1/25ページ

ダウンロード(3.9Mb)

低可搬ロボットの総合カタログ

このカタログについて

| ドキュメント名 | KUKA産業用ロボット 低可搬重量 |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 3.9Mb |

| 取り扱い企業 | KUKA Japan株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

Industrial robotics�low payloads

EN

Page2

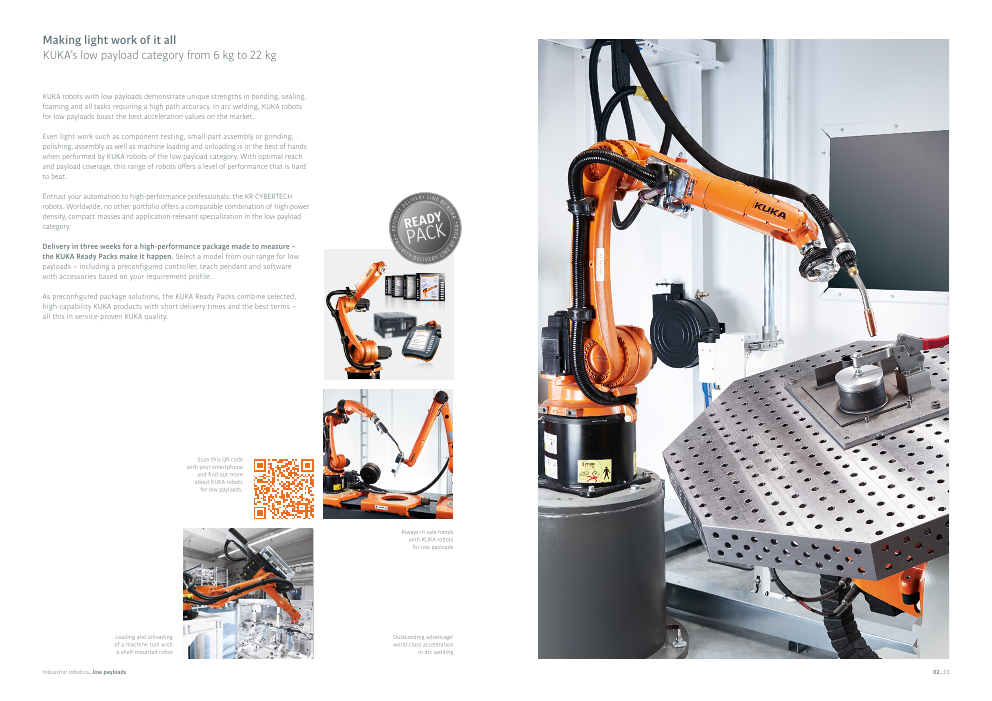

Making light work of it all

KUKA’s low payload category from 6 kg to 22 kg

KUKA robots with low payloads demonstrate unique strengths in bonding, sealing,

foaming and all tasks requiring a high path accuracy. In arc welding, KUKA robots

for low payloads boast the best acceleration values on the market.

Even light work such as component testing, small-part assembly or grinding,

polishing, assembly as well as machine loading and unloading is in the best of hands

when performed by KUKA robots of the low payload category. With optimal reach

and payload coverage, this range of robots offers a level of performance that is hard

to beat.

Entrust your automation to high-performance professionals: the KR CYBERTECH

robots. Worldwide, no other portfolio offers a comparable combination of high power

density, compact masses and application-relevant specialization in the low payload

category.

Delivery in three weeks for a high-performance package made to measure –

the KUKA Ready Packs make it happen. Select a model from our range for low

payloads – including a preconfigured controller, teach pendant and software

with accessories based on your requirement profile.

As preconfigured package solutions, the KUKA Ready Packs combine selected,

high-capability KUKA products with short delivery times and the best terms –

all this in service-proven KUKA quality.

Scan this QR code

with your smartphone

and find out more

about KUKA robots

for low payloads.

Always in safe hands

with KUKA robots

for low payloads

Loading and unloading Outstanding advantage:

