1/10ページ

ダウンロード(1Mb)

このカタログについて

| ドキュメント名 | D-Sub Selection Guide |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 1Mb |

| 関連製品 | |

| 登録カテゴリ | |

| 取り扱い企業 | ハーティング株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

HARTING

D-Sub Selection Guide

Page2

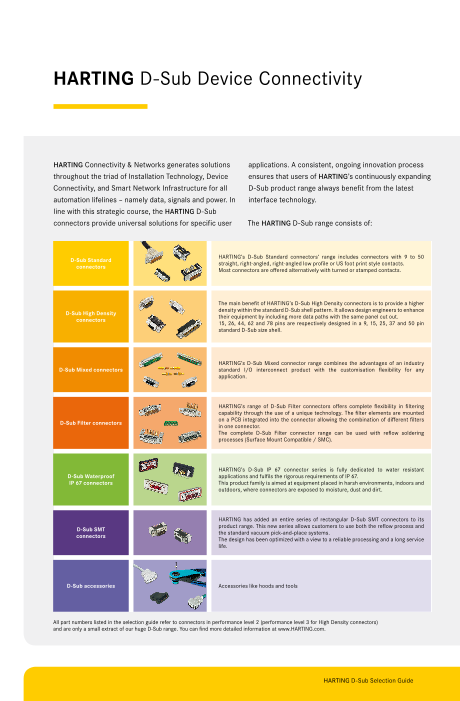

HARTING D-Sub Device Connectivity

Harting Connectivity & Networks generates solutions applications. A consistent, ongoing innovation process

throughout the triad of Installation Technology, Device ensures that users of Harting’s continuously expanding

Connectivity, and Smart Network Infrastructure for all D-Sub product range always benefit from the latest

automation lifelines – namely data, signals and power. In interface technology.

line with this strategic course, the Harting D-Sub

connectors provide universal solutions for specific user The Harting D-Sub range consists of:

D-Sub Standard HARTING’s D-Sub Standard connectors‘ range includes connectors with 9 to 50

connectors straight, right-angled, right-angled low profile or US foot print style contacts. Most connectors are offered alternatively with turned or stamped contacts.

The main benefit of HARTING’s D-Sub High Density connectors is to provide a higher

D-Sub High Density density within the standard D-Sub shell pattern. It allows design engineers to enhance

connectors their equipment by including more data paths with the same panel cut out.15, 26, 44, 62 and 78 pins are respectively designed in a 9, 15, 25, 37 and 50 pin

standard D-Sub size shell.

HARTING’s D-Sub Mixed connector range combines the advantages of an industry

D-Sub Mixed connectors standard I/O interconnect product with the customisation flexibility for any

application.

HARTING’s range of D-Sub Filter connectors offers complete flexibility in filtering

capability through the use of a unique technology. The filter elements are mounted

D-Sub Filter connectors on a PCB integrated into the connector allowing the combination of different filters in one connector.

The complete D-Sub Filter connector range can be used with reflow soldering

processes (Surface Mount Compatible / SMC).

HARTING’s D-Sub IP 67 connector series is fully dedicated to water resistant

D-Sub Waterproof applications and fulfils the rigorous requirements of IP 67.

IP 67 connectors This product family is aimed at equipment placed in harsh environments, indoors and

outdoors, where connectors are exposed to moisture, dust and dirt.

HARTING has added an entire series of rectangular D-Sub SMT connectors to its

D-Sub SMT product range. This new series allows customers to use both the reflow process and

connectors the standard vacuum pick-and-place systems.The design has been optimized with a view to a reliable processing and a long service

life.

D-Sub accessories Accessories like hoods and tools

All part numbers listed in the selection guide refer to connectors in performance level 2 (performance level 3 for High Density connectors)

and are only a small extract of our huge D-Sub range. You can find more detailed information at www.HARTING.com.

