1/4ページ

ダウンロード(2.2Mb)

個々のお客様の要件に応じたさまざまなバリエーション

ライスターの新しいMAXIレーザー溶接システムは、大型部品をレーザー溶接するために広くお使いいただけます。

たとえば、自動車産業でヘッドライトやバンパーの溶接に使用可能です。

レーザー溶接システムは、その他にも繊維産業で防水性のある屋外用衣類の溶接にも使用できます。

<MAXIレーザー溶接システムの最も重要な利点の概要>

・さまざまな業界の大型プラスチック部品のレーザー溶接

・お客様固有のソリューション

・回転割出テーブルで、また搬送ベルトのアプリケーションでもスループットの向上が可能

・特にオプションのロボットの統合に対応したソフトウェア

・ロボットの操作に必要な専門知識は不要

・「良不良」の部品評価のあるオンライン制御

・プロセスおよび生産ラインに統合可能

・効率の向上のための高いスループット

詳しく仕様や特徴は資料をダウンロードしてご確認ください

このカタログについて

| ドキュメント名 | MAXIレーザー溶接システム(英文) |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 2.2Mb |

| 登録カテゴリ | |

| 取り扱い企業 | 株式会社ライスター・テクノロジーズ (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

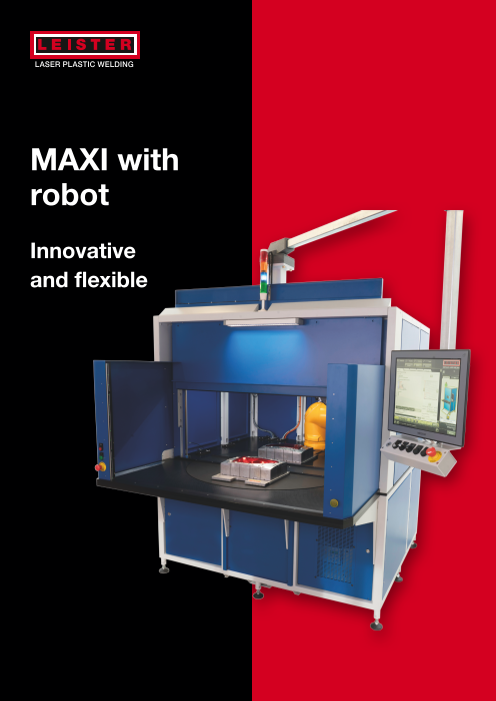

LASER PLASTIC WELDING

MAXI with

robot

Innovative

and flexible

Page2

Laser Plastic Welding

Established in 1998, the Leister business unit has many years of experience in laser welding of plastics. Leister is the owner of a number

of patents (such as Mask or GLOBO welding) and the only company with expertise in all standard laser plastic welding techniques.

The principle of laser welding

Joining pressure

In laser welding of thermoplastics, sometimes referred to as “laser

transmission welding” or “through transmission IR welding” (TTIr),

transparent and absorbent parts are bonded together.

The laser beam penetrates the transparent plastic and is converted Laser radiation

to heat in the absorbing plastic. Since both parts are pressed

together during the welding process, heat is conducted from the Weld seam

absorbent to the transparent plastic, allowing both materials to melt

and create a bond. In addition to the externally applied clamping

force an internal joining pressure is also generated through the

thermal expansion of the laser-heated plastic parts. The internal

and external joining pressures ensure strong welding of both parts.

Melt zone Transparent

Almost all thermoplastic plastics and thermoplastic elastomers joining part

can be welded with the laser beam – including ABS, PA, PC, PP,

PMMA, PS, PBT as well as glass fiber reinforced plastic types.

The achieved weld seam strength remains within the area of basic

material strength. Absorbent Joining pressure

joining part

GLOBO welding

A laser beam is focused at a point on the joining plane via an air

bearing, frictionless, freely rotating glass sphere. The glass sphere

not only focuses – it also serves as a mechanical clamping tool.

While the sphere rolls on the component, it applies continuous

pressure at a point on the joining plane. The glass sphere replaces

the mechanical clamping device and expands the scope of laser

welding to both continuous and three-dimensional applications.