of a machine tool with world-class acceleration

a shelf-mounted robot in arc welding

Industrial robotics�low payloads 02�03

Page3

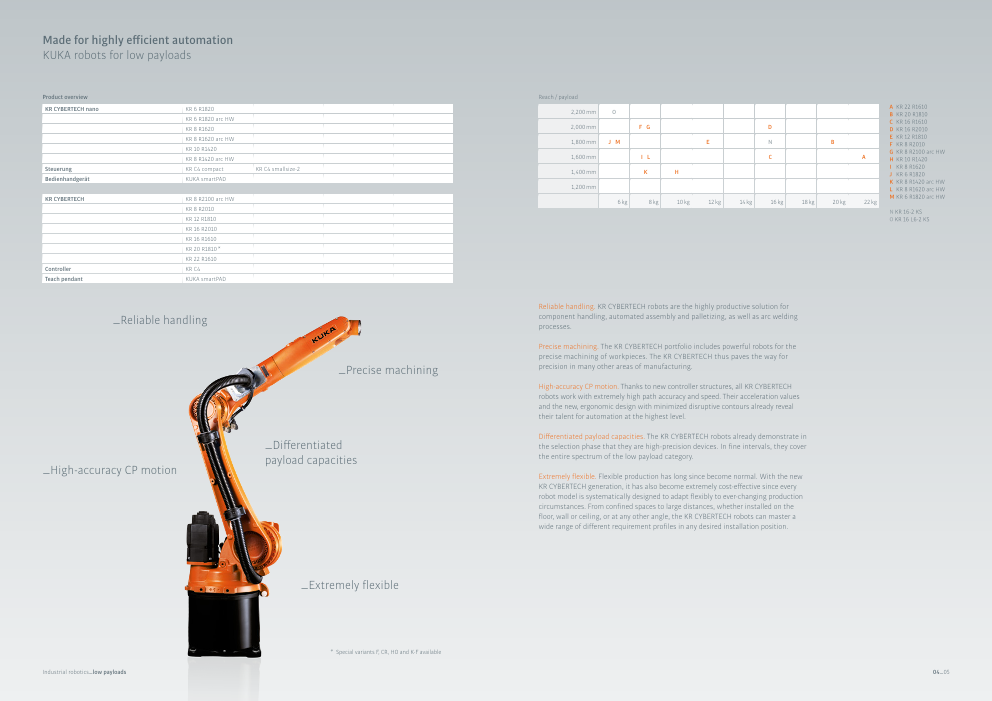

Made for highly efficient automation

KUKA robots for low payloads

Product overview Reach / payload

KR CYBERTECH nano KR 6 R1820 A KR 22 R16102,200 mm O B KR 20 R1810

KR 6 R1820 arc HW C KR 16 R1610

KR 8 R1620 2,000 mm F G D D KR 16 R2010

KR 8 R1620 arc HW E KR 12 R18101,800 mm J M E N B F KR 8 R2010

KR 10 R1420 G KR 8 R2100 arc HW

KR 8 R1420 arc HW 1,600 mm I L C A H KR 10 R1420

Steuerung KR C4 compact KR C4 smallsize-2 I KR 8 R16201,400 mm K H J KR 6 R1820

Bedienhandgerät KUKA smartPAD K KR 8 R1420 arc HW

1,200 mm L KR 8 R1620 arc HW

KR CYBERTECH KR 8 R2100 arc HW M KR 6 R1820 arc HW6 kg 8 kg 10 kg 12 kg 14 kg 16 kg 18 kg 20 kg 22 kg

KR 8 R2010 N KR 16-2 KS

KR 12 R1810 O KR 16 L6-2 KS

KR 16 R2010

KR 16 R1610

KR 20 R1810 *

KR 22 R1610

Controller KR C4

Teach pendant KUKA smartPAD

Reliable handling. KR CYBERTECH robots are the highly productive solution for

�Reliable handling component handling, automated assembly and palletizing, as well as arc welding

processes.

Precise machining. The KR CYBERTECH portfolio includes powerful robots for the

precise machining of workpieces. The KR CYBERTECH thus paves the way for

�Precise machining precision in many other areas of manufacturing.

High-accuracy CP motion. Thanks to new controller structures, all KR CYBERTECH

robots work with extremely high path accuracy and speed. Their acceleration values

and the new, ergonomic design with minimized disruptive contours already reveal

their talent for automation at the highest level.

Differentiated payload capacities. The KR CYBERTECH robots already demonstrate in

�Differentiated the selection phase that they are high-precision devices. In fine intervals, they cover

payload capacities the entire spectrum of the low payload category.

�High-accuracy CP motion

Extremely flexible. Flexible production has long since become normal. With the new

KR CYBERTECH generation, it has also become extremely cost-effective since every

robot model is systematically designed to adapt flexibly to ever-changing production

circumstances. From confined spaces to large distances, whether installed on the

floor, wall or ceiling, or at any other angle, the KR CYBERTECH robots can master a

wide range of different requirement profiles in any desired installation position.

�Extremely flexible

* Special variants F, CR, HO and K-F available

Industrial robotics�low payloads 04�05

Page4

KR CYBERTECH nano

KR 6 R1820

Perfected for handling and assembly. Fast and incredibly agile with the utmost Workspace Volume

precision. Down to the very last detail, KR CYBERTECH nano robots are KR 6 R1820 22.97 m3

designed as high-end handling robots.

Compact design. Reduced volume with greater payload capacity and longer

reach. KR CYBERTECH arc nano robots work in confined spaces.

Minimized interference radius. With an interference radius of just 67 mm,

the KR CYBERTECH nano robots have set a new global benchmark.

Maximum workspace. With their large working envelope to the rear and

long downward reach, KR CYBERTECH nano robots can work in areas

inaccessible to conventional robots. –137° +163°

80

Best-in-class repeatability. Besides many other innovative technical details,

the KR CYBERTECH nano robots impress with a repeatability of 0.04 mm. –185°

6

R 8

Flexibility in any position. Exceptional performance when installed on the –137° +163°

floor, wall or ceiling, or at any other angle. KR CYBERTECH nano robots +65° 80

are suitable for every installation position in their standard versions –

without requiring “extras”. 150

–185°

R 8

6

+65°

1,520 421

150 1,820

KR CYBERTECH nano KR 6 R1820

Max. reach 1,820 mm

Rated payload 6 kg

Rated suppl. load, arm/link arm/rot. 10 kg / – / – 1,520 421

Rated total load 16 kg

1,820

Pose repeatability ±0.04 mm

Number of axes 6 –170° 0

1,8

2

Installation position Floor, ceiling, wall, angle R

Variant

Robot footprint 260 mm x 260 mm

Weight (excluding controller), approx. 160 kg

+170°

–170° 820 1,

Axis data / R

Range of motion

Axis 1 (A1) +/–170°

Axis 2 (A2) +65°/–185°

Axis 3 (A3) +163°/–137° +170°

Axis 4 (A4) +/–185°

Axis 5 (A5) +/–120°

Axis 6 (A6) +/–350°

Operating conditions

Ambient temperature +5 °C to +45 °C

Protection rating

Protection rating of robot IP 54

The High Protection (HP) variant

Controller KR C4 compact, KR C4 smallsize-2 enables the standard robots to have

Teach pendant KUKA smartPAD a higher protection rating

Industrial robotics�low payloads 06�07

1,260

1,260

480.8 450 810

480.8 450 810

20

20

2,120

2,120

3,265

3,265

Page5

KR CYBERTECH arc nano

KR 6 R1820 arc HW

Perfected for continuous-path motion. Extremely high path accuracy and speed Workspace Volume

with new controller structures. KR CYBERTECH arc nano robots were created for KR 6 R1820 arc HW 23.19 m3

path applications at the very highest level – even deep inside the workpieces.

Compact design. Reduced volume with greater payload capacity and longer

reach. KR CYBERTECH arc nano robots work in confined spaces.

