1/74ページ

ダウンロード(11.1Mb)

ドイツPIセラミック社のピエゾアクチュエータカタログ

ピエゾセラミックの特性が最適化されているアクチュエータシリーズをご紹介。

サブミリセカンドの応答とサブナノメートルの分解能を実現。

・長寿命を確保

・幅広い温度範囲に対応

・優れた耐湿性

・優れた温度安定性

・高剛性

・ダイナミックアプリケーションに最適

このカタログについて

| ドキュメント名 | ピエゾアクチュエータ製品カタログ |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 11.1Mb |

| 登録カテゴリ | |

| 取り扱い企業 | ピーアイ・ジャパン株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

PPieiezozoeelelekctrtrisicc hAec tAukattoresn

B A UCEOLmEPMOENNETNET,s ,T ET ECCHHNNOOLLOOGGIIEE,s ,A ONPSETrEaUTEI ORNU N G

PWI WE ZWO. PTIECCE RHANMO ILCO. DGEY

Page2

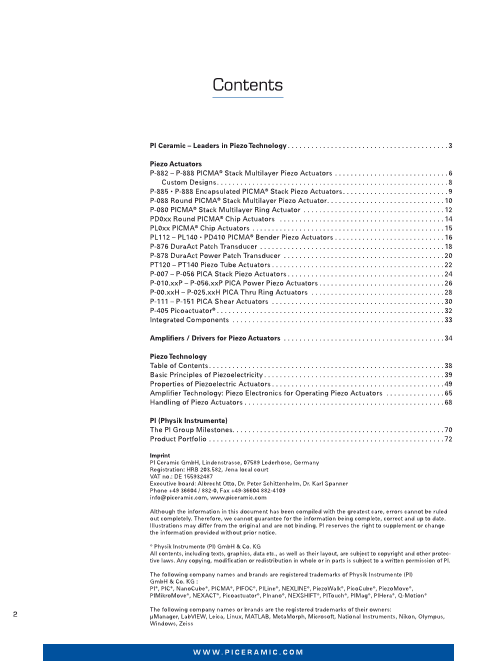

Contents

PI Ceramic – Leaders in Piezo Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Piezo Actuators

P-882 – P-888 PICMA® Stack Multilayer Piezo Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Custom Designs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

P-885 • P-888 Encapsulated PICMA® Stack Piezo Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

P-088 Round PICMA® Stack Multilayer Piezo Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

P-080 PICMA® Stack Multilayer Ring Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PD0xx Round PICMA® Chip Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

PL0xx PICMA® Chip Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

PL112 – PL140 • PD410 PICMA® Bender Piezo Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

P-876 DuraAct Patch Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

P-878 DuraAct Power Patch Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

PT120 – PT140 Piezo Tube Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

P-007 – P-056 PICA Stack Piezo Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

P-010 .xxP – P-056 .xxP PICA Power Piezo Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

P-00 .xxH – P-025 .xxH PICA Thru Ring Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

P-111 – P-151 PICA Shear Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

P-405 Picoactuator® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Integrated Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Amplifiers / Drivers for Piezo Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Piezo Technology

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Basic Principles of Piezoelectricity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Properties of Piezoelectric Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Amplifier Technology: Piezo Electronics for Operating Piezo Actuators . . . . . . . . . . . . . . . 65

Handling of Piezo Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

PI (Physik Instrumente)

The PI Group Milestones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Product Portfolio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Imprint

PI Ceramic GmbH, Lindenstrasse, 07589 Lederhose, Germany

Registration: HRB 203.582, Jena local court

VAT no.: DE 155932487

Executive board: Albrecht Otto, Dr. Peter Schittenhelm, Dr. Karl Spanner

Phone +49 36604 / 882-0, Fax +49-36604 882-4109

info@piceramic.com, www.piceramic.com

Although the information in this document has been compiled with the greatest care, errors cannot be ruled

out completely. Therefore, we cannot guarantee for the information being complete, correct and up to date.

Illustrations may differ from the original and are not binding. PI reserves the right to supplement or change

the information provided without prior notice.

© Physik Instrumente (PI) GmbH & Co. KG

All contents, including texts, graphics, data etc., as well as their layout, are subject to copyright and other protec-

tive laws. Any copying, modification or redistribution in whole or in parts is subject to a written permission of PI.

The following company names and brands are registered trademarks of Physik Instrumente (PI)

GmbH & Co. KG :

PI®, PIC®, NanoCube®, PICMA®, PIFOC®, PILine®, NEXLINE®, PiezoWalk®, PicoCube®, PiezoMove®,

PIMikroMove®, NEXACT®, Picoactuator®, PInano®, NEXSHIFT®, PITouch®, PIMag®, PIHera®, Q-Motion®

The following company names or brands are the registered trademarks of their owners:

2 µManager, LabVIEW, Leica, Linux, MATLAB, MetaMorph, Microsoft, National Instruments, Nikon, Olympus,

Windows, Zeiss

w w w . p i c e r a m i c . c o m

Page3

PI Ceramic

L e a d e r s i n P i e Z O T e C H n O L O G Y

PI Ceramic is one of the world’s market lea-

ders for piezoelectric actuators and sensors. Core Competences of

PI Ceramic provides everything from piezo- PI Ceramic

ceramic components to system solutions S tandard piezo com-

for research and industry in all high-tech ponents for actuator,

markets including medical engineering, ultrasonic and sensor

mechanical engineering and automobile application

manufacture, or semiconductor technology. System solutions

Manufacturing of piezo-

PI Ceramic is a subsidiary of Physik Instru- electric components of

mente (PI) and develops and produces all up to several 1,000,000

piezo actuators for PI’s nanopositioning sys- pieces per year

tems. The drives for PILine® ultrasonic pie- Development of custo-

zomotors and NEXLINE® high-load stepping mized solutions

drives also originate from PI Ceramic. tains its own laboratories, prototype manu- High degree of flexibility

facture as well as measurement and testing in the engineering pro-

Custom Designs equipment. Moreover, PI Ceramic works cess, short lead times,

The very nature of PI Ceramic makes it with leading universities and research insti- manufacture of individu-

possible to react to customer wishes in the tutions at home and abroad in the field of

al units and very small

quantities

shortest possible time. piezoelectricity. All key technologies

PI Ceramic has specialized in quantities of a Flexible Production and state-of-the-art

equipment for ceramic

few 100 to several 100,000. Our develop- In addition to the broad spectrum of production in-house

ment and consulting engineers have an standard products, a top priority is

enormous wealth of experience concerning C ertified in accordance the fastest possible implementation of with ISO 9001, ISO 14001

the application of piezo actuators and custom-engineered solutions. Our pressing and OHSAS 18001

sensors and already work very closely with and multilayer technology enables us to

the developers of our customers in the shape products with a short lead time.

