1/8ページ

ダウンロード(2.3Mb)

ケーブルアセンブリもワンストップで(英語)

ODUはケーブルアセンブリも承っております。

本カタログは英語になります。

このカタログについて

| ドキュメント名 | ODUのケーブルアセンブリ |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 2.3Mb |

| 登録カテゴリ | |

| 取り扱い企業 | オーディーユージャパン株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

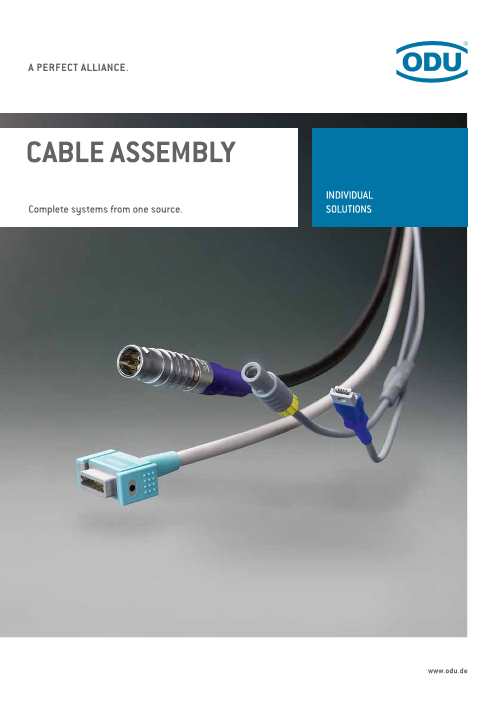

A perfect AlliAnce.

cAble ASSeMblY

individual

Complete systems from one source. solutions

www.odu.de

Page2

odu – an oveRview CustomeR-sPeCifiC solutions

• more than 70 years of connector experience Contacts, connectors and cable assembly to meet the

highest technical requirements – the products and services

• turnover of € 135 million

provided by odu are characterized by their uncompromising

• over 1,650 employees worldwide customer and results-oriented focus.

• 7 sales subsidiaries: China, denmark, france, italy, • P recise implementation of the application-specifi c

sweden, uk and the usa stipulations as regards to the design, function, cost

• technologies: design and development, machine tool and and exclusivity

special machine construction, injection, stamping, turning, • Customized connector solutions originated from

surface technology, assembly and cable assembly standard products

• w e operate in the following markets: medical, • know-how and project dedicated resources under one roof

measurement and testing, military and security,

• fast prototyping and quick production turn around

industrial, energy, automotive

Certifi ed quality

• din en iso 9001

• din iso ts 16949

• din en iso 14001

• iso 13485

• vast range of ul, Csa, sCa, vg, mil and vde approvals

• ul -certifi ed cable assembly

Page3

Cable assemblY

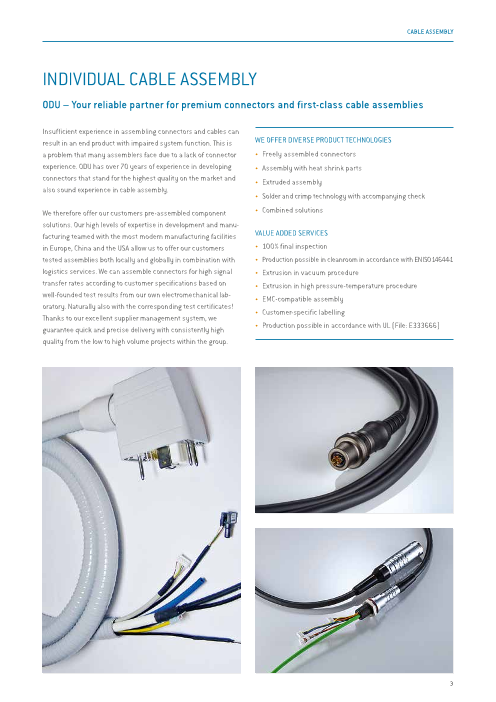

IndIvIdual Cable assembly

odu – Your reliable partner for premium connectors and first-class cable assemblies

Insufficient experience in assembling connectors and cables can

result in an end product with impaired system function. this is We offer dIverse produCt teChnologIes

a problem that many assemblers face due to a lack of connector • freely assembled connectors

experience. odu has over 70 years of experience in developing • assembly with heat shrink parts

connectors that stand for the highest quality on the market and

• extruded assembly

also sound experience in cable assembly.

• solder and crimp technology with accompanying check

We therefore offer our customers pre-assembled component • Combined solutions

solutions. our high levels of expertise in development and manu-

facturing teamed with the most modern manufacturing facilities value added servICes

in europe, China and the usa allow us to offer our customers • 100% final inspection

tested assemblies both locally and globally in combination with • production possible in cleanroom in accordance with en Iso 14644-1

logistics services. We can assemble connectors for high signal • extrusion in vacuum procedure

transfer rates according to customer specifications based on • extrusion in high pressure-temperature procedure

well-founded test results from our own electromechanical lab-

• emC-compatible assembly

oratory. naturally also with the corresponding test certificates!

• Customer-specific labelling

thanks to our excellent supplier management system, we

guarantee quick and precise delivery with consistently high • production possible in accordance with ul (file: e333666)

quality from the low to high volume projects within the group.

3

Page4

perfeCt InteraCtIon

everyone talks about functioning assemblies – we make them!

as manufacturers of a diverse range of high-end contacts, circular and

rectangular connectors and also customer- and application-specific

connectors, absolute quality and reliability are core values in our corporate

and product philosophy. our cable assembly department continuously

improves our product technology and testing methods to ensure high quality

results. the result is always perfect interaction between cable and connector.