Minimized disruptive contour. A streamlined arm/wrist design, a minimized

disruptive contour of axis 2 and optimal integration of the welding equipment.

Maximum workspace. With their large working envelope to the rear and long

80

downward reach, KR CYBERTECH nano robots can work in areas inaccessible

to conventional robots. 840

Functional wrist. 50 mm hollow wrist with a reduced wrist diameter of only

–120° +180°

150.2 mm. Hollow axis 6 is capable of infinite rotation and the main axis 80

motion is reduced, allowing extremely short cycle times combined with –185° 86840 R

utmost motion precision. Particularly where reaching backward is concerned

or moving up very close to the workpieces. +65°

–120° +180°

Flexibility in any position. Exceptional performance when installed on the

6

floor, wall or ceiling, or at any other angle. KR CYBERTECH nano robots 150 –185° R 8

are suitable for every installation position in their standard versions –

without requiring “extras”. +65°

1,523 352

KR CYBERTECH arc nano KR 6 R1820 arc HW

150 1,823.5

Max. reach 1,821 mm

Rated payload 6 kg

Rated suppl. load, arm/link arm/rot. column 10 kg / – / –

Rated total load 16 kg 1,523 352

Pose repeatability ±0.04 mm 1,823.5

Hollow shaft in the wrist flange Ø 50 mm

Number of axes 6

Installation position Floor, ceiling, wall, angle –170° 3.5,82

R 1

Variant –

Robot footprint 260 mm x 260 mm

Weight (excluding controller), approx. 180 kg

+17–01°70° 823

.5

1,

Axis data / R

Range of motion

Axis 1 (A1) +/–170°

Axis 2 (A2) +65°/–185°

Axis 3 (A3) +180°/–120° +170°

Axis 4 (A4) +/–165°

Axis 5 (A5) +140°/–150°

Axis 6 (A6) +/–350°

Operating conditions

Ambient temperature +5 °C to +45 °C

Protection rating

Protection rating of robot IP 54

Controller KR C4 compact, KR C4 smallsize-2

Teach pendant KUKA smartPAD

Industrial robotics�low payloads 08�09

1,260

1,260

484 450 810 200

484 450 810 200

2,123

2,123

3,271

3,271

Page6

KR CYBERTECH nano

KR 8 R1620

Perfected for handling and assembly. Fast and incredibly agile with the utmost Workspace Volume

precision. Down to the very last detail, KR CYBERTECH nano robots are KR 8 R1620 15.93 m3

designed as high-end handling robots.

Compact design. Reduced volume with greater payload capacity and longer

reach. KR CYBERTECH arc nano robots work in confined spaces.

Minimized interference radius. With an interference radius of just 67 mm,

the KR CYBERTECH nano robots have set a new global benchmark.

Maximum workspace. With their large working envelope to the rear and

long downward reach, KR CYBERTECH nano robots can work in areas –137° +165°

inaccessible to conventional robots. 80

Best-in-class repeatability. Besides many other innovative technical details, –185° 3

the KR CYBERTECH nano robots impress with a repeatability of 0.04 mm. R 8

Flexibility in any position. Exceptional performance when installed on the +65°

floor, wall or ceiling, or at any other angle. KR CYBERTECH nano robots –137° +165°

80

are suitable for every installation position in their standard versions – 150

without requiring “extras”.

–185°

R 8

3

1,320 431

1,620

+65°

KR CYBERTECH nano KR 8 R1620 150

Max. reach 1,620 mm

Rated payload 8 kg

Rated suppl. load, arm/link arm/rot. 10 kg / – / – 1,320 431

Rated total load 18 kg 1,620

Pose repeatability ±0.04 mm –170° 0 1,6

2

R

Number of axes 6

Installation position Floor, ceiling, wall, angle

Variant

Robot footprint 260 mm x 260 mm

+170°

Weight (excluding controller), approx. 155 kg

–170° 0

,62

Axis data / R 1

Range of motion

Axis 1 (A1) +/–170°

Axis 2 (A2) +65°/–185°

Axis 3 (A3) +163°/–137° +170°

Axis 4 (A4) +/–185°

Axis 5 (A5) +/–120°

Axis 6 (A6) +/–350°

Operating conditions

Ambient temperature +5 °C to +45 °C

Protection rating

Protection rating of robot IP 54

The High Protection (HP) variant

Controller KR C4 compact, KR C4 smallsize-2 enables the standard robots to have

Teach pendant KUKA smartPAD a higher protection rating

Industrial robotics�low payloads 10�11

1,260

1,260

280.9 450 810

280.9 450 810 20

20

1,920

1,920

2,865

2,865

Page7

KR CYBERTECH arc nano

KR 8 R1620 arc HW

Perfected for continuous-path motion. Extremely high path accuracy and speed Workspace Volume

with new controller structures. KR CYBERTECH arc nano robots were created for KR 8 R1620 arc HW 15.97 m3

path applications at the very highest level – even deep inside the workpieces.

Compact design. Reduced volume with greater payload capacity and longer

reach. KR CYBERTECH arc nano robots work in confined spaces.

Minimized disruptive contour. A streamlined arm/wrist design, a minimized

disruptive contour of axis 2 and optimal integration of the welding equipment.

630 80

Maximum workspace. With their large working envelope to the rear and long

downward reach, KR CYBERTECH nano robots can work in areas inaccessible –120°

to conventional robots.

