1/76ページ

ダウンロード(1.1Mb)

Robust Cylindrical Connectors with Threaded and Bayonet Locking

このカタログについて

| ドキュメント名 | ODU Heavy Duty Connectors |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 1.1Mb |

| 登録カテゴリ | |

| 取り扱い企業 | オーディーユージャパン株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

ODU Heavy Duty Connectors

Robust Cylindrical Connectors

with Threaded and Bayonet Locking

www.odu.de

Page2

The latest version of this

catalogue is also in the Internet

www.odu.de

www.odu-usa.com

www.odu-china.com

All shown connectors are according to DIN EN 61984:2009

connectors without breaking capacity (COC).

All dimensions in mm.

All figures are illustrations.

Changes reserved.

Page3

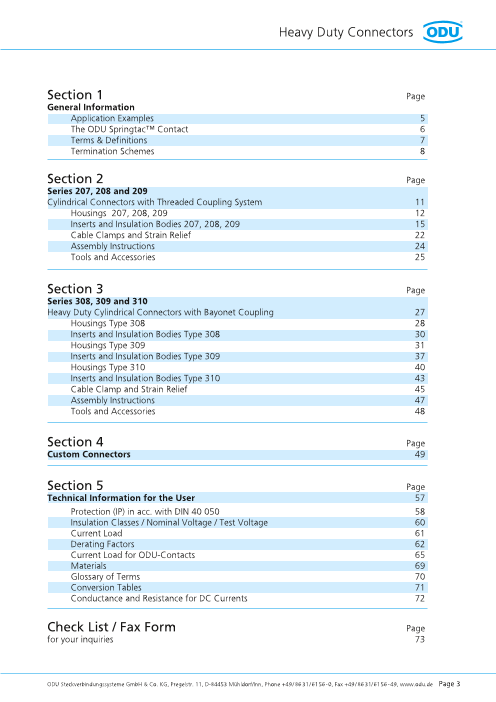

Heavy Duty Connectors

Section 1 Page

General Information

Application Examples 5

The ODU Springtac™ Contact 6

Terms & Definitions 7

Termination Schemes 8

Section 2 Page

Series 207, 208 and 209

Cylindrical Connectors with Threaded Coupling System 11

Housings 207, 208, 209 12

Inserts and Insulation Bodies 207, 208, 209 15

Cable Clamps and Strain Relief 22

Assembly Instructions 24

Tools and Accessories 25

Section 3 Page

Series 308, 309 and 310

Heavy Duty Cylindrical Connectors with Bayonet Coupling 27

Housings Type 308 28

Inserts and Insulation Bodies Type 308 30

Housings Type 309 31

Inserts and Insulation Bodies Type 309 37

Housings Type 310 40

Inserts and Insulation Bodies Type 310 43

Cable Clamp and Strain Relief 45

Assembly Instructions 47

Tools and Accessories 48

Section 4 Page

Custom Connectors 49

Section 5 Page

Technical Information for the User 57

Protection (IP) in acc. with DIN 40 050 58

Insulation Classes / Nominal Voltage / Test Voltage 60

Current Load 61

Derating Factors 62

Current Load for ODU-Contacts 65

Materials 69

Glossary of Terms 70

Conversion Tables 71

Conductance and Resistance for DC Currents 72

Check List / Fax Form Page

for your inquiries 73

ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/ 86 31/6156-0, Fax +49/86 31/6156-49, www.odu.de Page 3

Page4

Heavy Duty Connectors

For your notes:

Page 4 ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/8631/6156-0, Fax +49/8631/6156-49, www.odu.de

Page5

Heavy Duty Connectors

General Information – Application Examples

ODU Steckverbindungssysteme GmbH & Co. KG / Otto Dunkel GmbH manufactures heavy duty cylindrical

connectors for industrial applications.

The heavy duty connectors are divided into two groups: Series 207, 208, and 209, and the Series 308, 309,

and 310 as well as special connectors.

The Series 207, 208, and 209 is a family of cylindrical connectors with threaded coupling system. They are

available in three sizes: 207, 208, 209.

Typical applications are areas where mechanical durability, high reliability, small and compact design, and high

packing density are of concern. Examples are industrial measurement and control, testing, and power distri-

bution systems.

The Series 308, 309 and 310 offers cylindrical connectors with bayonet coupling system. This family of

connectors is also divided into three sizes: 308, 309, and 310. A few connectors can be supplied with water-

tight mounting flanges for IP 67 protection for up to 8 hours submersed at 3 bar, or a neoprene push-pull

locking scheme, IP 67 (8h –1bar).

