1/2ページ

ダウンロード(1004.7Kb)

レーザーを使用してのエンジンブロックボアの溶射前の下地処理を行う工法を紹介

サンドブラスト処理や工具を使用したメカニカルラフニング処理とは異なり、レーザーを使用し溶射前の下地処理を行う工法をご紹介します。

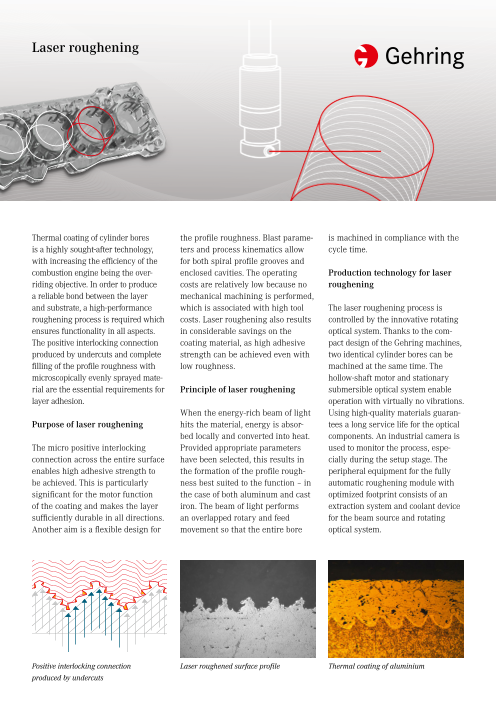

レーザーにより、ボア表面に細かな溝が形成され、溝の周囲は再凝固した細かなアルミが付着しアンダーカット形状を形成。

それらの再凝固した細かなアルミが次工程での溶射材と溶け合い固まり、より強固な密着となります。

レーザーラフニング後の溶射膜はスラスト方向、ラジアル方向のどちらも密着度が高く、方向性が無い事が特徴です。

本処理の利点として、メカニカルラフニングと比べ、溝を浅く小さくすることが出来き、次工程の溶射でコーティングの膜を薄くすることが出来き、溶射材の削減が可能でサイクルタイムの削減にも繋がります。

また、メカニカルラフニングで心配される工具の摩耗や欠け等の心配も無く、ツール交換に伴うツール代と交換の手間もかかりません。

ご興味ございましたらせひお問い合わせください。

このカタログについて

| ドキュメント名 | Gehring(ゲーリング)社 レーザーラフニング Laser Roughening |

|---|---|

| ドキュメント種別 | 事例紹介 |

| ファイルサイズ | 1004.7Kb |

| 取り扱い企業 | 株式会社シーケービー (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

Laser roughening

Thermal coating of cylinder bores the profile roughness. Blast parame- is machined in compliance with the

is a highly sought-after technology, ters and process kinematics allow cycle time.

with increasing the efficiency of the for both spiral profile grooves and

combustion engine being the over- enclosed cavities. The operating Production technology for laser

riding objective. In order to produce costs are relatively low because no roughening

a reliable bond between the layer mechanical machining is performed,

and substrate, a high-performance which is associated with high tool The laser roughening process is

roughening process is required which costs. Laser roughening also results controlled by the innovative rotating

ensures functionality in all aspects. in considerable savings on the optical system. Thanks to the com-

The positive interlocking connection coating material, as high adhesive pact design of the Gehring machines,

produced by undercuts and complete strength can be achieved even with two identical cylinder bores can be

filling of the profile roughness with low roughness. machined at the same time. The

microscopically evenly sprayed mate- hollow-shaft motor and stationary

rial are the essential requirements for Principle of laser roughening submersible optical system enable

layer adhesion. operation with virtually no vibrations.

When the energy-rich beam of light Using high-quality materials guaran-

Purpose of laser roughening hits the material, energy is absor- tees a long service life for the optical

bed locally and converted into heat. components. An industrial camera is

The micro positive interlocking Provided appropriate parameters used to monitor the process, espe-

connection across the entire surface have been selected, this results in cially during the setup stage. The

enables high adhesive strength to the formation of the profile rough- peripheral equipment for the fully

be achieved. This is particularly ness best suited to the function – in automatic roughening module with

significant for the motor function the case of both aluminum and cast optimized footprint consists of an

of the coating and makes the layer iron. The beam of light performs extraction system and coolant device

sufficiently durable in all directions. an overlapped rotary and feed for the beam source and rotating

Another aim is a flexible design for movement so that the entire bore optical system.

Positive interlocking connection Laser roughened surface profile Thermal coating of aluminium

produced by undercuts

Page2

Applications of laser roughening Advantages of laser roughening

Our many years of previous expe- causing a deterioration in the quality • High adhesive strength

rience with engines from different at the overflow ducts. • Saving on coating material thanks

performance classes show that to both low roughness and high

laser roughening is an innovative Localized, targeted laser roughening adhesive capability

and economical process for modern is possible for selective coating in • Suitable for cast iron and

series production. Laser roughening the piston‘s running area and also at aluminum

can be used as a pretreatment for the top deck chamfer. • Use with two-stroke engines

all conventional thermal coating • High level of flexibility in the form

processes. The use of powerful beam Gehring has extensive expertise in of the structural topography

sources makes it possible to machi- the entire „laser roughening, coating thanks to parameterization

ne aluminum alloys as well as cast and honing“ process chain. Harmo- • Suitable for all thermal coatings

iron. The special potential offered by nized process steps result in low- • Laser roughening is tested in

laser roughening becomes apparent friction, wear-resistant cylinder series production

when machining two-stroke engines. surfaces. • Economical series operations

In this process, the beam can come because no tool costs are incurred

out of the bore and then re-enter

the bore, where it remains, without

Spiral profile grooves Individually enclosed cavities Rotating optical system for laser

roughening

A trusted technology leader with extensive experience and global presence!

Innovative technology combined with an environmental focus that sets us apart from the rest.

Gehring Technologies GmbH • Gehringstrasse 28 • D-73760 Ostfildern

Phone: +49 711/3405-0 • Telefax: +49 711/3405-295 • info@gehring-group.com • www.gehring-group.com

www.dege-kommunikation.de 08/2018