1/461ページ

ダウンロード(23.4Mb)

Measurement and Control Product Catalog

このカタログについて

| ドキュメント名 | Signet Instrumentation - Product Range |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 23.4Mb |

| 取り扱い企業 | ジョージフィッシャー株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

GF Piping Systems

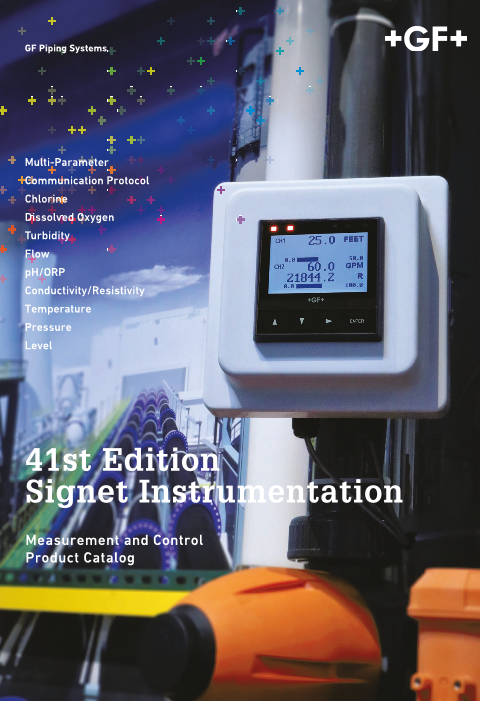

Multi-Parameter

Communication Protocol

Chlorine

Dissolved Oxygen

Turbidity

Flow

pH/ORP

Conductivity/Resistivity

Temperature

Pressure

Level

41st Edition

Signet Instrumentation

Measurement and Control

Product Catalog

41st Edition Signet Measurement and Control Product Catalog

Page2

GF Piping Systems

Your global system provider

We are dedicated to designing, manufacturing and marketing

piping systems for the safe and secure conveyance of liquids.

Customer Support

In choosing Georg Fischer, you can be assured of excellent customer

service through our extensive network of distributors located

throughout the world. Our sta are well qualifi ed to assist you in

every aspect of product selection thus assuring you of the right

solution for your liquid control needs.

Pipes

GF Quality, Sustainability and Security by Design

Quality Management: Our systems and products undergo rigorous

testing in accredited test laboratories, and our management and

production procedures are certified to ISO 9001, ISO 14001 and

OHSAS 18001 through ensuring that the systems and products we

provide are fit for the purpose, and may be used reliably throughout Fittings

the world.

GF Values

Jointing Technologies

We put customers fi rst

- Customer needs guide our product development

- We o er customer support and training worldwide

- We measure your satisfaction

We act fast

- Local presence worldwide Valves

- Superior logistics

- Speed in all details

We do what we say

- Tested quality

- Always trustworthy

Actuation

We reward performance

- We benchmark ourselves against the best

We respect people

- We value all contributions

Measurement and Control

Page3

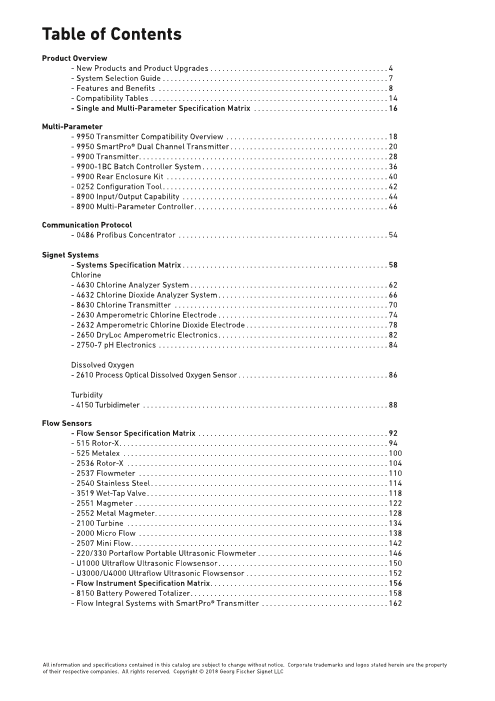

Table of Contents

Product Overview

- New Products and Product Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

- System Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

- Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

- Compatibility Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

- Single and Multi-Parameter Specification Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Multi-Parameter

- 9950 Transmitter Compatibility Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

- 9950 SmartPro® Dual Channel Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

- 9900 Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

- 9900-1BC Batch Controller System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

- 9900 Rear Enclosure Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

- 0252 Configuration Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

- 8900 Input/Output Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

- 8900 Multi-Parameter Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Communication Protocol

- 0486 Profibus Concentrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Signet Systems

- Systems Specification Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Chlorine

- 4630 Chlorine Analyzer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

- 4632 Chlorine Dioxide Analyzer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

- 8630 Chlorine Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

- 2630 Amperometric Chlorine Electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

- 2632 Amperometric Chlorine Dioxide Electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

- 2650 DryLoc Amperometric Electronics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

- 2750-7 pH Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Dissolved Oxygen

- 2610 Process Optical Dissolved Oxygen Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Turbidity

- 4150 Turbidimeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Flow Sensors

