1/8ページ

ダウンロード(829.8Kb)

様々な歯車を簡単・精密に測定可能

WENZEL社の新しい歯車試験機「GTシリーズ」は、歯車測定技術における高精度の要求を、正確・簡単・迅速に満たすために設計されました。GTシリーズは、優れた人間工学・使いやすさ・広範な測定・分析オプションを特徴としています。歯車や回転対称コンポーネントに最適なソリューションです。

GTシリーズでは、平歯車、円筒歯車、かさ歯車、ころ歯車のほか、はすば歯車、インボリュート歯車を測定および評価できます。

非接触センサーを搭載することもでき、タービンブレードなどの高精度な測定も行えます。

~ソフトウェア パッケージ~

WM|Gearは、WENZEL社の座標測定機でインボリュートのデータ収集と測定を行うための新しいソフトウェア パッケージです。

– 共通評価基準(GDE)のサポート

– 3軸・4軸測定機による測定

– 統計システムとの連携が可能

– 多くの評価パラメータは後からでも変更可能

– 多くのプレゼンテーションパラメータは後からでも変更可能

– 測定結果をPDF形式でアーカイブ

このカタログについて

| ドキュメント名 | WENZEL / 歯車測定器GTシリーズ |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 829.8Kb |

| 登録カテゴリ | |

| 取り扱い企業 | 株式会社シーケービー (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

EN

GEAR MEASURING MACHINE

GT 300 | GT 450 | GT 650

Technical Data

TDA_GT300-450-650_07-2021_EN | Valid as of: 07/2021

Page2

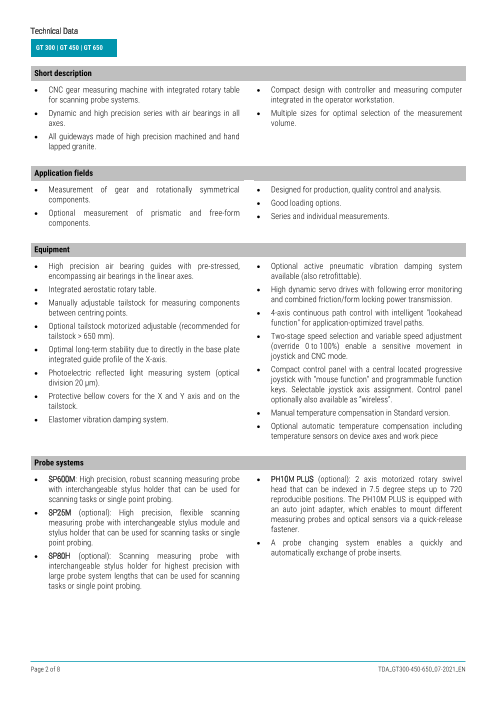

Technical Data

GT 300 | GT 450 | GT 650

Short description

CNC gear measuring machine with integrated rotary table Compact design with controller and measuring computer

for scanning probe systems. integrated in the operator workstation.

Dynamic and high precision series with air bearings in all Multiple sizes for optimal selection of the measurement

axes. volume.

All guideways made of high precision machined and hand

lapped granite.

Application fields

Measurement of gear and rotationally symmetrical Designed for production, quality control and analysis.

components. Good loading options.

Optional measurement of prismatic and free-form Series and individual measurements.

components.

Equipment

High precision air bearing guides with pre-stressed, Optional active pneumatic vibration damping system

encompassing air bearings in the linear axes. available (also retrofittable).

Integrated aerostatic rotary table. High dynamic servo drives with following error monitoring

Manually adjustable tailstock for measuring components and combined friction/form locking power transmission.

between centring points. 4-axis continuous path control with intelligent "lookahead

Optional tailstock motorized adjustable (recommended for function" for application-optimized travel paths.

tailstock > 650 mm). Two-stage speed selection and variable speed adjustment

Optimal long-term stability due to directly in the base plate (override 0 to 100%) enable a sensitive movement in

integrated guide profile of the X-axis. joystick and CNC mode.

Photoelectric reflected light measuring system (optical Compact control panel with a central located progressive

division 20 µm). joystick with “mouse function” and programmable function

keys. Selectable joystick axis assignment. Control panel

Protective bellow covers for the X and Y axis and on the optionally also available as “wireless”.

tailstock.

Manual temperature compensation in Standard version.

Elastomer vibration damping system.

Optional automatic temperature compensation including

temperature sensors on device axes and work piece

Probe systems

SP600M: High precision, robust scanning measuring probe PH10M PLUS (optional): 2 axis motorized rotary swivel

with interchangeable stylus holder that can be used for head that can be indexed in 7.5 degree steps up to 720

scanning tasks or single point probing. reproducible positions. The PH10M PLUS is equipped with

SP25M (optional): High precision, flexible scanning an auto joint adapter, which enables to mount different

measuring probe with interchangeable stylus module and measuring probes and optical sensors via a quick-release

stylus holder that can be used for scanning tasks or single fastener.

point probing. A probe changing system enables a quickly and

SP80H (optional): Scanning measuring probe with automatically exchange of probe inserts.

interchangeable stylus holder for highest precision with

large probe system lengths that can be used for scanning

tasks or single point probing.

