1/28ページ

ダウンロード(1.8Mb)

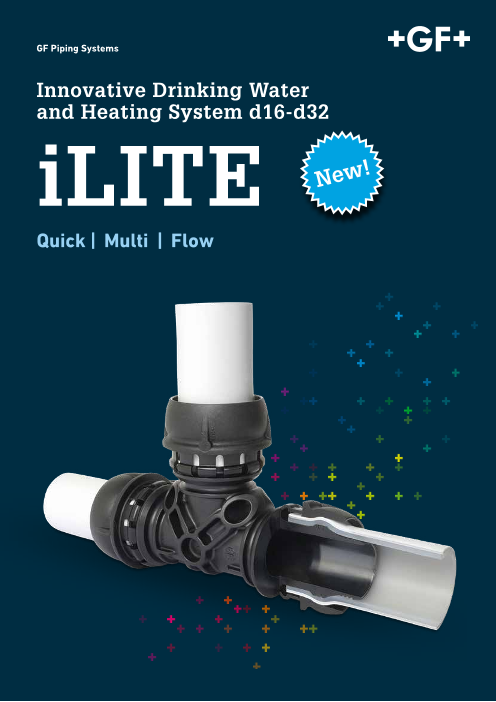

Innovative Drinking Water and Heating System d16-d32

iLITE - evolution in axial press technology

GF Piping Systems has achieved success with the new iLITE plastic piping

system by bringing real innovation to the market in the area of plumbing and

heating. This new system offers a quick and safe connection of various piping

materials while providing an excellent flow rate at the same time.

このカタログについて

| ドキュメント名 | iLITE - Lightweight with excellent flow rates |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 1.8Mb |

| 取り扱い企業 | ジョージフィッシャー株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

GF Piping Systems

Innovative Drinking Water

and Heating System d16-d32

iLITE New!

Quick | Multi | Flow

Page2

iLITE – evolution

in axial press

technology

GF Piping Systems has achieved success with the new iLITE plastic piping system by bringing real

innovation to the market in the area of plumbing and heating. This new system offers a quick and safe

connection of various piping materials while providing an excellent flow rate at the same time. iLITE is the

ideal choice for use in drinking water and heating distribution demonstrated by its long life span.

In comparison to conventional axial press systems, iLITE fittings are delivered with pre-assembled

sleeves. There are no loose, individual parts that can get lost. No additional tools or steps are required

for the expansion of the pipes. With the innovative design of the cone-shaped fitting nipple, the pipe is

expanded by itself while pushing the fitting onto the pipe. This leads to the excellent flow rate.

Finally, the pre-assembled sleeve will be pushed in the reverse direction for a safe and tight connection

of pipe and fitting. And all of this can easily be accomplished with one tool in a single step.

Properties

Inspection window

as additional safety

Multi-usable fitting

connects PE-X and ML pipes

Fitting nut for simple

usage of tool

EPDM o-ring provides

additional safety

Destinctive ribbing and

reinforcement for a

lightweight design with

maximal power

Cone-shaped fitting nipple

expands the pipe while

pushed onto fitting

2

Page3

A dvantages

Quick – 1 tool and 1 step

In a single step, the fitting and pipe are connected quickly

and easily with just one tool. No more loose spare

parts and no need for calibration or deburring of the pipe.

Additional tools are not necessary to expand the pipe.

Simply connect the pipe and fitting by hand, use the tool,

release with a double click, the connection is made. This

saves time during the installation and space in the tool

case.

Multi-usable fitting

The iLITE fitting is multi-functional for different pipe

materials. Both, full plastic pipes made from crosslinked

polyethylene (PE–Xa/c) as well as multilayer composite

pipes in the dimensions d16-32mm can be connected. No

change of the tool is necessary.

Flow – Excellent flow rate

The innovative design of the cone-shaped fitting nipple

ensures a perfectly circular expansion of the pipe when

pushed onto the fitting. With the fitting nipple, the pipe is

calibrated simultaneously. The sophisticated expansion of

the tube ensures excellent flow rates, low pressure losses

and low noise levels.