- Flow Sensor Specification Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

- 515 Rotor-X. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

- 525 Metalex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

- 2536 Rotor-X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

- 2537 Flowmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

- 2540 Stainless Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

- 3519 Wet-Tap Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

- 2551 Magmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

- 2552 Metal Magmeter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

- 2100 Turbine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

- 2000 Micro Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

- 2507 Mini Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

- 220/330 Portaflow Portable Ultrasonic Flowmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

- U1000 Ultraflow Ultrasonic Flowsensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

- U3000/U4000 Ultraflow Ultrasonic Flowsensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

- Flow Instrument Specification Matrix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

- 8150 Battery Powered Totalizer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

- Flow Integral Systems with SmartPro® Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

All information and specifications contained in this catalog are subject to change without notice. Corporate trademarks and logos stated herein are the property

of their respective companies. All rights reserved. Copyright © 2018 Georg Fischer Signet LLC

Page4

pH/ORP Electrodes and Electronics

- pH/ORP Electrodes Specification Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

- pH/ORP Electrodes Application Matrix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

- 2724-2726 DryLoc®. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

- 2734-2736 DryLoc®. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

- 2764-2767 DryLoc® Differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

- 2774-2777 Threaded DryLoc®. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

- 3719 Wet-Tap Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

- 2756-2757 Wet-Tap Electrodes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

- 2751 DryLoc® Smart Sensor Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

- 2760 DryLoc® Preamplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

- pH/ORP Instrument Specification Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Conductivity/Resistivity Electrodes and Electronics

- Conductivity/Resistivity Electrodes Specification Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

- 2818-2823 Stainless and Titanium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

- 2819-SX to 2821-TX Sanitary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

- 2839-1V(D)-2842-1V(D) PVDF Conductivity Electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

- 2850 Conductivity Sensor Electronics and Integral Systems with PVDF Sensor . . . . . . . . 228

- Conductivity/Resistivity Instrument Specification Matrix. . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

- 8860 Two-Channel ProcessPro® Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

- Conductivity Integral System with SmartPro® Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Level Sensors

- Level Specification Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

- Level Application Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

- 2250 Hydrostatic Pressure for Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

- 2260 Ultrasonic Level Transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

- 2260 Ultrasonic Level Transmitter with EX Approval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

- 2270 Ultrasonic Level Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

- 2280 Tuning Forks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

- 2281 Multipoint Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

- 2282 Guided Float Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

- 2284 Ultrasonic Gap Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

- 2285 Level Float Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

- 2290 Non-contact Radar Level Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

- 2291 Guided Wave Radar Level Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

- 2350 Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

- 2450 Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

- Temperature, Pressure Instrument Specification Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

- Temperature Integral System with SmartPro® Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . 294

- Pressure Integral System with SmartPro® Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Calibration and Testing Accessories

- pH/ORP Buffer Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

- Calibration Kits for Turbidimeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

- Formazin Stock Kit for Turbidimeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

- 2759 pH/ORP System Tester. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

- Conductivity/Resistivity Certification Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Other Products, Fittings, Accessories & Replacement Parts

- 0252 Configuration Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

- 7310 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

- 8058 Signal Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

- 8059 External Relay Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

- Installation Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

- Accessories & Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

Installation & Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

Technical Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 396

- Submersion Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 429

Operating Temperature & Pressure Graphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 438

Product Retirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .446

Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 448

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 454

The contents in this publication are based on information available at the time of publication. In view of the possibility of human error, we accept no responsibility for any

errors or omissions in this publication. The technical data is not binding and may be subject to modification. It neither provides a guarantee of product performance and

durability nor constitutes coverage under warranty. In case of doubt or uncertainty, we strongly recommend consultation with the factory or your local GF Sales o¥ce.

For the most up-to-date information please refer to our website at www.gfsignet.com.

Temperature/ Technical Installation Other Temperature, Level Conductivity/ pH/ORP Flow Turbidity Dissolved Chlorine Communication Multi-

Pressure Reference & Wiring Products Pressure Resistivity Oxygen Protocol Parameter

Graphs Instruments

Page5

New Products and

Product Upgrades

9950 Dual Channel Transmitter

Top Features Ideal for

• One instrument for multiple • Wastewater Treatment

sensor types • Reverse Osmosis

• Multiple language support for • Deionization

Simplifi ed Chinese, English, • Chemical Manufacturing/Addition

French, German and Spanish • Metal and Plastic Finishing

• Two di erent sensor types can • Cooling Tower

• Media Filtration

be combined in one instrument

• Confi gurable display

• Relay Modules available with

2 or 4 relays and optional

binary inputs

• Single channel Direct

Conductivity/Resistivity module

available

• Two, passive, 4 to 20 mA current

loop outputs in base unit

• Dual Channel 4 to 20 mA current

loop modules available to

expand to 4 or 6 loop outputs

• USB Port for Field Upgrades

using standard USB Flash Drive

9900 Transmitter (Generation IV)

Top Features Ideal for

• Modbus Module supports RS485 • Wastewater Treatment

Serial Modbus Communications • Reverse Osmosis

• Multiple sensor types supported • Deionization

with one instrument - Ultra Pure Water

• Large auto-sensing backlit - Two Bed System

display with large characters, - Mixed Bed System

"dial-type" digital bar graph, • Chemical Manufacturing / Addition

relay and warning LEDs for • Metal and Plastic Finishing

at-a-glance monitoring • Media Filtration

• Field replaceable • Batch operation with optional batch

plug-in modules module or 9900-1BC batch system

• Customize process label, dial

settings, units and decimals

• 4 to 20 mA Output Module

adds second output to a 9900

SmartPro Transmitter

• Customizable features including

Modbus Module digital label for custom

identifi cation

The following is a brief overview of the new products and product upgrades you will fi nd in this catalog. For more details, please refer to the

individual product pages.

