1/2ページ

ダウンロード(392.4Kb)

特許取得済み最先端技術で3D形状レーザー樹脂溶着

現在日本語カタログ準備中!!

LPKF PowerWeld3D 8000は大サイズの樹脂部品の量産向けに設計されています。例えば、自動車分野において徐々に使用されることが多くなってきています。A、B、Cピラーや、フェンダー、サンルーフ、そして特にテールランプの生産に利用されます。

この装置のユニークな特長はウォブル溶着です。準同時溶着工法ではありますが、それに加えて溶着線が進む方向に対して直行するレーザービームが重ねられています。これにより溶着線の幅を1-5㎜まで容易に調整できます。この場合温度は一定に保たれます。こうしてとても短い生産サイクルで強固な溶着プロセスが可能となります。クランプ用の8つのサーボドライブにより溶着中に局所的なずれを修正することも可能です。この装置は大きなサイズの部品の溶着に向いており、最大寸法 1000 mm x 750 mm x 400 mmに対応しています。沈み込み量モニタリングにより品質も担保されます。

関連メディア

このカタログについて

| ドキュメント名 | 大型3D形状部品向けレーザー樹脂溶着装置 PowerWeld3D 8000 |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 392.4Kb |

| 登録カテゴリ | |

| 取り扱い企業 | LPKF Laser&Electronics株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

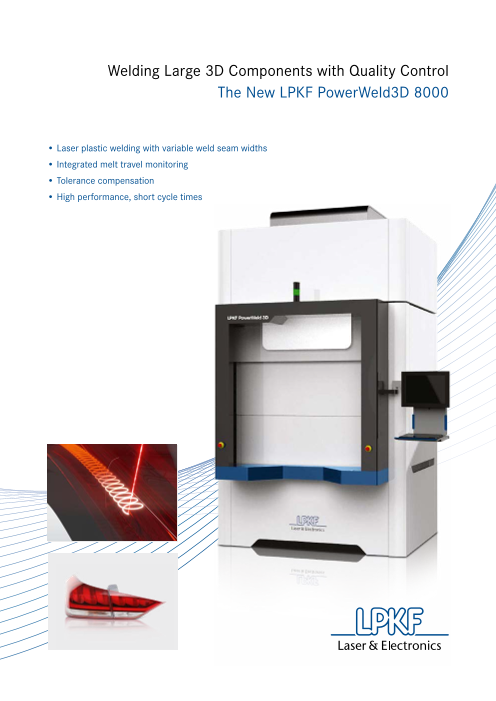

Welding Large 3D Components with Quality Control

The New LPKF PowerWeld3D 8000

• Laser plastic welding with variable weld seam widths

• Integrated melt travel monitoring

• Tolerance compensation

• High performance, short cycle times

Page2

Laser Plastic Welding in a New Dimension

The LPKF PowerWeld3D 8000 is a high-performance welding system for large 3D components up to

1000 mm x 750 mm using an innovative technology. Especially remarkable is the flexibility in the Z

direction: This welding system can handle height differences of up to 400 mm, as well as controlling

the welding process with an integrated melt travel monitoring system.

The LPKF PowerWeld3D 8000 is designed for the 8000 is supplied with the intuitively operated WeldPro

series production of large plastic components, which system software, and LPKF ProSeT 3D for fast project

for example are increasingly used in the automotive set up. Both programs automatically control the wobble

sector: A, B and C pillars, fenders, sun roofs, and function, and determine uniform energy inputs, even

especially, tail lights. when the height of the weld parts changes.

A unique feature of this system is the wobble welding: The experts at the LPKF Application Center in Fürth,

In this quasi-simultaneous method, additional Germany, engage potential customers by offering to

amplitudes are superimposed onto the laser beam process custom samples.

orthogonal to the feed direction. This allows easy

adjustment of the width of the weld seam between

1 mm and 5 mm – which have a particularly homo-

geneous temperature distribution. This leads to a

very short cycle time, and a robust process. Eight

independent servo drives for clamping can compensate

for local tolerances during welding. The system is

capable of welding large components with maximum

dimensions of 1000 mm x 750 mm x 400 mm

(X/Y/Z), and the quality is safeguarded by melt travel

monitoring.

The LPKF PowerWeld3D 8000 is controlled by a Soft

PLC. This enhances flexibility and simplifies system

connection to the client’s own MES. The PowerWeld3D The variable wobble contour produces a homogeneous weld seam

LPKF PowerWeld3D 8000

Laser class 1

Laser parameters Power: 400 W; spot: 1 mm – 5 mm

Clamping pressure range Up to 20 kN

Max. working area (W x D x H) 1000 mm x 750 mm x 400 mm

Welding machine dimensions (W x D x H) 1800 mm x 1700 mm x 3600 mm

Power supply 400 V, 32 A

Compressed air 6 bar

Weight ~ 2500 kg

Ambient temperature 18 °C – 35 °C

LPKF Laser & Electronics AG (Headquarters) LPKF WeldingQuipment GmbH

Osteriede 7 30827 Garbsen Germany Alfred-Nobel-Str. 55 – 57 90765 Fürth Germany

Phone +49 (5131) 7095-0 info@lpkf.com www.lpkf.com Phone +49 (911) 669859-0 info.laserwelding@lpkf.com www.lpkf.com

LPKF AG, 10068437-101016-EN Photos may also show optional accessories. Specifications subject to change without prior notice. www.jenko-sternberg.de