1/8ページ

ダウンロード(10.1Mb)

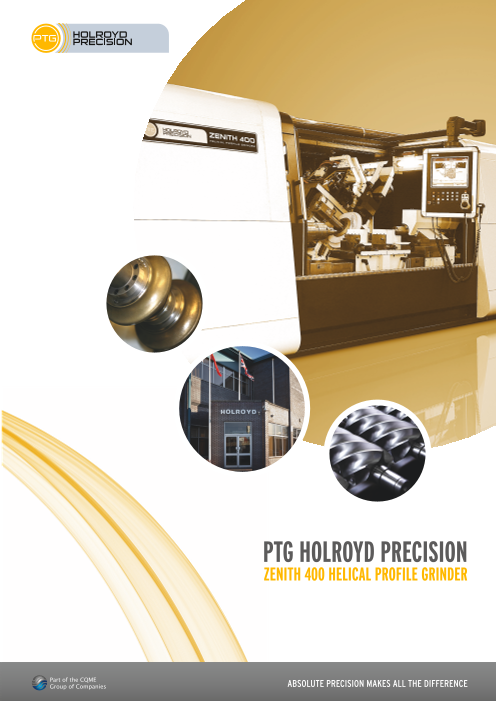

イギリス HOLROYD(ホルロイド)社製 ヘリカルプロファイル研削盤 ZENITH400をご紹介

ヘリカルプロファイル研削盤ZENITH400は、HOLROYD社のプロファイル研削盤技術の頂点に位置する機械です。

最大ワークサイズ420mmの研削能力があり、最大ワーク重量が700kgと非常に高い汎用性を持っています。

"高精度なヘリカルプロファイル研削盤であることに加え、ZENITH400は高い切り屑除去率を実現し、

生産率と精度は個々の製造要件に合わせて調整可能です。

"HPMS(Holroydプロファイルマネージメントシステム)は、スクリューローター、バキュームスクリュー、ポンプスクリュー用の幅広いヘリカルプロファイルを開発するための一連のサブプログラムで構成されており、当社の研削技術のいくつかでオプションとして提供されています。

HPMSは、製造段階でのプロファイルの制御や、操作時の噛み合わせ条件の最適化を支援するためにも使用できます。

関連メディア

このカタログについて

| ドキュメント名 | イギリス HOLROYD(ホルロイド)社製 ヘリカルプロファイル研削盤 ZENITH400 |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 10.1Mb |

| 取り扱い企業 | 株式会社シーケービー (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

A world oF AbsoluTe Precision

PTG Holroyd Precision has a global network of sales agents.

To find your nearest representative, please visit:

holroyd.com

Holroyd Precision Ltd

Harbour Lane North PTG Holroyd Precision

Milnrow, Rochdale

Lancashire OL16 3LQ ZeniTH 400 HelicAl ProFile Grinder

FM 09259 United Kingdom

PTG operate a quality management system

which complies with the requirements of

BS EN ISO 9001;2008 Tel: +44 (0)1706 526590

Fax: +44 (0)1706 353350

Holroyd Precision Limited.

Registered in England and Wales. Email: info@holroyd.com

Registration No. 05844176

www.holroyd.com Part of the CQME

Group of Companies ABSOLUTE PRECISION MAKES ALL THE DIFFERENCE

PTG-ZENITH-8P-A4-BROCHURE-FINAL-ENGLISH-2015.indd 1-2 08/02/2015 21:04

Page2

ZeniTH 400

Absolute precision in helical profile grinding

Welcome to the future of helical profile grinding. Welcome to the

Zenith 400 from Holroyd Precision Limited.

The Holroyd name has long been a benchmark for superior, ultra-precise

grinding solutions amongst screw compressor rotor manufacturers.

Now, with the Zenith 400, we bring even greater levels of capability,

flexibility and efficiency to your manufacturing strategies.

Developed to precision grind components weighing up to 700kg,

and measuring up to 420mm in diameter and 2.2 metres in length,

the Zenith 400 provides exceptional versatility.