Functional wrist. 50 mm hollow wrist with a reduced wrist diameter of only +180°

150.2 mm. Hollow axis 6 is capable of infinite rotation and the main axis –185° R 8

6

motion is reduced, allowing extremely short cycle times combined with 630 80

utmost motion precision. Particularly where reaching backward is concerned +65°

or moving up very close to the workpieces. –120°

Flexibility in any position. Exceptional performance when installed on the 150 +180°

floor, wall or ceiling, or at any other angle. KR CYBERTECH nano robots

–185° 86

are suitable for every installation position in their standard versions – R

without requiring “extras”. 1,521 419

1,621+65°

KR CYBERTECH arc nano KR 8 R1620 arc HW

Max. reach 1,621 mm 150

Rated payload 8 kg

Rated suppl. load, arm/link arm/rot. 10 kg / – / –

Rated total load 18 kg 1,521 419

Pose repeatability ±0.04 mm 1,621

Hollow shaft in the wrist flange Ø 50 mm –170° 620

1

1,

Number of axes 6 R

Installation position Floor, ceiling, wall, angle

Variant –

Robot footprint 260 mm x 260 mm

Weight (excluding controller), approx. 175 kg +170°

–170° 1

,62

0

Axis data / R 1

Range of motion

Axis 1 (A1) +/–170°

Axis 2 (A2) +65°/–185°

Axis 3 (A3) +180°/–120° +170°

Axis 4 (A4) +/–165°

Axis 5 (A5) +140°/–150°

Axis 6 (A6) +/–350°

Operating conditions

Ambient temperature +5 °C to +45 °C

Protection rating

Protection rating of robot IP 54

Controller KR C4 compact, KR C4 smallsize-2

Teach pendant KUKA smartPAD

Industrial robotics�low payloads 12�13

1,260

1,260

282 450 810 200

282 450 810 200

1,921

1,921 2,866

2,866

Page8

KR CYBERTECH nano

KR 10 R1420

Perfected for handling and assembly. Fast and incredibly agile with the utmost Workspace Volume

precision. Down to the very last detail, KR CYBERTECH nano robots are designed KR 10 R1420 10.64 m3

as high-end handling robots.

Compact design. Reduced volume with greater payload capacity and longer

reach. KR CYBERTECH arc nano robots work in confined spaces.

Minimized disruptive contour. A streamlined arm/wrist design, a minimized

disruptive contour of axis 2 and optimal integration of the welding equipment.

660 80

Maximum workspace. With their large working envelope to the rear and long

downward reach, KR CYBERTECH nano robots can work in areas inaccessible +165°

–137°

to conventional robots.

Best-in-class repeatability. Besides many other innovative technical details, –185° 83.

2

R

the KR CYBERTECH nano robots impress with a repeatability of 0.04 mm.

660+65° 80

Flexibility in any position. Exceptional performance when installed on the

floor, wall or ceiling, or at any other angle. KR CYBERTECH nano robots

150 +165°

are suitable for every installation position in their standard versions – –137°

without requiring “extras”.

1,120 363 –185° .2

R 8

3

1,420

+65°

KR CYBERTECH nano KR 10 R1420 150

Max. reach 1,420 mm

Rated payload 10 kg 1,120 363

Rated suppl. load, arm/link arm/rot. 10 kg / – / –

1,420

Rated total load 20 kg –170°

420

Pose repeatability ±0.04 mm 1,R

Number of axes 6

Installation position Floor, ceiling, wall, angle

Variant

+170°

Robot footprint 260 mm x 260 mm

Weight (excluding controller), approx. 145 kg

–170° 20

Axis data / ,4R 1

Range of motion

Axis 1 (A1) +/–170°

Axis 2 (A2) +65°/–185°

Axis 3 (A3) +163°/–137° +170°

Axis 4 (A4) +/–185°

Axis 5 (A5) +/–120°

Axis 6 (A6) +/–350°

Operating conditions

Ambient temperature +5 °C to +45 °C

Protection rating

Protection rating of robot IP 54

The High Protection (HP) variant

Controller KR C4 compact, KR C4 smallsize-2 enables the standard robots to have

Teach pendant KUKA smartPAD a higher protection rating

Industrial robotics�low payloads 14�15

1,060

1,060

263.5 450 610

263.5 450 610 20

20

1,720

1,720

2,483

2,483

Page9

KR CYBERTECH arc nano

KR 8 R1420 arc HW

Perfected for handling and assembly. Fast and incredibly agile with the utmost Workspace Volume

precision. Down to the very last detail, KR CYBERTECH nano robots are designed KR 8 R1420 arc HW 10.68 m3

as high-end handling robots.

Compact design. Reduced volume with greater payload capacity and longer

reach. KR CYBERTECH arc nano robots work in confined spaces.

Minimized disruptive contour. A streamlined arm/wrist design, a minimized

disruptive contour of axis 2 and optimal integration of the welding equipment. 630 80

Maximum workspace. With their large working envelope to the rear and long

downward reach, KR CYBERTECH nano robots can work in areas inaccessible –120°

to conventional robots.

630 80

+180°

Best-in-class repeatability. Besides many other innovative technical details, –185° 87R

the KR CYBERTECH nano robots impress with a repeatability of 0.04 mm. –120°

+65°

Flexibility in any position. Exceptional performance when installed on the +180°

floor, wall or ceiling, or at any other angle. KR CYBERTECH nano robots –185°

R 8

7

are suitable for every installation position in their standard versions – 150

without requiring “extras”.

+65°

1,121 351

1,421

150

KR CYBERTECH arc nano KR 8 R1420 arc HW

1,121 351

Max. reach 1,421 mm

1,421

Rated payload 8 kg

Rated suppl. load, arm/link arm/rot. 10 kg / – / –

Rated total load 18 kg

Pose repeatability ±0.04 mm

Hollow shaft in the wrist flange Ø 50 mm

Number of axes 6

Installation position Floor, ceiling, wall, angle –170°

21

Variant – 1,4R

Robot footprint 260 mm x 260 mm

Weight (excluding controller), approx. 165 kg

–170°

21

1,4

Axis data / +170° R

Range of motion

Axis 1 (A1) +/–170°

Axis 2 (A2) +65°/–185°

Axis 3 (A3) +180°/–120° +170°

Axis 4 (A4) +/–165°

Axis 5 (A5) +140°/–150°

Axis 6 (A6) +/–350°

Operating conditions

Ambient temperature +5 °C to +45 °C

Protection rating

Protection rating of robot IP 54

Controller KR C4 compact, KR C4 smallsize-2

Teach pendant KUKA smartPAD

Industrial robotics�low payloads 16�17

1,060 1,060

264 450 264 610 450 200 610 200

1,721 1,721

2,485 2,485

Page10

KR CYBERTECH arc

KR 8 R2100 arc HW

Reliable handling. KR CYBERTECH robots are the ultimate productive solution Workspace Volume

for component handling, automated assembly and palletizing, as well as KR 8 R2100 arc HW 36.58 m3

arc welding processes.

