録カテゴリ | |

| 取り扱い企業 | 株式会社ゴーショー (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

Powder

Compaction

Tooling

Reference Clamping Systems

for Powder Compaction,

Machining and Tool Shop

Page2

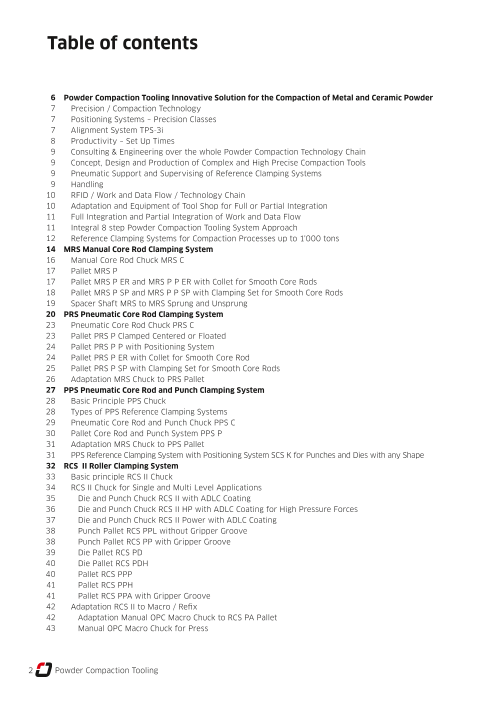

Table of contents

6 Powder Compaction Tooling Innovative Solution for the Compaction of Metal and Ceramic Powder

7 Precision / Compaction Technology

7 Positioning Systems – Precision Classes

7 Alignment System TPS-3i

8 Productivity – Set Up Times

9 Consulting & Engineering over the whole Powder Compaction Technology Chain

9 Concept, Design and Production of Complex and High Precise Compaction Tools

9 Pneumatic Support and Supervising of Reference Clamping Systems

9 Handling

1 0 RFID / Work and Data Flow / Technology Chain

1 0 Adaptation and Equipment of Tool Shop for Full or Partial Integration

1 1 Full Integration and Partial Integration of Work and Data Flow

1 1 Integral 8 step Powder Compaction Tooling System Approach

1 2 Reference Clamping Systems for Compaction Processes up to 1'000 tons

1 4 MRS Manual Core Rod Clamping System

1 6 Manual Core Rod Chuck MRS C

1 7 Pallet MRS P

1 7 Pallet MRS P ER and MRS P P ER with Collet for Smooth Core Rods

1 8 Pallet MRS P SP and MRS P P SP with Clamping Set for Smooth Core Rods

1 9 Spacer Shaft MRS to MRS Sprung and Unsprung

2 0 PRS Pneumatic Core Rod Clamping System

2 3 Pneumatic Core Rod Chuck PRS C

2 3 Pallet PRS P Clamped Centered or Floated

2 4 Pallet PRS P P with Positioning System

2 4 Pallet PRS P ER with Collet for Smooth Core Rod

2 5 Pallet PRS P SP with Clamping Set for Smooth Core Rods

2 6 Adaptation MRS Chuck to PRS Pallet

2 7 PPS Pneumatic Core Rod and Punch Clamping System

2 8 Basic Principle PPS Chuck

2 8 Types of PPS Reference Clamping Systems

2 9 Pneumatic Core Rod and Punch Chuck PPS C

3 0 Pallet Core Rod and Punch System PPS P

3 1 Adaptation MRS Chuck to PPS Pallet

3 1 PPS Reference Clamping System with Positioning System SCS K for Punches and Dies with any Shape

