1/16ページ

ダウンロード(3.3Mb)

Paddlewheel,In-line Rotor,Turbine,Magnetic,Ultrasonic

GF flow sensors can be used in a wide variety of fluid media types.

All GF Signet fl ow sensors comply with the high and specifi c requirements of the industry.

GF provides reliable quality systems with worldwide support, long service life and cost-effi ciency

このカタログについて

| ドキュメント名 | Signet and Ultrasonic Flow Sensors - Product Range |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 3.3Mb |

| 取り扱い企業 | ジョージフィッシャー株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

GF Piping Systems

Signet and Ultrasonic

Flow Sensors

Paddlewheel, In-line Rotor,

Turbine, Magnetic, Ultrasonic

Page2

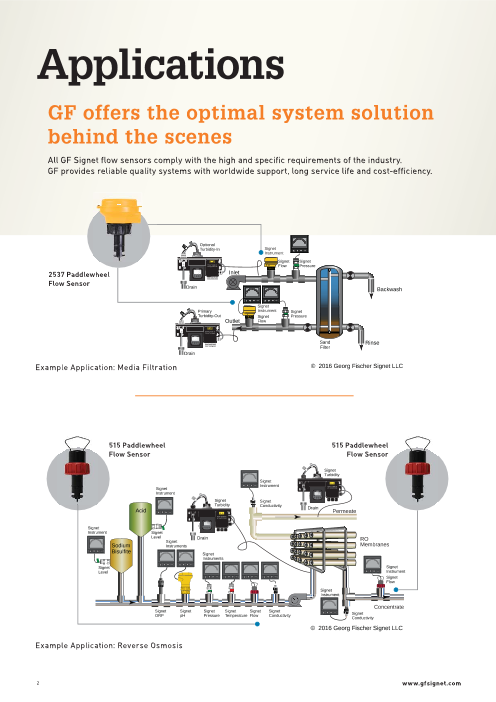

Applications

GF offers the optimal system solution

behind the scenes

All GF Signet fl ow sensors comply with the high and specifi c requirements of the industry.

GF provides reliable quality systems with worldwide support, long service life and cost-effi ciency.

Optional

Turbidity-In Signet ENTER

Instrument

Signet Signet

Power Supply &

Wiring Terminals Flow Pressure

2537 Paddlewheel Signet Turbidimeter InletENTER

Flow Sensor Drain Backwash

ENTER ENTER

Signet

Primary Instrument Signet

Turbidity-Out Signet Pressure

Outlet Flow

Power Supply &

Wiring Terminals

Signet Turbidimeter

ENTER Sand Rinse

Filter

Drain

Example Application: Media Filtration © 2016 Georg Fischer Signet LLC

515 Paddlewheel 515 Paddlewheel

Flow Sensor Flow Sensor

Signet

Turbidity

Signet

ENTER Instrument Power Supply &

Signet Wiring Terminals

Instrument

Signet Turbidimeter

ENTER

Signet Signet

Turbidity Conductivity

Acid DrainENTER Permeate

Power Supply &

Wiring Terminals

Signet Turbidimeter

Signet ENTER

Instrument Signet

Level Drain

Signet RO

Sodium Instruments Membranes

ENTER Bisulfite Signet

Instruments

ENTER ENTER

Signet Signet

Level ENTER Instrument

ENTER ENTER ENTER ENTER Signet

Flow

Signet

Instrument

Concentrate

Signet Signet Signet Signet Signet Signet ENTER

ORP pH Pressure Temperature Flow Conductivity SignetConductivity

© 2016 Georg Fischer Signet LLC

Example Application: Reverse Osmosis

2 www.gfsignet.com

Page3

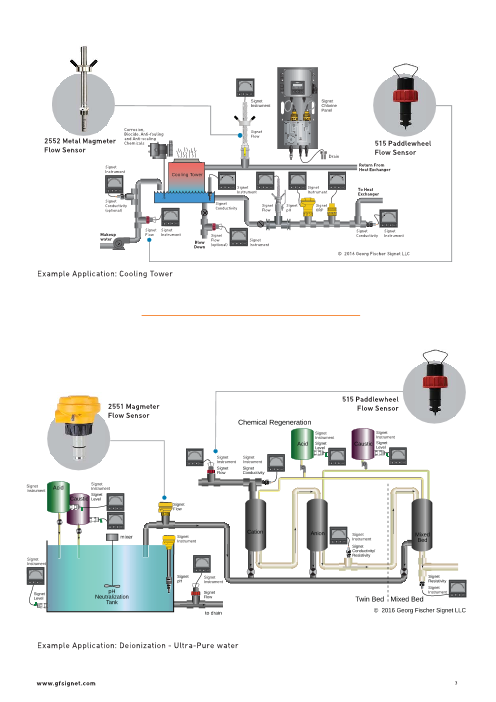

Signet Chlorine

Transmitter

Relay 1 Relay 2

ENTER

ENTER

Signet Signet

Instrument Chlorine

Panel

Corrosion, pH ClSignet

Biocide, Anti-fouling

2552 Metal Magmeter and Anti-scaling

Flow OUT

IN

Chemicals 515 Paddlewheel

Flow Sensor Flow Sensor

Drain

Signet Return From

Instrument Heat Exchanger

Cooling Tower

ENTER Signet ENTER ENTER Signet ENTER

ENTER To HeatInstrument Instrument Exchanger

Signet

Conductivity Signet Signet Signet Signet

(optional) Conductivity Flow pH ORP

ENTER

ENTER

Signet Signet Signet Signet

Makeup Flow Instrument Signet Conductivity Instrument

water

Blow Flow Signet

Down (optional)