HARTING D-Sub Selection Guide

Page3

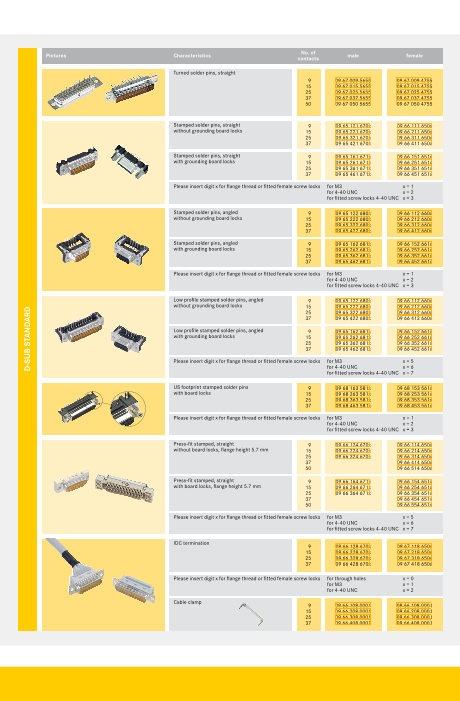

Pictures Characteristics No. of contacts male female

Turned solder pins, straight

9 09 67 009 5655 09 67 009 4755

15 09 67 015 5655 09 67 015 4755

25 09 67 025 5655 09 67 025 4755

37 09 67 037 5655 09 67 037 4755

50 09 67 050 5655 09 67 050 4755

Stamped solder pins, straight 9 09 65 121 670x 09 66 111 650x

without grounding board locks 15 09 65 221 670x 09 66 211 650x

25 09 65 321 670x 09 66 311 650x

37 09 65 421 670x 09 66 411 650x

Stamped solder pins, straight 9 09 65 161 671x 09 66 151 651x

with grounding board locks 15 09 65 261 671x 09 66 251 651x

25 09 65 361 671x 09 66 351 651x

37 09 65 461 671x 09 66 451 651x

Please insert digit x for flange thread or fitted female screw locks for M3 x = 1

for 4-40 UNC x = 2

for fitted screw locks 4-40 UNC x = 3

Stamped solder pins, angled 9 09 65 122 680x 09 66 112 660x

without grounding board locks 15 09 65 222 680x 09 66 212 660x

25 09 65 322 680x 09 66 312 660x

37 09 65 422 680x 09 66 412 660x

Stamped solder pins, angled 9 09 65 162 681x 09 66 152 661x

with grounding board locks 15 09 65 262 681x 09 66 252 661x

25 09 65 362 681x 09 66 352 661x

37 09 65 462 681x 09 66 452 661x

Please insert digit x for flange thread or fitted female screw locks for M3 x = 1

for 4-40 UNC x = 2

for fitted screw locks 4-40 UNC x = 3

Low profile stamped solder pins, angled 9 09 65 122 680x 09 66 112 660x

without grounding board locks 15 09 65 222 680x 09 66 212 660x

25 09 65 322 680x 09 66 312 660x

37 09 65 422 680x 09 66 412 660x

Low profile stamped solder pins, angled 9 09 65 162 681x 09 66 152 661x

with grounding board locks 15 09 65 262 681x 09 66 252 661x

25 09 65 362 681x 09 66 352 661x

37 09 65 462 681x 09 66 452 661x

Please insert digit x for flange thread or fitted female screw locks for M3 x = 5

for 4-40 UNC x = 6

for fitted screw locks 4-40 UNC x = 7

US footprint stamped solder pins 9 09 68 163 581x 09 68 153 561x

with board locks 15 09 68 263 581x 09 68 253 561x

25 09 68 363 581x 09 68 353 561x

37 09 68 463 581x 09 68 453 561x

Please insert digit x for flange thread or fitted female screw locks for M3 x = 1

for 4-40 UNC x = 2

for fitted screw locks 4-40 UNC x = 3

Press-fit stamped, straight 9 09 66 124 670x 09 66 114 650x

without board locks, flange height 5.7 mm 15 09 66 224 670x 09 66 214 650x

25 09 66 324 670x 09 66 314 650x

37 09 66 414 650x

50 09 66 514 650x

Press-fit stamped, straight 9 09 66 164 671x 09 66 154 651x

with board locks, flange height 5.7 mm 15 09 66 264 671x 09 66 254 651x

25 09 66 364 671x 09 66 354 651x

37 09 66 454 651x

50 09 66 554 651x

Please insert digit x for flange thread or fitted female screw locks for M3 x = 5