Usage is in severe industrial environments such as heavy duty crane and lifting equipment at sea ports, contai-

ner handling equipment, heavy duty transport systems, mobile cooling equipment, machine tools, railroads,

and steel mills.

Custom connectors based on any of the above connector systems are available. They can be designed to

application-specific requirements in cooperation with the customer. ODU will work with the customer to defi-

ne specifications and establish mechanical, electrical, and environmental requirements.

ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/8631/6156-0, Fax +49/8631/6156-49, www.odu.de Page 5

Page6

Heavy Duty Connectors

General Information – The Contact Principle

The ODU Springtac™ Contact

The springwire contact is the ingenious invention of Otto Dunkel, the founder of ODU. The figure below

shows the concept of the springwire contact with the Springtac™ socket and a solid pin.

The socket has many springwires parallel to the mating direction. The springwires are fixed at the bottom of

the socket but are allowed to move at the entrance end of the socket. A guide ring at the entrance to the

socket provides easy insertion of the pin and prevents damage to the springwires during the contact mating.

The springwires form a resilient gage with many independent contact points along the surface of the pin.

This creates an almost constant contact pressure between the pin surface and the springwires. Even a rela-

tively small socket, such as for an AWG #20 pin (1.02 mm dia.), contains at least 15 independent springwires.

As the size of the contact increases, so does the number of springwires. The result is a large contact area for

efficient current transmission. Springtac™ contacts are available from as small as 0.6 mm to as large as 50

mm diameter.

Contact retention in a connector insulation body is via militarystyle contact clips or via glueing or mechanical

pinching.

Socket Pin

A

A

Socket and Pin

in mated condition

Springwire

Surface finish

Socket wall

Significant advantages of the

ODU Springtac™ contact:

l Very high contact reliability

l Low contact resistance

l High current load

l Excellent performance under vibration Contact

area

l Low insertion & withdrawal force Contact pin

l High number of mating cycles

l Long service life

Section

A - A

Page 6 ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/8631/6156-0, Fax +49/8631/6156-49, www.odu.de

Page7

Heavy Duty Connectors

General Information – Terms & Definitions

A typical connector consists of a plug with a cable and a panel-mounted receptacle.

Receptacle Plug

A cable-to-cable connection requires a free receptacle and a plug.

IFnr-eLein-ree cRepcteapctlaecle Plug

A connector (receptacle, in-line receptacle or plug) generally has a housing, an insulation body, and contacts. In-line

recept acles and plugs also can have a cable clamp with cable strain relief.

Receptacle

Receptacle Insulation body Guide ring

with pin

In-Line Receptacle

Cable clamp Housing Insulation body Guide ring

with pin

Plug

Insulation body Housing Cable clamp

with socket

ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/8631/6156-0, Fax +49/8631/6156-49, www.odu.de Page 7

Page8

Heavy Duty Connectors

General Information – Different Types of Contact Termination

All ODU heavy duty connectors have pin and socket contacts. ODU offers no button contacts due to their inherent unre-

liability.

Insulation bodies and inserts with pins can be mounted in a receptacle or plug. As a rule, sockets are preferred inside the

part of the connection which supplies the current. This is to prevent injury due to accidental touching.

The type of termination determines the mounting of the contacts inside the insulation body.

Available Terminations are:

l Threaded Stud

l Solder Cup

l Crimp

Threaded stud and solder cup termination requires that the contacts are mounted permanently (fixed) inside the insu-

lation body. Insulation bodies with fixed contacts are called inserts. Inserts are ordered with one part number which inclu-

des the contacts.

Crimp contacts are snap-in contacts and can be removed from the insulation body. They are first crimped to the cable

and then inserted into the insulation body. When ordering crimp inserts, the contacts and the insulation bodies have

separate part numbers. Crimp contacts can be removed after installation, please see page 9 for details.

Page 8 ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/8631/6156-0, Fax +49/8631/6156-49, www.odu.de

Page9

Heavy Duty Connectors

Crimp Termination

Crimp termination provides a long-lasting, corrosion-free, and reliable connection between the contact and

the conductor.

Crimping cold-forms the conductors and the crimp barrel of the contact. The result is a gas-tight connection

with high contact-to-cable retention force.

Crimping is suitable for all contact sizes, from the smallest to the largest contact diameter.

