1/2ページ

ダウンロード(171.3Kb)

大型部品向けスタンドアローンタイプレーザー樹脂溶着装置

現在日本語カタログ準備中!!

LPKF PowerWeld 6600は中~大サイズの部品の生産向けに設計されています。秀逸な装置のコンセプトで簡単な操作とシンプルなメンテナンスができるようになっています。校正用スキャンフィールドがあるのでプロセスデータは複数のPowerWeld 6600レーザーシステムの間で何の調整をすることなく使用することができます。システムはお客様自身のMESとの通信にも対応しておりますので、さらに上層の制御システムへも滞りなくインテグレートできます。

可変サーボクランプ技術でクランプ圧力のとても正確な制御を実現します。用途特有の圧力プロファイルが、二つのクランプ治具を使用するときなどに複雑なプロセスを実現することを助けます。溶着エリアは500mmx350mmなので、大きなサイズの部品の生産や複数の部品の生産に向いています。二つのクランプ治具を使用するときには、システムが二つの沈み込み量を分離してモニタリングします。

関連メディア

このカタログについて

| ドキュメント名 | 大型部品向けレーザー樹脂溶着装置 LPKF PowerWeld 6600 |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 171.3Kb |

| 登録カテゴリ | |

| 取り扱い企業 | LPKF Laser&Electronics株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

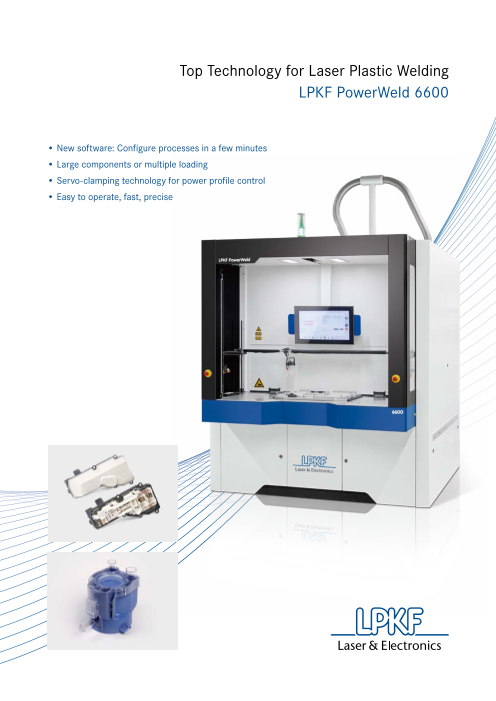

Top Technology for Laser Plastic Welding

LPKF PowerWeld 6600

• New software: Configure processes in a few minutes

• Large components or multiple loading

• Servo-clamping technology for power profile control

• Easy to operate, fast, precise

Page2

High-Speed Laser Welding – LPKF PowerWeld 6600 for

the Economical Series Production of Large Components

Cutting-edge technology for the leading joining method: The LPKF PowerWeld 6600 makes the laser

plastic welding of large components even more efficient and flexible. It combines short cycle time

with high weld quality.

The LPKF PowerWeld 6600 is designed for the With a laser power of up to 400 W, and a fast scanner

production of medium-sized and large series. system, the LPKF PowerWeld 6600 is optimized for

The sophisticated machine concept is configured for short cycle times. The integrated time-travel moni-

easy operation and simple maintenance. Thanks to toring of the melt travel provides reliable data on the

the calibrated scanning field, the process data can welding quality. Additional monitoring methods can

be swapped between PowerWeld 6600 laser systems also be integrated.

without the need for any adjustments. The system is

prepared for communication with the client’s own MES, The machine is controlled by a Soft PLC – making

and inte grates itself seamlessly into the upper-level this system future-proof. The interface to the operator

production control system. is provided by the intuitively operated LPKF WeldPro

software. It visualizes all the process-relevant data,

The variable servo-clamping technology ensures and is optimized for touch operation.

extremely precise control of the clamping forces.

Application specific force profiles help realize sophisti- The laser process is set up using the LPKF ProSeT 3D

cated processes, such as when using double clamping processing software. This reads the data formats

tools. The working area measuring 500 mm x 350 mm of the most important CAD programs, and previous

allows the production of large components, or the LPKF welding processes. It takes only a few minutes

processing of several components per load. When to create an optimized welding contour. A number of

using double clamping equipment the system monitors intelligent program routines determine the fastest

the melt travel of the two parts separately. cycle times, take clamping tools into account, and

can even reduce complex contours to simple curve

progressions – with a simple mouse-click.

LPKF PowerWeld 6600

Laser class 1

Laser parameters Power: 300 W and 400 W; spot: 1.8 mm – 6.8 mm

Clamping pressure range Up to 4 kN

Max. component size (X/Y) Single clamping: 500 mm x 350 mm; Double clamping: 220 mm x 350 mm

Welding system dimensions (B x T x H) 1750 mm x 2300 mm x 2310 mm

Power supply 400 V, 16 A, max. 3 kW

Weight 2200 kg

Compressed air 4.5 bar – 10 bar

Ambient temperature 18 °C – 35 °C

LPKF Laser & Electronics AG (Headquarters) LPKF WeldingQuipment GmbH

Osteriede 7 30827 Garbsen Germany Alfred-Nobel-Str. 55 – 57 90765 Fürth Germany

Phone +49 (5131) 7095-0 info@lpkf.com www.lpkf.com Phone +49 (911) 669859-0 info.laserwelding@lpkf.com www.lpkf.com

LPKF AG, 10068439-101016-EN Photos may also show optional accessories. Specifications subject to change without prior notice. www.jenko-sternberg.de