r un-up to a project. This allows you to put We are able to manufacture individual

successful products on the market faster. prototypes as well as high-volume produc-

tion runs. All processing steps are under-

Materials Research and Development taken in-house and are subject to con-

PI Ceramic develops all its piezoceramic tinuous controls, a process which ensures

m aterials itself . To this end PI Ceramic main- quality and adherence to deadlines.

Company building of PI Ceramic in Lederhose, Thuringia, Germany.

3

p i e z o t e c h n o l o g y

Page4

Reliability and Close Contact with our Customers

O u r m I s s I O N

Our aim is to maintain high, tested qua- After-Sales Service

PI Ceramic provides lity for both our standard products and for Even after the sale has been completed, our

Piezoceramic materials custom-engineered components. We want specialists are available to you and can ad-

(PZT) you, our customers, to be satisfied with vise you on system upgrades or technical

Piezoceramic the performance of our products. At issues .

components PI Ceramic, customer service starts with an

C ustomer- and initial informative discussion and extends This is how we at PI Ceramic achieve our ob-

application-specific far beyond the shipping of the products. jective: Long-lasting business relations and

transducers a trusting communication with customers

P ICMA® monolithic mul- Advice from Piezo Specialists and suppliers, both of which are more im-

tilayer piezo actuators portant than any short-term success.

You want to solve complex problems – we

Miniature piezo won’t leave you to your own devices. We

actuators use our years of experience in planning, PI Ceramic supplies piezo-ceramic solutions

PICMA® multilayer developing, designing and the production to all important high-tech markets:

bending actuators of individual solutions to accompany you I ndustrial automation

P ICA high-load piezo from the initial idea to the finished product.

actuators S emiconductor technology

Piezo tube actuators We take the time necessary for a detailed M edical technology

understanding of the issues and work out a

P reloaded actuators M echanical and precision engineering

with casing comprehensive and optimum solution at an

early stage with either existing or new tech- Aviation and aerospace

Piezocomposites – nologies .

DuraAct patch A utomotive industry

transducers T elecommunications

4

w w w . p i c e r a m i c . c o m

Page5

Experience and Know-How

s TaT e - O F - T H e - a r T M a n u Fa C T u r i n G T e C H n O L O G Y

Developing and manufacturing piezo- particularly high degree of precision.

ceramic components are very complex Special milling machines accurately

processes. PI Ceramic has many years of shape the components when they are still in

experience in this field and has developed the “green state”, i .e . before they are

sophisticated manufacturing methods. Its sintered. Sintered ceracmic blocks are ma-

machines and equipment are state of the chined with precision saws like the ones

art . used to separate individual wafers. Very fine

holes, structured ceramic surfaces, even

Rapid Prototyping complex, three-dimensional contours can

The requirements are realized quickly and be produced.

flexibly in close liaison with the customer.

Prototypes and small production runs of Automated Series Production –

custom-engineered piezo components are Advantage for OEM Customers

available after very short processing times. An industrial application often requires

The manufacturing conditions, i.e. the com- large quantities of custom-engineered

position of the material or the sintering components. At PI Ceramic, the transition

temperature, for example, are individually to large production runs can be achieved

adjusted to the ceramic material in order to in a reliable and low-cost way while

achieve optimum material parameters. maintaining the high quality of the products.

PI Ceramic has the capacity to produce and

Precision Machining Technology process medium-sized and large production

PI Ceramic uses machining techniques from runs in linked automated lines. Automatic

the semiconductor industry to machine screen printers and the latest PVD units are

the sensitive piezoceramic elements with a used to metallize the ceramic parts.

Automated processes optimize throughput

5

p i e z o t e c h n o l o g y

Page6

PICMA® Stack Multilayer Piezo Actuators

C e r a M i C - i n s u L aT e d H i G H - P O W e r a C T u aT O r s

P-882 – P-888

S uperior lifetime

High stiffness

UHV-compatible to 10-9 hPa

Microsecond response

Sub-nanometer resolution

L arge choice of designs

Patented PICMA® Stack Multilayer Piezo Actuators with Suitable Drivers

High Reliability E-610 Piezo Amplifi er / Controller

Operating voltage -20 to 120 V. Ceramic insulation, poly- E-617 High-Power Piezo Amplifi er

mer-free. Humidity resistance. UHV-compatible to 10-9 hPa, E-831 OEM Piezo Amplifi er Module

no outgassing, high bakeout temperature. Encapsulated

versions for operation in splash water or oil Valid Patents

German Patent No . 10021919C2

Custom Designs with Modifi ed Specifi cations German Patent No . 10234787C1

For high operating temperature up to 200°C German Patent No . 10348836B3

Special electrodes for currents of up to 20 A German Patent No . 102005015405B3

Variable geometry: Inner hole, round, rectangular German Patent No . 102007011652B4

