1/102ページ

ダウンロード(8.3Mb)

Robust Circular Connectors ODU DOCK

このカタログについて

| ドキュメント名 | Connectors for Docking and Robot Systems |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 8.3Mb |

| 登録カテゴリ | |

| 取り扱い企業 | オーディーユージャパン株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

ODU DOCK

Connectors for

Docking and Robot Systems

www.odu.de

Page2

Connectors for

Docking and Robot Systems

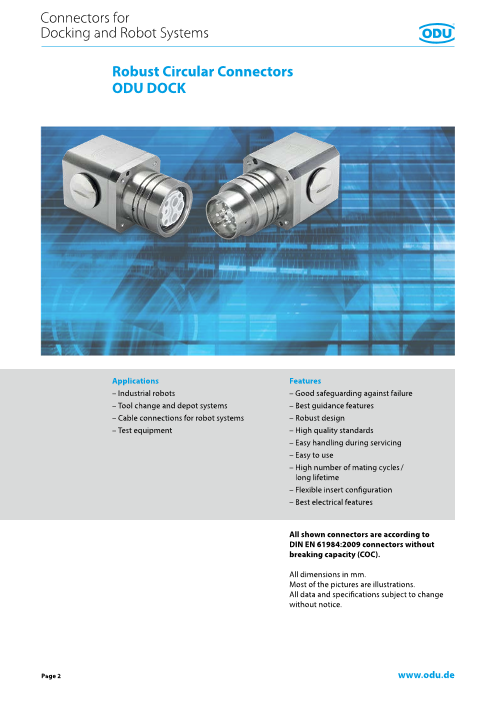

Robust Circular Connectors

ODU DOCK

Applications Features

– Industrial robots – Good safeguarding against failure

– Tool change and depot systems – Best guidance features

– Cable connections for robot systems – Robust design

– Test equipment – High quality standards

– Easy handling during servicing

– Easy to use

– High number of mating cycles /

long lifetime

– Flexible insert configuration

– Best electrical features

All shown connectors are according to

DIN EN 61984:2009 connectors without

breaking capacity (COC).

All dimensions in mm.

Most of the pictures are illustrations.

All data and specifications subject to change

without notice.

Page 2 www.odu.de

Page3

Table of Contents

Connectors for

Docking and Robot Systems

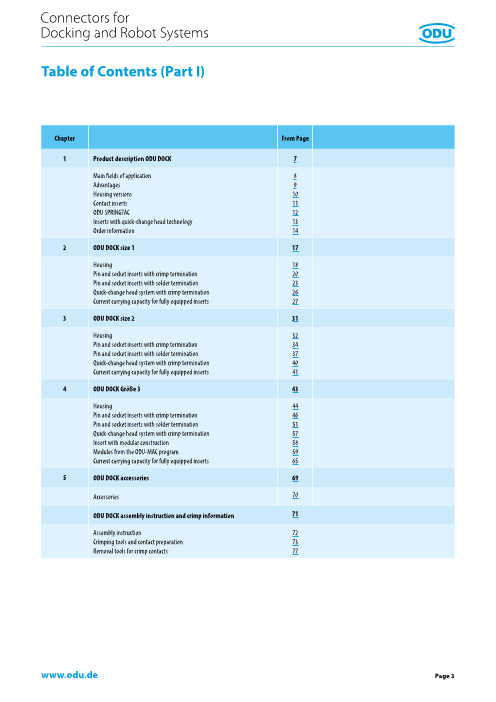

Table of Contents (Part I)

Chapter From Page

1 Product description ODU DOCK 7

Main fields of application 8

Advantages 9

Housing versions 10

Contact inserts 11

ODU SPRINGTAC 12

Inserts with quick-change head technology 13

Order information 14

2 ODU DOCK size 1 17

Housing 18

Pin and socket inserts with crimp termination 20

Pin and socket inserts with solder termination 23

Quick-change head system with crimp termination 26

Current carrying capacity for fully equipped inserts 27

3 ODU DOCK size 2 31

Housing 32

Pin and socket inserts with crimp termination 34

Pin and socket inserts with solder termination 37

Quick-change head system with crimp termination 40

Current carrying capacity for fully equipped inserts 41

4 ODU DOCK Größe 3 43

Housing 44

Pin and socket inserts with crimp termination 46

Pin and socket inserts with solder termination 51

Quick-change head system with crimp termination 57

Insert with modular construction 58

Modules from the ODU-MAC program 59

Current carrying capacity for fully equipped inserts 65

5 ODU DOCK accessories 69

Accessories 70

ODU DOCK assembly instruction and crimp information 71

Assembly instruction 72

Crimping tools and contact preparation 73

Removal tools for crimp contacts 77

www.odu.de Page 3

Page4

Connectors for

Docking and Robot Systems

Table of Contents (Part II)