ENTER Instrument

© 2016 Georg Fischer Signet LLC

Example Application: Cooling Tower

515 Paddlewheel

2551 Magmeter Flow Sensor

Flow Sensor

Chemical Regeneration

Signet Signet

Instrument Instrument

Acid Signet Caustic Signet

Level Level

Signet Signet

Instrument Instrument ENTERENTER

ENTER

Signet Signet ENTER

Flow Conductivity

Signet Signet

Instrument Acid Instrument

Signet

Caustic Level

Signet

ENTER Flow

ENTER

Cation Anion

mixer Signet Signet Mixed

Instrument InstrumentENTER Bed

Signet

Conductivity/

Resistivity

Signet

Instrument

ENTER

Signet Signet Signet

ENTER pH Instrument Resistivity

Signet

Signet pH Signet Instrument

Level Neutralization

ENTER

Flow

Tank Twin Bed Mixed Bed

to drain © 2016 Georg Fischer Signet LLC

Example Application: Deionization - Ultra-Pure water

www.gfsignet.com 3

Page4

Applications

GF flow sensors can be used in a wide

variety of fluid media types.

Flow rate measurements can be conducted in media ranging from highly pure to highly

contaminated, and allows a tailor made solution for almost any application in accordance

with the application requirements. Refer to the charts for sensor recommendations.

Paddlewheel Flow

- 515

- 525

- 2536

- 2537

- 2540

Paddlewheel Ultrasonic Turbine Magmeter

Industrial

Rotor/Turbine Flow Ultra-Pure x

DI Water x x x

- 2000 Tap Water x x x x

- 2507

- 2100 Brackish Water x x x

Sea Water x x

Brine Water x x

Conductive x x x

Chemical Contaminants

Organics x x x x

Magmeter Flow Corrosives x x

Chemical

- 2551 Transport x x x x

- 2552 Batch/Mix x x x

Waste Water

Particles x x

Fibers x

Municipal

Drinking x x x x

Wastewater x x

Ultrasonic Flow

- U1000

- U3000/4000

- 220/330

4 www.gfsignet.com

Page5

515 525 2536 2537 2540 2000 2507 2100 2551 2552 U1000 U3000 PF220U4000 PF330

Batch Process x x x x x

Boiler Feedwater Monitoring x x x

Chemical Dosing x x x

Chemical Processing x x x x

Chemical Production x x x x x

Chemical Transport x x

Chilled Water Metering x x x x x

Clarified Effluent x

Commercial Pools, Spas

and Aquariums x x x x x

Cooling Systems x x x x x x

Demineralized Water x x x x x

Fertigation x

Filtration Systems x x x

Fluid Dispensing x x

Gravity Feed Lines x x x

Ground Water Remediation x x

Heat Exchangers x x

High-Purity

Chemical Dispensing x

HVAC Systems x x x x x

Hydraulic Systems x x

Industrial Water Distribution x x x

Irrigation x x

Laboratory and

Clinical Wet Benches x

Leak Detection x x x x

Liquid Delivery Systems x x x

Metal Recovery and

Landfill Leachate x

Mining Applications x

Municipal Water Distribution x

Neutralization Systems x x x

Potable Water x

Process and Coolant Flow x x x x

Process Control x x x

Process Water Metering x x x x x x

Pump Protection x x x x x x

Pure Water Production x x x

Reverse Osmosis x x x x

River Water x

Scrubber Systems x x x x x

Textile Dyeing x x x

Turf Irrigation x

Ultra-Pure

Water measurement x x x

Wastewater Treatment x

Water Dilution x x x x

Water and

Wastewater Monitoring x x x x

Water Distribution x

Water Process Flow x x x x x x

Water/Glycol Solutions x x

Page6

Measuring Principals

GF flow sensors have a variety of

measurement types to fit your needs

All GF fl ow sensors belong to the broad category of velocity-based fl ow measurement

devices. Here is a general overview. Principles of operation vary considerably. Choose

the appropriate sensor for optimal fl ow measurement results.

Sine Wave Frequency output measurements

– 515 Sinusoidal sensors produce a signal

Volts

– 525 typical of self generating, non-powered

paddlewheel sensors. The frequency

Hz

and amplitude (voltage) both vary

directly with flow rate.

Open Collector frequency output measurements

5 to 24 VDC – 2536 Open Collector sensors produce a

±10% regulated – 2540 transistor-type square wave typical

of powered flow sensors with

– 2000 frequency output.