3 2 RCS II Roller Clamping System

3 3 Basic principle RCS II Chuck

3 4 RCS II Chuck for Single and Multi Level Applications

3 5 Die and Punch Chuck RCS II with ADLC Coating

3 6 Die and Punch Chuck RCS II HP with ADLC Coating for High Pressure Forces

3 7 Die and Punch Chuck RCS II Power with ADLC Coating

3 8 Punch Pallet RCS PPL without Gripper Groove

3 8 Punch Pallet RCS PP with Gripper Groove

3 9 Die Pallet RCS PD

4 0 Die Pallet RCS PDH

4 0 Pallet RCS PPP

4 1 Pallet RCS PPH

4 1 Pallet RCS PPA with Gripper Groove

4 2 Adaptation RCS II to Macro / Refi x

4 2 Adaptation Manual OPC Macro Chuck to RCS PA Pallet

4 3 Manual OPC Macro Chuck for Press

2 Powder Compaction Tooling Powder Compaction Tooling 3

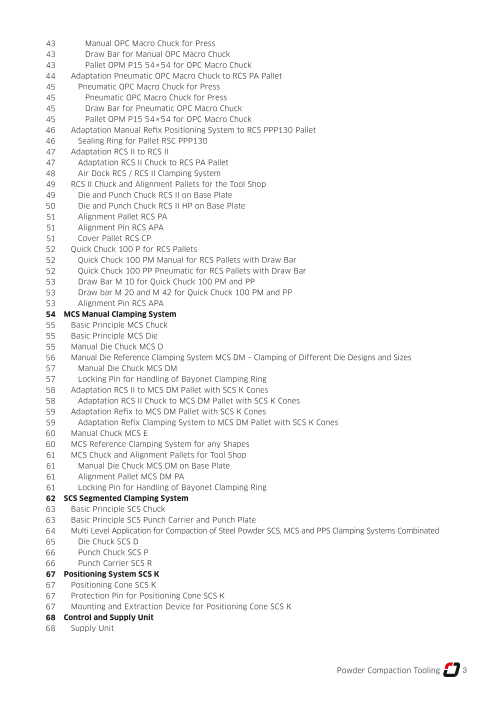

Page3

4 3 Manual OPC Macro Chuck for Press

4 3 Draw Bar for Manual OPC Macro Chuck

4 3 Pallet OPM P15 54×54 for OPC Macro Chuck

4 4 Adaptation Pneumatic OPC Macro Chuck to RCS PA Pallet

4 5 Pneumatic OPC Macro Chuck for Press

4 5 Pneumatic OPC Macro Chuck for Press

4 5 Draw Bar for Pneumatic OPC Macro Chuck

4 5 Pallet OPM P15 54×54 for OPC Macro Chuck

4 6 Adaptation Manual Refi x Positioning System to RCS PPP130 Pallet

4 6 Sealing Ring for Pallet RSC PPP130

4 7 Adaptation RCS II to RCS II

4 7 Adaptation RCS II Chuck to RCS PA Pallet

4 8 Air Dock RCS / RCS II Clamping System

4 9 RCS II Chuck and Alignment Pallets for the Tool Shop

4 9 Die and Punch Chuck RCS II on Base Plate

5 0 Die and Punch Chuck RCS II HP on Base Plate

5 1 Alignment Pallet RCS PA

5 1 Alignment Pin RCS APA

5 1 Cover Pallet RCS CP

5 2 Quick Chuck 100 P for RCS Pallets

5 2 Quick Chuck 100 PM Manual for RCS Pallets with Draw Bar

5 2 Quick Chuck 100 PP Pneumatic for RCS Pallets with Draw Bar

5 3 Draw Bar M 10 for Quick Chuck 100 PM and PP

5 3 Draw bar M 20 and M 42 for Quick Chuck 100 PM and PP

5 3 Alignment Pin RCS APA

5 4 MCS Manual Clamping System

5 5 Basic Principle MCS Chuck

5 5 Basic Principle MCS Die

5 5 Manual Die Chuck MCS D

5 6 Manual Die Reference Clamping System MCS DM – Clamping of Different Die Designs and Sizes

5 7 Manual Die Chuck MCS DM

5 7 Locking Pin for Handling of Bayonet Clamping Ring

5 8 Adaptation RCS II to MCS DM Pallet with SCS K Cones

5 8 Adaptation RCS II Chuck to MCS DM Pallet with SCS K Cones

5 9 Adaptation Refi x to MCS DM Pallet with SCS K Cones

5 9 Adaptation Refi x Clamping System to MCS DM Pallet with SCS K Cones

6 0 Manual Chuck MCS E

6 0 MCS Reference Clamping System for any Shapes

6 1 MCS Chuck and Alignment Pallets for Tool Shop

6 1 Manual Die Chuck MCS DM on Base Plate

6 1 Alignment Pallet MCS DM PA

6 1 Locking Pin for Handling of Bayonet Clamping Ring

6 2 SCS Segmented Clamping System

6 3 Basic Principle SCS Chuck

6 3 Basic Principle SCS Punch Carrier and Punch Plate

6 4 Multi Level Application for Compaction of Steel Powder SCS, MCS and PPS Clamping Systems Combinated