4 www.gfsignet.com

Page6

2751 DryLoc® pH/ORP Smart Sensor Electronics

Top Features Ideal for

• Probe health monitoring, glass • Cooling Towers

impedance and broken glass • Fruit and Vegetable Washing

detection • Water Distribution

• Wastewater Odor Control

• Memory chip interface that allows • Poultry and Meat Processing

for transferable calibration, • UPW Treatment

runtime data, and manufacturing • Hospital and Healthcare Facilities

information

• In-line integral mount and

submersible installation versions

• Automatic temperature

compensation

• Auto configuration for pH or ORP

operation

2536 PVC Paddlewheel Flow Sensor

Top Features Ideal for

• PVC 2536 version DN15 to DN100 • Sodium Hypochlorite Transfer/

(½ to 4 in.) for concentrated Sodium Injection/Batching

Hypochlorite 12.5% applications • Pure Water Production

• Operating range 0.1 to 6 m/s • Filtration Systems

(0.3 to 20 ft/s) • Chemical Production

• Open-collector output • Liquid Delivery Systems

• Simple, economical design • Pump Protection

• Scrubber/Gas Stacks

• Gravity Feed Lines

2290 Non-contact Level Transmitter

Top Features Ideal for

• 19° beam angle • Bulk Storage Tanks

• Tank mapping function • Day Tanks

• Large dot matrix LCD display • Process Vessels for Mixing and

• Predefinded tank shapes Batching

• Works with fumes, condensation, • Buer Tanks

and light foam layers • Conditioning Vessels

• Metal or Plastic

PP

2291 Guided Wave Radar Level Transmitter

Top Features Ideal for

• Measuring range up to 6 m (19.6 ft) • Inventory Tanks

• Accuracy: ± 5 mm (0.2 in) • Day Tanks

• Rod & cable versions available • Process Vessels for Mixing and

• 2-wire version Batching

• 4 to 20 mA + HART output • Bypass Applications (requires

• Graphic LCD display calibration)

• Stilling-wells

www.gfsignet.com 5

Page7

New Products and

Product Upgrades

2260 Ultrasonic Level

Top Features Ideal for

• 2-wire compact transmitters • River Water

• Non-contact level metering • Seawater

• Narrow 5° beam angle • Potable Water

• Fully temperature compensated electronics • Demineralized Water

• PP or PVDF sensor body provides best • Treated Water

chemical resistance

2270 Ultrasonic Level Sensor

Top Features Ideal for

• 2-wire compact transmitters • River Water

• Non-contact level metering • Seawater

• Narrow 5° beam angle • Potable Water

• PP or PVDF sensor body provides best • Demineralized Water

chemical resistance • Treated Water

• Compact Housing

• 4 to 20 mA / HART Interface

2280 Tuning Forks

Top Features Ideal for

• Maintenance free vibrating principle • Potable Water

• Selectable sensitivity • River Water

• Relay or electronic output • Cooling Water

• Temperatures up to 130 degrees • Demineralized Water

• ATEX and WHG approvals • Water/Glycol Solutions

2281 Multipoint Switch

Top Features Ideal for

• Easy on site probe length confi guration • Potable Water

• Up to 4 relays for pump and valve control • Cooling Water

• Adjustable sensitivity • Chemicals

• Adjustable delay time • Pump Control

2282 Guided Float Switch

Top Features Ideal for

• Optimized chemical compatibility • Cooling Water

• Very compact design • Demineralized Water

• PP and PVDF version available • Water/Glycol Solutions

• For small tanks • Chemicals

2284 Ultrasonic Gap Switch

Top Features Ideal for

• Relay output • Cooling Water

• Corrosion resistant PPS body • Demineralized Water

• 1" and 3/4" threaded mounting • Water/Glycol Solutions

• Small in-tank dimensions • Chemicals

2285 Level Float Switch

Top Features Ideal for

• Hermetically molded, double chamber • Tap Water

• Mercury free operated micro switch • River Water

• Use for drinking and wastewater • Sump Shafts

6 www.gfsignet.com

Page8

System Selection Guide

This section provides tips Step 1: Determine Application

and suggestions on how

to choose just the right Requirements

measurement system Defining the following variables before building your system will

for your specific liquid ensure peak performance from your Signet sensors

application needs. For and instruments.

specific product information, • Measurement range • Performance requirements

refer to the individual • Installation requirements of sensor

catalog pages. • Pipe size and material • Particle and fiber load

• Chemical compatibility in fluid

of all wetted parts to • Viscosity of liquids

process chemicals • Hazardous location

• System specifications requirements

(such as temperature

and pressure)

Note: Please contact Step 2: Select Sensor Technology

your local Georg Fischer Based on the application requirements determined in

sales and support o¥ce Step 1, choose a sensor.

if you need assistance in

choosing any one of these

products. Determine your signal output requirement to allow you to

match just the right instrument (see Step 3). If you’re not

purchasing an instrument, select the sensor electronics

package that best suits your needs.

