1/20ページ

ダウンロード(805.7Kb)

Industry ASTM Portfolio - The right solution for your applications

製品カタログ

Superior Piping Systems for the World’s Most Demanding Applications

Georg Fischer Harvel LLC produces the pipes and fittings for domestic and international markets in metric and inch standards across many materials. GF Harvel products complement the strong valve, measurement and control product offerings, making Georg Fischer Piping Systems a full system solution provider in America and across the globe.

このカタログについて

| ドキュメント名 | Industry ASTM Portfolio - The right solution for your applications |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 805.7Kb |

| 取り扱い企業 | ジョージフィッシャー株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

GF Piping Systems

ASTM

Portfolio

The right solution

for your applications

Page2

ASTM

Portfolio

Superior Piping Systems for the World’s

Most Demanding Applications

Recognized for superior quality for more than 50 years,

Georg Fischer Harvel LLC is the industry’s leading manufacturer of

plastic piping systems.

Georg Fischer Harvel LLC produces the pipes and fittings for

domestic and international markets in metric and inch standards

across many materials. GF Harvel products complement the strong

valve, measurement and control product offerings, making Georg

Fischer Piping Systems a full system solution provider in America

and across the globe.

Backed by an unwavering dedication to innovation and unrivalled

technical expertise, GF Harvel serves industries around the world

including chemical processing, energy, marine, cooling technology,

water treatment, microelectronics, and plumbing systems for resi-

dential, commercial, and high-rise construction.

GF Harvel also produces a full range of specialty piping systems for

emerging technologies including renewable energy, algae and bio-

tech development.

Locally Produced, Globally Available

California Pennsylvania

Arkansas

2

Page3

PVC Piping Systems

Comprehensive simplicity

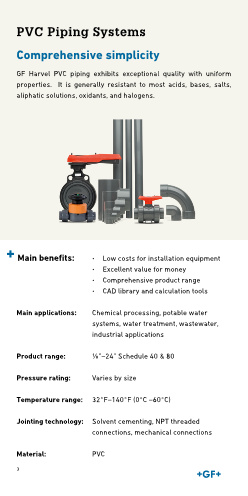

GF Harvel PVC piping exhibits exceptional quality with uniform

properties. It is generally resistant to most acids, bases, salts,

aliphatic solutions, oxidants, and halogens.

Main benefits: • Low costs for installation equipment

• Excellent value for money

• Comprehensive product range

• CAD library and calculation tools

Main applications: Chemical processing, potable water

systems, water treatment, wastewater,

industrial applications

Product range: ⅛”–24” Schedule 40 & 80

Pressure rating: Varies by size

Temperature range: 32°F–140°F (0°C –60°C)

Jointing technology: Solvent cementing, NPT threaded

connections, mechanical connections

Material: PVC

3

Page4

CPVC Piping Systems

The best of the best

Impact resistance, good fire resistance capabilities and can handle

most of the temperature/pressure requirements of today’s typical

process plants. Generally resistant to most acids, bases, salts, ali-

phatic solutions, oxidants, and halogens.

Main benefits: • Low costs for installation equipment

• Long support distances

• Very good chemical resistance

• CAD library and calculation tools

Main applications: Chemical processing, plating,

hot and cold potable water systems, water,

treatment, wastewater,

hot corrosive fluid transfer

Product range: ¼”–24” Schedule 40 & 80

Pressure rating: Varies by size

Temperature range: 32°F–200°F (0°C–93°C)

Jointing technology: Solvent cementing, NPT threaded

connections, mechanical connections

Material: CPVC

4

Page5

Clear PVC Piping System

FDA approved material

Versatile, cost-effective alternative for many piping applications,

particularly those where visual monitoring of processes is critical.

GF Harvel Clear PVC is corrosion-resistant, has smooth interior

walls and is non-contaminating.