The 8-point crimp tool is used for small cable cross sections from 0.5 – 2.5 mm2. Larger cable cross sections

require a hexagonal crimp tool. The dimension across a hexagonal crimp, measured from corner to corner,

should not increase over the original crimp barrel outer diameter. The cable insulation (jacket) is not dama-

ged during crimping and can butt up against the endface of the crimp barrel.

Cross Section of a Hexagonal Crimp

Contact with Hexagonal (1) and 8-Point Crimp (2).

1

2

1 Polished Cut-Away View of a Hexagonal (1) and 8-Point Crimp (2)

2

In an 8-Point Crimp two crimps are behind each other.

ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/8631/6156-0, Fax +49/8631/6156-49, www.odu.de Page 9

Page10

Heavy Duty Connectors

For your notes:

Page 10 ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/8631/6156-0, Fax +49/8631/6156-49, www.odu.de

Page11

Heavy Duty Connectors

Section 2

Series 207, 208 and 209

Cylindrical Connectors with Threaded Coupling System

Technical Information

Positions: 2 – 37

Test Voltage: to 2750 V AC

Max. Single Contact Load: to 210 A

Insulation Body: Thermoplastic. glass-filled, UL 94 V-0 or PTFE (Crimp Termination)

Insert Material: Duroplast, glass-filled, UL 94 V-0 (Solder Termination)

Contact: Springwire socket and solid pin

Contact Finish: Silver-plated, passivated

Housing Material: Aluminum Alloy or Brass, Ni-plated

Housing Finish: Black anodized

Coupling System: Threaded Ring

Environmental Protection: IP 54

ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/8631/6156-0, Fax +49/8631/6156-49, www.odu.de Page 11

Page12

Heavy Duty Connectors

Series 207, 208, 209

Straight Receptacle C D G

(with Pin insert)

A E

B F

Inserts see Page 15 – 21

Recommended

Panel Cutout

A

(All dimensions in mm)

Series Material and Finish Part Number Dim. Dim. Dim. Dim. Dim. Dim. Dim. Dim. Dim.A B Ø C D E F G Ø H Ø K

Alu-anodized 207.010.000.632.000

207 24 32 3.2 1.5 4 23.5 38.5 25.5 26

Brass-Ni-plated 207.010.000.304.000

Alu- anodized 208.010.000.632.000

208 34 46 3.3 2 6 27 41 32 32.5

Brass-Ni-plated 208.010.000.304.000

Alu-anodized 209.010.000.632.000

209 48 60 4.5 3 7 33 55 46 46.5

Brass-Ni-plated 209.010.000.304.000

Straight plug

A

Inserts see Page 15 – 21

(All dimensions in mm)

Series Material and Finish Part Number 1) Dim. Dim. Cable SizeA B Pg 1) Comments

Alu-anodized 207.020.000.632.000 L = in mated condition

207 70 32 16

Brass-Ni-plated 207.020.000.304.000 with 207.010 L = 79

Alu- anodized

208 208.020.000.632.000

L = in mated condition

92 45 21

Brass-Ni-plated 208.020.000.304.000 with 208.010 L = 101

Alu-anodized

209 209.020.000.632.000

L = in mated condition

108 60 36

Brass-Ni-plated 209.020.000.304.000 with 209.010 L = 123

1) Cable size is not shown in Part Number (see Page 22 and 23)

Assembly Instructions Page 24

Page 12 ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/8631/6156-0, Fax +49/8631/6156-49, www.odu.de

B

A

A

B

K

H

C

Pg

Page13

Heavy Duty Connectors

Series 207, 208, 209

In-line Receptacle

A

Inserts see Page 15 – 21

(All dimensions in mm)

Series Material and Finish Part Number 1) Dim. Dim. Cable SizeA B Pg 1) Comments

Alu-anodized 207.030.000.632.000 In mated condition

207 55 29 16

Brass-Ni-plated 207.030.000.304.000 with 207.020 L = ~ 110

Alu-anodized 208.030.000.632.000 In mated condition

208 75 60 21

Brass-Ni-plated 208.030.000.304.000 with 208.020 L = ~ 150

Alu-anodized 209.030.000.632.000 In mated condition

209 100 56 36

Brass-Ni-plated 209.030.000.304.000 with 209.020 L = ~ 190

Right-Angle Plug

A

Inserts see Page 15 – 21 Pg

(All dimensions in mm)