High-accuracy CP motion. As a result of new controller structures, all

KR CYBERTECH robots move with extremely high path accuracy and speed.

A glance at their acceleration values and their new, ergonomic design with min-

imized disruptive contours already reveals their talent for automation

at the highest level. 854.5 160.5

854.5 160.5

Precise machining. The product range of the KR CYBERTECH includes powerful +175° Payload

–138°

robots for machining workpieces with pinpoint accuracy. The KR CYBERTECH +175° Payload

–138°

thus paves the way for precision in many other areas of manufacturing.

Greater volume of working envelope. Especially the KR 8 R2100 arc HW, with –185° Lz

its combination of an 8 kg payload and 2,100 mm reach, has an enormous –185° Lz +175° .5

working envelope to the rear. Ceiling mounting ensures long reach and high 0+175° R 9 5

accessibility, while opening up additional floor space for further peripheral 90

.

R

equipment. +65°

+65°

160

160 468

468

1,781

KR CYBERTECH arc KR 8 R2100 arc HW

1,781 2,101

Max. reach 2,101 mm

Rated payload 8 kg 2,101

Rated suppl. load, arm/link arm/rot. 10 kg / – / –

Rated total load 18 kg

Pose repeatability ±0.04 mm

Number of axes 6

Installation position Floor, ceiling, wall, angle

Robot footprint 430 mm x 380 mm

Weight (excluding controller), approx. 255 kg

01

Axis data / Speed with 1

R 2

,

Range of motion rated payload 18 kg –185° 01,1

R 2

Axis 1 (A1) +/–185° 200°/s –185°

Axis 2 (A2) +65°/–185° 175°/s

Axis 3 (A3) +175°/–138° 190°/s

Axis 4 (A4) +/–165° 430°/s

Axis 5 (A5) +140°/–115° 430°/s

Axis 6 (A6) +/–350° 630°/s

+185°

Operating conditions

+185°

Ambient temperature +5 °C to +55 °C

Protection rating

Protection rating of robot IP 65

Protection rating of in-line wrist IP 54

Controller KR C4

Teach pendant KUKA smartPAD

Industrial robotics�low payloads 18�19

526 526 520 520 980 980

220 220

Lxy Lxy

2,4612,461

3,7893,789

Page11

KR CYBERTECH

KR 8 R2010

Reliable handling. KR CYBERTECH robots are the ultimate productive solution Workspace Volume

for component handling, automated assembly and palletizing, as well as KR 8 R2010 32.50 m3

arc welding processes.

High-accuracy CP motion. As a result of new controller structures, all

KR CYBERTECH robots move with extremely high path accuracy and speed.

A glance at their acceleration values and their new, ergonomic design with

minimized disruptive contours already reveals their talent for automation

at the highest level. 860 153

860 153

Precise machining. The product range of the KR CYBERTECH includes powerful Payload

robots for machining workpieces with pinpoint accuracy. The KR CYBERTECH –138° Payload–138°

thus paves the way for precision in many other areas of manufacturing.

Greater volume of working envelope. The robots of the KR CYBERTECH series –185° Lz

have an enormous working envelope to the rear. Ceiling mounting ensures –185° Lz

.255

long reach and high accessibility, while opening up additional floor space +175° 6+175° 15 .2R 156

for further peripheral equipment. R

+65°

+65°

160

160

423

423

KR CYBERTECH KR 8 R2010

Max. reach 2,010 mm 1,693 2,0131,693 2,013

Rated payload 8 kg

Rated suppl. load, arm/link arm/rot. 10 kg / – / –

Rated total load 18 kg

Pose repeatability ±0.04 mm

Number of axes 6

Installation position Floor, ceiling, wall, angle

Robot footprint 430 mm x 380 mm

Weight (excluding controller), approx. 270 kg

13

Axis data / 2,

0

,01

3

Range of motion –185° RR 2–185°

Axis 1 (A1) +/–185°

Axis 2 (A2) +65°/–185°

Axis 3 (A3) +172°/–142°

Axis 4 (A4) +/–350°

Axis 5 (A5) +/–130°

Axis 6 (A6) +/–350°

Operating conditions +185°+185°

Ambient temperature +5 °C to +55 °C

Protection rating

Protection rating of robot IP 65

Controller KR C4

Teach pendant KUKA smartPAD

Industrial robotics�low payloads 20�21

1,510,5000

434838 525020 989080

151050

LxLyxy

2,237,3373

3,63,16414

Page12

KR CYBERTECH

KR 12 R1810

Reliable handling. KR CYBERTECH robots are the ultimate productive solution Workspace Volume

for component handling, automated assembly and palletizing, as well as KR 12 R1810 23.30 m3

arc welding processes.

High-accuracy CP motion. As a result of new controller structures, all

KR CYBERTECH robots move with extremely high path accuracy and speed.

A glance at their acceleration values and their new, ergonomic design with

minimized disruptive contours already reveals their talent for automation

860 153 Payload

at the highest level.

860 153 Payload

Precise machining. The product range of the KR CYBERTECH includes powerful –138°

robots for machining workpieces with pinpoint accuracy. The KR CYBERTECH

thus paves the way for precision in many other areas of manufacturing. –138°

–185° Lz

25

Greater volume of working envelope. The robots of the KR CYBERTECH series +175° 6

.

–185° 15Lz R

have an enormous working envelope to the rear. Ceiling mounting ensures .25+175° 56

long reach and high accessibility, while opening up additional floor space 1+65° R

for further peripheral equipment.