Characteristics and application:

• Arbitrary joining geometries in two and three dimensions

• Welding without a clamping device

• Suitable for robotic applications

Examples

Head-up Display Fabrics Liquid vapor separator

2

Page3

MAXI with robot - developed for laser welding of large and three-dimensional components. The easy to use Leister HMI control

system not only is the platform for laser specific adjustments but also visualizes and adjusts the robot’s movement within the cell. The

system is ideal for GLOBO applications and, for the first time, offers a complete solution from a single source.

MAXI with robot

The MAXI is a configurable manual turnkey system equipped with

all necessary components for laser plastic welding.

The Human Machine Interface (HMI) software visualizes the full

process and assists while parameterizing the welding process.

The HMI shows the welding contour as well as the local limits of

the robot within the operation cell. The contour is displayed by a

sequence of points where each point can be edited with an addi-

tional function like change of speed or laser power.

In addition, the HMI transmits process data like laser power, speed

and clamping pressure to the system where this data is saved in

relation to a specific project.

Not only can the system be configured with the robot but also with

other motion systems. Furthermore, the system can be equipped

with a conveyor belt or with no feeding system at all.

• Laser welding system based on a 6-axis-robot

• Several applications eligible for production

• Process-independent HMI Software

• Laser safety class 1

Technical Data

laser type diode laser or fiber laser

Spot, line, ring, field

beam shape

DOE, radial

laser power < 600 W

pilot laser/aiming beam LED

working area

bis ca. 1450 x 800 mm

robot

welding speed < 200 mm/s

max. working load 14 kg

compressed air 6 bar

integrated PLC, HMI,

controller

robot

data interface Leister HMI, robot

dimensions (L x W x H)

1760 x 1500 x 2200 mm

operation cell

weight < 2000 kg

line voltage 400 V ~

max. current consumption 16 A

frequency 50 / 60 Hz

environmental conditions 15 – 35°C

3

Page4

Leister headquarter Switzerland

Leister subsidiary company

Leister Resellers and Partners

Headquarters Switzerland

Leister Technologies AG

Galileo-Strasse 10

CH-6056 Kaegiswil / Switzerland

phone: +41 41 662 74 74

info.laser@leister.com

Germany

Leister Technologies

Deutschland GmbH

58093 Hagen / Germany We are local. Worldwide.

phone: +49-(0)2331-95940

contact: Matthias Poggel

matthias.poggel@leister.com Distribution addresses of the Leister Sales and Service Centers

USA, Canada, Mexico

Leister Technologies LLC Europe Denmark / Sweden Asia

Itasca, IL 60143 / USA

phone: +1 630 760 1000 Netherlands Weldingseller aps Malaysia

contact: Andrew Geiger Aeson AV Huizen /NL contact: Kasper Knudsen SnR Gold Wave Resources Sdn Bhd

andrew.geiger@leisterusa.com contact: Rudolf Dasbach kk@weldingseller.dk contact: Abdul Wahab

China r.dasbach@aeson.nl awahab@snrgw.com

Leister Technologies Ltd. Russia

Shanghai 201 109 / PRC Belgium / Luxembourg Olmax Taiwan

phone: +86 755 27440399

contact: Cai Sheng Hupico bvba contact: Maxim Shchekin GreatDing Technology Co., Ltd.

sheng.cai@leister.cn contact: P ierre Huyghebaert olmax@olmax.ru contact: David Hsu

pierre@hupico.be david_hsu@greatding.com

Japan

Leister Technologies KK Middle East

Yokohama 222-0033 / Japan UK / Ireland Israel

phone: +81 (45) 477 3637 Horizon Instruments Ltd. Su-Pad (1987) ltd

contact: Nobuaki Suzuki

nobuaki.suzuki@leister.com contact: Daniel Bolton contact: Ziv Sadeh

dbolton@horizoninstruments.co.uk ziv@su-pad.com

India

Leister Technologies

India Pvt. Ltd.

phone: +91 44 45583436 - 8

contact: Arun Kumar

arunkumar@leister.in

© Copyright by Leister, Switzerland

Your Leister Sales and Service Center:

Swiss Made. Leister Technologies AG is an ISO 9001 certified enterprise. subject to change without prior notice.

www.leister.com/laserplasticwelding

MAXI with robot / EN / 09.2019