Ceramic or metal end pieces in many versions

US Patent No . 7,449,077 A pplied SGS sensors for positional stability

Japan Patent No. 4667863

Fields of Application China Patent No. ZL03813218.4

Research and industry. Cryogenic environment with

reduced displacement. For high-speed switching, precision

6 positioning, active and adaptive systems

Ww Ww wW . pP i Cc e r a Mm i Cc . cC Oo Mm

Physik Instrumente (PI) GmbH & Co. KG 2012. Subject to change without notice. Latest releases available at www.pi.ws. 12/04/24.0

Page7

Order number* Dimensions Nominal Max. Blocking force Stiffness Electrical Resonant

A x B x L [mm] displacement displacement [N] (0 – 120 V) [N/µm] capacitance frequency

[µm] (0 – 100 V) [µm] (0 – 120 V) [µF] ±20% [kHz] ±20%

P-882 .11 3 × 2 × 9 6 .5 ±20% 8 ±20% 190 24 0 .15 135

P-882 .31 3 × 2 × 13 .5 11 ±20% 13 ±20% 210 16 0 .22 90

P-882 .51 3 × 2 × 18 15 ±10% 18 ±10% 210 12 0 .31 70

P-883 .11 3 × 3 × 9 6 .5 ±20% 8 ±20% 290 36 0 .21 135

P-883 .31 3 × 3 × 13 .5 11 ±20% 13 ±20% 310 24 0 .35 90

P-883 .51 3 × 3 × 18 15 ±10% 18 ±10% 310 18 0 .48 70

P-885 .11 5 × 5 × 9 6 .5 ±20% 8 ±20% 800 100 0 .6 135

P-885 .31 5 × 5 × 13 .5 11 ±20% 13 ±20% 870 67 1 .1 90

P-885 .51 5 × 5 × 18 15 ±10% 18 ±10% 900 50 1 .5 70

P-885 .91 5 × 5 × 36 32 ±10% 38 ±10% 950 25 3 .1 40

P-887 .31 7 × 7 × 13 .5 11 ±20% 13 ±20% 1700 130 2 .2 90

P-887 .51 7 × 7 × 18 15 ±10% 18 ±10% 1750 100 3 .1 70

P-887 .91 7 × 7 × 36 32 ±10% 38 ±10% 1850 50 6 .4 40

P-888 .31 10 × 10 × 13 .5 11 ±20% 13 ±20% 3500 267 4 .3 90

P-888 .51 10 × 10 × 18 15 ±10% 18 ±10% 3600 200 6 .0 70

P-888 .91 10 × 10 × 36 32 ±10% 38 ±10% 3800 100 13 .0 40

* For optional solderable contacts, AWG 32 (Ø 0 .49 mm); P-885, P-887, Resonant frequency at 1 Vpp, Operating temperature

change order number extension to .x0 P-888: AWG 30 (Ø 0.61 mm). unloaded, free on both sides. range: -40 to 150°C.

(e . g . P-882 .10) . Recommended preload for dynamic The value is halved for unilate- Custom designs or different

Piezo ceramic type: PIC252. operation: 15 MPa. ral clamping. specifi cations on request.

Standard electrical interfaces: PTFE-in- Maximum preload for constant force: Capacitance at 1 Vpp, 1 kHz, RT .

sulated wire leads, 100 mm, P-882, P-883: 30 MPa . Operating voltage: -20 to 120 V.

B 0.2

<B+0.6

PICMA® Stack actuators, L, A, B see table

B 0.2

<B+0.6

7

p PiieezZoO TteeCcHhnnOoLlOoGgYy

A 0.3

< A+2.0 L 0.05

A 0.3

< A+2.0 L 0.05

Page8

Custom Designs

P i C M a ® s Ta C K P i e Z O a C T u aT O r s

Variety of Tips

Spherical tips. PI Ceramic has suitable tips with standard

dimensions in stock and mounts them prior to delivery.

Application-specifi c tips can be manufactured on request.

PICMA® Actuators for Maximum Dynamics

For high-dynamics applications, the multilayer actuators

are equipped with electrodes for especially high currents

of up to 20 A. Together with a high-performance swit-

ching driver such as the E-618, high operating frequen-

cies in the kHz range can be attained. The rise times for

the nominal displacement are a few tens of microse-

conds.

PICMA® Multilayer Actuators with Ceramic-Insulated

Inner Hole

A new technology allows multilayer piezo actuators

to be manufactured with an inner hole. Using special

manufacturing methods the holes are already made in

the unsintered actuator. As with the PICMA® standard

actuators, the co-fi ring process of the ceramics and the

internal electrodes is used to create the ceramic encapsu-

lation which protects the piezo actuator against humidity

and considerably increases its lifetime compared to

conventional polymer-insulated piezo actuators. PICMA®

stack actuators with an inner hole are ideally suited for

applications such as fi ber stretching.

PICMA® actuators with holes are manufactured on re-

quest.

High Operating Temperature of up to 200°C

For especially high-dynamics applications or high ambi-

ent temperatures, there are PICMA® multilayer actuator

versions that can reliably function at temperatures of

up to 200°C.

8

w W wW wW . pP i cC e r a Mm i Cc . Cc oO mM

Page9

Encapsulated PICMA® Stack Piezo Actuators

F O r T O u G H i n d u s T r i a L e n v i r O n M e n T s

P-885 • P-888

S plash-resistant full encapsulation

S uperior lifetime

High stiffness

UHV-compatible to 10-9 hPa

Microsecond response

S ub-nanometer resolution

L arge choice of designs

Encapsulated PICMA® Stack Multilayer Piezo Order Dimensions Nominal Max. Blocking Stiff- Electrical Resonant

Actuators with Inert Gas Filling num- OD x L displace- displace- force ness capacit- frequency

Operating voltage -20 to 120 V. UHV-compatible ber* [mm] ment [µm] ment [µm] [N] (0 – [N/ ance [kHz] ±20%

to 10-9 hPa. Version for operation in environ- (0 – 100 V) (0 – 120 V) 120 V) µm] [µF] ±20%

ments where exposure to splash water, high P-885 .55 11 .2 × 22 .5 14 ±10% 17 ±10% 850 50 1 .5 60

humidity or oil occurs P-885 .95 11 .2 × 40 .5 30 ±10% 36 ±10% 900 25 3 .1 35

P-888 .55 18 .6 × 22 .5 14 ±10% 17 ±10% 3400 200 6 .0 60

Piezo ceramic type: PIC252. clamping. Capacitance at 1 Vpp, 1 kHz, RT .