Chapter From Page

6 Application specific connectors for Docking and Robot Systems 79

Additional docking connectors 80

Application specific docking systems 81

7 Technical information 83

International Protection (IP) Classes in accordance with DIN EN 60 529 84

Explanations and information according to VDE 85

Conversions AWG – sross section 88

Principles of current carrying capacity 89

Current load 90

Line current load 91

Technical information / definitions / terms 92

8 Company information 95

Quality management 96

Your partner in many application areas 97

The complete ODU product range 98

Everything from one source 99

Application specific connectors 100

Page 4 www.odu.de

Page5

Connectors for

Docking and Robot Systems ODU DOCK

Connectors for Docking and Robot Systems – a Special Kind of Connector

Connectors for Docking and Robot Systems are connec-

tors that have restricted guidance and that can be insert-

ed automatically. The force can be applied manually,

electrically or pneumatically.

Connectors for Docking and Robot Systems require sim-

ple constructed connectors with very different contacts.

Often a large number of mating cycles are called for. The

docking system stands or falls on the guide and the

contact system that are selected.

Following are some of the features that are critical

when connectors for Docking and Robot Systems are

used:

– Good safeguarding against failure

– Best guidance features

– Robust design

– High quality standards

– Easy handling during servicing

– Easy to use

– High number of mating cycles / long lifetime

– Flexible insert configuration

– Best electrical features.

Connectors for Docking and Robot Systems are ideally

suited for such use and satisfy these requirements.

From simple standard connectors for Docking and Robot

Systems to the complex docking unit – ODU supplies the

complete range.

www.odu.de Page 5

Page6

Connectors for

Docking and Robot Systems ODU DOCK

Application of Connectors for Docking and Robot Systems

Connectors for Docking and Robot Systems have become

indispensable in automation engineering.

Industrial robots, tool change and depot systems, cable

connections and test equipment are just a few examples

of the applications for these systems.

ODU docking systems are built into combined quick

coupling systems (electrical/pneumatic) where they

enable the greatest possible flexibility.

Page 6 www.odu.de

Page7

Product Description ODU DOCK

Connectors for

Docking and Robot Systems

Product Description

ODU DOCK

www.odu.de Page 7

Product Descr.

ODU DOCK

Page8

Connectors for

Docking and Robot Systems Product Description ODU DOCK

Main Fields of Application

ODU DOCK systems are

mostly used for the

following applications:

– Tool change and

depot systems

– Test equipment

– Industrial robot systems.

Page 8 www.odu.de

Product Description

ODU DOCK

Page9

Connectors for

Docking and Robot Systems Product Description ODU DOCK

Advantages of the ODU DOCK Connectors

– Easy assembly – High contact reliability due to the established

– Temperature range: – 40° C up to +100° C ODU SPRINGTAC contacts

– Robust housing made out of aluminium or plastic – High number of mating cycles – up to 100,000

– Housing with EMC protection available – Versions with quick-change head available for

– 3 sizes mating cycles of more than 1 million

– Contacts with crimp and solder termination available – Floating mounting on docking plates

– Exchange of crimp contact within a few seconds – Easy assembly of the insulator – anti-rotation

– Positions: 2 + PE up to 36 + PE, mixed inserts, power – High density with small contact diameter

inserts (e.g. 31 x ∅ 0.76 mm in size 1)

– Protection class: up to IP 65 available – High variety of contact inserts.

– Straight and right-angled cable exit possible

The ODU DOCK connection system consists of housing,

insulator and contacts. These three components can be

combined in a multitude of ways. In the crimp version, the

contacts can be installed into and removed from the

insulator in just a few seconds. The appropriate tools are

available for this.

In the solder version the contacts are permanently

mounted in the insulator and cannot be removed.

www.odu.de Page 9

Product Description

ODU DOCK

Page10

Connectors for

Docking and Robot Systems Product Description ODU DOCK

Housing Versions for ODU DOCK

There are three housing versions available: Plastic housing

– Plastic housing

– Aluminium housing, nickel-plated

– Aluminium housing, black anodized.