Series Material and Finish Part Number 1) Dim. Dim. Cable SizeA B Pg 1) Comments

Alu-anodized 207.040.000.632.000 L = in mated condition

207 ~ 83 34 16

Brass-Ni-plated 207.040.000.304.000 with 207.010 L = ~ 90

Alu-anodized 208.040.000.632.000 L = in mated condition

208 ~ 92 45 21

Brass-Ni-plated 208.040.000.304.000 with 208.010 L = ~ 100

Alu-anodized 209.040.000.632.000 L = in mated condition

209 ~ 117 60 29

Brass-Ni-plated 209.040.000.304.000 with 209.010 L = ~ 131

1) Cable size is not shown in Part Number (see Page 22 and 23)

For Assembly Instructions Page 24

ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/8631/6156-0, Fax +49/8631/6156-49, www.odu.de Page 13

Pg

B

B

Page14

Heavy Duty Connectors

Series 207, 208, 209

Cover for Receptacle and Plug Cover for Plug (Straight and Right-Angle)

Series Material and Finish Part Number Part NumberCover for Receptacle Cover for Plug Comments

Alu-anodized 207.097.002.632.000 207.097.001.632.000

207

Brass-ni-plated 207.097.002.304.000 207.097.001.304.000

Alu-anodized 208.097.002.632.000 208.097.001.632.000

208

Brass-Ni-plated 208.097.002.304.000 208.097.001.304.000

Alu-anodized 209.097.002.632.000 209.097.001.632.000

209

Brass-Ni-plated 209.097.002.304.000 209.097.001.304.000

Extension for Receptacle

C F

D

A Pg

B E

(All dimensions in mm)

Series Material and Finish Part Number 1) Dim. Dim. Dim. Dim. Dim. Dim. Dim.A B C D E F Pg 1)

Alu-anodized 207.095.211.632.000

207 24 32 M3 / 7 mm deep Ø 46 26 30 16

Brass-Ni-plated 207.095.211.304.000

Alu-anodized 208.095.211.632.000

208 34 46 M3 / 10 mm deep Ø 56 45 50 16

Brass-Ni-plated 208.095.211.304.000

Alu-anodized 209.095.211.632.000

209 48 60 M4 / 12 mm deep Ø 79 52 55 29

Brass-Ni-plated 209.095.211.304.000

1) Cable Size not shown in Part Number (see Page 22 and 23)

Assembly instructions see Page 24

Page 14 ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/8631/6156-0, Fax +49/8631/6156-49, www.odu.de

A

B

Page15

Heavy Duty Connectors

Type 207

Inserts for Solder Contacts

Pos. Part Number Contact Test Voltage Single Contact Term. Cross Ø (mm) VDE 0627 Load (max.) Section Comments

Socket Insert

207.703.150.002.000

1750 V

2 3.0 40 A 2.5 mm2

AC

Pin Insert

Ø 17 207.803.150.002.150

Socket Insert

207.703.152.003.000 1750 V

2+ 3.0 40 A 2.5 mm2

AC

Pin Insert

207.803.152.003.150

Socket Insert

207.702.150.004.000 1750 V

3+ 2.0 40 A 2.5 mm2

AC

Pin Insert

207.802.150.004.150

Socket Insert

207.702.150.005.000 1250 V

4+ 2.0 35 A 1.5 mm2

AC

Pin Insert

207.802.150.005.150

Socket Insert

207.702.150.007.000 1250 V

6+ 2.0 35 A 1.5 mm2

AC

Pin Insert

207.802.150.007.150

Socket Insert

207.701.150.010.000 1250 V

9+ 1.0 24 A 1.0 mm2

AC

Pin Insert

207.801.150.010.150

Additional contact inserts upon request.

Contact finish silver, other surface finish upon request.

= Ground, first-make, last-break

= For additional information see Section 5 “Technical Information”

ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/8631/6156-0, Fax +49/8631/6156-49, www.odu.de Page 15

Page16

Heavy Duty Connectors

Type 207

Insulation Bodies for Crimp Contacts

Contact Test Voltage Single Contact

Pos. Part Number Ø (mm) VDE 0627 Load Comments

(max.)