In addition to being a high-precision, helical profile grinding machine,

the Zenith 400 also offers high stock removal rates and aggressive semi-

finishing, with production rates and accuracies tailored to your precise needs.

The Zenith 400 is also the only helical profile grinding machine to offer

all three grinding technologies: aluminium oxide, ‘diamond hard’ plated

CBN (Cubic Boron Nitride) and vitrified, dressable CBN.

To see the Zenith 400 in action, visit: PTG Holroyd on YouTube

www.holroyd.com

PTG Key features

n Accelerated and simplified set-up n 2.2-metre maximum n Holroyd 3D CMM component

The first name in precision component length scanning probe with fully automatic

n Fully automated grinding wheel

compensation feedback for

balancing system n Powerful, menu-driven touch

class-leading accuracy

Holroyd Precision Limited is a member of the Precision Technologies Group screen programming for

n Three grinding wheel options:

(PTG) – an organisation that has established itself at the forefront of high- exceptional ease of use n Advanced in-process dressing

vitrified Al2O3, vitrified CBN and

precision machine tool design, build and supply. systems

plated CBN n High stock removal rates,

aggressive semi-finishing and n Engineered for complete

The PTG range includes ultra-precision grinding machines for rotor, thread n 420mm maximum diameter

precision fine finishing integration with automated parts

and gear operations; rotor milling machines; heavy duty lathes; deep grinding capability

handling systems

hole boring machines; friction stir welding machines and special purpose n Twin operating functions: simplified

n 700kg maximum component weight

machine tools for the manufacture of precision components. production or development

Holroyd Profile Management System (HPMS)

An industry-leading development tool, HPMS consists of

a family of sub-programs that allow the manipulation and

analysis of profiles for Holroyd profile grinders.

HPMS is used in the development and control of a wide

range of helical profiles for screw rotors, vacuum and

pump screws.

Available as an additional option with the Zenith 400,

HPMS can also be used to assist control of the profile

during production.

Part of the CQME

Group of Companies ABSOLUTE PRECISION MAKES ALL THE DIFFERENCE

PTG-ZENITH-8P-A4-BROCHURE-FINAL-ENGLISH-2015.indd 3-4 08/02/2015 21:04

Page3

ZeniTH 400

Absolute precision in helical profile grinding

Welcome to the future of helical profile grinding. Welcome to the

Zenith 400 from Holroyd Precision Limited.

The Holroyd name has long been a benchmark for superior, ultra-precise

grinding solutions amongst screw compressor rotor manufacturers.

Now, with the Zenith 400, we bring even greater levels of capability,

flexibility and efficiency to your manufacturing strategies.

Developed to precision grind components weighing up to 700kg,

and measuring up to 420mm in diameter and 2.2 metres in length,

the Zenith 400 provides exceptional versatility.

In addition to being a high-precision, helical profile grinding machine,

the Zenith 400 also offers high stock removal rates and aggressive semi-

finishing, with production rates and accuracies tailored to your precise needs.

The Zenith 400 is also the only helical profile grinding machine to offer

all three grinding technologies: aluminium oxide, ‘diamond hard’ plated

CBN (Cubic Boron Nitride) and vitrified, dressable CBN.

To see the Zenith 400 in action, visit: PTG Holroyd on YouTube

www.holroyd.com

PTG Key features

n Accelerated and simplified set-up n 2.2-metre maximum n Holroyd 3D CMM component

The first name in precision component length scanning probe with fully automatic

n Fully automated grinding wheel

compensation feedback for

balancing system n Powerful, menu-driven touch

class-leading accuracy

Holroyd Precision Limited is a member of the Precision Technologies Group screen programming for

n Three grinding wheel options:

(PTG) – an organisation that has established itself at the forefront of high- exceptional ease of use n Advanced in-process dressing

vitrified Al2O3, vitrified CBN and

precision machine tool design, build and supply. systems

plated CBN n High stock removal rates,

aggressive semi-finishing and n Engineered for complete

The PTG range includes ultra-precision grinding machines for rotor, thread n 420mm maximum diameter

precision fine finishing integration with automated parts

and gear operations; rotor milling machines; heavy duty lathes; deep grinding capability

handling systems

hole boring machines; friction stir welding machines and special purpose n Twin operating functions: simplified

n 700kg maximum component weight

machine tools for the manufacture of precision components. production or development

Holroyd Profile Management System (HPMS)

An industry-leading development tool, HPMS consists of

a family of sub-programs that allow the manipulation and

analysis of profiles for Holroyd profile grinders.