Plastic housing

– Material: POM, black

– Protection class: IP 65 in mated condition

– Operating temperature: – 40° C up to +100° C

– 3 housing sizes

– Easy assembly from rear of panel

– Straight and right-angled cable exit possible, sealing

plug for unused cable exit is included in the delivery Aluminium housing

– Two-part housing nickel-plated

– More than 100,000 mating cycles¹)

Aluminium housing, nickel-plated

– Material: aluminium, nickel-plated

– Protection class: IP 65 in mated condition

(depends on version)

– Operating temperature: – 40° C up to +100° C

– 3 housing sizes

– Easy assembly from rear of panel

– Straight and right-angled cable exit possible, sealing

plug for unused cable exit is included in the delivery

– Two-part housing Aluminium housing black anodized

– Available with and without EMC protection

– More than 100,000 mating cycles¹)

Aluminium housing, black anodized

– Material: aluminium, black anodized

– Protection class: IP 40

– Operating temperature: – 40° C up to +100 °C

– 3 housing sizes

– Mountable from front of panel

– Straight and right-angled cable exit possible, sealing

plug for unused cable exit is included in the delivery

1 Housing without shielding and without o-ring: min. 100,000 mating cycles.

– Two-part housing Housing with shielding and without o-ring: min. 50,000 mating cycles.

– More than 100,000 mating cycles¹) It is recommended to change the front parts of the housing after 50,000 mating

cycles, both socket and pin side.

Housing with o-ring: min. 25,000 mating cycles without maintenance and

min. 100,000 mating cycles with maintenance.

Page 10 www.odu.de

Product Description

ODU DOCK

Page11

Connectors for

Docking and Robot Systems Product Description ODU DOCK

Contact Inserts for ODU DOCK

Pin and socket inserts with crimp termination

The contact inserts consist of an insulator (contact carrier)

and the associated number of pin or socket contacts.

In the crimped model, the insulator and contacts must be

ordered separately. This flexible design allows the contact

insert to be equipped individually. Crimp contacts can be

installed and removed very quickly.

Material

Insulator PBT-GF (UL 94V-0)

Contacts Cu-alloy

surface contact from ∅ 1.0 mm Au

surface contact from ∅ 1.5 mm Ag

Pin and Socket inserts with solder termination

The contact inserts consist of an insulator (contact carrier)

and the associated number of pin or socket contacts.

Our solder inserts can cover a larger connection range.

The contacts in the solder version are already mounted in

the insulator, which means that the delivered contact

insert is already completely equipped.

Material

Insulator fibre-glass reinforced polyester resin

(UL 94V-0)

Contacts surface Ag

www.odu.de Page 11

Product Description

ODU DOCK

Page12

Connectors for

Docking and Robot Systems Product Description ODU DOCK

ODU SPRINGTAC® (Contacts with Springwire Technology)

The springwire contact is the inspired Unmated

invention of Otto Dunkel. It offers the

highest number of contact surfaces. The Socket Pin

springwires are mounted individually

and joined optimally to a turned carrier.

The individual springwires contact and

cushion independently of one another.

Advantages

– More than 100,000 mating cycles

– Low contact resistances

– Large number of independently

cushioning contact springs Carrier Expansion ring Spring wires Spark protection

– Low insertion forces

– Extremely secure contacting

– High resistance to vibrations and Mated

impacts

– Long life span due to premium Socket Pin

materials and surfaces.

Page 12 www.odu.de

Product Description

ODU DOCK

Page13

Connectors for

Docking and Robot Systems Product Description ODU DOCK

Inserts with Quick-Change Head Technology (QCH)

for an extremely high number of mating cycles

Die ODU SPRINGTAC contacts offer

contact stability for up to 100,000

mating cycles. The ODU DOCK quick-

change head is suitable for applica-

tions that require even more mating

cycles.

Principle behind the quick-change

head

The connection system consists of an

interchangeable front part (connector

piece) and a back part (terminal

piece). When the contacts suffer from

wear, the front part is exchanged in a

very short time without it being

necessary to separate the connections

that are made with the contacts of the

back part.

Material

Insulator PBT-GF (UL 94V-0)

Contacts Cu-alloy

Crimp contact Crimp contact

Part B Part A Part C Part D

Terminal Connector Connector Terminal

piece piece piece piece

Socket side Pin side

Terminal pieces stay wired.

Connector pieces are exchanged in the Docking System.

Contacts at the Terminal piece B and D are respectively

crimp contacts.

www.odu.de Page 13

Product Description

ODU DOCK

Page14

Connectors for

Docking and Robot Systems Product Description ODU DOCK

Order Information ODU DOCK

Order example with crimp insert

Housing, insulator and contacts must be ordered

separately when crimp contacts are used.

– ODU DOCK, size 2

– Housing: Aluminium, black anodized

– 6 positions with earthing pin.