6 5 Die Chuck SCS D

6 6 Punch Chuck SCS P

6 6 Punch Carrier SCS R

6 7 Positioning System SCS K

6 7 Positioning Cone SCS K

6 7 Protection Pin for Positioning Cone SCS K

6 7 Mounting and Extraction Device for Positioning Cone SCS K

6 8 Control and Supply Unit

6 8 Supply Unit

2 Powder Compaction Tooling Powder Compaction Tooling 3

Page4

6 8 Control Box with Pneumatic Indicator

6 9 Control Box with Digital Air Flow Monitor

6 9 Foot Pedal

6 9 Control Box Tool Shop

6 9 Booster Tool Shop

7 0 Compaction Tools and Filler Plates

7 0 Compaction Tools for Multi Axial Compaction - Closed, Opened and Splitted Die

7 1 Filler Plate Manual

7 1 Locking Pin for Handling Filler Plate Ring

7 1 Filler Plate Automatic

7 2 Manipulation Fixtures for Compaction Tools and Press Levels

7 2 Manipulation Fixture Die RCS 130

7 2 Clamping Ring for Block Set Up of Die RCS 130 with Punch RCS 60 / RCS 95

7 2 Mounting Block for Blocked Set Up of Die RCS 130 with Punch RCS 60 / RCS 95

7 2 Handling of Press Levels – Press Level Change Technology

7 3 Automation of Manufacturing of Tools and Compaction Processes

7 3 Tool Shop– Fully Automated Production of Compaction Tools

7 3 Quality Assurance – Fully Automated Measurement and Calibration of Compaction Tools with TCQ System

7 3 Press – Fully Automated Tool and Powder Set Up inclusive of Automated Set Up of the Press

7 4 Alignment, Measurement and Analysis Systems

4 Powder Compaction Tooling Powder Compaction Tooling 5

Page5

Pictograms

Following pictograms are used for a quick description of the applications and properties

of the ProGrit products:

Product properties

Manual operation

Automatic operation

Operate with compressed air jet

Operate with manual pneumatic valve or control unit

Operate with electro pneumatic valve or control unit

Central fl ushing

Corrosion resistant

Fields of application

Electro discharge machining EDM

Wire electro discharge machining WEDM

Chip removal machining (turning, milling, grinding, drilling….)

Compacting, cutting, punching, ironing, forming

4 Powder Compaction Tooling Powder Compaction Tooling 5

Page6

Powder Compaction Tooling

Innovat ive Solution for the Compaction

of Metal and Ceramic Powder

There are two main reasons for the usage of reference clamping systems for the compaction of metal

and ceramic powders – precision / compaction technology and productivity.

Precision / Compaction Technology

• Increase of compaction quality, burr less / burr free

compaction

• Compaction of high precision green parts

• Reduction of compaction tool clearance

• Co axial compaction – splitted punch

• Multi axial compaction – closed, opened and splitted die

• Compaction of multi cavities

Productivity

• Reduction of set up times due to decreased batch sizes

• Reduction of compaction tool costs due to increased

wear and damage of tools

• Reduction of production costs and through put times of

the compaction tools

ProGrit provides system solutions for different requirements – from tool design, compaction tools over

the tool shop up to the reference clamping systems for the presses.

Single Level Multi Level High Power Application

5–100 tons 5–100 tons 50–1'000 tons

6 Powder Compaction Tooling Powder Compaction Tooling 7

Page7

Precision / Compaction Technology

Burr free or burr less compacting requires highest precision in the tool shop, the press and the compaction

process. The Powder Compaction System of ProGrit achieves this precision by high precision positioning

of the tool clamping system and precise alignment of these positioning systems to each other in the press.