Page 2 of 8 TDA_GT300-450-650_07-2021_EN

Page3

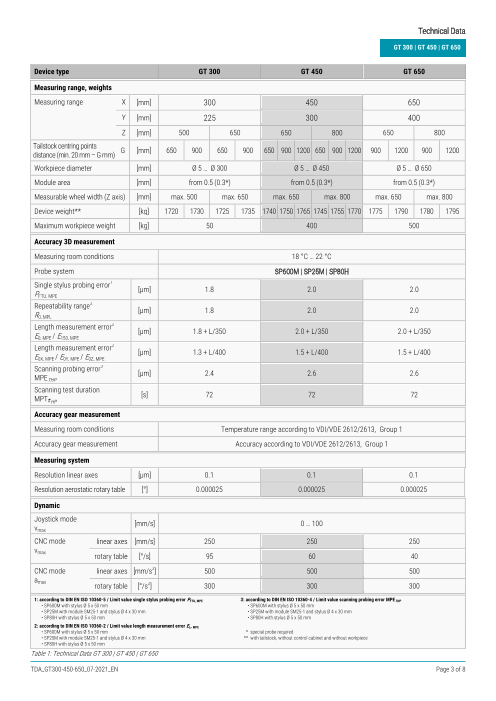

Technical Data

GT 300 | GT 450 | GT 650

Device type GT 300 GT 450 GT 650

Measuring range, weights

Measuring range X [mm] 300 450 650

Y [mm] 225 300 400

Z [mm] 500 650 650 800 650 800

Tailstock centring points

G [mm] 650 900 650 900 650 900 1200 650 900 1200 900 1200 900 1200

distance (min. 20 mm – G mm)

Workpiece diameter [mm] Ø 5 … Ø 300 Ø 5 … Ø 450 Ø 5 … Ø 650

Module area [mm] from 0.5 (0.3*) from 0.5 (0.3*) from 0.5 (0.3*)

Measurable wheel width (Z axis) [mm] max. 500 max. 650 max. 650 max. 800 max. 650 max. 800

Device weight** [kg] 1720 1730 1725 1735 1740 1750 1765 1745 1755 1770 1775 1790 1780 1795

Maximum workpiece weight [kg] 50 400 500

Accuracy 3D measurement

Measuring room conditions 18 °C … 22 °C

Probe system SP600M | SP25M | SP80H

1

Single stylus probing error

[µm] 1.8 2.0 2.0

PFTU, MPE

2

Repeatability range

[µm] 1.8 2.0 2.0

R0, MPL

2

Length measurement error

[µm] 1.8 + L/350 2.0 + L/350 2.0 + L/350

E0, MPE / E150, MPE

2

Length measurement error

[µm] 1.3 + L/400 1.5 + L/400 1.5 + L/400

E0X, MPE / E0Y, MPE / E0Z, MPE

3

Scanning probing error

[µm] 2.4 2.6 2.6

MPETHP

Scanning test duration

[s] 72 72 72

MPTτHP

Accuracy gear measurement

Measuring room conditions Temperature range according to VDI/VDE 2612/2613, Group 1

Accuracy gear measurement Accuracy according to VDI/VDE 2612/2613, Group 1

Measuring system

Resolution linear axes [µm] 0.1 0.1 0.1

Resolution aerostatic rotary table [°] 0.000025 0.000025 0.000025

Dynamic

Joystick mode

[mm/s] 0 … 100

vmax

CNC mode linear axes [mm/s] 250 250 250

vmax

rotary table [°/s] 95 60 40

CNC mode 2

linear axes [mm/s ] 500 500 500

amax 2

rotary table [°/s ] 300 300 300

1: according to DIN EN ISO 10360-5 / Limit value single stylus probing error PFTU, MPE 3: according to DIN EN ISO 10360-4 / Limit value scanning probing error MPETHP

• SP600M with stylus Ø 5 x 50 mm • SP600M with stylus Ø 5 x 50 mm

• SP25M with module SM25-1 and stylus Ø 4 x 30 mm • SP25M with module SM25-1 and stylus Ø 4 x 30 mm

• SP80H with stylus Ø 5 x 50 mm • SP80H with stylus Ø 5 x 50 mm

2: according to DIN EN ISO 10360-2 / Limit value length measurement error EL, MPE

• SP600M with stylus Ø 5 x 50 mm * special probe required

• SP25M with module SM25-1 and stylus Ø 4 x 30 mm ** with tailstock, without control cabinet and without workpiece