Socket piece Pin piece

Housing 1 × 656.162.051.000.000 1 × 656.162.052.000.000 Picture for example only.

Cable clamp 1 × 027.825.090.170.007 1 × 027.825.090.170.007

Insulator 1 × 208.703.004.007.000 1 × 208.803.004.007.000

Contacts 7 × 170.382.000.201.000 6 × 180.334.000.301.000

Earthing contact 1 × 180.335.000.301.000

Order example with solder insert

Housing and insert must be ordered separately when the

solder version is used. The contacts are already fixed in the

insulator and don’t need to be ordered separately.

– ODU DOCK, size 1

– Housing: aluminium, black anodized

– 4 positions.

Socket part Pin part Picture for example only.

Housing 1 × 656.164.051.000.000 1 × 656.164.052.000.000

Cable clamp 1 × 027.820.070.130.007 1 × 027.820.070.130.007

Insert 1 × 656.164.702.150.004 1 × 656.164.802.150.004

Page 14 www.odu.de

Product Description

ODU DOCK

Page15

Connectors for

Docking and Robot Systems Product Description ODU DOCK

Order example with flexible insert

With the flexible inserts, the housing, insulator and the

flexibly interchangeable modules must be ordered

separately. The insulator must be completely filled with

modules.

– ODU DOCK, size 3

– Housing: aluminium, black anodized

– 2 × power modules from the ODU-MAC program

for AWG 14.

Socket part Pin part

Housing 1 × 656.163.051.000.000 1 × 656.163.052.000.000

Cable clamp 1 × 027.832.070.150.007 1 × 027.832.070.150.007

Flexible insert 1 × 209.610.000.000.000 1 × 209.611.000.000.000

ODU-MAC modules* 2 × 610.162.103.923.000 2 × 611.162.103.923.000

Contacts* 6 × 172.582.100.201.000 6 × 182.582.000.301.000

* Order information and technical data see from page 59, as well as the ODU-MAC

product catalogue.

Order example for the quick-change head

The housing and inserts must be ordered separately for

the quick-change head version.

The contacts for the inserts are included in the delivery.

– ODU DOCK QCH, size 3

– Housing: plastic

– 36 positions with earthing pin.

Socket part Pin part Part B Part A Part C Part D

Housing 1 × 656.163.011.000.000 1 × 656.163.012.000.000 Terminal Connector Connector Terminal

Cable clamp 1 × 027.832.070.150.007 1 × 027.832.070.150.007 piece piece piece piece

A C

1 × 252.058.001.037.000 1 × 252.059.001.037.000

Insert QCH Socket side Pin side

B D

1 × 252.061.001.037.000 1 × 252.061.002.037.000

www.odu.de Page 15

Product Description

ODU DOCK

Page16

Connectors for

Docking and Robot Systems For Your Notes

Page 16 www.odu.de

Product Description

ODU DOCK

Page17

ODU DOCK Size 1

Connectors for

Docking and Robot Systems

ODU DOCK

Size 1

www.odu.de Page 17

ODU DOCK

Size 1

Page18

Connectors for

Docking and Robot Systems ODU DOCK Size 1

Housing

Plastic

– Material: POM, black

– Protection class: IP 65 in mated condition

– Operating temperature: – 40° C up to +100° C

– Easy assembly from rear of panel

– Straight and right-angled cable exit possible, sealing

plug for unused cable exit is included in the delivery

– Two-part housing

Description Part number

Socket piece 656.164.011.000.000

Pin piece 656.164.012.000.000

Socket piece Pin piece

M 20 × 1.5 M 20 × 1.5 36

50 31.5 44 50

Aluminium, nickel-plated

– Material: aluminium, nickel-plated

– Protection class: IP 65 in mated condition (depends on version)