Safe connection

Axial sliding sleeve connections are among the safest

connections of pipes and fittings. Through the expansion of

the pipe and the sleeve’s axial pressing, a large sealing

surface is created between the fitting nipple and pipe. The

O-ring provides additional safety. With the inspection

window, the plumber has a simple control mechanism to

check whether the connection is correct and tight.

Connections are immediately ready for pressure. Missed

connections will immediately leak during the pressure test.

3

Page4

iLITE

Flexible pipe choice

for your application

Pipes

Multilayer Composite Pipes PE-X Pipes

iLITE composite pipes combine the advantages of plastic and PE-X pipes consist of three-dimensionally cross-linked

metal. Thanks to the flexibility of the plastic and the stability polyethylene and is commonly used in hot and cold water

of the metal, the pipes are ideally suited for the wide pipework systems. The cross-linking provides an

temperature and pressure range in hot and cold drinking improvement of the creep resistance, low-temperature

water systems. impact strength and stress-cracking resistance. Therefore,

it also provides safety in drinking water installations along

The pipe’s composition is made out of five layers: with a high level of quality. A characteristic of our PE-X pipe

an extruded inner layer made out of PE-RT, bonding agent, includes is its low weight, as well as resistance to abrasive

longitudinal butt welded aluminium pipe, an additional waters, corrosion and deposits. Due to their flexibility, these

bonding layer and an extruded outer layer made out of pipes are very easy to install and are ideally suited for cold

PE-RT. and hot water installations.

PE-RT was developed by renowned manufacturers precisely

for building technology applications and is approved for use In our product range, multilayer composite pipes and PE-X

with food and drinking water. pipes are available both as insulated pipe and as a pipe in

pipe version with conduit pipe.

• Oxygen diffusion resistant and opaque thanks to a butt

welded aluminium layer

• High temperature and pressure resistance for use in

heating and sanitary applications

• High flexibility and yet stable installation; simple and

economical workmanship

• Resistant to numerous chemicals

• Low thermal expansion comparable to metal pipes

Protective layer made of PE-RT

Bonding layer

Homogeneous longitudinal butt -

welded aluminum pipe

Bonding layer

Pipe wall made

of PE-RT

4

Page5

The pipe is cut to length and connected to

the fitting by hand. There is no need for calibration

or deburring of the pipe.

With the cone-shaped design of the fitting nipple,

the pipe is simultaneously expanded while pushed

onto the fitting.

The pre-assembled sleeve is pressed in the

opposite direction over the connection.

Due to the self-locking design, the pressed

sleeve prevents potential pulling out of the pipe.

5

Page6

iLITE

Lightweight with

maximal power

iLITE plastic fittings from the high-performance plastic PPSU, also commonly used in air

and space travel, are lightweight and nevertheless extremely sturdy and stable.

PPSU is hygienic, resistant to corrosion, durable and therefore an ideal choice for your

installation. The unique construction and design with distinctive ribbing is the result of

decades of experience in the development of drinking water systems.

This patented design enables finding the optimal weight-stability proportion for the fittings.

Consequentially the result for the customer is a competitive price and simultaneously a high

level of quality. The fittings have a smooth inner surface and are fabricated as one part and

from one material.

PPSU Fittings

• Pre-assembled sleeves with inspection window

• Low pressure losses

• Reinforcement thanks to distinctive ribbing

• Good impact strength

6

Page7

Threaded Fittings

Our iLITE threaded fittings consist of a hygienic, drinking • UBA-compliant brass

water quality brass alloy that is listed on the Federal • Pre-assembled sleeves with inspection window

Environment Agency (UBA)’s published positive list. • Low pressure losses

• Plastic protective cap to prevent transport damage

The fitting nipple of all metal fittings is provided with plastic • Spacer to avoid contact corrosion

protective caps to prevent transport damage.