0 VDC – 2100

– 2507

– 2537

In-Line Rotor fl ow rate measurements

– 2000 In-line rotor type sensors produce a

– 2507 transistor-type square wave output

signal. Positioned in the flow cell,

Flow Flow

they are able to measure lower

flow rates.

6 www.gfsignet.com

Page7

Turbine fl ow rate measurements

– 2100 Turbine fl ow sensors are full-bore

devices designed for low fl ow

measurements. Similar to paddlewheels,

they rely on the energy in the fl ow stream

to spin a rotor (turbine). The diff erence is

Flow the shaft is in the center of, and parallel

to, the fl ow stream. The velocity of the

liquid spins the turbine for detection by

external electronic circuitry, producing

a transistor-type square wave with a

frequency directly proportional to the

fl ow rate.

Sensor Magnetic inductive fl ow rate measurements

– 2551 Electromagnetic fl ow sensors operate

Magnetic

Core – 2552 on Faraday‘s principal of electromagnetic

Fitting induction, and have no moving parts.

As a conductive fl uid (>20μS) moves

through the magnetic fi eld produced at

Flow the sensor tip, a voltage occurs that is

Flow directly proportional to the fl uid velocity.

Flow Internal electronics then convert this

Magnetic Flow voltage to a frequency and/or 4 to 20 mA

Lines of Force

Electrodes output.

Ultrasonic clamp-on fl ow rate measurements

Sensor Blocks – U1000 Ultrasonic flow meters work on the

A B

– U3000 basis of the Transit Time principle of

ultrasonic ultrasonic sound in liquid media.

beam – U4000Flow Two transducers send and receive

– PF220

inside of pipe ultrasonic bursts into the pipe up and

– PF330 down stream the of flow. Depending

on the flow velocity there is a

noticeable time difference between

the up and down stream signal. The

difference is proportional to the

actual flow rate.

www.gfsignet.com 7

Page8

Performance Data

515 Paddlewheel Flow Sensor

Sensor type 515 insertion paddlewheel

Operating range m/s 0.3 - 6 m/s

Accuracy n/a

Repeatability ± 0.5% of max. range

Linearity ± 1% of max. range

Frequency 19.7 Hz per m/s nominal

Pipe size range 0.5 in. - 36 in.

Supply voltage None

Source impedance 8 KΩ

Sensor body PP, PVDF

Rotor PVDF, ETFE

Rotor pin Titanium, Hastelloy-C, Natural PVDF, Ceramic,

Stainless Steel, Tantalum

O-ring FPM, EPDM, FFPM

Operating temperature PP: -18 °C - 90 °C

PVDF: -18 °C - 100 °C

Operating pressure PP: 12.5 bar @ 20 °C PVDF: 14 bar @ 20 °C

PP: 1.7 bar @ 90 °C PVDF: 1.4 bar @ 100 °C

Output AC frequency

Approvals RoHS compliant, China RoHS, Lloyd's Register,

NSF (-PX version only)

525 Paddlewheel Flow Sensor

Specifications

Sensor type 525 insertion paddlewheel

Operating range m/s 0.5 - 6 m/s

Accuracy n/a

Repeatability ± 0.5% of max range

Linearity ± 1% of max range

Frequency 39 Hz per m/s nominal

Pipe size range 0.5 in. - 12 in.

Supply voltage None

Source impedance 11.6 KΩ

Sensor body SS 316

Rotor 17-4PH-1 Stainless Steel

Rotor pin Tungsten Carbide, Stainless Steel 316

Operating temperature -18 °C - 149 °C

Operating pressure 103 bar @ 149 °C

Approvals RoHS compliant, China RoHS

8 www.gfsignet.com

Page9

2536 Paddlewheel Flow Sensor

Specifications

Sensor type 2536 insertion paddlewheel

Operating range m/s 0.1 - 6 m/s

Accuracy n/a

Repeatability ± 0.5% of max. range

Linearity ± 1% of max. range

Frequency 49 Hz per m/s nominal

Pipe size range 0.5 in. - 36 in.

Supply voltage 5 - 24 VDC

Sensor body PP, PVDF, PVC

Rotor PVDF, ETFE, PVC

Rotor pin Titanium, Hastelloy-C, Natural PVDF, Ceramic,

Stainless Steel, Tantalum

O-ring FPM, EPDM, FFPM

Operating temperature PP: -18 °C - 85 °C

PVC: 0 °C - 60 °C

PVDF: -18 °C - 85 °C

Operating pressure PP: 12.5 bar @ 20 °C

PP: 1.7 bar @ 85 °C

PVC: 12.5 bar @ 20 °C

PVC: 6.9 bar @ 60 °C

PVDF: 14 bar @ 20 °C

PVDF: 1.7 bar @ 85 °C

Approvals CE, FCC, NSF (3-2536-PX only)

2537 Paddlewheel Flow Sensor

Specifications

Sensor type 2537 insertion paddlewheel

Operating range m/s 0.1 - 6 m/s

Accuracy n/a

Repeatability ± 0.5% of max. range

Linearity ± 1% of max. range

Frequency n/a

Pipe size range 0.5 in. - 8 in.