for 4-40 UNC x = 6

for fitted screw locks 4-40 UNC x = 7

IDC termination 9 09 66 128 670x 09 67 118 650x

15 09 66 228 670x 09 67 218 650x

25 09 66 328 670x 09 67 318 650x

37 09 66 428 670x 09 67 418 650x

Please insert digit x for flange thread or fitted female screw locks for through holes x = 0

for M3 x = 1

for 4-40 UNC x = 2

Cable clamp 9 09 66 108 0001 09 66 108 0001

15 09 66 208 0001 09 66 208 0001

25 09 66 308 0001 09 66 308 0001

37 09 66 408 0001 09 66 408 0001

D-Sub STANDARD

Page4

Pictures Characteristics No. of contacts male female

Crimp terminal 9 09 67 009 5601 09 67 009 4701

15 09 67 015 5601 09 67 015 4701

25 09 67 025 5601 09 67 025 4701

37 09 67 037 5601 09 67 037 4701

50 09 67 050 5601 09 67 050 4701

Stamped crimp contacts

AWG 24-20 09 67 000 81x8 09 67 000 82x8

AWG 28-24 09 67 000 71x8 09 67 000 72x8

Please insert digit x f or 500 pieces bulk x = 7

for 500 pieces / reel x = 6

for 10,000 pieces / reel x = 5

Turned crimp contacts, performance level 1

AWG 22-18 09 67 000 3576 09 67 000 3476

AWG 24-20 09 67 000 8576 09 67 000 8476

AWG 26-22 09 67 000 5576 09 67 000 5476

AWG 28-24 09 67 000 7576 09 67 000 7476

Turned solder cups

9 09 67 009 5615 09 67 009 4715

15 09 67 015 5615 09 67 015 4715

25 09 67 025 5615 09 67 025 4715

37 09 67 037 5615 09 67 037 4715

50 09 67 050 5615 09 67 050 4715

High Density, solder pins, straight 15 09 56 161 7700 09 56 151 7500

26 09 56 261 7700 09 56 251 7500

44 09 56 361 7700 09 56 351 7500

62 09 56 461 7700 09 56 451 7500

78 09 56 561 7700 09 56 551 7500

High Density, solder pins, straight 15 09 56 161 771x 09 56 151 751x

with spacer and board locks 26 09 56 261 771x 09 56 251 751x

44 09 56 361 771x 09 56 351 751x

62 09 56 461 771x 09 56 451 751x

78 09 56 561 771x 09 56 551 751x

Please insert digit x for flange thread or fitted female screw locks for 4-40 UNC x = 2

for fitted screw locks 4-40 UNC x = 3

High Density, solder pins, angled 15 09 56 162 781x 09 56 152 761x

with board locks 26 09 56 262 781x 09 56 252 761x

44 09 56 362 781x 09 56 352 761x

62 09 56 462 781x 09 56 452 761x

78 09 56 552 761x

Please insert digit x for flange thread or fitted female screw locks for 4-40 UNC x = 2