Step 3: Choose Instrument

Choose an instrument. Instruments are available in ¼

DIN size and oered in panel mount configurations. Field

mount versions are also oered for certain models.

Instruments are available with either digital, analog,

or analog/digital display. Various retrofit adapters and

mounting accessories are also available (see Accessories

section). In cases where the sensor feeds directly to a PLC

or PC system, GF oers a wide range of instruments and

sensors with 4 to 20 mA outputs.

Step 4: Determine Installation

Requirements

GF oers a wide selection of installation fittings for

flow sensors and in-line pH/ORP electrodes. These

fittings are specifically designed to ensure the proper

placement of the flow sensor in the piping system to

achieve optimum performance. Other pH/ORP electrodes

as well as all temperature, pressure and conductivity/

resistivity electrodes use NPT or ISO standard fittings. All

submersion electrodes require conduit piping and fixtures

not supplied with unit.

www.gfsignet.com 7

Page9

Features and Benefits

Transmitters

9950 Dual Channel Transmitter:

• One instrument for multiple sensor types

• Multiple language support for Simplifi ed Chinese, English, French,

German and Spanish

• Two di erent sensor types can be combined in one instrument

• Confi gurable display

• Relay Modules available with 2 or 4 relays and optional binary inputs

• Single channel Direct Conductivity/Resistivity module available

• Two, passive, 4 to 20 mA current loop outputs in base unit

• Dual Channel 4 to 20 mA current loop modules available to expand

to 4 or 6 loop outputs

• USB Port for Field Upgrades using standard USB Flash Drive

9900 Transmitter (Generation IV):

• One unit can replace ProPoint® and single-channel

ProcessPro® instruments, dramatically reducing part numbers

and inventory levels

• Large auto-sensing backlit display for indoor/outdoor

“at-a-glance” visibility with

–“Dial-type” digital bar graph

– Relay and Warning LEDs

• Multiple and time based relay modes

• Derived functions allow for sum, di erence and ratio of similar

measurements

• Reverse Osmosis e¥ ciency calculations using two fl ow or

conductivity measurements

• Optional plug-in modules to adapt to customers' changing needs

– Batch Module: Add a batch and relay module to convert a

9900 Transmitter (Generation II) to a batch controller

– Relay Module: Adds two programmable dry contact relays

– Direct Conductivity/Resistivity Module: Interfaces

Conductivity/Resistivity and Salinity electrodes directly to the

9900 transmitter

- 4 to 20 mA Output Module: Adds a second 4 to 20 mA

output to the 9900 Transmitter (Generation III and later)

- H COMM Module (HART®): Enables two-way communication

and access to additional information beyond the normal

process variables

- Modbus Module: Access Primary and Secondary readings,

sensor status, engineering units via RS485 Modbus

– 0252 Tool: Enables confi guration and programming

from a PC

Modbus Module • Customizable features

– Label: Customize identifi cation of the unit

– Bar Graph (Dial): Adjust min. and max. settings

– Units and decimals

• Built-in 4 to 20 mA and open collector outputs (standard)

• 4 to 20 mA Output Module adds second output to a 9900 SmartPro

Transmitter

• Outputs can be used for Primary or Secondary measurements

- Primary – Flow, Conductivity, pH, etc.

- Secondary – Temperature and Volume

8 www.gfsignet.com

Page10

9900 Transmitter Accessory

Rear Enclosure:

• Designed to fi t onto 9900-1P Panel Mount Transmitters

(Compatible with all Generations of 9900-1P)

• Two models available

– Hinged Cover for Wall Mount and Pipe Mount Installations

– Flat Cover for Panel Mount Installation

Communication products

0486 Profi bus Concentrator:

• Interface six Signet blind sensor or relay modules and a proportional

valve to a Profi bus network with a single device

• Four Channels support (S3L) or fl ow frequency devices two channels

support (S3L) or 4 to 20 mA current loops

• Convenient DIN Rail or surface mountable enclosure

0252 Confi guration Tool:

• Back up and restore SmartPro® Transmitters and blind sensors

confi gurations to a computer fi le

• User-friendly interface

• Confi gure settings such as instrument type, units, scale 4 to 20 current

loops and modify labels from the computer

• Use a single fi le to clone multiple SmartPro® Transmitters and

blind sensors

• Red and blue LED indicators for power and data

Systems

4632 Chlorine Dioxide Analyzer System:

• Reagent free measuring

• Complete panel system allows for quick and easy installation

• Built-in fl ow regulator maintains constant fl ow and pressure to

the sensors

• Pre-wired panel includes a 100/240 VAC power supply

• Two 4 to 20 mA outputs and two mechanical relays

www.gfsignet.com 9

Page11

Features and Benefits

Flow sensors

Insertion Paddlewheel Sensors:

• Four-bladed paddle design ensures optimal performance and

lower flow rates than five or six-bladed rotors that have a higher

weight/bearing inertia.

• The open-cell design and the controlled insertion depth work

2536 Paddlewheel

Flow Sensor together to deliver a linear and repeatable output over a wide

dynamic range, with virtually no pressure drop in the

process pipe.