– Operating temperature: – 40° C up to +100° C

– Easy assembly from rear of panel

– Straight and right-angled cable exit possible, sealing

plug for unused cable exit is included in the delivery

– Two-part housing

– Available with and without EMC protection

Description Part number IP 40 IP 65 EMC protection

656.164.021.000.000 ● ●

656.164.023.000.000 ●

Socket piece

656.164.024.000.000 ● ●

656.164.025.000.000 ●

Pin piece 656.164.022.000.000 ● ● ●

Socket piece Pin piece

M 20 × 1.5 M 20 × 1.5

50 31.5 44 50 36

Page 18 www.odu.de

ODU DOCK

Size 1

∅ 27.8 ∅ 27.8

∅ 27.8

∅ 27.8

Page19

Connectors for

Docking and Robot Systems ODU DOCK Size 1

Aluminium, black anodized

– Material: aluminium, black-anodized

– Protection class: IP 40 in mated condition

– Operating temperature: – 40° C up to +100° C

– Mountable from front of panel

– Straight and right-angled cable exit possible, sealing

plug for unused cable exit is included in the delivery

– Two-part housing

Description Part number Thread X

656.164.051.000.000 M 20 × 1.5

Socket piece

656.164.001.000.000 PG 16

656.164.052.000.000 M 20 × 1.5

Pin piece

656.164.002.000.000 PG 16

Socket piece Pin piece

X X

50 31.5 44 50 36

Assembly drilling for all size 1 versions

±0.5° Board spacing

25°

.11

+0 2 in mated position: A .0

∅ 2

8 +0 61 ± 0.5 mm

Board thickness “X”

20 mm: ± 0.1

∅ 34 ±0.1 14 mm: ± 0.1

Hole A: ∅ 3 for pin ∅ 3 10 mm: ± 0.1B ±0.5° H9 m6

25° Hole B: ∅ 2H9 for pin ∅ 2m6

www.odu.de Page 19

∅ 28

∅ 28

6±0.5 X

ODU DOCK

Size 1

Page20

Connectors for

Docking and Robot Systems ODU DOCK Size 1

Pin and Socket Inserts with Crimp Termination

2 positions with earthing

Socket Pin Contact Description Part number

configuration

Socket

View on the

mating side

Insulator socket 207.703.004.003.000

Insulator pin 207.803.004.003.000

1 2 Sealing plug 021.341.136.304.000

Socket contact 170.382.000.201.000

Pin contact 180.334.000.301.000 30 3.0 2.5 31 ± 10

Earthing pin contact 180.335.000.301.000

29 ± 10

Socket contact 170.499.100.201.000

Pin contact 180.374.000.301.000 25 3.0 1.5 31 ± 10

Earthing pin contact 180.375.000.301.000

Voltage information Metal housing Plastic housing Dimensions insulator (socket piece/pin piece)

acc. DIN EN*)

Rated voltage 500 V 200 V 630 V 250 V 11.1

2

Rated impulse voltage 3 kV 4 kV

6 1 3

1 Po2llution degree 2 3 2 3

5 4

Crimping tools from page 73.

*DIN EN 60664-1 (VDE 0110-1) : 2008-01 5 15 16.5 3.5

29 13.1 29

1 2

6 positions with earthing

Socket Pin C1oBntac3t Description Part number

con4 figurati7on

2 8 12

13 Socket 16

6 1 3 17 19

5 4 View on the

mating side

Insulator socket 207.702.004.007.000

2 Insulator pin 207.802.004.007.000

6 1 3 Sealing plug 021.341.135.923.000

1 2

5 4 Socket contact 170.381.000.201.000

Pin contact 180.332.000.301.000 25 2.0 1.5 40 ± 13

Earthing pin contact 180.333.000.301.000

1 2 37 ± 13

3 5 Socket contact 170.827.100.201.000

B 8 10

1 3 11 14

18 Pin contact 180.827.000.301.000 20 2.0 1.0

40

4 7 2122 24 ± 13

8 12 27 29 Earthing pin contact 180.828.000.301.00030 31

13 16

17 19

Voltage information Metal housing Plastic housing Dimensions insulator (socket piece/pin piece)

acc. DIN EN*)

Rated voltage 500 V 116B0 V 3 500 V 200 V 12.6

Rated impulse voltage 3 kV 4 7 3 kV

2 8 12Pollution degree 2 13 3 16 2 3

6 1 3 17 19

5 Cr4imping tools from page 73.

*DIN EN 60664-1 (VDE 0110-1) : 2008-01 76 8 5 15 10.6 16.5 3.5

5 1 9

1 2 4 2

3 5 29 293

8 10

11 14 11 10

18 21 B

22 24

27 29

30 31

Page 20 www.odu.de

1 2

3 5

B 8 10

1 3 11 14

4 7 18 2122 24

8 12 27 2930 31

13 16

17 19

7

6 8

5 1 9

4 2

3

11 10

B

7

6 8

5 1 9

1 2 4 2

3 5 3

8 10

11 14 11 10

18 21 B

22 24

27 29

30 31

7

6 8

5 1 9

4 2

3

11 10

B

ODU DOCK

Size 1

∅17 ∅17

∅17 ∅17

∅21.5 ∅21.5

Current in A Current in A

nominal single nominal single

contact current load contact current load

Contact diameter Contact diameter

in mm in mm

Termination cross- Termination cross-

section in mm² section in mm²

Mating force in N Mating force in N

Demating force in N Demating force in N