Special fittings

• Easy installation by hand

• Detachable and reusable

Reduction

Reduce direct on

the fitting

Double Socket

Direct fitting to

fitting connection Cap

Closing direct

on the fitting

detachable and

reusable

7

Page8

iLITE

The intelligence is

in the tool

For the connection of the iLITE pipes and fittings, only one tool is needed.

Per dimension, there is a pair of jaws consisting of a fitting mounting and a pipe clamping jaw.

The basis of our iLITE battery tool originate from a renowned tool Optimised and modified for the iLITE system, the battery tool

maker with longstanding experience and expertise in the tool has two holding fixtures for the fitting jaws, an optical check on

manufacturing industry. the tool head, which immediately indicates whether the tool is

in the initial position, a double spring for a full return into initial

This basis tool has already established and proved its quality position and release with a simple double click.

on the market. This handy and lightweight tool for single-

hand operation has an ergonomic handle, a battery with a The GF patented pair of jaws are a masterpiece of Swiss

very short charging time and is captivating with its reliability engineering. The system’s intelligence lays within the tool jaws

and high quality of workmanship. in combination with the sophisticated fitting design.

The expanding of the pipes and the two axial movements in the

opposite direction are put into one step using one tool.

Tool

Jaw Holding Fixture

Optical

Check

Pipe Clamping

Makita

Battery

Fitting Mounting

15min charging time

for 200 cycles (d20)

8

Page9

9

Page10

iLITE

Compliance to standards

and one of the safest

connections make

iLITE the number one

choice

Technical Data

Operating pressure max. 10 bar

Temperature range 0°-70°C in continious operation, short- term up to 95°C

Life span 50 years (DVGW)

Dimensions d16 - 32mm

Materials Plastic Body

PPSU (Polyphenylsulfone)

High resistance to chemicals, good impact strength,

and inherent fire resistance

Sliding Sleeve

PA6GF30 (glass fibre reinforced polyamide)

Threaded Fittings

Brass – UBA compliant

Multilayer Pipe

PE-RT / AL / PE-RT (Polyethylene Raised-Temperature)

Plastic Pipe

PE-X (cross-linked Polyethylen)

Standards Pipes

DVGW W542 (multi-layer composite pipe)

EN ISO 21003 (multi-layer composite pipe)

EN ISO 15875 (PE-X pipe)

Fittings

DVGW W534

EN ISO 21003-5

System Permissions

Registration number: DW8501CSO320

CSTB, WRAS and IIP in Process

10

Page11

iLITE

Convincing quality

GF Piping Systems is one of the leading suppliers of plastic With the burst test, it is clearly visible that with a burst

and metal pipes with a global presence with more than pressure between 130 bar and 245 bar, iLITE PPSU fittings

60,000 products and over 200 years of experience in withstand more than 10 times of the normal pipeline

research and development. We aspire to deliver our pressure. They provide security against pressure surges

customers only products with a consistent, excellent level of thanks to an intelligent design with ribbing and fitting

quality. reinforcements in critical areas.

Quality provides security and is the basis for trust. By

systematically integrating business partners and suppliers,

we pursue a holistic approach to quality, thus warranting a

binding claim to quality along the entire value-added chain.

Like other GF Piping Systems products, our iLITE System is

developed, produced, and tested for compliance with all

relevant norms and standards.

For example, the weld seam of all multilayer pipes is directly

tested during the production process inline. Likewise, a

100% inspection of the internal diameter of the finished

pipes is examined with a special ball.