for fitted screw locks 4-40 UNC x = 3

High Density, crimp terminal 15 09 56 100 5601 09 56 100 4701

26 09 56 200 5601 09 56 200 4701

44 09 56 300 5601 09 56 300 4701

62 09 56 400 5601 09 56 400 4701

78 09 56 500 5601 09 56 500 4701

High Density, stamped crimp contacts

AWG 26-24 09 56 000 81x7 09 67 000 82x7

Please insert digit x for 500 pieces bulk x = 7

for 500 pieces / reel x = 6

for 10,000 pieces / reel x = 5

High Density, solder cups 15 09 56 100 5604 09 56 100 4704

26 09 56 200 5604 09 56 200 4704

44 09 56 300 5604 09 56 300 4704

62 09 56 400 5604 09 56 400 4704

78 09 56 500 5604 09 56 500 4704

Mixed shells with signal solder cup contacts 5W1 09 69 111 5051 09 69 101 5051

7W2 09 69 211 5072 09 69 201 5072

9W4 09 69 311 5094 09 69 301 5094

11W1 09 69 211 5111 09 69 201 5111

13W3 09 69 311 5133 09 69 301 5133

13W6 09 69 411 5136 09 69 401 5136

17W2 09 69 311 5172 09 69 301 5172

21W1 09 69 311 5211 09 69 301 5211

21WA4 09 69 411 5214 09 69 401 5214

24W7 09 69 511 5247 09 69 501 5247

25W3 09 69 411 5253 09 69 401 5253

27W2 09 69 411 5272 09 69 401 5272

36W4 09 69 511 5364 09 69 501 5364

43W2 09 69 511 5432 09 69 501 5432

D-Sub MIxeD D-Sub HIGH DeNSITy D-Sub STANDARD

Page5

Pictures Characteristics No. of contacts male female

Mixed shells for signal crimp contacts

and special contacts

Signal crimp contacts see page 3 5W1 09 69 112 0051 09 69 102 0051

7W2 09 69 212 0072 09 69 202 0072

11W1 09 69 212 0111 09 69 202 0111

13W3 09 69 312 0133 09 69 302 0133

17W2 09 69 312 0172 09 69 302 0172

21W1 09 69 312 0211 09 69 302 0211

21WA4 09 69 412 0214 09 69 402 0214

36W4 09 69 512 0364 09 69 502 0364

Mixed shells for special contacts

2W2 09 69 110 0522 09 69 100 0522

2W2C 09 69 110 0022 09 69 100 0022

3W3 09 69 210 0033 09 69 200 0033

3W3C 09 69 210 0633 09 69 200 0633

5W5 09 69 310 0055 09 69 300 0055

7W7 09 69 410 0077 09 69 400 0077

8W8 09 69 410 0088 09 69 400 0088

Pictures Characteristics Rating male female

Power contacts, solder cup

10 A 09 69 281 5420 09 69 181 5420

20 A 09 69 281 5421 09 69 181 5421

30 A 09 69 281 5422 09 69 181 5422

40 A 09 69 281 5423 09 69 181 5423

Power contacts, crimp

10 A 09 69 282 5420 09 69 182 5420

20 A 09 69 282 5421 09 69 182 5421

30 A 09 69 282 5422 09 69 182 5422

40 A 09 69 282 5423 09 69 182 5423

High voltage contacts, solder version

09 69 281 2550 09 69 181 2550

High voltage contacts, crimp

09 69 282 2550 09 69 182 2550

Pictures Characteristics for cables male female

Coaxial contacts for 50 Ω

RG 174 09 69 281 5140 09 69 181 5140

RG 178 09 69 281 5141 09 69 181 5141

RG 58 09 69 281 5143 09 69 181 5143

Many other coaxial contacts are available on

request

Coaxial contacts for 75 Ω

RG 179 09 69 282 5230 09 69 182 5230

RG 59 09 69 282 5232 09 69 182 5232

RGD 179 09 69 282 5233 09 69 182 5233

Many other coaxial contacts are available on

request

Pictures Characteristics inner Ø air tube male female

Pneumatic contacts

2 mm 09 69 287 0060 09 69 187 0060

2.6 mm 09 69 287 0061 09 69 187 0061

3 mm 09 69 287 0062 09 69 187 0062

4 mm 09 69 287 0063 09 69 187 0063

HARTING D-Sub Selection Guide

D-Sub MIxeD

SPeCIAl CoNTACTS

Page6