+65°

160

160 393

1,493

393

1,813

1,493

1,813

KR CYBERTECH KR 12 R1810

Max. reach 1,810 mm

Rated payload 12 kg

Rated suppl. load, arm/link arm/rot. 10 kg / – / –

Rated total load 22 kg

Pose repeatability ±0.04 mm

Number of axes 6

Installation position Floor, ceiling, wall, angle

Robot footprint 430 mm x 380 mm

Weight (excluding controller), approx. 264 kg

3

Axis data / 1,8

1

Range of motion –185° R

13,8

Axis 1 (A1) +/–185° 1–185° R

Axis 2 (A2) +65°/–185°

Axis 3 (A3) +172°/–142°

Axis 4 (A4) +/–350°

Axis 5 (A5) +/–130°

Axis 6 (A6) +/–350°

+185°

Operating conditions +185°

Ambient temperature +5 °C to +55 °C

Protection rating

Protection rating of robot IP 65

Controller KR C4

Teach pendant KUKA smartPAD

Industrial robotics�low payloads 22�23

1,300 1,300

421 425120 520 780 780

150 150

Lxy Lxy

2,173 2,173

3,233 3,233

Page13

KR CYBERTECH

KR 16 R2010

Reliable handling. KR CYBERTECH robots are the ultimate productive solution Workspace Volume

for component handling, automated assembly and palletizing, as well as KR 16 R2010 32.50 m3

arc welding processes.

High-accuracy CP motion. As a result of new controller structures, all

KR CYBERTECH robots move with extremely high path accuracy and speed.

A glance at their acceleration values and their new, ergonomic design with

minimized disruptive contours already reveals their talent for automation

at the highest level. 860 153

860 153

Precise machining. The product range of the KR CYBERTECH includes powerful Payload

robots for machining workpieces with pinpoint accuracy. The KR CYBERTECH –138° Payload–138°

thus paves the way for precision in many other areas of manufacturing.

Greater volume of working envelope. The robots of the KR CYBERTECH series –185° Lz

have an enormous working envelope to the rear. Ceiling mounting ensures –185° Lz

+175° 6.2

5

5

long reach and high accessibility, while opening up additional floor space +175° 15 6.2R 15

for further peripheral equipment. R

+65°

+65°

160

160

423

423

KR CYBERTECH KR 16 R2010

Max. reach 2,010 mm 1,693 2,0131,693 2,013

Rated payload 16 kg

Rated suppl. load, arm/link arm/rot. 10 kg / – / –

Rated total load 26 kg

Pose repeatability ±0.04 mm

Number of axes 6

Installation position Floor, ceiling, wall, angle

Robot footprint 430 mm x 380 mm

Weight (excluding controller), approx. 270 kg

13

Axis data / 2,

0 13,0

Range of motion –185° R 2–185° R

Axis 1 (A1) +/–185°

Axis 2 (A2) +65°/–185°

Axis 3 (A3) +172°/–142°

Axis 4 (A4) +/–350°

Axis 5 (A5) +/–130°

Axis 6 (A6) +/–350°

Operating conditions +185°+185°

Ambient temperature +5 °C to +55 °C

Protection rating

Protection rating of robot IP 65

Controller KR C4

Teach pendant KUKA smartPAD

Industrial robotics�low payloads 24�25

1,51,05000

434838 525020 989080

151050

LxLyxy

2,23,73373

3,36,16414

Page14

KR CYBERTECH

KR 16 R1610

Reliable handling. KR CYBERTECH robots are the ultimate productive solution Workspace Volume

for component handling, automated assembly and palletizing, as well as KR 16 R1610 16.25 m3

arc welding processes.

High-accuracy CP motion. As a result of new controller structures, all

KR CYBERTECH robots move with extremely high path accuracy and speed.

A glance at their acceleration values and their new, ergonomic design with

minimized disruptive contours already reveals their talent for automation 655 153 Payload

at the highest level. 655 153 Payload

–138°

Precise machining. The product range of the KR CYBERTECH includes powerful

robots for machining workpieces with pinpoint accuracy. The KR CYBERTECH –138°

thus paves the way for precision in many other areas of manufacturing. –185° Lz

5

–185° +175° 6

.2

Lz 15

Greater volume of working envelope. The robots of the KR CYBERTECH series R

+175° 6.2

5

have an enormous working envelope to the rear. Ceiling mounting ensures 15R

+65°

long reach and high accessibility, while opening up additional floor space

for further peripheral equipment. +65°

160

160

1,292 410

1,292 410 1,612

1,612

KR CYBERTECH KR 16 R1610

Max. reach 1,610 mm

Rated payload 16 kg

Rated suppl. load, arm/link arm/rot. 10 kg / – / –

Rated total load 26 kg

Pose repeatability ±0.04 mm

Number of axes 6

Installation position Floor, ceiling, wall, angle

Robot footprint 430 mm x 380 mm

Weight (excluding controller), approx. 263 kg

Axis data / 61

2

Range of motion –185° R 1

,

12

Axis 1 (A1) +/–185° –185° 1,

6

R

Axis 2 (A2) +65°/–185°

Axis 3 (A3) +172°/–142°

Axis 4 (A4) +/–350°

Axis 5 (A5) +/–130°

Axis 6 (A6) +/–350°

+185°

Operating conditions +185°

Ambient temperature +5 °C to +55 °C

Protection rating

Protection rating of robot IP 65

Controller KR C4

Teach pendant KUKA smartPAD

Industrial robotics�low payloads 26�27

1,300 1,300

220 220 520 520 780 780

150 150

Lxy Lxy

1,972 1,972

2,831 2,831

Page15

KR CYBERTECH

KR 20 R1810

Reliable handling. KR CYBERTECH robots are the ultimate productive solution Workspace Volume

for component handling, automated assembly and palletizing, as well as KR 20 R1810 23.30 m3

arc welding processes.