• Choice of corrosive resistant plastics and rugged metals enable

use in many aggressive fluids.

PVC version • NIST traceable test certification with all -X0, -X1 plastic sensors

provides superior price-to-performance.

• The widest choice of installation fitting materials, sizes and

connections on the market that meet endless application needs.

• Insertion design lowers installation and maintenance costs.

• Self-powered sensors are well suited for remote locations.

• Paddlewheel design has barely measurable pressure drop,

making it ideal for gravity flows.

2540 Stainless Steel • Hot-Tap designs are available to allow service and maintenance

Paddlewheel without shutting-down the process; saves costly downtime.

Flow Sensor • Selected models are NSF and Lloyds Register approved.

• PVC 2536 version DN15 to DN100 (½ to 4 in.) for concentrated

Sodium Hypochlorite 12.5% dosing application in water treatment

Flow-Through Rotor Sensors:

• Operating flow ranges from 400 mL/min to 12,000 mL/min

(0.01 US gpm to 3.2 US gpm) in clean opaque or clear liquids ideal

for precise low flow applications such as dosing.

2507 Mini • Hall-eect devices provide excellent noise immunity

Flow Sensor output signals.

• Sensor body design allows easy access for cleaning, inspection

and rotor replacement without the need for powering down.

• Flexibility with end connections allow flexible tubing or rigid

pipe installations.

• Four fully encapsulated magnets provide high resolution

signal output.

In-line Turbine Sensors:

• Small compact design for tightly spaced installations.

2100 Turbine • Superior ceramic bearing provides long life without the need

Flow Sensor for maintenance.

• Detachable electronics means sensor maintenance is possible

without the need to cut power to unit.

• Composed of highly chemical resistant materials.

• Wide selection of end connections in hose barb or union ends.

• Two flow ranges available for optimum measurement resolution.

• NIST traceable test certification included.

10 www.gfsignet.com

Page12

Insertion Magmeter Sensors:

• No moving parts.

• Insertion design provides easier installation and removal than full

line magmeters.

• Model 2551 fits pipe sizes ranging from DN15 to DN900 (½ to 36 in.).

2551

Display Magmeter • Fluid diagnostics via LED indicators.

• Bi-directional flow and empty pipe detection.

• Rugged design with good chemical resistance suitable for

tough applications.

• Available with a choice of analog 4 to 20 mA or digital (S3L) /

frequency outputs provide signals to remote flowmeters and data

acquisition. Also available with digital (S3L) output for compatibility

with Multi-Parameter Instruments.

• High input impedance provides low sensitivity to coating which

makes it ideal for dirty liquids.

• Isolated outputs provide barrier to help prevent “ground loops.”

• NIST traceable test certification included.

• Selected models are NSF and Lloyds Register approved.

Hot-Tap Magmeter Sensors:

• No moving parts.

• Insertion design provides easier installation and removal than full

line magmeters.

• Model 2552 Metal Magmeter available for pipe sizes up to

2552 DN2550 (102 in.).

Metal Magmeter • Hot-Tap design allows for installation into full, pressurized pipes.

• Fluid diagnostics via LED indicators

• Bi-directional flow and empty pipe detection.

• Analog 4 to 20 mA and frequency outputs provide signals to remote

flowmeters and data acquisition. Also available with digital (S3L)

output for compatibility with Multi-Parameter Instruments.

• High input impedance provides low sensitivity to coating which

makes it ideal for dirty liquids.

• Isolated outputs provide barrier to help prevent “ground loops.”

• NIST traceable test certification included.

Portaflow 220 / 330:

• No moving parts.

• Sensor is not in contact with the liquid. No contamination of

Portaflow sensor and/or liquid.

330 • Easy, fast clamp-on installation.

• Large, easy to read graphic display with backlighting.

• Transducers and flexible guide rail covers a wide range of

pipe sizes.

• Rechargeable battery for up to 20 hours of mobile operation.

• Integrated data logger for 198k data points.

Ultraflow U3000 / U4000:

• No moving parts.

Ultraflow • Sensor is not in contact with the liquid. No contamination of

U3000 sensor and/or liquid.

• Easy, fast clamp-on installation.

• Large, easy to read graphic display with backlighting.

• Transducers and flexible guide rail covers a wide range of

pipe sizes.

• Integrated data logger for 198k data points.

www.gfsignet.com 11

Page13

Features and Benefits

Temperature, Pressure, Level and

Analytical sensors

Temperature Sensors:

• Unibody PVDF construction for use in either high purity or

aggressive fluid conditions.

2350 • Choice of output, 4 to 20 mA or digital (S

3L) signal for long

Temperature cable runs.

Sensor • Dual threaded ¾ in. NPT for easy installation.

• Easily converted to an integral system to mount a 9900 transmitter.

• Easily converts to allow the sensor to be used as a submersible

solution in an open or closed tank.

• Cable end threads permit conduit for full tank submersion.

Pressure/Level Sensors:

• ½ in. male union process connection to suit installation needs.

• Three pressure ranges to meet specific requirements and

provide optimal resolution.

• Choice of output, 4 to 20 mA or digital (S3L) signal for long

cable runs.

2450 2250 • NIST traceable test certification included.