• SP80H with stylus Ø 5 x 50 mm

Table 1: Technical Data GT 300 | GT 450 | GT 650

TDA_GT300-450-650_07-2021_EN Page 3 of 8

Page4

Technical Data

GT 300 | GT 450 | GT 650

Measurement reference temperature GT 300 GT 450 GT 650

Measuring room conditions

Temperature range 18 °C to 22 °C

for length measurement error EL, MPE K

(3D measurement) per hour 1 /h

K

spatial 1 /m

K

per day 2 /d

Temperature range for gear measurement Temperature range according to VDI/VDE 2612/2613, Group 1

Table 2: Measurement reference temperature GT 300 | GT 450 | GT 650

Operating conditions GT 300 GT 450 GT 650

Ambient temperature 15 °C to 30 °C

Relative humidity 40 % to 70 % (non-condensing)

Max. height of the installation site 2000 m over sea level

Electrical connection values Electricity quality according to EN 60204-1:2019-06

Single phase alternating current (1P+N+PE), 115/230 V (±10 %), 50/60 Hz

Electrical power consumption max. 1000 VA

Pneumatic connection values Supply pressure min. 6 bar, max. 10 bar, pre-filtered

with elastomer

vibration damping system Compressed air quality according to DIN ISO 8573-1:2010 [1:3:1]

Air consumption Ø 69 Nl/min Ø 69 Nl/min Ø 69 Nl/min

max. 69 Nl/min max. 69 Nl/min max. 69 Nl/min

Pneumatic connection values Supply pressure min. 6 bar, max. 10 bar, pre-filtered

with pneumatic

vibration damping system Compressed air quality according to DIN ISO 8573-1:2010 [1:3:1]

(optional) Air consumption Ø 85 Nl/min Ø 85 Nl/min Ø 85 Nl/min

max. 100 Nl/min max. 100 Nl/min max. 100 Nl/min

Table 3: Operating conditions GT 300 | GT 450 | GT 650

Specification GT 300 GT 450 GT 650 Unit

Measuring range X 300 450 650 mm

Y 225 300 400 mm

Z 500 650 650 800 650 800 mm

Rotary table diameter C2 Ø 200 Ø 300 Ø 400 mm

Max. workpiece diameter C1 Ø 300 Ø 450 Ø 650 mm

Tailstock G 650 900 650 900 650 900 1200 650 900 1200 900 1200 900 1200 mm

Machine foot print Length L1 1183 1388 1678 mm

(without control cabinet)

Width B1 1079 1229 1429 mm

Height H3 1843 1993 1993 2143 1993 2143 mm

Height H2 1962 2212 1962 2212 1962 2212 2512 1962 2212 2512 2212 2512 2212 2512 mm

Control cabinet (L x W x H) 900 x 770 x 1130 900 x 770 x 1130 900 x 770 x 1130 mm

Required space Length L4 2533 2758 3058 mm

(machine foot print incl.

control cabinet, working and Width B3 2390 2540 2740 mm

danger area) Height H1 2343 2343 2493 2493 2493 2493 2562 2643 2643 2643 2493 2562 2643 2643 mm

Table 4: Dimensions GT 300 | GT 450 | GT 650

Page 4 of 8 TDA_GT300-450-650_07-2021_EN

Page5

Technical Data

GT 300

Figure 1: Layout GT 300

TDA_GT300-450-650_07-2021_EN Page 5 of 8

Page6

Technical Data

GT 450

Figure 2: Layout GT 450

Page 6 of 8 TDA_GT300-450-650_07-2021_EN

Page7

Technical Data

GT 650

Figure 3: Layout GT 650

TDA_GT300-450-650_07-2021_EN Page 7 of 8

Page8

INNOVATION MEETS TRADITION

The WENZEL Group is a market leader in innovative power generation and medicine. WENZEL looks at today

Metrology. WENZEL offers a comprehensive product on an installed base of more than 10,000 machines

portfolio in the fields of Coordinate Metrology, worldwide. Subsidiaries and agencies in more than 50

Computed Tomography and Optical High Speed countries support sales and provide after -sales service for

Scanning. The technology of WENZEL is used in all our customers. The WENZEL Group today employs more

industries, including the automotive sector, aeronautics, than 600 people.

YOUR LOCAL CONTACT PERSON

WENZEL GROUP GMBH & CO. KG

Werner-Wenzel-Straße

97859 Wiesthal

Phone: +49 6020 201-0

E-Mail: info@wenzel-group.com

We are there for you worldwide. You can find our subsidiaries, sales and service

partners at www.wenzel-group.com.

W ENZEL Group GmbH & Co. KG | Werner-Wenzel-Straße | 97859 Wiesthal | Germany

Phone: +49 6020 201-0 | Fax: +49 6020 201-1999 | E-Mail: info@wenzel-group.com www.wenzel-group.com

TDA_GT300-450-650_07-2021_EN | © 2021 WENZEL Group GmbH & Co. KG

Subject to changes in design and specification without prior notice.