Socket Insulation Body

207.703.004.003.000

1750 V Without contacts

2+ 3.0 40 A

AC (see below)

Pin Insulation Body

207.803.004.003.150

Socket Insulation Body

207.702.004.007.000 1250 V Without contacts

6+ 2.0 35 A

AC (see below)

Pin Insulation Body

207.802.004.007.150

Socket Insulation Body

207.742.001.031.000 750 V Without contacts

31 0.76 11 A

AC (see below)Pin Insulation Body

207.842.001.031.150

Socket Insulation Body

207.702.003.003.000 Material PTFE1250 V

2+ 2.0 35 AAC

Pin Insulation Body Without contacts

207.802.003.003.150 (see below)

Socket Insulation Body

207.702.003.005.000 Material PTFE1250 V

4+ 2.0 35 AAC

Pin Insulation Body Without contacts

207.802.003.005.150 (see below)

= Ground, first-make, last-break

= Additional information see Section 5 “Technical Information”

Crimp Contacts

For Insulation body: Part Number Part Number Term. Cross Part Number Removal Tool 2)Std. Contact Grd. Contact Section. 1) Dummy Contact Crimp Tool 3)

Socket 207.703.004.003.000 170.382.000.201.000 170.382.000.201.000 2.5 mm2 021.341.136.304.000 087.170.136.000.000

Pin 207.803.004.003.150 180.334.000.301.000 180.335.000.301.000 2.5 mm2 021.341.136.304.000 080.000.012.000.000

Socket 207.702.004.007.000 170.381.000.201.000 170.381.000.201.000 1.5 mm2 021.341.135.324.000 087.170.364.000.000

Pin 207.802.004.007.150 180.332.000.301.000 180.333.000.301.000 1.5 mm2 021.341.135.924.000 080.000.014.000.000

Socket 207.742.001.031.000 170.361.700.207.000 – AWG 22 021.341.123.923.000 087.170.361.000.000

Pin 207.842.001.031.150 180.381.000.307.000 – AWG 22 021.341.123.923.000 080.000.014.000.000

Socket 207.702.003.003.000 170.577.100.200.000 170.577.100.200.000 1.5 mm2 – No removal tool required.

Pin 207.802.003.003.150 180.566.000.301.000 180.567.000.301.000 1.5 mm2 – 080.000.014.000.000

Socket 207.702.003.005.000 170.577.100.200.000 170.577.100.200.000 1.5 mm2 – No removal tool required.

Pin 207.802.003.005.150 180.566.000.301.000 180.567.000.301.000 1.5 mm2 – 080.000.014.000.000

Contact Finish: .201. and .301. = silver-plated, .207. and .307. = gold-plated, .200. = Inconel Springs.

1) Smaller termination cross sections on request. 2) 3) Removal Tool and Crimp Tool are the same for Pin and Socket.

Page 16 ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/8631/6156-0, Fax +49/8631/6156-49, www.odu.de

Page17

Heavy Duty Connectors

Type 208

Inserts for Solder Contacts

Pos. Part Number Contact Test Voltage. Single Contact Term. Cross Ø (mm) VDE 0627 Load (max.) Section Comments

Socket Insert

208.705.150.002.105

1750 V

2 5.0 80 A 10 mm2

AC

Pin Insert

Ø 208.805.150.002.15025.5

Socket Insert

208.704.150.005.105 1750 V

4+ 4.0 50 A 6 mm2

AC

Pin Insert

208.804.150.005.150

Socket Insert

208.703.150.007.105 1750 V

6+ 3.0 40 A 2.5 mm2

AC

Pin Insert

208.803.150.007.150

Socket Insert

9+ 208.702.150.010.105 1250 V

2.0 35 A 1.5 mm2

AC

Pin Insert

208.802.150.010.150

Socket Insert

11+ 208.745.150.012.105 1750 V

1.5 22 A 0.75 mm2

AC

Pin Insert

208.845.150.012.150

Socket Insert

208.702.153.016.105 1250 V

15+ 2.0 35 A 1.5 mm2

AC

Pin Insert

208.802.152.016.150

Socket Insert

208.701.150.024.105 1250 V

23+ 1.0 24 A 1.0 mm2

AC

Pin Insert

208.801.150.024.150

Additional contact inserts upon request.

Contact finish silver, other surface finish upon request.