Thermal shock tests, internal pressure creep testing and

bending tests analyse and show the excellent combination of

the iLITE pipe and fitting and the security of the connection. Pipeline pressure

max. 10 bar

Burst pressure

min. 130 bar

Burst pressure

max. 245 bar

11

Page12

Made

for you

12

Page13

iPLITipE es

Muulitlliatyelra pyipeesr composite pipes

iLITE Multilayer pipe

• Description: in bars

• Material: PE-RT / AL / PE-RT

d DN JRG GF Weight l s

(mm) (mm) Code Code (kg ⁄ m) (m) (mm)

16 12 E600.016 351 816 802 0.129 5 2.00

20 15 E600.020 351 820 802 0.202 5 2.50

26 20 E600.026 351 826 802 0.296 5 3.00

32 25 E600.032 351 832 802 0.365 5 3.00

iLITE Multilayer pipe

• Description: in coils

• Material: PE-RT / AL / PE-RT

d DN JRG GF Weight l s

(mm) (mm) Code Code (kg ⁄ m) (m) (mm)

16 12 E604.016 351 816 814 0.129 100 2.00

20 15 E604.020 351 820 814 0.202 50 2.50

26 20 E604.026 351 826 814 0.296 50 3.00

32 25 E604.032 351 832 814 0.365 50 3.00

iLITE Multilayer pipe, insulated 6mm

• Description: in coils

• Material: PE-RT / AL / PE-RT, insulation W/mK 0.040

d DN JRG GF Weight d1 l s s1 Thermal conductivity

(mm) (mm) Code Code (kg ⁄ m) (mm) (m) (mm) (mm) (W ⁄ mK)

16 12 E606.016 351 816 835 0.152 28 50 2.00 6 0.040

20 15 E606.020 351 820 835 0.225 32 50 2.50 6 0.040

26 20 E606.026 351 826 835 0.326 38 50 3.00 6 0.040

13

Page14

iLITE

Mulitlayer composite pipes

iLITE Multilayer pipe, insulated 10mm

• Description: in coils

• Material: PE-RT / AL / PE-RT, insulation W/mK 0.040

d DN JRG GF Weight d1 l s s1 Thermal conductivity

(mm) (mm) Code Code (kg ⁄ m) (mm) (m) (mm) (mm) (W ⁄ mK)

16 12 E606.116 351 816 836 0.164 36 50 2.00 10 0.040

20 15 E606.120 351 820 836 0.239 40 50 2.50 10 0.040

26 20 E606.126 351 826 836 0.338 46 50 3.00 10 0.040

32 25 E606.132 351 832 836 0.431 52 25 3.00 10 0.040

iLITE Multilayer pipe, insulated 6mm

• Description: in coils

• Material: PE-RT / AL / PE-RT, insulation W/mK 0.035

d DN JRG GF Weight d1 l s s1 Thermal conductivity

(mm) (mm) Code Code (kg ⁄ m) (mm) (m) (mm) (mm) (W ⁄ mK)

16 12 E608.016 351 816 735 0.160 28 50 2.00 6 0.035

20 15 E608.020 351 820 735 0.224 32 50 2.50 6 0.035

26 20 E608.026 351 826 735 0.325 38 50 3.00 6 0.035

iLITE Multilayer pipe, insulated 10mm

• Description: in coils

• Material: PE-RT / AL / PE-RT, insulation W/mK 0.035

d DN JRG GF Weight d1 l s s1 Thermal conductivity

(mm) (mm) Code Code (kg ⁄ m) (mm) (m) (mm) (mm) (W ⁄ mK)

16 12 E608.116 351 816 736 0.166 36 50 2.00 10 0.035

20 15 E608.120 351 820 736 0.239 40 50 2.50 10 0.035

26 20 E608.126 351 826 736 0.325 46 50 3.00 10 0.035

14

Page15

iLITE

Mulitlayer composite pipes

iLITE Multilayer pipe, insulated 20mm

• Description: in coils

• Material: PE-RT / AL / PE-RT, insulation W/mK 0.035

d DN JRG GF Weight d1 l s s1 Thermal conductivity

(mm) (mm) Code Code (kg ⁄ m) (mm) (m) (mm) (mm) (W ⁄ mK)

16 12 E608.216 351 816 737 0.222 36 50 2.00 20 0.035

20 15 E608.220 351 820 737 0.296 40 50 2.50 20 0.035

26 20 E608.226 351 826 737 0.401 46 25 3.00 20 0.035

iLITE Multilayer pipe, with protection pipe

• Description: in coils

• Material: PE-RT / AL / PE-RT

d DN JRG GF Weight d1 l s

(mm) (mm) Code Code (kg ⁄ m) (mm) (m) (mm)