HPMS is used in the development and control of a wide

range of helical profiles for screw rotors, vacuum and

pump screws.

Available as an additional option with the Zenith 400,

HPMS can also be used to assist control of the profile

during production.

Part of the CQME

Group of Companies ABSOLUTE PRECISION MAKES ALL THE DIFFERENCE

PTG-ZENITH-8P-A4-BROCHURE-FINAL-ENGLISH-2015.indd 3-4 08/02/2015 21:04

Page4

sPeciFicATion

General information

Workhead Dressing Unit

n Torque motors and roller bearings on n CNC controlled wheel dresser

rotary axes

n Operates using two diamond dressing disks

n Large capacity bore

n Automatic wheel profile calculation for each

n Integral work ejector system dress cycle

n Optional ultrasonic system to detect grinding

Tailstock wheel contact

n Full movement control through CNC

n Optional rough wheel dressing system

Work Loading

Automatic Inspection Station

n Built-in non-contact, high-accuracy

inductive sensors for checking journal Renishaw SP80 scanning probe; resolution 1

run-outs micrometre in X, Y and Z axes for measurement

of the following features:

Grinding Spindle n Flute position

n High-efficiency, high-speed spindle n Shaft run out

n Interchangeable arbour system with n Profile depth

HSK interface

n Helical lead

n Radio Frequency Information tags for

accelerated set-up n Profile scan

n Vitrified Al2O3, vitrified CBN or CNC

electro-plated CBN wheels

n Holroyd X8 8-axis CNC system

n Fully automatic machine

balancing system n Advanced touch screen interface

n Optional ultrasonic contact detection n Integrated profile management system

of dressing disc to grinding wheel n Intuitive dialogue programming option

(ensures full dress of wheel) (Wizard)

Grinding wheel options

Dressable Aluminium Oxide Vitrified Cubic Boron Nitride (CBN)

n High levels of profile accuracy n Extended wheel life

n Dress with the correct profile for every n Highly cost-effective

component

n Dressable to achieve the accuracy required

n The ‘low cost’ solution

n Only infrequent dressing needed

n Suited to ‘high-variety’ rotor production

Electro-Plated Cubic Boron Nitride (CBN)

n Suited to volume production

n Dressing time is eliminated

n Profile is ‘fixed’ for the lifetime of the wheel

n Automatic compensation for wheel wear

Part of the CQME

Group of Companies ABSOLUTE PRECISION MAKES ALL THE DIFFERENCE

PTG-ZENITH-8P-A4-BROCHURE-FINAL-ENGLISH-2015.indd 5-6 08/02/2015 21:04

Page5

sPeciFicATion

General information

Workhead Dressing Unit

n Torque motors and roller bearings on n CNC controlled wheel dresser

rotary axes

n Operates using two diamond dressing disks

n Large capacity bore

n Automatic wheel profile calculation for each

n Integral work ejector system dress cycle

n Optional ultrasonic system to detect grinding

Tailstock wheel contact

n Full movement control through CNC

n Optional rough wheel dressing system

Work Loading

Automatic Inspection Station

n Built-in non-contact, high-accuracy

inductive sensors for checking journal Renishaw SP80 scanning probe; resolution 1

run-outs micrometre in X, Y and Z axes for measurement

of the following features:

Grinding Spindle n Flute position

n High-efficiency, high-speed spindle n Shaft run out

n Interchangeable arbour system with n Profile depth

HSK interface

n Helical lead

n Radio Frequency Information tags for

accelerated set-up n Profile scan

n Vitrified Al2O3, vitrified CBN or CNC

electro-plated CBN wheels

n Holroyd X8 8-axis CNC system

n Fully automatic machine

balancing system n Advanced touch screen interface

n Optional ultrasonic contact detection n Integrated profile management system

of dressing disc to grinding wheel n Intuitive dialogue programming option

(ensures full dress of wheel) (Wizard)

Grinding wheel options

Dressable Aluminium Oxide Vitrified Cubic Boron Nitride (CBN)

n High levels of profile accuracy n Extended wheel life

n Dress with the correct profile for every n Highly cost-effective

component

n Dressable to achieve the accuracy required

n The ‘low cost’ solution

n Only infrequent dressing needed

n Suited to ‘high-variety’ rotor production

Electro-Plated Cubic Boron Nitride (CBN)

n Suited to volume production

n Dressing time is eliminated

n Profile is ‘fixed’ for the lifetime of the wheel

n Automatic compensation for wheel wear

Part of the CQME

Group of Companies ABSOLUTE PRECISION MAKES ALL THE DIFFERENCE

PTG-ZENITH-8P-A4-BROCHURE-FINAL-ENGLISH-2015.indd 5-6 08/02/2015 21:04

Page6

MAcHine ProGrAMMinG sPindle sPeed Torque/Power

n Profile input and measurement in either axial or transverse planes 500 90

Mmax Pmax

n Suitable for rotor, worm or screw grinding 450 80

n Fully automatic programmable cycles, including:

400 70

• Dressing with full compensation for dressing disk wear

350

• Profile grinding, with optional probing and profile measurement 60

with full feedback for in-cycle profile adjustment 300

• Repeat cycles with nesting up to 99 times 50

250 PN

n Grinding during forward and/or return stroke 40

n Component indexing at left-hand, right-hand or both ends of 200 MN

grinding stroke 30

150

n Linear lead adjustment via CNC input

100 20

n Programmable constant peripheral grinding wheel speed, based

on actual wheel diameter 50 10

0 0

0 500 100 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 7000 7500

Speed [RPM]

insTAllATion diAGrAMs ZeniTH 400 sPeciFicATion

WORKPIECE GRINDING HEAD AND WORKSLIDE

Maximum diameter Ø 420mm Range of Feedrate (along the Helix) 25mm to 4000mm/min

Maximum diameter with component loading table Ø 400mm Rapid traverse rate 15000 mm/min

Swingover worktable (diameter) Ø 530mm Maximum wheel diameter Ø 500mm

Minimum diameter Zero Minimum wheel diameter to root of profile Ø 250mm

Maximum component weight 700kg Maximum dressable profile depth 100mm

Maximum component traverse 1400mm Wheel shift axis stroke 260mm

Maximum lead angle from vertical -90°/+90° Maximum wheel width on machine spindle 200mm

Maximum component length - the distance between

2200mm Maximum dressable wheel width (depends on profile) 200mm

work spindle centre and retracted tailstock centre

Minimum distance from work spindle centre to

200mm Wheel speed (infinitely variable) 1000 to 6500 RPM

retracted tailstock centre

WORKHEAD Maximum in-feed rate 7500mm/min

Maximum distance from component centre line to centre

Width Diameter of bore in spindle Ø 130mm 600mm

line of grinding wheel

Minimum distance from component centre line to centre

Spindle speed (infinitely variable) 0,5 to 50 RPM 200mm

line of grinding wheel

MOTOR POWER GUARANTEED MACHINE ACCURACIES

DIMENSIONS Wheel spindle 42kW In-feed position repeatability 0,002mm

Model Width Depth Height - - Divide accuracy of machine on 250mm (80 µ rad) 0,010mm

Zenith 400 6415mm 4620mm 3335mm - - Lead linearity of machine in 300mm 0,003mm

Part of the CQME

Group of Companies ABSOLUTE PRECISION MAKES ALL THE DIFFERENCE

PTG-ZENITH-8P-A4-BROCHURE-FINAL-ENGLISH-2015.indd 7-8 08/02/2015 21:04

Depth

Height

Torque [Nm]