Pictures Characteristics No. of contacts male female

Filter, turned solder pins, straight

with through holes

9 09 64 122 7800 09 64 112 7800

15 09 64 222 7800 09 64 212 7800

25 09 64 322 7800 09 64 312 7800

Filter, turned solder buckets

with through holes

9 09 64 121 7800 09 64 111 7800

15 09 64 221 7800 09 64 211 7800

25 09 64 321 7800 09 64 311 7800

37 09 64 421 7800 09 64 411 7800

Filter, turned solder pins, right angled,

with 4-40 UNC flange thread

9 09 64 123 7802 09 64 113 7802

15 09 64 223 7802 09 64 213 7802

25 09 64 323 7802 09 64 313 7802

37 09 64 423 7802 09 64 413 7802

Male / female filter adapters

9 09 64 100 72xx

15 09 64 200 72xx

25 09 64 300 72xx

37 09 64 400 72xx

Please insert digits xx f or 47 pF xx = 10

for 470 pF xx = 20

for 1000 pF xx = 30

for 3900 pF xx = 40

Filter, turned solder buckets

with through holes / clinch nut

9 09 64 121 72xy 09 64 111 72xy

15 09 64 221 72xy 09 64 211 72xy

25 09 64 321 72xy 09 64 311 72xy

37 09 64 421 72xy 09 64 411 72xy

Please insert digits x and y for 47 pF x = 1 for through holes y = 0

for 470 pF x = 2 for 4-40 UNC y = 7

for 1000 pF x = 3 for M3 y = 8

for 3900 pF x = 4

Filter, turned solder pins, straight,

with grounding board locks

9 09 64 122 72xy 09 64 112 72xy

15 09 64 222 72xy 09 64 212 72xy

25 09 64 322 72xy 09 64 312 72xy

37 09 64 422 72xy 09 64 412 72xy

Please insert digits x and y f or 47 pF x = 1 for 4-40 UNC y = 5

for 470 pF x = 2 for M3 y = 6

for 1000 pF x = 3

for 3900 pF x = 4

Filter, turned solder pins, right angled,

with brackets and board locks

9 09 64 124 72xy 09 64 114 72xy

15 09 64 224 72xy 09 64 214 72xy

25 09 64 324 72xy 09 64 314 72xy

37 09 64 424 72xy 09 64 414 72xy

Please insert digits x and y f or 47 pF x = 1 for through holes y = 1

for 470 pF x = 2 for 4-40 UNC y = 2

for 1000 pF x = 3 for M3 y = 3

for 3900 pF x = 4 for 4-40 UNC female screw locks y = 4

for M3 female screw locks y = 5

HARTING D-Sub Selection Guide

D-Sub FIlTeR

C-FIlTeR FeRRITe-FIlTeR

Page7

Pictures Characteristics No. of contacts male female

IP 67, turned solder cups

9 09 67 409 5615 09 67 409 4715

15 09 67 415 5615 09 67 415 4715

25 09 67 425 5615 09 67 425 4715

37 09 67 437 5615 09 67 437 4715

50 09 67 450 5615 09 67 450 4715

IP 67, turned solder cups

with rear plastic mounting frame 9 09 67 509 x615 09 67 509 y715

15 09 67 515 x615 09 67 515 y715

25 09 67 525 x615 09 67 525 y715

IP 67, turned solder cups

with rear metal mounting frame 9 09 67 609 x615 09 67 609 y715

15 09 67 615 x615 09 67 615 y715

25 09 67 625 x615 09 67 625 y715

37 09 67 637 x615 09 67 637 y715

50 09 67 650 x615 09 67 650 y715

Please insert digits x and y for 4-40 UNC x = 7; y = 6

for M3 x = 9; y = 8

IP 67, turned solder cups

with front plastic mounting frame 9 09 67 709 x615 09 67 709 y715

15 09 67 715 x615 09 67 715 y715

25 09 67 725 x615 09 67 725 y715

IP 67, turned solder cups

with front metal mounting frame 9 09 67 809 x615 09 67 809 y715

15 09 67 815 x615 09 67 815 y715

25 09 67 825 x615 09 67 825 y715

37 09 67 837 x615 09 67 837 y715

50 09 67 850 x615 09 67 850 y715

Please insert digits x and y f or 4-40 UNC x = 7; y = 6

for M3 x = 9; y = 8