Standard electrical interfaces: PTFE-insulated Operating voltage: -20 to 120 V.Operating

wire leads, 100 mm, AWG 30 (Ø 0.61 mm). temperature range: -40 to 150°C.

Resonant frequency at 1 Vpp, unloaded, free on Ask about custom designs!

both sides. The value is halved for unilateral

Encapsulated PICMA® Stack actuators can also be used when the application environment is

characterized by oil, splash water or continuously high humidity. The piezo actuators are surrounded

Encapsulated PICMA® actuators, dimensions in mm by inert gas 9

p PiieezZoO TteeCcHhnnOoLlOoGgYy

Page10

Round PICMA®Round PICMA® SSttaacckk MMuullttiillaayyeerr PPiieezzoo AAccttuuaattoorr

HiGH BLOCK inG FOrCe

H iGH BLOCK inG FOrCe

PP--008888

Superior lifetime

Superior lifetime

Ideal for dynamic operation

Ideal for dynamic operation

Flexible, adaptable overall height

Flexible, adaptable overall height

O EM versions available without

Os tEraMn dveedrs wioinress available without

stranded wires

Multilayer stack actuators Possible modifi cations

Multilayer stack actuators Possible modifi cations

The actuators are easily scaled, thanks to the stacked Different heights, easy to mount on customer request.

Tcohnes atrcutuctaitoonr,s fl a erxei belaes ialyd aspctaaletido,n t hoaf nthkes ttora tvheel rsatancgkee dis VDaifrfieerteyn ot fh sehigaphetss,. eParseyc itsoio mn-ogurnotu onnd ceunsdt opmlaeters r efoqru rees-t.

pcoonsssitbrulec.t iTohne, fla enxniubllaer a cdraopssta stieocnti oonf tehnes turraevse le raasnyg ien ties- Vdaurcieedty t oolfe srhaanpceess .S Pprheceirsicioanl -egnrdo upniedc eensd plates for re-

gproastsioibnl.e V. Terhseio annsn wuliathr csroolsdse rsaebclteio cno enntascutrse asr eea aslys oin UteH-V- duced tolerances Spherical end pieces

gcoramtipoant.i bVleer stoio 1n0s- 9w hiPtha .s Tohldee aracbtulea tcoorns tdaoct ns oatr eo uatlgsoa sU HV-

caonmd pcaanti bblee

-9

btoa k1e0d ohuPta a. tT hhieg hac tteumatpoerrsa dtuor enso.t outgas

and can be baked out at high temperatures.

PICMA® piezo linear actuators Fields of application

PICMA® piezo linear actuators Fields of application

Low operating voltage -20 to 100 V. Ceramic insulation. Industry and research. For laser tuning, microdispens-

HLoigwh orpeleiarabtiilnitgy vaonldta lgoen g-2 l0if etoti m10e0 V. Ceramic insulation. Iinndg,u lsitfrey s acniedn rceessearch. For laser tuning, microdispens-

10 High reliability and long lifetime ing, life sciences

w w w . P I . w s

w w ww. pwi cwe .rPaI .mwi cs . c o m

©P©hPyshiyks Iinks Itnrsutmruemnteen (tPe I()P GI)m GbmHb &H C&o C. Ko.G K 2G0 1260.1 S6.u Sbujebcjte tcot tcoh acnhgane gwei twhiothuot unto ntioceti.c Lea. tLeastte rset lreealseeass easv aaivlaabillaeb alet watw www.pwi..wpis.w. 1s6. /1069//0091/ .001 .0

Page11

P-088.721 P-088.741 P-088.781 Unit Tolerance

P-088.721 P-088.741 P-088.781 Unit Tolerance

Dimensions OD × L 16 x 16 16 x 36 16 x 77 mm

Dimensions OD × L 16 x 16 16 x 36 16 x 77 mm

Nominal travel range 14 32 70 µm -10 % / + 20 %

Nominal travel range 14 32 70 µm -10 % / + 20 %

Blocking force 7500 7500 7500 N

Blocking force 7500 7500 7500 N

Stiffness 535 235 105 N/µm

Stiffness 535 235 105 N/µm

Electrical capacitance 13 30 68 µF ±20 %

Electrical capacitance 13 30 68 µF ±20 %

Resonant frequency 68 35 17 kHz ±20 %

Resonant frequency 68 35 17 kHz ±20 %

Nominal travel range, blocking force and stiffness at 0 to 100 V.

SNtoamndinaardl tcraovnenle rcatniognes, :b 1l0o0ck minmg fPoTrcFeE -a innds usltaiftfende ssst ratn 0d etod 1w0i0re Vs., AWG 28 (Ø 0.69 mm).Optional: For solderable contacts without stranded wires,

cShtandgaer tdh ceo lnasnte dctigioitn os:f 1th0e0 omrmde rP TnFuEm- binesr utola t0e.d stranded wires, AWG 28 (Ø 0.69 mm).Optional: For solderable contacts without stranded wires,

Pchieaznog cee trhaem liacs tty dpieg:i tP oICf 2th5e2 .o credrearm niucm enbde rp tloa t0e.s made of Al2O3.

Piezo ceramic type: PIC252. ceramic end plates made of Al2O3.

Recommended preload for dynamic operation: 15 MPa.

MReacxoimmumen pdredlo parde lfoar dc ofonrs tdaynnt afmoricce o: p30e rMatPioan. : 15 MPa.

AMxaixailm reusmon parnetl ofraedq fuoern ccoyn: smtaenats fuorrecde :a 3t 01 MV P,a u.pp nloaded, unclamped. The value is halved for unilateral clamping.