Pressure Level • Easily converted to an integral system to mount a 9900 transmitter.

Sensor Sensor • Configure with 9900 transmitter to provide full level

measuring system (hydrostatic pressure).

• 2250 allows the sensor to be used as a submersible solution in

an open or closed tank.

• 2250 is provided with a ¾ in. union connector to add a conduit

for full tank submersion.

Radar Level Transmitters:

• 19° beam angle

• Tank mapping function

• Large dot matrix LCD display

• Predefined tank shapes

2290 2291 • Measuring range up to 6 m (19.6 ft)

Non-Contact Guided • Accuracy: ± 5 mm (0.2 in)

Radar Level Wave Radar • Rod & cable versions available

Transmitter Level

Transmitter • 4 to 20 mA + HART output

Conductivity/Resistivity Electrodes:

• Flow-through design ensures continuous measurement without

air entrapment.

• Reversible threaded connections for in-line integral mount or

tank submersion.

• Standard parts oer application flexibility for the user.

2818-2823 • Every sensor uses standard electrical cable. No need to incur

Series Sensors additional costs for “patch” type cable connections.

• NIST calibration certificate available upon request.

Dissolved Oxygen Sensor:

• Optical DO measurement no flow requirements.

• Rugged construction.

• Calibration built into the measurement cap 2% of range 0 to 20 mg/L.

• Two year measurement cap life.

2610 Process • No membranes or filling solutions.

Optical Dissolved • Flexible communications digital (S3L), 4 to 20 mA or Modbus.

Oxygen Sensors

12 www.gfsignet.com

Page14

Conductivity/Resistivity Sensor Electronics:

• Blind 4 to 20 mA output or digital output for long cable runs

2850 beyond 30 m (100 ft) ensures a steady process signal resistant

Sensor and Universal to electrical noise.

Electronics Mount • EasyCal calibration automatically recognizes standard

calibration solutions.

• Designed to be used with all Signet conductivity/

resistivity electrodes.

• NIST traceable test certifi cation included.

Standard pH/ORP Electrodes:

• Patented reference design for exceptional performance

• ¾” NPT or ISO 7/1-R 3/4 threaded sensors for use with reducing

tees DN15 to DN100 (½ to 4 in.)

• Designed to mount in standard Signet fi ttings ½ in. to 4 in. or a

variety of ¾ in. fi ttings.

• Special design allows for installation at any angle, even inverted or

horizontal

• PTFE Reference Junction resists fouling and chemical attack

(273X only)

2724-2726 • Longer reference path and larger reference volume means

2734-2736 extended service life.

pH/ORP • Flat glass surface sensor design. Resistant to fouling and

Electrodes abrasion in dirty applications, and prevents accidental damage

Series

to extend electrode life.

• NIST traceable test certifi cation included.

• 2724-2726 are general purpose electrode design for use in

most applications.

• 2734-2736 are high performance electrodes designed for

demanding applications

Di£ erential pH/ORP Electrodes:

• pH and reference signals are measured against third electrode,

a solution ground, to ensure a stable reading.

• The di erential reference is designed to protect the reference

- - -

2764-2767 element from Bromide (Br ), Iodide (I ), Cyanide (CN ), Sulfi des

-

pH/ORP (S ) and other harsh compounds that react with Silver (Ag+).

2

Electrode Also protects the reference electrolyte from Mercury (Hg++),

-

Copper (Cu+), lead (Pb++), Perchlorate (ClO ), or other compounds

4

that react with chlorides.

• Unique DryLoc® design is robust and watertight, ensuring

rugged installation.

• Designed to mount in 1 in. standard pipe fi ttings for

2774-2777 easy installation.

pH/ORP • Flat glass surface sensor design that is resistant to fouling and

Electrode abrasion in dirty applications.

• Large reference volume and replaceable salt bridge allows the

user to rebuild the reference and extend the service life of the

electrode.

pH/ORP Sensor Electronics:

• Probe health monitoring, glass impedance and broken

glass detection.

• Memory chip interface that allows for transferable calibration,

runtime data, and manufacturing information.

In-line Submersible • In-line integral mount and submersible installation versions.

2751 2751 • Automatic temperature compensation.

• Auto confi guration for pH or ORP operation.

• Designed for SmartPro and Multi-Parameter transmitters.

www.gfsignet.com 13

Page15

Signet Flow System

Compatibility

Table 1

The chart below outlines the compatibility between Signet Flow sensors, instruments and sensor fittings. Refer to individual

product pages and fittings section of the catalog for more information.