Supply voltage 5 - 24 VDC

Sensor body PP, PVDF

Rotor PVDF, ETFE

Rotor pin Titanium, Hastelloy-C, Natural PVDF, Ceramic,

Stainless Steel, Tantalum

O-ring FPM, EPDM, FFPM

Other n/a

Operating temperature PP: -18 °C - 90 °C

PVDF: -18 °C - 100 °C

Operating pressure PP: 12.5 bar @ 20 °C

PP: 1.7 bar @ 90 °C

PVDF: 14 bar @ 20 °C

PVDF: 1.4 bar @ 100 °C

Output Open collector, 4-20 mA, Digital (S3L), DCR relay,

SSR relay

Approvals CE, FCC, UL, NSF (3-2537-XC-PX version only)

2540 Paddlewheel Flow Sensor

Specifications

Sensor type 2540 (insertion paddlewheel)

Operating range m/s 0.1 - 6 m/s

Accuracy n/a

Repeatability ± 0.5% of max. range

Linearity ± 1% of max. range

Frequency 49 Hz per m/s nominal

Pipe size range 1.5 in. - 36 in.

Supply voltage 5 - 24 VDC

Sensor body SS 316

Rotor 17-4PH-1 Stainless Steel

Rotor pin Tungsten Carbide, Stainless Steel 316

O-ring FPM, EPDM

Other Carbon fiber reinforced PTFE bearing

Operating temperature -18 °C - 100 °C

Operating pressure 17 bar @ 100 °C

Output Open collector

Approvals CE, FCC, RoHS compliant, China RoHS

www.gfsignet.com 9

Page10

2551 Magmeter

Specifications

Additional features: Sensor type 2551 Insertion magmeter

- Empty pipe detection Operating range m/s 0.05 - 10 m/s

Accuracy n/a

- Bi-directional Repeatability ± 0.5% of reading

- Relay Linearity ± 1% of reading

- Multi-language Pipe size range 0.5 in. - 36 in.

display version Supply voltage 5 - 24 VDC

- Min. conductivity Sensor body PP, PVDF

20 uS/cm Other SS 316L, Hastelloy-C, Titanium

Operating temperature Ambient -10 °C - 70 °C

Media 0 °C - 85 °C

Operating pressure 10.3 bar @ 25 °C

1.4 bar @ 85 °C

Output Frequency, S3L, 4 to 20 mA

Approvals CE, UL, CUL, RoHS compliant

2552 Metal Magmeter

Specifications

Additional features: Sensor type 2552 Insertion magmeter

- Empty pipe detection Operating range m/s 0.05 - 10 m/s

Accuracy ± 2% of measured value

- Bi-directional Repeatability ± 0.5% of reading

- Min. conductivity Linearity ± 1% of reading

20 uS/cm Frequency 5 to 6.5 VDC 15 mA maximum

Pipe size range 2 in. - 102 in.

Supply voltage 5 - 24 VDC

Sensor body SS 316L

Other PVDF

Operating temperature Ambient -15 °C - 70 °C

Media -15 °C - 85 °C

Operating pressure 20.7 bar @ 25 °C

Output Frequency, S3L, 4-20 mA

Approvals CE, RoHS compliant

2000 Micro Flow Sensor

Specifications

Additional features: Sensor type 2000 In-line rotor

Operating range m/s 0.11 to 12.11 l/m

- L owest flow range Accuracy n/a

110 mL/min. Pipe size range ¼ in. tubing

- P PS body for Supply voltage 5 - 24 VDC

tough service Sensor body PPS

- Good chemical Rotor PEEK™

resistance O-ring FPM

Operating temperature 0 °C to 80 °C

Operating pressure 80 psi

Output Open collector

2507 Micro Flow Sensor

Specifications

Additional features: Sensor type 2507 In-line rotor

Operating range m/s 0.4 to 12.0 l/m

- Detachable signal Accuracy ± 2.0% of reading

connector Repeatability ± 0.25% of full range

- Replacement inserts Pipe size range ¼ in. tubing

for different flow Supply voltage 5 - 24 VDC

ranges Sensor body PVDF

- Good chemical Rotor PVDF

resistance O-ring FPM

Operating temperature -30 °C to 120 °C

Operating pressure 80 psi

Output Open collector

Approvals CE, FCC, RoHS compliant, China RoHS

10 www.gfsignet.com

Page11

2100 Turbine Flow Sensor

Specifications

Sensor type 2100 In-line turbine

Operating range m/s 0.38 to 38.0 l/m

Accuracy ± 3% of reading

Repeatability ± 0.5% of reading

Pipe size range ¼“, ⅜“, ½“ (tubing), ½“ (piping)

Supply voltage 5 ~ 24 VDC

Sensor body PVDF

Rotor PVDF

O-ring FPM, EPDM

Other Ceramic bearing

Operating temperature -20 °C to 70 °C

Operating pressure 130 psi

Output Open collector

Approvals CE, FCC, RoHS compliant, China RoHS

U1000 Ultrafl ow Ultrasonic Flow Sensor

Specifications

Additional features: Sensor type U1000 Ultrasonic Clamp-on

- Bi-directional Operating range m/s 0.1 ~ 10 m/s

Accuracy ±3 % of flow reading

Repeatability ±5 % of measured flow

Pipe size range 1 in. - 4.5 in.