Axial resonant frequency: measured at 1 Vpp, unloaded, unclamped. The value is halved for unilateral clamping.

Electrical capacitance: measured at 1 Vpp, 1 kHz, RT

Electrical capacitance: measured at 1 Vpp, 1 kHz, RT

Operating voltage: -20 to 100 V.

Operrattiing tveomltapgeera: t-u2r0e t ora 1n0g0e V: .-40 to 150 °C.

Operating temperature range: -40 to 150 °C.

Ask about custom designs!

Ask about custom designs!

P-088 PICMA® Stack Multilayer Piezo Actuator, dimensions in mm

P-088 PICMA® Stack Multilayer Piezo Actuator, dimensions in mm 11

w w w . P I . w s

p i e zwow twe c. PhIn. wo lso g y

©P©hPyshiyks Iinks Itnrsutmruemnteen (tPe I()P GI)m GbmHb &H C&o C. Ko.G K 2G0 1260.1 S6.u Sbujebcjte tcot tcoh acnhgane gwei twhiothuot unto ntioceti.c Lea. tLeastte rset lreealseeass easv aaivlaabillaeb alet watw www.pwi..wpis.w. 1s6. /1069//0091/ .001 .0

Page12

P ®PIICCMMAA® SSttaacckk MMuullttiillaayyeerr RRiinngg AAccttuuaattoorr

WiTH inner HOLe

WiTH inner HOLe

PICMA® Stack Multilayer Ring Actuator

With inner hole

PP--008800

■ I nI nneer rh hoolele f ofor rp prereloloaadd o or ra ass

a Inapnpeeerrtru thuroerel ef of foro ror o ppptritecicaloal ala dap poplri lcaicasa- -

taitpoioennrstsure for optical applica-

tions

■ S Suuppeeriroior rl ilfiefetitmimee

S uperior lifetime

■ I dIdeeaal lf ofor rd dyynnaammicic o oppeeraratitoionn

I deal for dynamic operation

■ M Micicrorosseeccoonndd r eressppoonnssee

M icrosecond response

■ S Suubb-nnaannoommeetteerr rreessoolluuttiioonn

S ub-nanometer resolution

Multilayer Stack Actuators Available Options

Multilayer Stack Actuators Available Options

Flexible travel range up to 30 µm. Annular cross-section Different heights, easy to mount on customer request.

Ffoler xeiabsley tirnatveeglr aratinogne. up to 30 µm. Annular cross-section DVaifrfieerteyn ot fh sehigahptess,. eParseyc itsoio mn-ogurnotu onnd ceunsdt opmlaeters r efoqru est.

UfoHr Ve-acsoym inptaetgibralet itoon 1. 0-9 hPa, high bakeout temperature Vreadriuecteyd o tfo slhearapnecse. sPrecision-ground end plates for

UHV-compatible to 10-9 hPa, high bakeout temperature reduced tolerances

PICMA® Piezo Linear Actuators Fields of Application

PICMA® Piezo Linear Actuators Fields of Application

Low operating voltage -20 to 100 V. Ceramic insulation. Research and industry. For laser tuning, micro-

LHoigwh orpeleiarabtiilnitgy vaonldta lgoen g-2 l0if etoti m10e0 V. Ceramic insulation. dRiesspeeanrschin agn, dlif ien sdcuisetnrcye. sFor laser tuning, micro-

12 High reliability and long lifetime dispensing, life sciences

Multilayer Stack Actuators Available Options

Flexible travel range up to 30 µm. Annular cross-section Different heights, easy to mount on customer request.

for easy integration. w w w . P I . w sw w ww. pwi cwe .rPaI .mVwaircsie.tyc oof mshapes. Precision-ground end plates for

UHV-compatible to 10-9 hPa, high bakeout temperature reduced tolerances

PICMA® Piezo Linear Actuators Fields of Application

Low operating voltage -20 to 100 V. Ceramic insulation. Research and industry. For laser tuning, micro-

10 High reliability and long lifetime dispensing, life sciences

w w ww. pwi cwe.rpai .mwi cs . c o m

©Physik Instrumente (PI) GmbH & ©CPo©h. PKyshGiyk 2s Ii0nk1s I3tnr. suStmruubemjnetecent (ttPeo I ()cP hGI)am nGbgmHeb w&Hi tC&hoo C.u Kot .Gn K o2Gt0i c12e50..1 LS5a.u tSbeusjetb crjtee tcloet a tcsohe acsnh agavnea gwielai twbhlioeth uaott unwto wntiocwet.i.pc Lei.a.w tLesas.t tRe rs1et l1re3ea/ls1ee0as/s0 ea2sv . 0aaivlaabillaeb alet watw www.pwi..wpis.w. Rs.2 R 125 /1056//0061/ .001 .0

Page13

Preliminary data P-080.311 P-080.341 P-080.391 Unit

Dimensions OD × ID × L 8 × 4.5 × 8.5 8 × 4.5 × 16 8 × 4.5 × 36 mm × mm × mm

Nominal travel range 5.5 ±20 % 11 ±20 % 25 ±10 % µm

PBrloelcikmininga froyr cdea t a P8-0008 0.311 P8-2058 0.341 P8-5008 0.391 UNn it

DStimiffennesiso n s OD × ID × L 81 4×5 4 .5 × 8.5 87 5× 4.5 × 16 83 4× 4.5 × 36 mN/mµm × mm × mm

NEloemctirnicaal lt rcavpealc riatanngcee 50..58 6± 20 % 11.7 ± 20 % 245.0 ± 10 % µmF

BRleoscokninagn tf ofrrecqeu ency 813050 ±20 % 8255 ± 20 % 84500 ± 20 % NkH z

ASllt difaftnae asts 0 to 100 V. 145 75 34 N/µm

Standard connections: PTFE-insulated stranded wires, 100 mm, AWG 30 (Ø 0.61 mm).