Flow Sensors

Instruments 515 2536 2537 525 2000 2507 2100 2540 2551 2552

8150 Battery Powered Flow Totalizer • •

8900 Multi-Parameter Controller • • • • • • • • • •

9900 Transmitter • • • • • • • • • •

9900-1BC Batch Controller • • • • • • • • • •

9950 Dual Channel Transmitter • • • • • • • • • •

Fittings - Customer Supplied

¼ inch tubing or rigid pipe • •

Wide choice of end connectors - see individual

•

data sheet

1¼ inch NPT or ISO 7/1-R 1¼ • •

1½ inch NPT or ISO 7/1-R 1½ • •

GF Fittings

PPMTEXXX Metric PP Wafer EPR (EPDM) • • • •

PPMTFXXX Metric PP Wafer (FKM) • • • •

PPMT0XX Metric PP Union Tee • • • •

SFMT0XX Metric PVDF Union Tee • • • •

SFMTFXXX Metric PVDF Wafer (FKM) • • • •

MPV8T0XXF PVC SCH 80 Tee • • • •

MPV8T0XX PVC SCH 80 Tee w/pipe • • • •

MCPV8T0XXF PVC-C SCH 80 Tee • • • •

MCPV8T0XX PVC-C SCH 80 Tee w/pipe • • • •

PV8S0XX PVC Clamp-on Saddle • • • •

FPT0XX Fiberglass Glue-On Tee • • • •

IR4T0XX Iron Threaded Tee (NPT) • • • •

IR8SXXX Iron Strap-On Saddle • • • •

CUKT0XX Copper Sweat-On Tee • • • •

BR4BXXX Brass Brazolet • • • •

CS4T0XX Carbon Steel Tee (NPT) • • • •

CS4WXXX Carbon Steel Weldolet • • • •

CR4T0XX 316 SS Threaded Tee (NPT) • • • •

CR4WXXX 316 SS Weldolet • • • •

P526-20XX Metalex Socket Weld •

P526-2XXX Metalex Weld-On Mini-Tap •

PV8S1XX PVC Glue-On Large Saddle • • • •

BR4T0XX Brass Threaded Tee (NPT) • • • •

PVMT0XX /PVAT0XX Metric/BSP PVC Union Tee* • • • •

PVMS0XX /PVAS0XX Metric/BSP PVC Saddle* • • • •

Plastic Weld-On Fittings (PVC) • • • •

Plastic Weld-On Fittings (PP) • • • •

Plastic Weld-On Fittings (PE) • • • •

Steel Weld-On Fittings (SS 1.4435) • • • •

Electrofusion Transition Saddles • •

Strap-on Saddles, Threaded • •

*Available only through your local Georg Fischer sales o¥ce.

14 www.gfsignet.com

Page16

Signet pH/ORP, Conductivity/

Resistivity System Compatibility

Table 2

The chart below outlines the compatibility between Signet pH/ORP and conductivity/resistivity electrodes, instruments and sensor

fittings. Refer to individual product pages and fittings section of the catalog for more information.

Electrodes

pH/ORP Conductivity

Instruments, Sensor Electronics, 2724- 2734- 2764- 2774- 2818- 2822- 2839-

and Preamplifiers 2726 2736 2767 2777 2821 2823 2842

2751 pH/ORP Smart Sensor Electronics • • • •

2760 pH/ORP Preamplifier • • •

2850 Conductivity Sensor Electronics • • •

8900 Multi-Parameter Controller with Sensor Electronics • • • • • • •

9900 Transmitter with Sensor Electronics or Module • • • • • • •

9950 Dual Channel Transmitter with Sensor Electronics or

• • • • • • •

Module(s)

Fittings -Customer Supplied

¾ in. process connections • • • • • •

ISO 7/1-R3/4 process connections • • •

Tri-clamp fittings •

1 in. process connections •

GF Fittings For use with fittings up to DN100 (4 in.) only

FPSXXX Fiberglass Glue-On Saddle • •

PPMT0XX Metric PP Union Tee • •

SFMT0XX Metric PVDF Union Tee • •

MPV8T0XXF PVC SCH 80 Tee • •

MPV8T0XX PVC SCH 80 Tee w/pipe • •

MCPV8T0XXF PVC-C SCH 80 Tee • •

MCPV8T0XX PVC-C SCH 80 Tee w/pipe • •

PV8S0XX PVC Clamp-on Saddle • •

FPT0XX Fiberglass Glue-On Tee • •

IR4T0XX Iron Threaded Tee (NPT) • •

IR8SXXX Iron Strap-On Saddle • •

CUKT0XX Copper Sweat-On Tee • •

BR4BXXX Brass Brazolet • •

CS4T0XX Carbon Steel Tee (NPT) • •

CS4WXXX Carbon Steel Weldolet • •

CR4T0XX 316 SS Threaded Tee (NPT) • •

CR4WXXX 316 SS Weldolet • •

BR4T0XX Brass Threaded Tee (NPT) • •

PVMT0XX/PVAT0XX Metric/BSP PVC Union Tee* • •

PVMS0XX/PVAS0XX Metric/BSP PVC Saddle* • •

*Available only through your local Georg Fischer sales o¥ce.

www.gfsignet.com 15

Page17

Signet Single and

Multi-Parameter

Specification Matrix

9950 9900 - Panel Mount

Multi-Channel, Single-Channel,

Description

Multi-Parameter Controller Multi-Parameter Transmitter

Modular Components Yes

2 Permanent 1 Permanent

Number of Flow Totalizers

2 Resettable 1 Resettable

Max. Sensor Inputs 2 frequency or S3L inputs 1

Mounting Options Panel Panel, Wall, Pipe, Tank

Display LCD, Dot matrix LCD with digital bar graph

(2) Standard Passive, 4 to 20 mA Outputs (2) Passive 4 to 20 mA

(2) or (4) Optional passive, 4 to 20 mA Outputs (1) Standard, (1) Optional with

Analog Output Types

via Channel Dual Modules 4 to 20 mA Output module

(2) Passive 4 to 20 mA HART optional with H COMM module

4 Mechanical Relays or 1 open collector (standard)

Max. Relays / O.C.