Supply voltage 12 to 24 VAC or DC

Enclosure material Polycarbonate

Keypad 4 key tactile feedback membrane keypad

Operating temperature 0 °C to 85 °C

Operating humidity Max. 90% relative humidity @ 50 °C

Output Analog, Pulse output

Approvals CE

U3000/U4000 Ultrafl ow Ultrasonic Flow Sensor

Specifications

Additional features: Sensor type U3000-4000 Ultrasonic Clamp-on

- Datalogger 198K data Operating range m/s 0.1 ~ 20 m/s

Accuracy ±0.5% to ±3% of flow reading for Pipe ID >75 mm

points

±3% of flow reading Pipe ID 13 mm - 75 mm

Repeatability ±0.5% of measured value or ±0.2 m/s whichever

is greater

Pipe size range 0.5 in. - 78 in.

Supply voltage 12 - 24 VAC or DC; 86 - 264 VAC

Operating temperature -20 °C to 50 °C

Pipe wall temperature -20 °C to 135 °C

Operating humidity Max. 90% relative humidity @ 50 °C

Output 4 to 20 mA, 0 to 20 mA, 0 to 16 mA, Pulse output,

2 Alarm outputs

Approvals CE

220/330 Portafl ow Portable Ultrasonic Flow Sensor

Specifications

Sensor type 220/330 Ultrasonic Clamp-on

Operating range m/s 0.1 ~ 20 m/s

Accuracy ±0.5% to ±3% of flow reading for Pipe ID >75 mm

±3% of flow reading Pipe ID 13 mm - 75 mm

Repeatability ±0.5% of measured value or ±0.2 m/s whichever is

greater

Pipe size range 13 mm to 2000 mm OD

Supply voltage Battery power

Enclosure material ABS and aluminium

Operating temperature -20 °C to 50 °C

Pipe wall temperature -20 °C to 135 °C

Output Analog, Pulse output, USB, RS232

Approvals - Electrical UL, CUL, TUV, CB, CE

Approvals - Data logger CE, RoHS compliant

www.gfsignet.com 11

Page12

Temperature/

Pressure Graphs

Note:

The pressure/temperature graphs are specifically for the Signet sensor. During system design the specifications of all

components must be considered. In the case of a metal piping system, a plastic sensor will reduce the system specification.

When using a PVDF sensor in a PVC piping system, the fitting will reduce the system specification.

515 Paddlewheel Flow Sensor 2536 & 2537 Paddlewheel Flow Sensor

(psi) (bar) (psi) (bar)

210 14.5 210 14.5

200 13.8 200 13.8

190 13.1 190 13.1

180 12.4 180 12.4

170 11.7 170 11.7

160 11.0 160 11.0

150 10.3 150 10.3

140 9.7 140 9.7

130 9.0 130 9.0

120 8.3 120 8.3

110 7.6 110 7.6

100 6.9 100 6.9

90 6.2 90 6.2

80 5.5 80 5.5

70 4.8 70 4.8

60 4.1 60 4.1

50 3.4 50 3.4

40 2.8 40 2.8

30 2.1 30 2.1

20 1.4 20 1.4

10 .7 10 .7

0 0

°C -20 0 20 40 60 80 100 120 °C -20 0 20 40 60 80 100 120

°F -4 32 68 104 140 176 212 248 °F -4 32 68 104 140 176 212 248

*2537 Only: Graph applies to wetted materials (sensor) only.

Maximum ambient temperature is 65°C.

525 Paddlewheel Flow Sensor 2540 Paddlewheel Flow Sensor

(psi) (bar) (psi) (bar)

1800 124.1 300 20.7

280 19.3

1700 117.2

260 17.9

1600 110.3

Tee or Mini-Tap Fitting 240 16.5

1500 103.4

220 15.2

1400 96.5

200 13.8

1300 89.6

180 12.4

1200 82.7

160 11.0

1100 75.8

140 9.7

1000 68.9

120 8.3

900 62.1

800 55.2 100 6.9

80 5.5

700 48.3

60 4.1

600 41.4

40 2.8

500 34.5

20 1.4

400 27.6 Saddle Fitting

0

300 20.7 °C -20 0 20 40 60 80 100 120

200 13.8 °F -4 32 68 104 140 176 212 248

100 6.9

0

°C -40 -20 0 20 40 60 80 100 120 140 160

°F -40 -4 32 68 104 140 176 212 248 284 320

12 www.gfsignet.com

EPDM O-ring

FPM O-ring

ne

opy

le

PVD

F Poly

pr

ylen

e

VDF olyp

rop

P P

Page13

2551 Magmeter 2507 Micro Flow Sensor

(psi) (bar) (psi) (bar)

180 12.4 120 8.2

170 11.7 100 6.9

160 11.0 80 5.5

150 10.3 60 4.1

140 9.7 40 2.8

130 9.0 20 1.4

120 8.3 0

110 7.6 °C -40 -20 0 20 40 60 80 100 120

°F -40 -4 32 68 104 140 176 212 248

100 6.9

90 6.2

80 5.5

70 4.8 2100 Turbine Flow Sensor

60 4.1

50 3.4 (psi) (bar)