Electrical capacitance 0.86 1.7 4.0 µF

For optional solderable contacts without stranded wires, change order number extension to 0.

PRieezsoo cnearanmt ifcr etyqpuee PnICcy25 2. Ceramic end plates made of Al2O13.60 85 40 kHz

Recommended preload for dynamic operation: 15 MPa.

AMlal xdiamtau amt 0p rteol o1a0d0 Vfo. r constant force: 30 MPa.

SAtxainald raersdo cnoannnt efrcetiqounesn: cPyT:F mE-einasurlaetde da ts 1tr Vanppd, eudn lwoairdeesd, ,1 u00n cmlam,p AeWd.G 30 (Ø 0.61 mm).

FTohre o vpatliuoen aisl shoaldverda fboler ucnoinlatatecrtsa lw ciltahmopuitn sgtr.anded wires, change order number extension to 0.

PEilezcotr iccearla cmapica tcyitpaen PceIC: T2o5l2e.r aCnecraem ±2ic0 e%n,d m pelatseusr emda adte 1 o Vfp Ap,l 21O k3H. z, RT.

ROepceormatmingen vdoeltda gpere: l-o2a0d t ofo 1r0 d0y Vn.amic operation: 15 MPa.

MOpaexrimatiunmg tpermelpoearda tfuore c orannsgtaen: t- 4fo0 rtcoe :1 350 °MC.Pa.

Axskia al breosuotn caunstt ofrmeq duesnigcyn:s m! easured at 1 Vpp, unloaded, unclamped.

The value is halved for unilateral clamping.

Electrical capacitance: Tolerance ±20%, measured at 1 Vpp, 1 kHz, RT.

Operating voltage: -20 to 100 V.

Operating temperature range: -40 to 150°C.

Ask about custom designs!

+

max. 9

+0,5

8 -0,3

0

4,4 -0,3

+

P-080, dimensions in mm

max. 9

+0,5

8 -0,3

0

4,4 -0,3

P-080.390, dimensions in mm

13

w w w . P I . w s 11

p i e z o t e c h n o l o g y

p i e zwow twe c. phin. wo lso g y

max. 10,5 L ±0,5

max. 10,5 L ±0,5

©Physik Instrum©Pehnytes i(kP IIn) sGtrmubmHe n&t eC (oP. IK) GGm 20b1H3 .& S Cuob.j eKcGt t 2o0 c1h5a. nSgueb wjeictth toou ct hnaontgicee .w Liathteosutt r neoletaicsee.s L aavteasilta rbellee aast ewsw awva.pilia.wblse. aRt1 w 1w3/w10.p/0i.2w .0s. R2 15/06/01 .0

Page14

Round PICMA® Chip Actuators

MiniaTure MuLT iLaYer P ieZO aCTuaTOr WiTH and WiTHOuT inner HOLe

Pd0xx

Superior lifetime

Ultra-compact: From 5 mm Ø

Ideal for dynamic operation

Microsecond response

S ubnanometer resolution

Piezo linear actuator with PICMA® multilayer technology Possible modifi cations

Operating voltage -20 to 100 V. Ceramic insulation, poly- PTFE-insulated wire leads. Various geometric shapes, inner

mer-free. Humidity resistance. UHV-compatible to 10-9 hole. Precision-ground ceramic end plates

hPa, no outgassing, high bakeout temperature.

Fields of application

Flexible thanks to numerous designs. Versions with rectan- Industry and research. For laser tuning, microdispensing,

gular, round or annular cross section life sciences

PD050.3x PD080.3x PD120.3x PD150.3x PD160.3x PD161.3x Unit Tolerance

ID 5 ±0 .2 8 ±0 .3 12 ±0 .4 15 ±0 .3 16 ±0 .5 16 ±0 .5 mm

OD 2 .5 ±0 .15 4 .5 ±0 .15 6 ±0 .2 9 ±0 .15 8 ±0 .25 – mm

TH 2 .5 ±0 .05 2 .5 ±0 .05 2 .5 ±0 .05 2 ±0 .05 2 .5 ±0 .05 2 .5 ±0 .05 mm

Travel 2 2 2 1 .8 2 2 .3 µm ±20 %

range*

Blocking force >400 >1000 >2500 >3300 >4400 >6000 N

Electrical 110 300 900 1000 1700 2400 nF ±20 %

capacitance**

Axial resonant >500 >500 >500 >500 >500 >500 kHz

frequency***

Standard connections: PDxxx.31: PTFE-insulated wire leads, 100 mm, AWG 32, Ø 0.49 mm; PDxxx.30: Solderable contacts

Blocking force: At 0 to 100 V

*** At 0 to 100 V. The values refer to the unattached component and can be lower when glued on.

*** measured at 1 Vpp, 1 kHz, RT

*** measure at 1 Vpp, unloaded, open on both sides. The value is halved for unilateral clamping. Lateral resonant frequencies can be lower than

the axial ones, depending on the installation situation.

14 Ask about custom designs!

w w wW. pWi cWe .rPai .mWi cs . c o m

©Physik Instrumente (PI) GmbH & Co. KG 2015. Subject to change without notice. Latest releases available at www.pi.ws. 16/08/30.0

Page15

PICMA® Chip Actuators

MiniaTure MuLT iLaYer P ieZO aCTuaTOrs

PL0xx

S uperior lifetime

U ltra-compact: From

2 mm × 2 mm × 2 mm

Ideal for dynamic operation

Microsecond response

Subnanometer resolution

Piezo linear actuator with PICMA® multilayer technology Available Options

Operating voltage -20 to 100 V. Ceramic insulation, poly- PTFE-insulated wire leads. Various geometric shapes, inner

mer-free. Humidity resistance. UHV-compatible to 10-9 hole. Precision-ground ceramic end plates

hPa, no outgassing, high bakeout temperature.