2 Mechanical and 2 Solid State Relays 2 relays (optional relay module)

6 Derived Measurements

Derived Measurements Sum, Delta (Dierence), Ratio, N/A

% Passage% Reject, % Recovery

English, French, German, Spanish and

Languages English

Simplified Chinese

DC -10 °C to 70 °C (14 °F to 158 °F)

Ambient Temperature (°C) -10 °C to 70 °C (14 °F to 158 °F)

AC -10 °C to 60 °C (14 °F to 140 °F)

Storage Temperature (°F) -15 °C to 70 °C (5 °F to 158 °F)

-15 °C to 70 °C (5 °F to 158 °F)

Relative Humidity 0 to 95% non-condensing

DC - 24 VDC nominal

24 VDC input; range:

Power Requirements (12 to 32 VDC, ±10% regulated)

10.8 to 35.2 VDC regulated

AC - 100 to 240 VAC, 50 to 60 Hz, 24 V

CE, FCC, UL, CUL, CE, FCC, UL, CUL, RoHS compliant,

RoHS compliant, China RoHS, NEMA TYPE 4X/ Lloyd's Register, China RoHS, NEMA TYPE 4X/

Standards and Approvals

IP65 (front face only on panel mount); IP65 (front face only on panel mount);

field mount is 100% NEMA TYPE 4X/IP65 field mount is 100% NEMA TYPE 4X/IP65

16 www.gfsignet.com

Page18

9900-1BC 8900

Single-Channel, Multi-Channel,

Description

Single Parameter Controller Multi-Parameter Controller

Modular Components Yes

1 Permanent 6 Permanent

Number of Flow Totalizers

1 Resettable 6 Resettable

(up to 2 frequency and 4 (S3L) or 6 (S3L)

Max. Sensor Inputs 1

6 total sensor inputs

Panel, Wall, Pipe, Tank installation

Mounting Options Panel

using rear enclosure

Display LCD with digital bar graph LCD

(4) Passive/Active 4 to 20 mA or

Analog Output Types (1) Passive 4 to 20 mA

(4) 0 to 5/10 VDC

1 open collector

Max. Relays / O.C. up to 8 relays (via 8059)

2 relays

Sum, Dierence, % Recovery, % Reject, %

Derived Measurements N/A

Passage, Ratio, Power (BTU)

English, French, German, Spanish,

Languages English

Italian, and Portuguese

Ambient Temperature (°C) -10 °C to 70 °C (14 °F to 158 °F) -10 °C to 55 °C (14 °F to 131 °F)

Storage Temperature (°F) -15 °C to 70 °C (5 °F to 158 °F) -15 °C to 80 °C (5 °F to 176 °F)

Relative Humidity 0 to 95% non-condensing

24 VDC input; range: 12 to 24 VDC ±10%, regulated or

Power Requirements

10.8 to 35.2 VDC regulated 100 to 240 VAC ±10%, regulated, 50/60 Hz

CE, UL, CUL, FCC, RoHS compliant, CE, UL, CUL, FCC, RoHS compliant,

Standards and Approvals China RoHS , NEMA TYPE 4X/IP65 China RoHS, NEMA 4X/IP65

(front face only) (front face only)

www.gfsignet.com 17

Page19

Signet 9950 Transmitter

Compatibility Overview

The 9950 Transmitter provides a single

channel interface for:

- Flow

- pH/ORP

- Conductivity/Resistivity Flo

- Salinity Temperature and re

w – U

- Temperature lPressure sensors su tra

- Pressure es son

- Level Pr ic

- Volume –

- Other 4-20 mA

- Dissolved Oxygen

9950

The 9950 is available for Panel Mount Conductivity

installations Module

Features and Benefi ts

One Instrument for Multiple Sensor Types

- Two di erent sensor types can be

combined in one instrument

Confi gurable Display

- Derived Measurements

- Advanced Boolean Logic

- Units and Decimals

Optional Modules can be Added for

Additional Capabilities Conductivity /

Resistivity

USB Port for Field Upgrades Using Sensors

Standard USB Flash Drive

…making updates easier

2850

Universal

Mount

18 www.gfsignet.com

istivity

ivity

/Res – Tem

t pc er

du

atu

n ro e

el Len veln –a Sh alini

gle

C ty –

in C

ORP –

Dissolved O

– p

H/ xygen

ow – Fl S

Page20

Absolute Input Versatility!

Paddlewheel and Magmeter

Flow sensors

e

Flow –

r Uu ltra

ess s

Pr

oni

– c

pH / ORP fl at, bulb and

di erential electrodes

with 2751

Dissolved

Oxygen

sensor

4 to 20 to S3L

i-GO® Signal

Converter

8058-1

*

*Ultrasonic, Radar, Hydrostatic and 8058-3

Point Level (*Note: requires 8058-3)

www.gfsignet.com 19

/Resistivityy –t Tevi mcti

per

du

atu

n ro e

Level

han

nel – Salinit

gle

C y –

in C

RP – DissoO lv

pH/

ed Ox

y

w –

gen –

lo F S