= Ground, first-make, last-break

= For additional information see Section 5 “Technical Information”

ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/8631/6156-0, Fax +49/8631/6156-49, www.odu.de Page 17

Page18

Heavy Duty Connectors

Type 208

Insulation Bodies for Crimp Contacts

Contact Test Voltage Single Contact

Pos. Part Number Ø (mm) VDE 0627 Load ( max.) Comments

Socket Insulation Body

208.703.004.005.105

2250 V Without contacts

4+ 3.0 40 A

AC (see below)

Pin Insulation Body

208.803.004.005.150

Socket Insulation Body

208.703.004.007.105 2250 V Without contacts

6+ 3.0 40 A

AC (see below)

Pin Insulation Body

208.803.004.007.150

Socket Insulation Body

208.702.004.016.105 1250 V Without contacts

15+ 2.0 35 A

AC (see below)

Pin Insulation Body

208.802.004.016.150

= Ground, first-make, last-break

= Additional information see Section 5 “Technical Information“

Crimp Contacts

For Insulation body: Part Number Part Number Contact Cross Part Number Removal Tool 2)Std. Contact Grd. Contact section 1) Dummy Contact Crimp Tool 3)

Socket 208.703.004.005.105 170.382.000.201.000 170.382.000.201.000 2.5 mm2 021.341.136.304.000 087.170.136.000.000

Pin 208.803.004.005.150 180.334.000.301.000 180.335.000.301.000 2.5 mm2 021.341.136.304.000 080.000.012.000.000

Socket 208.703.004.007.105 170.382.000.201.000 170.382.000.201.000 2.5 mm2 021.341.136.304.000 087.170.136.000.000

Pin 208.803.004.007.150 180.334.000.301.000 180.335.000.301.000 2.5 mm2 021.341.136.304.000 080.000.012.000.000

Socket 208.702.004.016.105 170.381.000.201.000 170.381.000.201.000 1.5 mm2 021.341.135.924.000 087.170.364.000.000

Pin 208.802.004.016.150 180.332.000.301.000 180.333.000.301.000 1.5 mm2 021.341.135.924.000 080.000.014.000.000

Contact Finish: .201. and .301. = silver-plated, .207. and .307. = gold-plated.

1) Smaller cross section on request. 2) 3) Removal Tool and Crimp Tool same for Pin and Socket.

Page 18 ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/8631/6156-0, Fax +49/8631/6156-49, www.odu.de

Page19

Heavy Duty Connectors

Type 209

Inserts for Solder Contacts

Pos. Part Number Contact Test Voltage. Single Contact Term. Cross Ø (mm) VDE 0627 Load (max.) Section Comments

Socket Insert

209.708.150.004.108

1750 V

3+ 8.0 145 A 25 mm2

AC

Pin Insert

209.808.150.004.150

40 Ø

Socket Insert

209.706.152.005.108 2250 V

4+ 6.0 110 A 16 mm2

AC

Pin Insert

209.806.150.005.150

Socket Insert

3+ 209.700.150.006.108 6.0 2750 V 110 A 16 mm2

+2 Pi 1.5 1750 V 35 A 1.5 mm2

Pin Insert AC

209.800.150.006.150

Socket Insert

3+ 209.700.153.007.108 5.0 2750 V 80 A 10 mm2

+3 S 1.5 1750 V 35 A 1.5 mm2

Pin Insert AC

209.800.153.007.158

Socket Insert

3+ 209.700.152.009.108

+5 S 5.0 2750 V 80 A 10 mm2

2Pin Insert 1.5 1750 V 35 A 1.5 mm

209.800.152.009.150 AC

Socket Insert

209.703.153.014.108 2250 V

13+ 3.0 45 A 4.0 mm2

AC

Pin Insert

209.803.153.014.150

Socket Insert

209.746.150.022.108 1750 V

21+ 2.3 40 A 2.5 mm2

AC

Pin Insert

209.846.150.022.150

Additional contact inserts upon request.

Contact finish silver, other surface finish upon request.

= Ground, first-make, last-break

Pi = Pilot contact, last mating

S = Signal contact

= For additional information see Section 5 “Technical Information“

ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/8631/6156-0, Fax +49/8631/6156-49, www.odu.de Page 19

Page20

Heavy Duty Connectors

Type 209

Inserts for Solder Contacts

Pos. Part Number Contact Test Voltage Single Contact Term. Cross Ø (mm) VDE 0627 Load (max.) Section Comments

Socket Insert

209.745.150.027.108

1750 V

26+ 1.5 35 A 1.5 mm2

AC

Pin Insert

209.845.150.027.150

Socket Insert

209.745.152.037.108 1750 V

36+ 1.5 35 A 1.5 mm2

AC

Pin Insert

209.845.152.037.150

Additional contact inserts upon request.

Contact finish silver, other surface finish upon request.

= Ground, first-make, last-break

= For additional information see Section 5 “Technical Information“

For your notes:

Page 20 ODU Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Phone +49/8631/6156-0, Fax +49/8631/6156-49, www.odu.de