300 20.7

40 2.8

280 19.3

30 2.1

260 17.9

20 1.4

240 16.5 PVDF

10 .7

220 15.2

0

°C -20 0 20 40 60 80 100 120 200 13.8

°F -4 32 68 104 140 176 212 248 180 12.4

160 11.0

140 9.7

2552 Metal Magmeter 120 8.3

100 6.9

(psi) (bar)

80 5.5

360 24.8 60 4.1

340 23.4 40 2.8

320 22.0 20 1.4

300 20.7 0

280 19.3 °C -40 -20 0 20 40 60 80

260 17.9 °F -40 -4 32 68 104 140 176

240 16.5

220 15.2 Pressure Drop - Very Low Flow

200 13.8

(psi) (bar)

180 12.4

2.5 0.17

160 11.0

140 9.7 2.0 1.4

120 8.3

100 6.9 1.5 0.10

80 5.5

60 4.1

1.0 0.07

40 2.8

20 1.4

0.5 .03

0

°C -20 0 20 40 60 80 100 120

°F -4 32 68 104 140 176 212 248 0

LPM 0 0.19 0.38 0.57 0.75 0.95

GPM 0 0.05 0.1 0.15 0.2 0.25

Flow

2000 Micro Flow Sensor

Pressure Drop - Low Flow

Pressure Drop - Low Flow

2100 - Pressure Drop-Low Flow

(psi) (bar) (psi) (bar)