16 12 E602.016 351 816 834 0.204 25 50 2.00

20 15 E602.020 351 820 834 0.294 30 50 2.50

15

Page16

iLITE

PE-X pipes

PE-X pipes

JRG Sanipex PE-X pipe, blue

• Description: in coils

• Material: PE-Xc

d DN JRG GF Weight L s

(mm) (mm) Code Code (kg) (m) (mm)

16 12 5717.016 355 516 316 12.000 100 2.2

20 15 5717.020 355 516 320 8.600 50 2.8

JRG Sanipex PE-X pipe, blue, with protection pipe

• Description: in coils

• Material: PE-Xc

d DN JRG GF Weight d1 L s

(mm) (mm) Code Code (kg) (mm) (m) (mm)

16 12 5716.016 355 516 317 9.500 25 50 2.2

20 15 5716.020 355 516 321 13.100 29 50 2.8

16

Page17

iLITE

Fittings

Fittings

PPSU

Coupler

• Material: PPSU

d JRG GF Weight l1 z1

(mm) Code Code (kg) (mm) (mm)

16 E690.016 351 816 920 0.010 51 9

20 E690.020 351 820 920 0.018 61 13

26 E690.026 351 826 920 0.032 72 14

32 E690.032 351 832 920 0.058 88 18

Elbow 90°

• Material: PPSU

d JRG GF Weight l1 l2 z1 z2

(mm) Code Code (kg) (mm) (mm) (mm) (mm)

16 E670.016 351 816 922 0.013 39 39 18 18

20 E670.020 351 820 922 0.024 48 48 24 24

26 E670.026 351 826 922 0.045 58 58 29 29

32 E670.032 351 832 922 0.084 71 71 36 36

T-piece equal

• Material: PPSU

d-d-d JRG GF Weight

(mm) Code Code (kg)

16 - 16 - 16 E650.016 351 816 921 0.019

20 - 20 - 20 E650.020 351 820 921 0.035

26 - 26 - 26 E650.026 351 826 921 0.066

32 - 32 - 32 E650.032 351 832 921 0.123

d-d-d d1 d2 d3 l1 l2 l3 z1 z2 z3

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

16 - 16 - 16 16 16 16 39 39 39 18 18 18

20 - 20 - 20 20 20 20 48 48 48 24 24 24

26 - 26 - 26 26 26 26 58 58 58 29 29 29

32 - 32 - 32 32 32 32 71 71 71 36 36 36

17

Page18

iLITE

Fittings

T-piece reduced

• Material: PPSU

d-d-d JRG GF Weight

(mm) Code Code (kg)

20 - 16 - 16 E652.110 351 820 934 0.026

20 - 16 - 20 E652.112 351 820 931 0.030

26 - 16 - 26 E652.214 351 826 931 0.052

26 - 20 - 20 E652.218 351 826 934 0.048

26 - 20 - 26 E652.220 351 826 932 0.057

32 - 20 - 32 E652.324 351 832 932 0.098

32 - 26 - 32 E652.330 351 832 933 0.107

d-d-d d1 d2 d3 l1 l2 l3 z1 z2 z3

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

20 - 16 - 16 20 16 16 42 42 48 21 21 24

20 - 16 - 20 20 16 20 48 42 48 24 21 24

26 - 16 - 26 26 16 26 58 46 58 29 25 29

26 - 20 - 20 26 20 20 52 52 58 28 28 29

26 - 20 - 26 26 20 26 58 52 58 29 28 29

32 - 20 - 32 32 20 32 71 57 71 36 33 36

32 - 26 - 32 32 26 32 71 63 71 36 34 36

Double Socket

• Description: reusable

• Material: PPSU

d JRG GF Weight l1 z1

(mm) Code Code (kg) (mm) (mm)