Main benefits: • Clear and uniform color

• Smooth interior walls

• Lower overall installed cost

• Same easy installation as standard PVC

Main applications: Tubing containment, visual flow and leak

detection, sight glasses

Product range: ¼”–12” Schedule 40

¼”–6” Schedule 80

Pressure rating: Varies by size

Temperature range: 32°F–140°F (0°C–60°C)

Jointing technology: Solvent cementing, NPT threaded

connections

Material: Clear PVC

5

Page6

EnviroKing®

Energy solution for algae and more

GF Harvel EnviroKing is a clear UV resistant PVC pipe that is suita-

ble for exposure to sunlight. Unique UV blocking technology reduces

harmful ultraviolet light wavelengths from penetrating the plastic

while allowing beneficial wavelengths through.

Main benefits: • Lower overall installed cost than glass

• Same easy installation as standard PVC

• Fully compatible with standard PVC

• Thin wall or Schedule 40

Main applications: Photo-bioreactor vessels

Green technology applications

Product range: 2”–12” Thin wall

½”–6” Schedule 40

Pressure rating: Varies by size

Temperature range: 32°F–140°F (0°C–60°C)

Jointing technology: Solvent cementing

Material: Clear PVC

6

Page7

PPro-Seal™ Natural PP

The natural choice

PPro-Seal Natural PP is a highly pure product ideal for use in piping

systems where purity is not only required, but is essential.

PPro-Seal has excellent resistance to most organic and inorganic

chemicals in common laboratory use.

Main benefits: • Hazen-Williams c-factor of 150

• FDA 21.CFR 177.1520 Sections A1, B, C

• Easy to operate electrofusion machine

• Bagged & sealed to ensure cleanliness

Main applications: Deionized water and reverse osmosis sys-

tems, chemical effluent treatment plants,

chemical & food and beverage processing

Product range: ½”–3” Schedule 80

Pressure rating: 150 PSI (PN10)

Temperature range: 32°F–176°F (0°C–80°C)

Jointing technology: Electrofusion, threaded

Material: PPn

7

Page8

Harvel LXT®

Low-extractable piping system

Harvel LXT by GF Piping Systems provides a cost-effective alterna-

tive to other piping system materials typically used for purified lab

water applications. Lower material costs combined with fast, reli-

able installation greatly reduce installation costs.

Main benefits: • Advanced material reduces leach out

• Proprietary one-step cementing

• Fast joining method reduces TOC

• Bagged, sealed and boxed in-line

Main applications: Lab grade RO/DI, pharmaceutical, hospital,

dialysis, flat panel display

Product range: ½”–6” Schedule 80

Pressure rating: Varies by size

Temperature range: 32°F–140°F (0°C–60°C)

Jointing technology: One step solvent cementing

Material: Blue translucent PVC

8

Page9

Fuseal® PP Corrosive Waste

The one and only DWV solution

Excellent chemical resistance and physical properties ideal for

handling corrosive waste mixtures of acids, bases and solvents.

Diluted mineral acids and aqueous solutions of acid salts, which

are destructive to most metals.

Main benefits: • Simple installation procedures

• Great corrosion resistance

• Maintenance-free service

• Low installation cost

Main applications: Corrosive waste drainage from laboratory,

industrial or food and beverage processing

Product range: 1½”–18” Schedule 40

1½”–12” Schedule 80

Pressure rating: Up to 50 PSI for pressure waste applications

(subject to manufacturers review of design)

Temperature range: 32°F–212°F intermittently (0°C–100°C)

Jointing technology: Electrofusion, mechanical joint, butt fusion

Material: PPNFR, PPFR

9

Page10

Fuseal 25/50™ PVDF

Excellence in corrosive waste

Engineered to solve many of the problems with return air plenum

piping or handling aggressive chemicals at elevated temperatures.

Thermal stability as well as a low flame spread and smoke density

as per ASTM E84.

Main benefits: • UL certified

• Outstanding corrosion resistance

• Easy to join with electrofusion

• Reliable and trouble free

Main applications: Corrosive waste drainage for return air ple-

nums or at elevated temperatures from lab-

oratory, industrial or food and beverage

processing.