30 2.1 30 2.1

20 1.4 20 1.4

low w

Low

F Flo

10 0.7 10 .7 Low

0 0

LPM 0 0.8 1.5 2.3 3.0 3.8 LPM 0 0.8 1.5 2.3 3.0 3.8

GPM 0 0.2 0.4 0.6 0.8 1.0 GPM 0 0.2 0.4 0.6 0.8 1.0

Flow Flow

www.gfsignet.com 13

Pressure Drop

Pressure Drop Pressure Drop

Very Low Flow

Maximum Hot-Tap

Page14

Flow Range Charts

Paddlewheel and Electromagnetic Sensors -GPM

Signet Models 515, 525, 2536, 2537, 2540, 2551, 2552

GPM Flow Rates for DN15 to DN450 (½ in. to 18 in.) pipe sizes

Nominal Pipe Size 2551/2552 2536/8512/2537/2540 515 and 8510 525

Metric Min Max Min Max Min Max Min Max

Inch DN

(mm) 0.15 ft/s 33 ft/s 0.3 ft/s 20 ft/s 1 ft/s 20 ft/s 1.6 ft/s 20 ft/s

0.5 15 0.14 31.25 0.28 18.94 0.95 18.94 1.52 18.94

0.75 20 0.25 54.85 0.50 33.24 1.66 33.24 2.66 33.24

1 25 0.40 88.89 0.81 53.88 2.69 53.88 4.31 53.88

1.25 32 0.70 153.84 1.40 93.24 4.66 93.24 7.46 93.24

1.5 40 0.95 209.40 1.90 126.91 6.35 126.91 10.15 126.91

2 50 1.57 345.15 3.14 209.18 10.46 209.18 16.73 209.18

2.5 65 2.24 492.45 4.48 298.46 14.92 298.46 23.88 298.46

3 80 3.46 760.39 6.91 460.84 23.04 460.84 36.87 460.84

4 100 5.95 1309.40 11.90 793.57 39.68 793.57 63.49 793.57

5 125 9.35 2057.74 18.71 1247.12 62.36 1247.12 99.77 1247.12

6 150 13.51 2971.57 27.01 1800.95 90.05 1800.95 144.08 1800.95

8 200 23.39 5145.63 46.78 3118.57 155.93 3118.57 249.49 3118.57

10 250 36.87 8110.73 73.73 4915.59 245.78 4915.59 393.25 4915.59

12 300 52.33 11512.97 104.66 6977.56 348.88 6977.56 558.20 6977.56

14 350 - - 126.49 8432.82 421.64 8432.82 - -

16 400 - - 165.24 11015.97 550.80 11015.97 - -

18 450 - - 209.16 13943.74 697.19 13943.74 - -

14 www.gfsignet.com

Page15

Paddlewheel and Electromagnetic Sensors - LPM

Signet Models 515, 525, 2536, 2537, 2540, 2551, 2552

LPM Flow Rates for DN15 to DN450 (½ in. to 18 in.) pipe sizes

Nominal Pipe Size 2551/2552 2536/8512/2537/2540 515 and 8510 525

Min Max Min Max Min Max Min Max

Inch Metric DN(mm) 0.05 m/s 10 m/s 0.1 m/s 6 m/s 0.3 m/s 6 m/s 0.5 m/s 6 m/s

0.5 15 0.6 117.6 1.2 70.6 3.5 70.6 5.9 70.6

0.75 20 1.0 206.4 2.1 123.9 6.2 123.9 10.3 123.9

1 25 1.7 334.5 3.3 200.7 10.0 200.7 16.7 200.7

1.25 32 2.9 579.0 5.8 347.4 17.4 347.4 28.9 347.4

1.5 40 3.9 788.1 7.9 472.8 23.6 472.8 39.4 472.8

2 50 6.5 1298.9 13.0 779.4 39.0 779.4 64.9 779.4

2.5 65 9.3 1853.3 18.5 1112.0 55.6 1112.0 92.7 1112.0

3 80 14.3 2861.7 28.6 1717.0 85.9 1717.0 143.1 1717.0

4 100 24.6 4927.8 49.3 2956.7 147.8 2956.7 246.4 2956.7

5 125 38.7 7744.2 77.4 4646.5 232.3 4646.5 387.2 4646.5

6 150 55.9 11183.3 111.8 6710.0 335.5 6710.0 559.2 6710.0

8 200 96.8 19365.3 193.7 11619.2 581.0 11619.2 968.3 11619.2

10 250 152.6 30524.2 305.2 18314.5 915.7 18314.5 1526.2 18314.5

12 300 216.6 43328.4 433.3 25997.0 1299.9 25997.0 2166.4 25997.0

14 350 - - 523.7 31419.1 1571.0 31419.1 - -

16 400 - - 684.1 41043.4 2052.2 41043.4 - -

18 450 - - 865.9 51951.7 2597.6 51951.7 - -

In-line Rotor and Turbine Sensors - GPM/LPM

Signet Models 2000, 2100, and 2507

GPM and LPM Flow Rates

GPM LPM

Model and Size Description Min Max Min Max

3-2000-1X Micro Flow - Low 0.030 0.700 0.110 2.600

3-2000-2X Micro Flow - High 0.300 3.200 1.130 12.110

3-2100-XL and -31 Kits Turbine Low - 1/2” Tubing 0.100 1.000 0.380 3.800

3-2100-XL and -32 Kits Turbine Low - 3/8” Tubing 0.100 1.000 0.380 3.800

3-2100-XL and -33 Kits Turbine Low - 1/4” Tubing 0.100 1.000 0.380 3.800

3-2100-XL and -34 thru -38 Kits Turbine Low - 1/2” Pipe 0.100 1.000 0.380 3.800

3-2100-XH and -31 kits Turbine High - 1/2” Tubing 0.800 10.000 3.000 38.000

3-2100-XH and -34 thru -38 Kits Turbine High - 1/2” Pipe 0.800 10.000 3.000 38.000

3-2507.100-2V Mini Flow - 2 mm Insert 0.106 0.740 0.500 2.800

3-2507.100-3V Mini Flow - 3 mm Insert 0.198 1.123 0.750 4.250

3-2507.100-4V Mini Flow - 4 mm Insert 0.330 1.585 1.250 6.000

3-2507.100-6V Mini Flow - 6 mm Insert 0.792 3.170 3.000 12.000

www.gfsignet.com 15

Page16

GF Piping Systems

Worldwide at home

Our sales companies and representatives

ensure local customer support in over 100 countries.

www.gfsignet.com

Argentina / Southern South America France Mexico / Northern Latin America Singapore

Georg Fischer Central Plastics Georg Fischer SAS Georg Fischer S.A. de C.V. George Fischer Pte Ltd

Sudamérica S.R.L. 95932 Roissy Charles de Gaulle Cedex Apodaca, Nuevo Leon 11 Tampines Street 92, #04-01/07

Buenos Aires, Argentina Phone +33 (0) 1 41 84 68 84 CP66636 Mexico 528 872 Singapore

Phone +54 11 4512 02 90 fr.ps@georgfi scher.com Phone +52 (81) 1340 8586 Phone +65 6747 0611

gfcentral.ps.ar@georgfi scher.com www.gfps.com/fr Fax +52 (81) 1522 8906 Fax +65 6747 0577

www.gfps.com/ar mx.ps@georgfi scher.com sgp.ps@georgfi scher.com

Germany www.gfps.com/mx www.gfps.com/sg

Australia Georg Fischer GmbH

George Fischer Pty Ltd 73095 Albershausen Middle East Spain / Portugal

Riverwood NSW 2210 Australia Phone +49 (0) 7161 302-0 Georg Fischer Georg Fischer S.A.

Phone +61 (0) 2 9502 8000 info.de.ps@georgfi scher.com Piping Systems (Switzerland) Ltd 28046 Madrid

australia.ps@georgfi scher.com www.gfps.com/de Dubai, United Arab Emirates Phone +34 (0) 91 781 98 90

www.gfps.com/au Phone +971 4 289 49 60 es.ps@georgfi scher.com

India gcc.ps@georgfi scher.com www.gfps.com/es

Austria Georg Fischer Piping Systems Ltd www.gfps.com/int

Georg Fischer 400 076 Mumbai Sweden

Rohrleitungssysteme GmbH Phone +91 224007 2001 Netherlands Georg Fischer AB

3130 Herzogenburg branchoffi ce@georgfi scher.com Georg Fischer N.V. 117 43 Stockholm

Phone +43 (0) 2782 856 43-0 www.gfps.com/in 8161 PA Epe Phone +46 (0) 8 506 775 00