Positioning Systems – Precision Classes

Precision Classes Positioning Systems

Prism Power P

Precision class I

PC I +/- 0,5µm

PC II +/- 1µm

Cone SCS K

Precision class I–II

PC III +/- 2µm

Spring Lip M

Precision class II–III 0 0,5 1,0 1,5 2,0 2,5

Repeatability (3σ value) +/- [µm]

Alignment System TPS-3i

The Tooling Positioning System TPS-3i is able to align the reference clamping systems in the press in an

accuracy of X, Y, Z better than 1 micron and in C better than 1 arc second to another. A perfect symmetrical

distribution of the compaction clearance can be guaranteed through the TPS-3i technology.

Alignment accuracy of reference clamping systems in the press X,Y,Z < 1 micron C < 1 arc second

Mobile measurement module compact Software TPS-3i Measurement tools TPS-3i

6 Powder Compaction Tooling Powder Compaction Tooling 7

Page8

Comparison of alignment accuracy for different alignment technologies

TPS-3i 0,2µm–0,5µm

Method

«Clearence calculation» 5µm–20µm

Method

«Zero tool» 5µm–40µm

0,1 1 10 100

Alignment accuracy in µm

The ProGrit TPS-3i alignment technology delivers 10 to 40 times higher alignment accuracy than other on the

market available alignment technologies.

Productivity – Set Up Times

Cost reduction by reducing set up times and concurrent elimination of tool damage in the compacting process results

in pay back times of less than 0,5 years for the investment in a Powder Compacting Tooling System.

Total set up time = Change of tools + Alignment of tools

Conventional

clamping 2-4 h

Single-level

Reference

clamping system 98% Savings

2-4 min

0 2 4

Tool setup times [h]

Conventional

clamping 12-24 h

Multi-level

Refere n c e

clamping system 95% Savings

1-1,5 h

0 12 24

Tool setup times [h]

8 Powder Compaction Tooling Powder Compaction Tooling 9

Page9

Consulting & Engineering over the whole Powder Compaction

Technology Chain

ProGrit supplies customized developments, concepts und solutions for

• Reference clamping systems for single and multi-level applications

• Co axial compaction – splitted Punch

• Multi axial compaction – closed, open and splitted die

• Compaction with multi cavities

• Design and standardization of compaction tools and filler plates

• Development of manufacturing concept for the tool shop

• Measurement technology for measurement, correction and referencing of presses and die sets

• Measurement technology for alignment of reference clamping systems in the press

• Palletization technology for positioning of existing compaction tools and position correction

of new produced compaction tools

• System integration in press and die set

• Production technology and adaption and set up of the tool shop

• Full automated powder and compaction tool change

Concept, Design and Production of Complex

and High Precise Compaction Tools

The concept, design and production of complex and

high precise compaction tools was adapted on the

base of the longtime know how of ProGrit in the fi eld

compaction of metal and ceramic powder to the

usage of reference clamping systems.

ProGrit supplies for complex product geometries in

the fi eld of

• Multi cavities tools

• Co axial compaction – splitted punch

• Multi axial compaction – closed, opened and

splitted die

the complete tool technology as well as the pro-

duction of the compaction tools.

Pneumatic Support and Supervision of

Reference Clamping Systems

The pneumatic support and supervision of reference

clamping systems is done by control boxes and

air supply units which are installed in the press.

Due to safety aspects the reference clamping systems

are supervised regarding their operation behavior

and status during the compaction process.

Handling

Applications for compaction forces over 100 tons leading

to compaction tools and changeable parts of the press

or the die set in the range of more than 50 kilograms.

ProGrit develops and supplies gripper and handling solutions

for those parts.

8 Powder Compaction Tooling Powder Compaction Tooling 9

Page10

RFID / Work and Data Flow / Technology Chain

The continuous production of compaction tools on pallets places high demands on an optimal work and data

fl ow from the tool shop up to the usage of the compaction tool in the press. Shortest set up times of machine

tools combined with highest manufacturing precision reduces the tool manufacturing costs.