Product range: 1½”–6” Schedule 40

Pressure rating: Up to 50 PSI for pressure waste applications

(subject to manufacturers review of design)

Temperature range: -4°F–284°F (-20°C–40°C)

Jointing technology: Electrofusion

Material: PVDF

10

Page11

Fuseal Squared®

Mathematically the best solution

Fuseal Squared physical properties make this system ideal to

handle corrosive waste solutions for buried laboratory and indus-

trial DWV applications. Closure couplings comply with the ASME

B31.3.

Main benefits: • Outstanding chemical resistance

• Free-floating primary pipe

• Maintenance-free service

• Very cost effective

Main applications: Corrosive waste drainage from laboratory,

industrial or food and beverage processing

Product range: 1½”–8” primary pipe

4”–12” containment pipe

Pressure rating: Up to 50 PSI for pressure waste applications

(subject to manufacturers review of design)

Temperature range: 32°F–212°F intermittently (0°C–100°C)

Jointing technology: Electrofusion

Material: PPNFR, PPFR

11

Page12

Contain-It™

Easy double containment

Retrofit made easy. Ideal choice for containment piping of hazard-

ous piping systems. Requires fewer and less expensive tools than

other containment piping systems. Injection bonding with visual

inspection of sealing.

Main benefits: • Retrofit of piping system

• Fits over any primary piping system

• Visual leak detection

• Lightweight, easy to install

Main applications: Containment piping of chemical process

lines, fuel lines

Product range: Can contain primary pipe up to 4” (110 mm)

Containment sizes 3”–6”

Pressure rating: Up to 32 PSI (PN3)

Temperature range: 32°F–140°F (0°C–60°C) PVC

Jointing technology: Adhesive joint

Material: Clear PVC

12

Page13

Double-See™ Containment

Fast and easy installation

Easy to install and available with a complete selection of pipe, fit-

tings, and valves. Innovative “valve-in-valve” design allows a full

containment pressure rating. Simultaneous joining throughout a

system or in combination with patented closure couplings.

Main benefits: • ASME B31.3 compliant closures

• Innovative centralizer design

• Pipe cut-length guidance system

• Factory assembled and 100% tested

Main applications: Water/wastewater treatment, chemical

processing, delivery/dosing, microelectronics,

metal plating, surface finishing, life sciences

Product range: ½”–6” primary pipe

2”–10” containment pipe

Pressure rating: Varies by size (primary)

50 PSI (PN4) (secondary)

Temperature range: Varies by material

Jointing technology: Solvent cementing

Material: PVC, CPVC, Clear PVC and Clear CPVC

13

Page14

SeaCor™ Piping System

Marine pressure and drainage

Complies with Part 2 “Smoke and Toxicity” and Part 5 “Surface

Flammability” of Annex 1 of the FTP code resolution and also meets

title 46 of the code of federal regulations known as the Jones Act.

M ain benefits: • U.S. Coast Guard approved

• Low costs for installation equipment

• Great corrosion resistance to salts

• CAD library

Main applications: Hot, cold, black and gray water and vent

systems

Product range: ½“–12“ Schedule 40 & 80

Pressure rating: Varies by size

Temperature range: 32°F–210°F (0°C– 99°C)

Jointing technology: Solvent cementing

Material: CPVC

14

Page15

SeaDrain™

Marine drainage piping system

SeaDrain PPFR is resistant to the corrosive action of salt solutions

and aqueous solutions of salts, which are destructive to most

metals. In general, SeaDrain PPFR will not rust, pit, scale, corrode

or be affected by electrolysis.