16 E692.016 351 816 940 0.014 51 30

20 E692.020 351 820 940 0.020 61 37

26 E692.026 351 826 940 0.028 72 43

32 E692.032 351 832 940 0.037 87 52

Cap

• Description: reusable

• Material: PPSU

d JRG GF Weight l1 z1

(mm) Code Code (kg) (mm) (mm)

16 E695.016 351 816 904 0.008 31 10

20 E695.020 351 820 904 0.012 38 14

26 E695.026 351 826 904 0.020 45 16

32 E695.032 351 832 904 0.070 55 20

18

Page19

iLITE

Fittings

Reduction

• Description: reusable

• Material: PPSU

d JRG GF Weight d1 l1 z1

(mm) Code Code (kg) (mm) (mm) (mm)

16 E730.200 351 820 926 0.000 20 59 6

16 E730.202 351 826 926 0.012 26 65 8

20 E730.204 351 826 927 0.020 26 71 9

20 E730.208 351 832 927 0.030 32 78 10

26 E730.210 351 832 928 0.035 32 84 11

iLITE

Fittings

DZR brass

Pipe outlet, single

• Material: brass, dezincification resistant

d1 JRG GF Weight

(mm) Code Code (kg)

16 E615.135 351 816 794 0.118

20 E615.235 351 820 794 0.137

d1 d3 G d4 d5 l l1 l3 l4 l5 l6 z1

(mm) (inch) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

16 1∕2 6.4 40 40 44 22 18 15 21 23

20 1∕2 6.4 40 40 50 22 18 15 21 26

Pipe outlet, double

• Material: brass, dezincification resistant

d-d JRG GF Weight

(mm) Code Code (kg)

19 16 - 16 E616.150 351 816 781 0.239

20 - 20 E616.170 351 820 781 0.275

d1 d2 d3 G d4 d5 d6 l l1 l2 l3 l4 l5 l6 z1 z2

(mm) (mm) (inch) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

16 16 1∕2 7 40 52 50 64 64 31 19 15 40 43 43

20 20 1∕2 7 40 52 50 69 69 31 19 16 40 45 45

Page20

DZR brass

Pipe outlet, single

• Material: brass, dezincification resistant

DZR brass

d1 JRG GF Weight

(mm) Code Code (kg)

Pipe outlet, si1ng6le E615.135 351 816 794 0.118

• 20 E615.235 351 820 794 0.137 Material: brass, dezincification resistant

d1 JRG GF Weight

(mm) Codd1e d3 G Codde 4 (kdg)5 l l1 l3 l4 l5 l6 z1

16 E61(5m.1m35) (3i5n1c h8)16 7(m94m) 0.(1m18m) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

20 E615.21365 351 18∕220 7964.4 0.13470 40 44 22 18 15 21 23

20 1∕2 6.4 40 40 50 22 18 15 21 26

d1 d3 G d4 d5 l l1 l3 l4 l5 l6 z1

(mm) (inch) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

16 1∕2 6.4 40 40 44 22 18 15 21 23

20 1∕2 6.4 40 40 50 22 18 15 21 26

iLITE

Fittings

Pipe outlet, double

Pipe outlet, double

• Material: brass, dezincification resistant

d-d

(mm)

• MJaRtGerial: braGsFs,W deeigzhitncification resistant

Code Code (kg)

16 - 16 E616.d15-0d 351 816 78J1RG0.239 GF Weight

20 - 20 E616.170 351 820 781 0.275

(mm) Code Code (kg)

d1 d2 1d36 G- 16d4 dE5616d.6150 l 35l1 81l62 78l13 l40.23l95 l6 z1 z2

(mm) (mm) 2(in0ch -) 2(m0m) (mEm6) 1(m6m.1) 7(0mm) 3(m5m1) 8(m2m0) 7(m8m1) (mm0) .2(m7m5) (mm) (mm) (mm)