IP 67, turned straight to PCB,

spacer and board lock 9 09 67 509 x675 09 67 509 y775

rear plastic mounting frame 15 09 67 515 x675 09 67 515 y775

25 09 67 525 x675 09 67 525 y775

IP 67, turned straight to PCB,

spacer and board lock 9 09 67 609 x675 09 67 609 y775

rear metal mounting frame 15 09 67 615 x675 09 67 615 y775

25 09 67 625 x675 09 67 625 y775

37 09 67 637 x675 09 67 637 y775

50 09 67 650 x675 09 67 650 y775

Please insert digits x and y for 4-40 UNC x = 7; y = 6

for M3 x = 9; y = 8

IP 67, turned angled to PCB,

spacer and board lock 9 09 67 509 x658 09 67 509 y758

rear plastic mounting frame 15 09 67 515 x658 09 67 515 y758

25 09 67 525 x658 09 67 525 y758

IP 67, turned angled to PCB,

spacer and board lock 9 09 67 609 x658 09 67 609 y758

rear metal mounting frame 15 09 67 615 x658 09 67 615 y758

25 09 67 625 x658 09 67 625 y758

37 09 67 637 x658 09 67 637 y758

50 09 67 650 x658 09 67 650 y758

Please insert digits x and y for 4-40 UNC x = 7; y = 6

for M3 x = 9; y = 8

IP 67, black plastic hood

9 09 67 009 043x

15 09 67 015 043x

25 09 67 025 043x

37 09 67 037 043x

50 09 67 050 043x

IP 67, metallized plastic hood

9 09 67 009 053x

15 09 67 015 053x

25 09 67 025 053x

37 09 67 037 053x

50 09 67 050 053x

Please insert digit x f or locking screws 4-40 UNC x = 8

for locking screws M3 x = 9

D-Sub WATeRPRooF IP 67

Page8

Pictures Characteristics No. of contacts male female

SMT standard, stamped solder pins, angled

with grounding board locks

9 09 55 166 68xx 741 09 55 156 66xx 741

15 09 55 266 68xx 741 09 55 256 66xx 741

25 09 55 366 68xx 741 09 55 356 66xx 741

37 09 55 466 68xx 741 09 55 456 66xx 741

Please insert digits xx f or M3 nut xx = 11

for 4-40 UNC nut xx = 12

for fitted M3 female screw locks xx = 21

for fitted 4-40 UNC female screw locks xx = 22

SMT low profile, stamped solder pins, angled

with grounding board locks

9 09 55 166 68xx 741 09 55 156 66xx 741

15 09 55 266 68xx 741 09 55 256 66xx 741

25 09 55 366 68xx 741 09 55 356 66xx 741

37 09 55 466 68xx 741 09 55 456 66xx 741

Please insert digits xx for M3 nut xx = 15

for 4-40 UNC nut xx = 16

for fitted M3 female screw locks xx = 19

for fitted 4-40 UNC female screw locks xx = 20

SMT standard, stamped solder pins, straight

without grounding board locks

9 09 55 129 68xx 741 09 55 115 66xx 741

15 09 55 229 68xx 741 09 55 215 66xx 741

25 09 55 329 68xx 741 09 55 315 66xx 741

37 09 55 429 68xx 741 09 55 415 66xx 741

Please insert digits xx for M3 nut xx = 11

for 4-40 UNC nut xx = 12

for fitted M3 female screw locks xx = 21

for fitted 4-40 UNC female screw locks xx = 22

Pictures Characteristics No. of contacts Screws 4-40 uNC Screws M3

Plastic hood top and side entry

black

9 09 67 009 0434 09 67 009 0430

15 09 67 015 0434 09 67 015 0430

25 09 67 025 0434 09 67 025 0430

37 09 67 037 0434 09 67 037 0430

Plastic hood top and side entry

metallized 9 09 67 009 0435 09 67 009 0431

15 09 67 015 0435 09 67 015 0431

25 09 67 025 0435 09 67 025 0431

37 09 67 037 0435 09 67 037 0431

Plastic hood top entry

black 9 09 67 009 0442

15 09 67 015 0442

25 09 67 025 0442

37 09 67 037 0442

50 09 67 050 0442