M ain benefits: • Low installation cost

• Great corrosion resistance

• Pressurized drainage up to 50 psi

• Easy to operate electrofusion jointing

Main applications: Black, gray water and vent systems

Product range: 1½”–12” Schedule 40

Pressure rating: Vacuum up to 25.5 psi (1.76 bar) intermit-

tent (drainage) with 25 % loading

Temperature range: 32°F–212°F intermittently (0°C–100°C)

Jointing technology: Electrofusion, mechanical joint

Material: PPFR

15

Page16

Machining Shapes

Ready to be machined

GF Harvel’s state-of-the-art extrusion process provides porosity-

free, stress-reduced products with optimum physical properties

and exacting tolerances. Available products include solid bar,

hollow bar, square, rectangular, hexagonal bar, and angles.

Main benefits: • Superior quality products

• Excellent chemical, corrosion resistance

• Ready to be machined

• Cost saving advantage

Main applications: Machined valve bodies, strainers, filters,

bulkhead fittings, pump components, bush-

ings, compression fittings, flanges, hang-

ers, hooks, spacers, nuts bolts, rollers and

numerous other mechanical components

Product range: ¼”–16”

Machining technology: Turning, boring, drilling, tapping and

threading.

Material: PVC, CPVC, PP, HDPE

16

Page17

Vinyl Duct Systems

Light weight

GF Harvel PVC material provides long-lasting, cost-effective solu-

tions for corrosive applications and the CPVC material has excep-

tional fire resistance, high heat distortion temperature and good

mechanical strength at elevated temperatures.

Main benefits: • Reduces labor and costs

• Corrosive fumes, gases and fluids

• Seamless, large-diameter extrusions

• Long system service life

Main applications: Industrial and institutional corrosive fume

exhaust and drain (PVC) hot corrosive fume

and drain service (CPVC)

Product range: 6”–24”

Temperature range: 32°F–140°F (0°C–60°C) PVC

32°F– 200°F (0°C–93°C) CPVC

Jointing technology: Solvent cementing

Material: PVC, CPVC

17

Page18

BlazeMaster® Fire Sprinkler Pipe

Quality-proven, code-approved

Proven performance with more than 25 years of service in demand-

ing installations around the world. It meets the requirements of all

major model codes, is UL and LPCB listed and FM approved, (NFPA

13, 13R & 13D systems).

Main benefits: • Conforms to all major building codes

• Meets NFPA light hazard applications

• Factory mutual approved

• Clean and fast installation

Main applications: Listed for more fire sprinkler applications

than any metallic system

Product range: ¾”–3”

Pressure rating: Working pressure of 175psi at 150°F for

fire sprinkler service

Temperature range: 32°F–210°F (0°C–99°C)

Jointing technology: One step solvent cementing, NPT threaded

connections, mechanical connections

Material: CPVC

18

Page19

Other products

and services

At GF Harvel, we not only make industry leading products and sys-

tems, we also offer customized products and services to better

serve the ever evolving market needs. Georg Fischer Piping

Systems, with over 210 years of industrial piping experience,

allows every customer to tap into a wealth of experience and dedi-

cation to serve the industry with innovation, reliability and

performance.

• Electro Plus® fusion machine

• FlameTech™ flame and

smoke containment pipe

• HydroKing® CTS plumbing pipe

• FlowGuard Gold® CTS

plumbing pipe

• SYGEF® pipe metric (PVDF)

• PROGEF® pipe metric (PP)

• COOL-FIT ABS® pipe metric

• Customizing and pre-fabrication

• Product and installation training

and certification

• Renowned technical and

field services

19

Page20

GF Piping Systems

Worldwide at home

Our sales companies and representatives ensure

local customer support in over 100 countries

Your local partner:

Georg Fischer Piping Systems Ltd

8201 Schaffhausen / Switzerland

Phone +41 52 631 30 03

Fax +41 52 631 28 93

info.ps@georgfischer.com

www.gfps.com

The technical data are not binding. They neither constitute expressly warranted

characteristics nor guaranteed properties nor a guaranteed durability.

They are subject to modification. Our General Terms of Sale apply.

Lit #1342 (11/2014) Printed in USA

©2014 Georg Fischer Piping Systems Ltd