Fields of Application

Large choice of designs. Versions with rectangular or Research and industry. For laser tuning, micro-dispensing,

annular cross-section life sciences

PL022.30 PL033.30 PL055.30 PL088.30 Unit

Dimensions A × B × TH 2 × 2 × 2 3 × 3 × 2 5 × 5 × 2 10 × 10 × 2 mm x mm x mm

Displacement 2 .2 2 .2 2 .2 2 .2 µm

Blocking force >120 >300 >500 >2000 N

Electrical capacitance 25 85 250 1100 nF

Resonant frequency >600 >600 >600 >600 kHz

Travel range: at 0 to 100 V, tolerance ±20 %. The values refer to the free component and can be lower when glued on.

Blocking force: at 0 to 100 V.

Electrical capacitance: Tolerance ±20 %, measured at 1 Vpp, 1 kHz, RT.

Axial resonant frequency: measured at 1 Vpp, unloaded, unclamped. The value is halved for unilateral clamping. Lateral resonant frequencies can

be lower than the axial ones, depending on the installation situation.

Piezo ceramic type: PIC252.

Standard connections: PLxxx.31: PTFE-insulated wire leads, 100 mm, AWG 32, Ø 0.49 mm; PLxxx.30: Solderable contacts

Operating voltage: -20 to 100 V.

Operating temperature range: -40 to 150 °C.

Recommended preload for dynamic operation: 15 MPa.

Maximum preload for constant force: 30 MPa.

Ask about custom designs! 15

p i e zWoW tWe c. Phin. Wo lso g y

©Physik Instrumente (PI) GmbH & Co. KG 2015. Subject to change without notice. Latest releases available at www.pi.ws. 16/08/30.0

Page16

PICMA® Bender Piezo Actuator

a L L - C e r a M i C B e n d e r a C T u aT O r s W i T H H i G H d i s P L a C e M e n T

PL112 – PL140 •

Pd410

L 0.5

Displacement to 2 mm

3

3 F ast response in the ms range

2 2

1 Na1nometer resolution

LF Low operating voltage

PICMA® Multilayer Bender Elements with High Reliability

Operating voltage 0 to 60 V. Bidirectional displacement.

Ceramic insulation, polymer-free. UHV-compatible to

10-9 hPa, no outgassing, high bakeout temperature.

Reliable even under extreme conditions

Displacement of the PICMA® bender actuator

Fields of Application

Research and industry, vacuum. For medical technology,

laser technology, sensor systems, automation tasks, +60 V (+30 V)

pneumatic valves

3

Vin Vout

2

0 ... +60 V

(-30 ... +30 V)

1

GND (-30 V)

Suitable Drivers

PICMA® Bender actuators require full differential-voltage control

16 E-650 Piezo Amplifi er for Multilayer Bender Actuators

wW wW Ww . Pp i Cc e r a mM i Cc . cC Oo mM

TH 0.1 W 0.2

ID 0.2

©Physik Instrumente (PI) GmbH & Co. KG 2012. Subject to change without notice. Latest releases aTvHaila0b.l1e at www.pi.ws. R2 O16D/080/2.56.0

Page17

Rectangullar bender actuators

Order Operatiing Diispllacement Free llength Diimensiions Bllockiing force Ellectriicall Resonant

number volltage [V] [µm] ±20% Lf [mm] L × W × TH [mm] [N] ±20% capaciitance [µF] ±20% frequency Hz] ±20%f

PL112 . .10* 0 - 60 (±30) ±80 12 18 . .0 × 9 . .6 × 0 . .65 ±2 . .0 2 * 1 . .1 2000

PL122 . .10 0 - 60 (±30) ±250 22 25 . .0 × 9 . .6 × 0 . .65 ±1 . .1 2 * 2 . .4 660

PL127 . .10 0 - 60 (±30) ±450 27 31 . .0 × 9 . .6 × 0 . .65 ±1 . .0 2 * 3 . .4 380

PL128 . .10* 0 - 60 (±30) ±450 28 36 . .0 × 6 . .3 × 0 . .75 ±0 . .5 2 * 1 . .2 360

PL140 . .10 0 - 60 (±30) ±1000 40 45 . .0 × 11 . .0 × 0 . .6 ±0 . .5 2 * 4 . .0 160

Round bender actuators

Order Operatiing Diispllacement Free llength Diimensiions Bllockiing force Ellectriicall Resonant

number volltage [V] [µm] ±20% Lf [mm] OD × IID × TH [mm] [N] ±20% capaciitance [µF] ±20% frequency Hz] ±20%f

PD410 . .10* 0 - 60 (±30) ±240 – 44 × 7 × 0 . .65 ±16 2 * 10 . .5 1000

For opttiionall 100 mm PTFE--iinsullatted wiire lleads,, AWG 32 ((Ø 0..49 mm)),, change order number exttensiion tto 1 ((e.. g.. PL112..11))..

Piiezo ceramiic ttype:: PIIC251,, *PIIC252..

Sttandard connecttiions:: Sollderablle conttactts..

Resonantt ffrequency att 1 Vpp,, cllamped on one siide wiitth ffree llengtth Lf,, wiitthoutt mass lload.. For PD410..10:: Resttraiintt wiitth rottattablle mounttiing on tthe outter f

ciircumfference . .

Capaciittance att 1 Vpp,, 1 kHz,, RT . .

Operattiing ttemperatture range:: --20 tto 85°C;; * --20 tto 150°C..

Recommended mounttiing:: Epoxy resiin adhesiive.. Allll speciififi cattiions depend on tthe reall cllampiing condiittiions and on tthe applliied mechaniicall lload..

Custtom desiigns or diifffferentt speciififi cattiions on requestt..