High-accuracy CP motion. As a result of new controller structures, all

KR CYBERTECH robots move with extremely high path accuracy and speed.

A glance at their acceleration values and their new, ergonomic design with

minimized disruptive contours already reveals their talent for automation

860 153 Payload

at the highest level.

860 153 Payload

Precise machining. The product range of the KR CYBERTECH includes powerful –138°

robots for machining workpieces with pinpoint accuracy. The KR CYBERTECH

thus paves the way for precision in many other areas of manufacturing. –138°

–185° Lz

25

Greater volume of working envelope. The robots of the KR CYBERTECH series +175° 6

.

–185° 5Lz R 1

have an enormous working envelope to the rear. Ceiling mounting ensures 25+175° 6.5

long reach and high accessibility, while opening up additional floor space 1+65° R

for further peripheral equipment.

+65°

160

160 393

1,493

393

1,813

1,493

1,813

KR CYBERTECH KR 20 R1810 *

Max. reach 1,810 mm

Rated payload 20 kg

Rated suppl. load, arm/link arm/rot. 10 kg / – / –

Rated total load 30 kg

Pose repeatability ±0.04 mm

Number of axes 6

Installation position Floor, ceiling, wall, angle

Robot footprint 430 mm x 380 mm

Weight (excluding controller), approx. 264 kg

3

Axis data / 1,8

1

Range of motion –185° R

,81

3

Axis 1 (A1) +/–185° 1–185° R

Axis 2 (A2) +65°/–185°

Axis 3 (A3) +172°/–142°

Axis 4 (A4) +/–350°

Axis 5 (A5) +/–130°

Axis 6 (A6) +/–350°

+185°

Operating conditions +185°

Ambient temperature +5 °C to +55 °C

Protection rating

Protection rating of robot IP 65

Controller KR C4

Teach pendant KUKA smartPAD

* Special variants F, CR, HO and K-F available

Industrial robotics�low payloads 28�29

1,300 1,300

421 425120 520 780 780

150 150

Lxy Lxy

2,173 2,173

3,233 3,233

Page16

KR CYBERTECH

KR 22 R1610

Reliable handling. KR CYBERTECH robots are the ultimate productive solution Workspace Volume

for component handling, automated assembly and palletizing, as well as KR 22 R1610 16.25 m3

arc welding processes.

High-accuracy CP motion. As a result of new controller structures, all

KR CYBERTECH robots move with extremely high path accuracy and speed.

A glance at their acceleration values and their new, ergonomic design with

minimized disruptive contours already reveals their talent for automation 655 153 Payload

at the highest level. 655 153 Payload

–138°

Precise machining. The product range of the KR CYBERTECH includes powerful

robots for machining workpieces with pinpoint accuracy. The KR CYBERTECH –138°

thus paves the way for precision in many other areas of manufacturing. –185° Lz

5

–185° +175°

.2

Lz 15

6

Greater volume of working envelope. The robots of the KR CYBERTECH series R 5

+175° 6.2

have an enormous working envelope to the rear. Ceiling mounting ensures 5R 1

+65°

long reach and high accessibility, while opening up additional floor space

for further peripheral equipment. +65°

160

160

1,292 410

1,292 410 1,612

1,612

KR CYBERTECH KR 22 R1610

Max. reach 1,610 mm

Rated payload 22 kg

Rated suppl. load, arm/link arm/rot. 10 kg / – / –

Rated total load 22 kg

Pose repeatability ±0.04 mm

Number of axes 6

Installation position Floor, ceiling, wall, angle

Robot footprint 430 mm x 380 mm

Weight (excluding controller), approx. 263 kg

Axis data / 261

Range of motion –185° ,R 1

12

Axis 1 (A1) +/–185° –185° 1,

6

R

Axis 2 (A2) +65°/–185°

Axis 3 (A3) +172°/–142°

Axis 4 (A4) +/–350°

Axis 5 (A5) +/–130°

Axis 6 (A6) +/–350°

+185°

Operating conditions +185°

Ambient temperature +5 °C to +55 °C

Protection rating

Protection rating of robot IP 65

Controller KR C4

Teach pendant KUKA smartPAD

Industrial robotics�low payloads 30�31

1,300 1,300

220 220 520 520 780 780

150 150

Lxy Lxy

1,972 1,972

2,831 2,831

Page17

KUKA shelf-mounted robots

for low payloads

Product overview Reach / payload

Robot KR 16-2 KS A KR 22 R16102,200 mm O B KR 20 R1810

KR 16 L6-2 KS C KR 16 R1610

Controller KR C4 compact 2,000 mm F G D D KR 16 R2010

Teach pendant KUKA smartPAD E KR 12 R18101,800 mm J M E N B F KR 8 R2010

G KR 8 R2100 arc HW

1,600 mm I L C A H KR 10 R1420

I KR 8 R1620

1,400 mm K H J KR 6 R1820

K KR 8 R1420 arc HW

1,200 mm L KR 8 R1620 arc HW

M KR 6 R1820 arc HW

6 kg 8 kg 10 kg 12 kg 14 kg 16 kg 18 kg 20 kg 22 kg

N KR 16-2 KS

O KR 16 L6-2 KS

�Versatile

�Fast Versatile. The intelligent payload and reach intervals allow simple, reliable planning.

KUKA also offers further shelf-mounted robots covering a payload range from

16 kg to 270 kg.

Light. KUKA shelf-mounted robots stand out for their low weight. They can be installed

directly on machines with minimum effort, thereby saving space.

�Reliable planning

Deep reach. KUKA shelf-mounted robots are designed for an especially large downward

reach. They optimally access the workspace from above. Thanks to their low height,

they require only a small amount of headroom.

Fast. Thanks to their low weight, KUKA shelf-mounted robots achieve high dynamic

�Light performance and very short cycle times. This enables higher productivity and cost-

effectiveness with rapid payback.

Reliable planning. Each KUKA robot family shares an identical mounting base hole

pattern. This allows different shelf-mounted robots to be used on machines of different

sizes – without any additional planning measures.