We offer cost effective versatile modular connector

solutions that can transfer data, power, signal, high

frequency, light and compressed air.

Cable-assemblY

4

Page5

single ContaCts CiRCulaR ConneCtoRs with Push-Pull

(odu sPRingtaC® / odu lamtaC®) and bReak-awaY loCking

Contact technology forms the backbone of our ten series in six sizes from 1 to 40 contact

company. We deliver optimal transmission quality positions satisfy every demand. Certified to

and high current carrying capacity connector mIl, ul and vde with 5,000 mating cycles and a

solutions. our innovative product development compact size, and suitable for use with robots.

responds consistently to all the market needs

and trends.

modulaR ConneCtoRs heavY-dutY ConneCtoRs

odu’s modular connectors are designed for odu’s heavy duty connectors are robust and

uncompromising quality, a high number of rugged solutions that prove the extended

mating cycles, extreme contact reliability and experience that we have in contact technology,

unlimited flexibility. We offer cost effective circular and rectangular connectors,

versatile modular connector solutions that can manufacturing & surface technology.

transfer data, power, signal, high frequency,

light and compressed air.

5

Page6

Cable assemblY

odu – Cable assembly Integrated solutIons

everything from one source

With assembly facilities around the world, odu offers its locations in China and the usa handle international logistics

customers a service that combines high quality connectors while the sites in germany and romania serve the european

with customer-specific cable assembly requirements. our sound market. short delivery and procurement channels and the use

knowledge of our own connectors combined with ultra modern of local manufacturers reduce the manufacturing times.

production facilities and the know-how to process products

from other sources offers the market a substantial advantage. odu – Your partner for connectors and first-class assemblies!

loCation mühldoRf – geRmanY loCation sibiu – Romania

manufaCturIng CapabIlItIes manufaCturIng CapabIlItIes

• prototype centre • manufacturing site europe

• special assemblies (potting, pressure test) • assemblies, potting of components and connectors

• laboratory manufacturing for new technologies • medium and large series

• small volume production • assembly of connectors for large series

value added servICes value added servICes

the development area and test laboratory in mühldorf make Quality control ensures special attention to overall

the location ideal for highly complex manufacturing. this in- manufacturing process. the romanian plant has automatic

cludes assemblies for underwater use which are then tested testing machines that conduct a visual check of the workpieces

in our pressure chamber at up to 100 bar. We also provide in a closed system to ensure that only perfect parts are sent

cable assembly solutions for medical applications that involve out. thus, complete quality assurance is guaranteed.

wearable or human implant applications. a camera system

ensures full documentation of this production step.

assembling a patient cable set that documents all solder points by using a here the pre-potting is an important step that has a major influence on the

camera system. the complete data set is then given to the end customer along extrusion result. odu romania’s many years of experience ensure consistently

with the cable. good results no matter how complex the components are.

6

Page7

Cable assemblY

geRmanY

Romania

usa

China

manufacturing location

loCation shanghai – China loCation CamaRillo – usa

manufaCturIng CapabIlItIes manufaCturIng CapabIlItIes

• manufacturing site asia • manufacturing site america

• assemblies, potting of components and connectors • assemblies, potting of components and connectors

• medium and large series • Itar-authorized operation (International traffic in arms regulation)

• assembly of connectors for large series • research and development of moulds for thermoplastic

extrusion

value added servICes

our factory in China has extensive know-how and connector ex- value added servICes

trusion was further perfected here. special materials for medical the odu-usa facility specializes in rapid prototyping development

technology are combined with our connectors to form a system. and projects ranging from low to mid sized volumes. the prototype

With various sizes of presses, we can flexibly adapt both the tools are manufactured on a high-precision milling centre using

size and the unit weight to fit the market requirements. direct data transfer from the Cad system. a 3d printer supports the

sales team by quickly providing “rapid prototyping” samples.

extrusion of assembled odu medI-snap connectors in a master mould with modular here we show our milling unit, which is used to produce prototype tools and

interchangeable inserts. here it is possible to react quickly and flexibly to the widest moulds for customer-specific applications. the simple configuration allows rapid

range of cable diameters that maintain a stable manufacturing process. implementation of small series with up to 2,000 units.

7

Page8

A perfect AlliAnce.

ODU GrOUp WOrlDWiDe

HeADQUArterS

ODU GmbH & co. KG

pregelstr. 11

84453 mühldorf a. Inn

germany

phone +49 8631 6156-0

fax +49 8631 6156-49

e-mail zentral@odu.de

SAleS SUbSiDiArieS

ODU Denmark ApS ODU Skandinavia Ab ODU-USA inc.

phone +45 2233 5335 phone +46 176 18261 phone +1 805 4840540

e-mail odu.denmark@odu.de e-mail sales@odu.se e-mail sales@odu-usa.com

www.odu-denmark.dk www.odu.se www.odu-usa.com

ODU france SArl ODU (Shanghai) further information and specialised

phone +33 1 3935-4690 international trading co., ltd. representatives can be found at:

e-mail odu@odu.fr phone +86 21 58347828-0 www.odu.de/sales

www.odu.fr e-mail oduchina@odu.com.cn

www.odu.com.cn

ODU italia S.r.l.

phone +39 331 8708847 ODU-UK ltd.

e-mail sales@odu-italia.it phone +44 1509 266433

www.odu.de e-mail sales@odu-uk.co.uk

www.odu-uk.co.uk

> stempelfeld – nicht lackieren <

simply scan Qr-Code for the complete

download of this brochure.

www.odu.de

KonfeKtIonIerung / b / 1114 / e the right is reserved to modify product and technical data.

cAble ASSeMblY