L 0..5

L 0..5

3

2 3

3

1

2 2

1 LFFF 1

LF

PL112 – PL140..10,, diimensiions iin mm.. PD410 round PIICMA® Bender Piiezo Acttuattor,, diimensiions

L,, LF,, W,, TH see datta ttablle iin mm.. IID,, OD,, TH see datta ttableF l

Mullttiillayer conttracttiing pllattes can be manuffacttured iin a Mullttiillayer bender acttuattors can be manuffacttured iin Benders wiitth uniidiirecttiionall diispllacementt consiistt off a

variietty off shapes,, e.. g.. recttangullar or diisk--shaped,, and allmostt any shape.. The manuffactturiing process allllows,, siinglle acttiive piiezoceramiic llayer tthatt iis gllued ttogetther wiitth

are avaiillablle on requestt.. These pllattes can be applliied among otther tthiings,, iinner holles wiitth an allll--ceramiic a substtratte off AII2O3 ceramiics or stainless steel. In compar-2 3 t i l t l. I -

e.. g.. tto mettall or siilliicon substtrattes,, iin order tto realliize iinsullattiion.. The heiightt off tthe acttiive llayers can be variied iison wiitth tthe biimorph sttructture,, tthese acttuattors achiieve

bender or pump ellementts wiitth llow conttroll vollttages.. ffrom a miiniimum heiightt off 15 µm so tthatt conttroll vollttag-- a hiigher sttiiffffness and a greatter diispllacementt,, whiich onlly

es off onlly 10 V can be used.. ttakes pllace iin one diirecttiion,, however.. 17

pPiieezZoO TteeCcHh nOoLlOoGgYy

TTHH 00..11 WW 00..22

TTHH 00..11 WW 00..22

IIDD 00..22

TTHH 00..11 OODD 00..55

Page18

DuraAct Patch Transducer

B e n d a B L e a n d r O B u s T

P-876

U se as actuator, sensor or

energy generator

Cost-effective

Min. bending radii of down to

12 mm

Patch Transducer

Functionality as actuator and sensor component. Nominal

operating voltage from 100 up to 1000 V, depending on

the active layer height. Power generation for self-suffi cient

systems possible up to the milliwatt range. Can also be

applied to curved surfaces

Robust, Cost-Effective Design

Laminated structure consisting of a piezoceramic plate,

electrodes and polymer materials. Manufactured with

bubble-free injection method. The polymer coating simul-

taneously serves as a mechanical preload as well as an

electrical insulation, which makes the DuraAct bendable

Design principle of the transducer

Custom DuraAct Patch Transducers

Flexible choice of size

Flexible choice of thickness and thus bending ability

F lexible choice of piezoceramic material

Variable design of the electrical connections

Combined actuator/sensor applications, even with

several piezoceramic layers

Multilayer piezo elements Valid Patents

Arrays German Patent No . 10051784C1

US Patent No . 6,930,439

Fields of Application

Research and industry. Can also be applied to curved Suitable Drivers

surfaces or used for integration in structures. For adaptive E-413 DuraAct and PICA Shear Piezo Amplifi er

18 systems, energy harvesting, structural health monitoring E-835 DuraAct Piezo Driver

Ww wW Ww . pP i cC e r a Mm i Cc . Cc Oo mM

Physik Instrumente (PI) GmbH & Co. KG 2012. Subject to change without notice. Latest releases available at www.pi.ws. 12/04/030

Page19

Order Operating Min. lateral Rel. lateral Blocking Dimensions Min. Piezo Electrical

Number voltage [V] contraction contraction force [N] [mm] bending ceramic capacitance

[µm/m] [µm/m/V] radius [mm] height [µm] [nF] ±20%

P-876 .A11 -50 to +200 400 1 .6 90 61 × 35 × 0 .4 12 100 150

P-876 .A12 -100 to +400 650 1 .3 265 61 × 35 × 0 .5 20 200 90

P-876 .A15 -250 to +1000 800 0 .64 775 61 × 35 × 0 .8 70 500 45

P-876 .SP1 -100 to +400 650 1 .3 n .a . 16 × 13 × 0 .5 - 200 8

Piezo ceramic type: PIC255

Standard connections: Solder pads

Operating temperature range: -20 to 150°C

Custom designs or different specifi cations on request.

When a voltage is applied, the DuraAct patch transducer contracts laterally.

P-876 DuraAct patch transducers use the so-called d31 effect, where the applied

fi eld is orthogonal with respect to the polarization of the piezo element.

P-876.A (left), P-876.SP1 (right), dimensions in mm

Electronic modules for sensor data processing,

controlling the DuraAct actuator or harvesting energy

can be connected close to the transducer

When arranged in an array, DuraAct patch transducers allow, for example,

the reliable monitoring of larger areas DuraAct patch transducers can be manufactured in various shapes

19

pPiieezZoO TteeCcHh nOoLlOoGgYy

Page20

DuraAct Power Patch transducer

H I G H E F F I C I E N C Y a N D r O B u s T

P-878

Useable as actuator, sensor or

energy generator

L ow voltages to 120 V

Compact design

I ndividual solutions

Patch Transducer Custom DuraAct Patch Transducers

Functionality as actuator and sensor component. Nomi- Flexible choice of size

nal operating voltages of -20 to 120 V. Power generation Variable design of the electrical connections

for self-suffi cient systems possible up to the milliwatt Combined actuator/sensor applications, even with

range. Can also be applied to curved surfaces.

several active piezoceramic layers

In longitudinal direction, the DuraAct Power uses the Arrays

high-effi ciency d33 effect

Robust, Cost-Effective Design

Laminated structure consisting of PICMA® multilayer piezo Fields of Application

element, electrodes and polymer materials. Manufactured Research and industry. Can also be applied to curved

with bubble-free injection method. The polymer coating surfaces or used for integration in structures.

simultaneously serves as electrical insulation and as For adaptive systems, energy harvesting, structural

20 mechanical preload, which makes the DuraAct bendable health monitoring

w w ww. pwi cwe .rPaI .mwi cs . c o m

©Physik Instrumente (PI) GmbH & Co. KG 2013. Subject to change without notice. Latest releases available at www.pi.ws. 13/08/29 .0