Tool Design

Tool Shop

Work and data fl ow supported by

QS Measurement • Reference clamping systems

Alignment • Measurement and alignment systems

• Automation

• Identifi cation systems

• Production cell management/Job management systems

Compaction

Technology chain – Powder Compaction Tooling

The Powder Compacting Tooling system guarantees the consistence of the interfaces from the tool shop up to

the press. Work fl ow and data fl ow are supported and optimized by reference clamping systems, RFID based

identifi cation systems and adapted measurement technologies.

The implementation of a Powder Compacting Tooling

system results in a closed technology chain - from

tool design to the tool shop over the quality assurance

up to the press.

Adaptation and Equipment of Tool Shop

for Full or Partial Integration

The Powder Compaction Tooling System works in the press with palletized and referenced compaction tools.

In the continuity of the manufacture and usage of compaction tools it can be distinguished between:

• Full integration

All machines of the tool shop are equipped on the machine table side with the Powder Compaction Tooling.

• Partial integration

The tool shop still manufactures compaction tools conventionally and is therefore not equipped with

the Powder Compaction Tooling System. The compaction tools are connected with the pallets and

positioned on the pallets in the quality assurance department by using the coordinate measuring

machine and the palletization alignment system PAS 3i.

10 Powder Compaction Tooling Powder Compaction Tooling 11

Page11

Full Integration and Partial Integration of Work and Data Flow

Full integration Partial integration

Tool Shop Tool Shop

External Tool Maker

QS Measurement QS Measurement

Alignment Alignment

Press Press

Technology chain – Powder Compaction Tooling

The Powder Compaction Tooling system can be operated as a full and a partial integrated system between the

departments tool shop, press and quality assurance.

Integral 8 Step Powder Compaction Tooling System Approach

∙ Implementation of system analysis and evaluations in the area of compaction of metal and ceramic powder

with reference clamping systems

• Implementation of cost-effectiveness, quality and precision improvement programs

• Support for problem analysis and troubleshooting

The integral 8 step Powder Compaction Tooling system approach by ProGrit is the turnkey for a complete system

solution which fulfi lls the high demands on quality and productivity.

Analysis Actual Situation Target Defi nition

• Spectrum of geometries • Tool design

• Tool design • Accuracy

• Tool shop • Press/Adapter

• Press • Cost/Target

• Profi tability/Productivity

Documentation Reporting Concept

• Project steps/milestones • Tool design

• Decisions • Reference clamping system

• Investment and procurement • Press/Adapter

• Project results • Manufacturing concept

• Adaption of existing tools

• Implementation and Migration

Implementation

• Migration tool shop Profi tability

• Migration press

• Migration/Palletization • Time analysis

existing compaction tools • Investment planing

• Productivity

• Payback

Testing

• Compaction tools Procurement

• Compaction process

• Product specifi cation

• Supply chain management

10 Powder Compaction Tooling Powder Compaction Tooling 11

Page12

Reference Clamping Systems for Compaction Processes up to 1'000 tons

1000 t

MCS

SCS

200 t

RCS II

PPS

25 t PRS

MRS

S ystem size 50 mm 250 mm 500 mm

Ball/Point Roll/Line Segment/Area Screw

Depending on the compaction forces the operating principle of the reference chuck will be adapted.

The clamping element for the transmission of the clamping and extraction forces changes with increasing

compaction forces from ball, roll to segments and screws.

MRS Manual Core Rod Clamping System Pages 14–19

Positioning system Centering X and Y

Positioning Z

Positioning system optional

Precision class >PK III

Clamping Spring force

Opening Manual

Diameter pallet 18–26 mm

Clamping force Locking

Max. allowed pressure 30–50 kN

Max. allowed tension 3–5 kN

PRS Pneumatic Core Rod Clamping System Pages 20–26

Positioning system Centering X and Y

Positioning Z

Positioning system optional

Precision class >PK III

Clamping Spring force

Opening Pneumatic

Diameter pallet 18–27 mm

Clamping force Locking

Max. allowed pressure 50 kN

Max. allowed tension 25 kN

12 Powder Compaction Tooling Powder Compaction Tooling 13

Compaction

force [tons]