austria.ps@georgfi scher.com Phone +31 (0) 578 678 222 info.se.ps@georgfi scher.com

www.gfps.com/at Indonesia nl.ps@georgfi scher.com www.gfps.com/se

George Fischer Pte Ltd – www.gfps.com/nl

Belgium / Luxembourg Representative Offi ce Switzerland

Georg Fischer NV/SA Phone +62 21 2900 8564 Norway Georg Fischer

1070 Bruxelles/Brüssel Fax +62 21 2900 8566 Georg Fischer AS Rohrleitungssysteme (Schweiz) AG

Phone +32 (0) 2 556 40 20 sgp.ps@georgfi scher.com 1351 Rud 8201 Schaff hausen

be.ps@georgfi scher.com www.gfps.com/sg Phone +47 67 18 29 00 Phone +41 (0) 52 631 30 26

www.gfps.com/be no.ps@georgfi scher.com ch.ps@georgfi scher.com

Italy www.gfps.com/no www.gfps.com/ch

Brazil Georg Fischer S.p.A.

Georg Fischer Sist. de Tub. Ltda. 20063 Cernusco S/N (MI) Philippines Taiwan

04795-100 São Paulo Phone +39 02 921 861 George Fischer Pte Ltd Georg Fischer Co., Ltd

Phone +55 (0) 11 5525 1311 it.ps@georgfi scher.com Representative Offi ce San Chung Dist., New Taipei City

br.ps@georgfi scher.com www.gfps.com/it Phone +632 571 2365 Phone +886 2 8512 2822

www.gfps.com/br Fax +632 571 2368 Fax +886 2 8512 2823

Japan sgp.ps@georgfi scher.com www.gfps.com/tw

Canada Georg Fischer Ltd www.gfps.com/sg

Georg Fischer Piping Systems Ltd 556-0011 Osaka, United Kingdom / Ireland

Mississauga, ON L5T 2B2 Phone +81 (0) 6 6635 2691 Poland George Fischer Sales Limited

Phone +1 (905) 670 8005 jp.ps@georgfi scher.com Georg Fischer Sp. z o.o. Coventry, CV2 2ST

Fax +1 (905) 670 8513 www.gfps.com/jp 05-090 Sekocin Nowy Phone +44 (0) 2476 535 535

ca.ps@georgfi scher.com Phone +48 (0) 22 31 31 0 50 uk.ps@georgfi scher.com

www.gfps.com/ca Korea poland.ps@georgfi scher.com www.gfps.com/uk

GF Piping Systems www.gfps.com/pl

China Georg Fischer Korea Co., Ltd. USA / Caribbean

Georg Fischer P iping Systems Ltd Unit 2501, U-Tower Romania Georg Fischer LLC

Shanghai 201319 120 HeungdeokJungang-ro (Yeongdeok-dong) Georg Fischer 9271 Jeronimo Road

Phone +86 21 3899 3899 Giheung-gu, Yongin-si, Gyeonggi-do, Korea Piping Systems (Switzerland) Ltd 92618 Irvine, CA

china.ps@georgfi scher.com Phone: +82 31 8017 1450 020257 Bucharest - Sector 2 Phone +1 714 731 88 00

www.gfps.com/cn Fax : +82 31 217 1454 Phone +40 (0) 21 230 53 80 Fax +1 714 731 62 01

kor.ps@georgfi scher.com ro.ps@georgfi scher.com us.ps@georgfi scher.com

Denmark / Iceland www.gfps.com/kr www.gfps.com/int www.gfps.com/us

Georg Fischer A/S

2630 Taastrup Malaysia Russia International

Phone +45 (0) 70 22 19 75 George Fischer (M) Sdn. Bhd. Georg Fischer Georg Fischer

info.dk.ps@georgfi scher.com 40460 Shah Alam, Selangor Darul Ehsan Piping Systems (Switzerland) Ltd Piping Systems (Switzerland) Ltd

www.gfps.com/dk Phone +60 (0) 3 5122 5585 Moscow 125047 8201 Schaff hausen/Switzerland

Fax +603 5122 5575 Phone +7 495 258 60 80 Phone +41 (0) 52 631 30 03

Finland my.ps@georgfi scher.com ru.ps@georgfi scher.com Fax +41 (0) 52 631 28 93

Georg Fischer AB www.gfps.com/my www.gfps.com/ru info.export@georgfi scher.com

01510 VANTAA www.gfps.com/int

Phone +358 (0) 9 586 58 25

Fax +358 (0) 9 586 58 29

info.fi .ps@georgfi scher.com

www.gfps.com/fi

The technical data is not binding. They neither constitute expressly

warranted characteristics nor guaranteed properties nor a guaranteed durability.

They are subject to modification. Our General Terms of Sale apply.

3-0000.731 (Rev A 11/16)

©2016 Georg Fischer Signet LLC

3401 Aero Jet Avenue, El Monte CA 91731-2882

Tel (626) 571-2770, Fax (626) 573-2057