Power [kW]

Page7

MAcHine ProGrAMMinG sPindle sPeed Torque/Power

n Profile input and measurement in either axial or transverse planes 500 90

Mmax Pmax

n Suitable for rotor, worm or screw grinding 450 80

n Fully automatic programmable cycles, including:

400 70

• Dressing with full compensation for dressing disk wear

350

• Profile grinding, with optional probing and profile measurement 60

with full feedback for in-cycle profile adjustment 300

• Repeat cycles with nesting up to 99 times 50

250 PN

n Grinding during forward and/or return stroke 40

n Component indexing at left-hand, right-hand or both ends of 200 MN

grinding stroke 30

150

n Linear lead adjustment via CNC input

100 20

n Programmable constant peripheral grinding wheel speed, based

on actual wheel diameter 50 10

0 0

0 500 100 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 7000 7500

Speed [RPM]

insTAllATion diAGrAMs ZeniTH 400 sPeciFicATion

WORKPIECE GRINDING HEAD AND WORKSLIDE

Maximum diameter Ø 420mm Range of Feedrate (along the Helix) 25mm to 4000mm/min

Maximum diameter with component loading table Ø 400mm Rapid traverse rate 15000 mm/min

Swingover worktable (diameter) Ø 530mm Maximum wheel diameter Ø 500mm

Minimum diameter Zero Minimum wheel diameter to root of profile Ø 250mm

Maximum component weight 700kg Maximum dressable profile depth 100mm

Maximum component traverse 1400mm Wheel shift axis stroke 260mm

Maximum lead angle from vertical -90°/+90° Maximum wheel width on machine spindle 200mm

Maximum component length - the distance between

2200mm Maximum dressable wheel width (depends on profile) 200mm

work spindle centre and retracted tailstock centre

Minimum distance from work spindle centre to

200mm Wheel speed (infinitely variable) 1000 to 6500 RPM

retracted tailstock centre

WORKHEAD Maximum in-feed rate 7500mm/min

Maximum distance from component centre line to centre

Width Diameter of bore in spindle Ø 130mm 600mm

line of grinding wheel

Minimum distance from component centre line to centre

Spindle speed (infinitely variable) 0,5 to 50 RPM 200mm

line of grinding wheel

MOTOR POWER GUARANTEED MACHINE ACCURACIES

DIMENSIONS Wheel spindle 42kW In-feed position repeatability 0,002mm

Model Width Depth Height - - Divide accuracy of machine on 250mm (80 µ rad) 0,010mm

Zenith 400 6415mm 4620mm 3335mm - - Lead linearity of machine in 300mm 0,003mm

Part of the CQME

Group of Companies ABSOLUTE PRECISION MAKES ALL THE DIFFERENCE

PTG-ZENITH-8P-A4-BROCHURE-FINAL-ENGLISH-2015.indd 7-8 08/02/2015 21:04

Depth

Height

Torque [Nm]

Power [kW]

Page8

A world oF AbsoluTe Precision

PTG Holroyd Precision has a global network of sales agents.

To find your nearest representative, please visit:

holroyd.com

Holroyd Precision Ltd

Harbour Lane North PTG Holroyd Precision

Milnrow, Rochdale

Lancashire OL16 3LQ ZeniTH 400 HelicAl ProFile Grinder

FM 09259 United Kingdom

PTG operate a quality management system

which complies with the requirements of

BS EN ISO 9001;2008 Tel: +44 (0)1706 526590

Fax: +44 (0)1706 353350

Holroyd Precision Limited.

Registered in England and Wales. Email: info@holroyd.com

Registration No. 05844176

www.holroyd.com Part of the CQME

Group of Companies ABSOLUTE PRECISION MAKES ALL THE DIFFERENCE

PTG-ZENITH-8P-A4-BROCHURE-FINAL-ENGLISH-2015.indd 1-2 08/02/2015 21:04