Page13

PPS Pneumatic Core Rod and Punch Clamping System Pages 27–31

Positioning system Centering X and Y

Positioning Z

Prism Power P optional

Precision class > PK III, PK I positioned

Clamping Spring force

Opening Pneumatic

Diameter pallet 40–95 mm

Clamping force 2'500–13'000 N

Max. allowed pressure 250–500 kN

Max. allowed tension 50–70 kN

RCS II Punch and Die Clamping System Pages 32–53

Positioning system Prisma Power P

Precision class PK I

Clamping Spring force

Opening Pneumatic

Diameter pallet 60–200 mm

Clamping force 12'000–38'000 N

Max. allowed pressure 300–4'700 kN

Max. allowed tension 60–100 kN

MCS Manual Punch and Die Clamping System Pages 54–61

Positioning system Cone SCS K

Precision class PK I–II

Clamping Manual, bayonet ring/screw

Opening Manual, bayonet ring/screw

Diameter pallet 150–600 mm

Clamping force 240–2'500 kN

Max. allowed pressure 8'700–30'000 kN

Max. allowed tension 120–1'000 kN

SCS Segmented Punch and Die Clamping System Pages 62–66

Positioning system Cone SCS K

Precision class PK I–II

Clamping Spring force

Opening Pneumatic

Diameter pallet 100–400 mm

Clamping force 2'500–10'000 N

Max. allowed pressure 700–7'000 kN

Max. allowed tension 120–480 kN

SCS K Cone Positioning System Page 67

Positioning system Cone SCS K

Precision class PK I–II

12 Powder Compaction Tooling Powder Compaction Tooling 13

Page14

MRS Manual Core Rod Clamping System

Manual reference clamping system for clamping of core rods

Modular design Adaptation to different core rod geometries and compressive and

tensile forces is possible.

Scaling Clamping system sizes can be combined with the smallest reference

clamping system for RCS for punches. Different pallet sizes cover

the requirements of compaction tools and the compaction process.

Operating The palette is inserted with light pressure in the chuck and locked

by an automatic mechanism. The opening of the chuck is done by

the operation of opening ring in vertical direction.

Inserting Clamped Opening

Technical data

Positioning system Centering X and Y, positioning Z

Positioning system optional

Repeatability X/Y +/- 0,020 mm (3σ value)

+/- 0,005 mm (3σ value) optional

Repeatability Z +/- 0,002 mm (3σ value)

Indexing 4×90° optional

Clamping Spring force

Opening Manual

Clamping force Locking

Max. allowed pressure 30–50 kN

Max. allowed tension 3–5 kN

14 Powder Compaction Tooling Powder Compaction Tooling 15

Page15

Pallets in various sizes can be clamped in the two core rod clamping systems MRS C23 and MRS C27.

MRS P18 MRS P22 MRS P18P MRS P22P MRS P26P

MRS C23 MRS C27

Through hole diameter of smallest punch clamping systems:

• ProGrit RCS 60 = 28,5 mm

• EROWA PM 56/60 = 25 mm

• System 3R Macro 90803.50 and 90804.41 = 23 mm (Draw bar 16 mm)

• System 3R Macro 600.17 and 600.27 = 20 mm (Draw bar 16 mm)

There are different pallet types and techniques available for the fi xing of the core rod with the palette available:

Soldering, gluing, screwing Clamping of smooth core rod

of core rod in standard pallets by collet

MRS Px and MRS PxP MRS P ER and MRS PP ER

14 Powder Compaction Tooling Powder Compaction Tooling 15

Page16

Clamping of smooth core rod Clamping of smooth core rod Floating fi xation

by clamping set by radial screw of core rod

MRS SP and MRS PP SP

Pallets are available in various sizes and types on request.