16 16 1∕2 7 40 52 50 64 64 31 19 15 40 43 43

20 20 1∕2 7 40 52 50 69 69 31 19 16 40 45 45

d1 d2 d3 G d4 d5 d6 l l1 l2 l3 l4 l5 l6 z1 z2

(mm) (mm) (inch) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

16 16 1∕2 7 40 52 50 64 64 31 19 15 40 43 43

20 20 1∕2 7 40 52 50 69 69 31 19 16 40 45 45

Wall penetration, single

Wall penetration, single

• Material: brass, dezincification resistant

• Material: brass, dezincification resistant d GN JRG GF Weight

(mm)d (incGhN) CoJdReG CodGeF Wei(kggh)t

(m16m) (in1c∕2h) E625C.1o4d0e 351 816C 7o5d1e 0.21(k0g)

16 1∕2 E625.140 351 816 751 0.210

d GN d1 d3 Rp d4 d5 d6 G l l1 l3 z1

(mm)d (incGhN) (mmd)1 d(i3nc Rh)p (mmd)4 (mmd)5 (idnc6h )G (mm) l (mml)1 (mml)3 (mmz)1

(m16m) (in1c∕2h) (m16m) (in1c∕2h) (m7m) (m40m) (in3c∕4h) (m45m) (m50m) (m65m) (m33m)

16 1∕2 16 1∕2 7 40 3∕4 45 50 65 33

Wall penetration, double

Wall penetration, double

• Material: brass, dezincification resistant • Material: brass, dezincification resistant d-d GN JRG GF Weight

(mdm-)d (incGhN) CoJdReG CodGeF Wei(kggh)t

16 -( m16m) (in1c∕2h) E626C.1o4d0e 351 816C 7o6d1e 0.29(k0g)

16 - 16 1∕2 E626.140 351 816 761 0.290

d-d d1 d2 d3 Rp d4 d5 d6 G l l1 l2 l3 z1 z2

(mdm-)d (mmd)1 (mmd)2 d(i3nc Rh)p (mmd)4 (mmd)5 (idnc6h )G (mm) l (mml)1 (mml)2 (mml)3 (mmz)1 (mmz)2

16 -( m16m) (m16m) (m16m) (in1c∕2h) (m7m) (m40m) (in3c∕4h) (m45m) (m54m) (m54m) (m65m) (m33m) (m33m)

16 - 16 16 16 1∕2 7 40 3∕4 45 54 54 65 33 33

20

Manifold 2-way

Manifold 2-way

• Material: brass, dezincification resistant • Material: brass, dezincification resistant d JRG GF Weight d1 R l1 l2 l3 l4 l5 z1 ⎔

(mm)d CoJdReG CodGeF Wei(kggh)t (idnc1h )R (mml)1 (mml)2 (mml)3 (mml)4 (mml)5 (mmz)1 ⎔

(m16m) E645C.2o1d6e 351 816C 7o6d6e 0.33(k3g) (in3c∕4h) 1(m26m) (m46m) (m36m) (m55m) (m35m) (m25m) 36

2106 EE664455.2.2106 335511 8 82106 7 7666 00.3.3833 3∕34∕4 112266 5426 3366 555 3355 2285 3366

20 E645.220 351 820 766 0.383 3∕4 126 52 36 55 35 28 36

Manifold 3-way

Manifold 3-way

• Material: brass, dezincification resistant

• Material: brass, dezincification resistant d JRG GF Weight d1 Rp l1 l2 l3 l4 l5 z1 ⎔

(mm)d CoJdReG CodGeF Wei(kggh)t d(i1nc Rh)p (mml)1 (mml)2 (mml)3 (mml)4 (mml)5 (mmz)1 ⎔

(m16m) E645C.3o1d6e 351 816C 7o6d7e 0.46(k9g) (in3c∕4h) 1(m81m) (m46m) (m36m) (m55m) (m35m) (m25m) 36

2106 EE664455.3.32106 335511 8 82106 7 76677 00.5.43629 3∕34∕4 118811 5426 3366 555 3355 2285 3366

20 E645.320 351 820 767 0.532 3∕4 181 52 36 55 35 28 36