�Deep reach

32�33

Page18

KR 16-2 KS

Versatile. The intelligent payload and reach intervals allow Workspace 1 Dimensions A Dimensions B Dimensions C Dimensions D Dimensions E Dimensions F Dimensions G Volume

simple, reliable planning. KUKA also offers further shelf-mounted

KR 16-2 KS 1,576 mm 2,691 mm 1,801 mm 1,081 mm 720 mm 453 mm 670 mm 12 m3

robots covering a payload range from 16 kg to 270 kg.

Light. KUKA shelf-mounted robots stand out for their low

weight. They can be installed directly on machines with

minimum effort, thereby saving space.

Deep reach. KUKA shelf-mounted robots are designed for an

especially large downward reach. They optimally access the G 115

workspace from above. Thanks to their low height, they

require only a small amount of headroom.

–130° +154°

Fast. Thanks to their low weight, KUKA shelf-mounted robots

achieve high dynamic performance and very short cycle times. –110°

This enables higher productivity and cost-effectiveness with G 115

rapid payback.

+80°

–130°

Reliable planning. Each KUKA robot family shares an identical +154°

mounting base hole pattern. This allows different shelf-mounted

robots to be used on machines of different sizes – without –110°

any additional planning measures.

F 450

E D

+80°

C

KR 16-2 KS KR 16-2 KS

Max. reach 1,801 mm

Rated payload 16 kg

Rated suppl. load, arm/link arm/rot. 10 kg / – / 20 kg

F 450

Rated total load 46 kg

–1E14° D

Pose repeatability ±0.05 mm C

Number of axes 6

Installation position Floor, ceiling

Variant –

Robot footprint 500 mm x 500 mm

Weight (excluding controller), approx. 245 kg

–114°

Axis data / Speed with

Range of motion rated payload 16 kg

Axis 1 (A1) +/–114° 120°/s

Axis 2 (A2) +80°/–110° 156°/s +114°

Axis 3 (A3) +154°/–130° 156°/s

Axis 4 (A4) +/–350° 330°/s

Axis 5 (A5) +/–130° 332°/s

Axis 6 (A6) +/–350° 616°/s

+114°

Operating conditions

Ambient temperature +5 °C to +55 °C

Protection rating

Protection rating of robot IP 65

Protection rating of in-line wrist IP 65

Controller KR C4

Teach pendant KUKA smartPAD

1 Relative to intersection of axes 4/5

Industrial robotics�low payloads 34�35

A A

880 35 880 35

235 680 235 680

C C

B B

Page19

KR 16 L6-2 KS

Workspace 1 Dimensions A Dimensions B Dimensions C Dimensions D Dimensions E Dimensions F Dimensions G Volume

Long reach. Expansion of the usable workspace, compared

with that of the KR 16-2 KS, with a 300 mm arm extension. KR 16 L6-2 KS 1,576 mm 2,691 mm 1,801 mm 1,081 mm 720 mm 453 mm 670 mm 12 m3

Process-optimized. Locating axis 2 further forward enlarges

the workspace downward. This makes the robot ideal for

unloading machines.

Space-optimized. Low disruptive contours of the robot and

the streamlined design of the wrist ensure high accessibility,

even in confined spaces. G 115

+154°

–130°

300

G 115

–110°

+154°

–130°

300

–+1180°450

E D

+80°

450

KR 16 L6-2 KS KR 16 L6-2 KS 403

F E C D

Max. reach 2,101 mm

Rated payload 6 kg

Rated suppl. load, arm/link arm/rot. 10 kg / variable / 20 kg

403

Rated total load 36 kg

F C

Pose repeatability ±0.05 mm

Number of axes 6

Installation position Floor

Variant –

Robot footprint 500 mm x 500 mm –114°

Weight (excluding controller), approx. 245 kg

Axis data / Speed with –114°

Range of motion rated payload 6 kg

Axis 1 (A1) +/–114° 120°/s

+114°

Axis 2 (A2) +80°/–110° 156°/s

Axis 3 (A3) +154°/–130° 156°/s

Axis 4 (A4) +/–350° 335°/s

Axis 5 (A5) +/–130° 335°/s

+114°

Axis 6 (A6) +/–350° 647°/s

Operating conditions

Ambient temperature +5 °C to +55 °C

Protection rating

Protection rating of robot IP 65

Protection rating of in-line wrist IP 65

Controller KR C4

Teach pendant KUKA smartPAD

1 Relative to intersection of axes 4/5

Industrial robotics�low payloads 36�37A

880 35

235 A 680

880 35

235 680

C

C

B

B

Page20

KL 250-3

Product overview Flexible. Long travel extends the work envelope by several

Linear unit KL 250-3 times the reach of the robot.

Designed for robot category Low payloads

Controller KR C4 Versatile. Floor-mounted and ceiling-mounted variants are

Teach pendant KUKA smartPAD available, as is a protective cover for keeping out dirt during

tasks in harsh environments.

Positionally accurate. Up to four robots can be operated on one

linear axis. Multiple robot positions on the linear axis allow

optimal adaptation to existing requirements and workspaces.

Productive. Moving workpieces/tools with additional carriages,

driven or non-driven (tender carriages) helps to shorten

cycle times.

Specially for low payloads. This linear unit is suitable for

robots with a payload from 5 to 16 kg.

Linear unit KL 250-3

Max. number of carriages 4

Rated payload 300 kg

Velocity with rated payload 1.47 m/s

Pose repeatability <±0.02 mm

Number of axes 1

Variant

Installation position Floor, ceiling

Mass of carriage 95 kg

Mass of beam per meter 175 kg

Min. rated travel 1,100 mm

Max. rated travel 30,100 mm

Max. gradation of rated travel 500 mm

Power transmission Rack

Operating conditions

Ambient temperature +10 °C to +55 °C

Controller KR C4

Teach pendant KUKA smartPAD

Covered

Industrial robotics�low payloads 38�39