Manual Core Rod Chuck MRS C

Material Steel, stainless

Positioning system Centering X and Y

Positioning Z

Positioning system optional

Clamping force Locking

Max. allowed pressure 30–50 kN

Max. allowed tension 3–5 kN

Air connection None

Operation Manual

Mechanical fi xing Screwed on piston rod

Application Press and machine tools for locking

of core rod pallets

Chuck MRS C23 MRS C27

Product number P-002 700 P-002 730

d 12 mm 15 mm

D 23 mm 27 mm

H 60 mm 75 mm

Clamping force Locking Locking

Max. allowed pressure 30 kN 50 kN

Max. allowed tension 3 kN 5 kN

Mechanical fi xing M12×1 M16×1

Weight 0,2 kg 0,3 kg

16 Powder Compaction Tooling Powder Compaction Tooling 17

Page17

Pallet MRS P

Material Steel, stainless

Positioning system Centering X and Y

Positioning Z

Positioning system optional

Chuck MRS C23 and MRS C27

Mechanical fi xing Soldering, gluing, screwing

Pitch circle None

Application Press and machine tools for fi xing

of core rods

Pallet MRS P18 MRS P22 MRS P18P MRS P22P MRS P26P

Product number P-001 312 P-001 310 P-002 739 P-002 738 P-002 737

Chuck MRS C23 MRS C23 MRS C27 MRS C27 MRS C27

d 12 mm 12 mm 15 mm 15 mm 15 mm

D 18 mm 22 mm 18 mm 22 mm 26 mm

h* 9 mm 9 mm 10 mm 10 mm 10 mm

H 28 mm 28 mm 31 mm 31 mm 31 mm

Max. allowed pressure 30 kN 30 kN 50 kN 50 kN 50 kN

Weight 0,05 kg 0,06 kg 0,06 kg 0,07 kg 0,08 kg

*Height h can be extended.

Pallet MRS P ER and MRS P P ER with Collet for Smooth Core Rods

Material Steel, stainless

Positioning system Centering X and Y

Positioning Z

Positioning system optional

Chuck MRS C23 and MRS C27

Mechanical fi xing Collet

Application Press and machine tools for fi xing

of core rods

Pallet MRS P ER11 MRS P ER16 MRS P ER11 P MRS P ER16 P MRS P ER20 P

Product number P-006 440 P-006 435 P-006 450 P-006 451 P-006 452

Chuck MRS C23 MRS C23 MRS C27 MRS C27 MRS C27

d 12 mm 12 mm 15 mm 15 mm 15 mm

dc 1–7 mm 1–10 mm 1–7 mm 1–10 mm 1–13 mm

Clamping range 0,5 mm 1 mm 0,5 mm 1 mm 1 mm

D/ERM 16 mm/11 22 mm/16 16 mm/11 22 mm/16 27 mm/20

h* 17 mm 38,5 mm 17 mm 38,5 mm 46,5 mm

H 36 mm 57,5 mm 36 mm 57,5 mm 65,5 mm

Max. allowed pressure 30 kN 30 kN 50 kN 50 kN 50 kN

Max. allowed tension - - - - -

Weight 0,05 kg 0,06 kg 0,05 kg 0,06 kg 0,06 kg

*Height h can be extended. Specify clamping diameter dc for order. Delivery inclusive of collet and clamping nut.

16 Powder Compaction Tooling Powder Compaction Tooling 17

Page18

Clamping nut ERM 11 ERM 16 ERM 20

Product number P-002 747 P-002 752 P-002 757

D/ERM 16 mm/11 22 mm/16 27 mm/20

Max. allowed tension - - -

Weight 0,05 kg 0,05 kg 0,05 kg

Collet Clamping diameter dc Product number

ER 11 0,5–7 P-006 441 + dc

Clamping range 0,5 mm

ER 16 0,5–10 P-006 442 + dc

Clamping range 1 mm

ER 20 0,5–13 P-006 443 + dc

Clamping range 1 mm

Specify clamping diameter dc for order.

Pallet MRS P SP and MRS P P SP with Clamping Set for Smooth Core Rods

Material Steel, stainless

Positioning system Centering X and Y

Positioning Z

Positioning system optional

Chuck MRS C23 and MRS C27

Mechanical fi xing Clamping set

Application Press and machine tools for fi xing

of core rods

Pallet MRS P SP, clamping diameter dc MRS P P SP, clamping diameter dc

4/5/6/7/8/9/10/11/12 4/5/6/7/8/9/10/11/12/14/15

Product number P-006 460 + dc P-006 466 + dc

d 10 mm 13 mm

dc 4/5/6/7/8/9/10/11/12 4/5/6/7/8/9/10/11/12/14/15

D 18–22 mm 18–27 mm

h* 22/29 mm 22/29 mm

H 41/48 mm 61/68 mm

Max. allowed pressure 30 kN 50 kN

Max. allowed tension - -

Weight 0,05 kg 0,06 kg

*Height h can be extended. Specify clamping diameter dc for order. Delivery inclusive of clamping set.