Plastic hood top entry

metallized 9 09 67 009 0443

15 09 67 015 0443

25 09 67 025 0443

37 09 67 037 0443

50 09 67 050 0443

Plastic hood side entry

grey, with internal metal screening 9 09 67 009 0573

15 09 67 015 0573

25 09 67 025 0573

37 09 67 037 0573

50 09 67 050 0573

Knurled screw with grey head

thread M3 0099 6677 000011 99996655

thread 4-40 UNC 0099 6677 000000 99997711

D-Sub ACCeSSoRIeS D-Sub SMT

Page9

Pictures Characteristics No. of contacts Screws 4-40 uNC Screws M3

Metal hood top entry

with grommet 9 09 67 009 0343 09 67 009 0348

15 09 67 015 0343 09 67 015 0348

25 09 67 025 0343 09 67 025 0348

37 09 67 037 0343 09 67 037 0348

50 09 67 050 0343 09 67 050 0348

Metal hood side entry

with grommet 9 09 67 009 0333 09 67 009 0336

15 09 67 015 0333 09 67 015 0336

25 09 67 025 0333 09 67 025 0336

37 09 67 037 0333 09 67 037 0336

50 09 67 050 0333 09 67 050 0336

Metal hood top entry

with cable clamp

9 09 67 009 0344 09 67 009 0349

15 09 67 015 0344 09 67 015 0349

25 09 67 025 0344 09 67 025 0349

37 09 67 037 0344 09 67 037 0349

50 09 67 050 0344 09 67 050 0349

Metal hood side entry

with cable clamp

9 09 67 009 0334 09 67 009 0335

15 09 67 015 0334 09 67 015 0335

25 09 67 025 0334 09 67 025 0335

37 09 67 037 0334 09 67 037 0335

50 09 67 050 0334 09 67 050 0335

Metal hood top and side entry

with different screw options 9 61 03 001 x010 61 03 001 y010

15 61 03 001 x016 61 03 001 y016

25 61 03 001 x017 61 03 001 y017

37 61 03 001 x018 61 03 001 y018

50 61 03 001 x019 61 03 001 y019

Metal hood side entry

with different screw options

9 61 03 001 x013 61 03 001 y013

15 61 03 001 x014 61 03 001 y014

25 61 03 001 x015 61 03 001 y015

Please insert digits x and y for knurled screw x = 0; y = 3

for hexagonal screw with

captive washer x = 2; y = 1

Cable clamp

Cable diameter 5 - 7 mm 9 - 37 61 03 000 0141

Cable diameter 7 - 10 mm 9 - 37 61 03 000 0144

Cable diameter 10 - 12 mm 9 - 37 61 03 000 0143

Cable diameter 11 - 14 mm 50 61 03 000 0145

Hand crimp tool for the standard contacts 09 99 000 0175

Hand crimp tool for the high density contacts 09 99 000 0535

Hand crimp tool for turned signal contacts 09 99 000 0501

Locator for turned signal contacts 09 99 000 0531

Insertion / Removal tool for the standard contacts 09 99 000 0171

Insertion / Removal tool for the high density contacts 09 99 000 0513

Hand crimp tool for the power contacts 09 99 000 0509

Locator for the power contacts 10 A to 40 A 09 99 000 0504

Insertion / Removal tool 09 99 000 0512

Hand crimp tool for the inner contact 09 99 000 0501

Locator for the inner coaxial contact 09 99 000 0507

Hand crimp tool for the outer ferrule 09 99 000 0503

Die for the outer ferrule 09 99 000 0508

Die for the outer ferrule 09 99 000 0515

Die for the outer ferrule 09 99 000 0518

Die for the outer ferrule 09 99 000 0519

HARTING D-Sub Selection Guide

D-Sub ACCeSSoRIeS

CoAxIAl PoWeR SIGNAl

Page10

HARTING Technology Group

Marienwerderstr. 3, 32339 Espelkamp – Germany

P.O. Box 11 33, 32325 Espelkamp – Germany

Phone +49 5772 47-0, Fax +49 5772 47-400

info@HARTING.com

www.HARTING.com

MO/2013-05-31/1.0 98 32 012 0201 version 2