Clamping set Clamping diameter dc 4/5/6/7/8/9/10/11/12/14/15

Product number P-004 670 + dc

dc 4/5/6/7/8/9/10/11/12/14/15

D 8–20 mm

H 15–28 mm

Max. allowed tension -

Weight 0,05 kg

Specify clamping diameter dc for order.

18 Powder Compaction Tooling Powder Compaction Tooling 19

Page19

Spacer Shaft MRS to MRS Sprung and Unsprung

Type A Type B

Chuck MRS manual sprung sprung

Material Steel, stainless

Positioning system Centering X and Y

Positioning Z

Positioning system optional

Operation Manual

Adaption basis chuck MRS manual

Material Steel, stainless

Positioning system Centering X and Y

Positioning Z

Positioning system optional

Clamping on basis A) Piston rod with MRS pallet profi l

B) Piston rod with MRS chuck

Electronical identifi cation RFID optional

Application Adaptation and compensation of fi lling

heights, punch lengths and system sizes.

Sprung type for compensation of

compaction problems

Spacer shaft MRS C23/MRS C23 MRS C23/MRS C23 MRS C27/MRS C27 MRS C27/MRS C27

Type A unsprung sprung unsprung sprung

Product number P-001 303 P-001 324 P-000 000 P-000 000

Spring stroke 0 mm 2 mm 0 mm 2 mm

D 23 mm 23 mm 27 mm 27 mm

H* 130 mm 180 mm mm mm

Clamping force Locking Locking Locking Locking

Max. allowed pressure 30 kN 30 kN 50 kN 50 kN

Max. allowed tension 3 kN 3 kN 5 kN 5 kN

Weight - kg - kg - kg - kg

*Extended height is to specify in the order.

Spacer shaft MRS C23/MRS P22 MRS C23/MRS P22 MRS C27/MRS P26 MRS C27/MRS P26

Type B unsprung sprung unsprung sprung

Product number P-006 431 P-006 430 P-000 000 P-000 000

Spring stroke 0 mm 2 mm 0 mm 2 mm

D 23 mm 23 mm 27 mm 27 mm

H* 103 mm 153 mm - mm - mm

Clamping force Locking Locking Locking Locking

Max. allowed pressure 30 kN 30 kN 50 kN 50 kN

Max. allowed tension 3 kN 3 kN 5 kN 5 kN

Weight - kg - kg - kg - kg

*Extended height is to specify in the order.

18 Powder Compaction Tooling Powder Compaction Tooling 19

Page20

PRS Pneumatic Core Rod Clamping System

Pneumatic reference clamping system for clamping of core rods

Modular design Adaptation to different core rod geometries and compressive and

tensile forces is possible.

Scaling Clamping system sizes can be combined with the smallest reference

clamping system for RCS for punches.

Different pallet sizes cover the requirements of compaction tools

and the compaction process.

Funktionsweise Chuck will be opened by compressed air and afterwards the pallet

can be inserted. After unpressurizing the chuck the pallet will be

clamped by a spring activated clamping mechanism. To unclamp the

pallet the chuck must be open by compressed air again.

Inserting Clamped Opening

Technical data

Positioning system Centering X and Y

Positioning Z

Positioning system optional

Repeatability X/Y +/- 0,020 mm centered (3σ value)

+/- 0,005 mm positioned (3σ value)

Repeatability Z +/- 0,002 mm (3σ value)

Exception fl oating type of chuck

Indexing 4×90° optional

Clamping Spring force

Opening Compressed air 10 bar

Clamping force Locking

Max. allowed pressure 50 kN

Max. allowed tension 25 kN

20 Powder Compaction Tooling Powder Compaction Tooling 21