1/6ページ

ダウンロード(128.6Kb)

このカタログについて

| ドキュメント名 | LOC110 Single Linear Optocoupler |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 128.6Kb |

| 取り扱い企業 | マウザー・エレクトロニクス (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

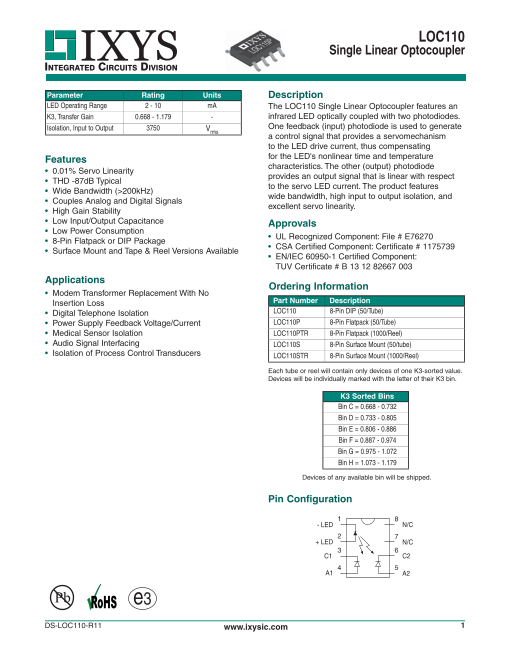

LOC110

Single Linear Optocoupler

INTEGRATED CIRCUITS DIVISION

Parameter Rating Units Description

LED Operating Range 2 - 10 mA The LOC110 Single Linear Optocoupler features an

K3, Transfer Gain 0.668 - 1.179 - infrared LED optically coupled with two photodiodes.

Isolation, Input to Output 3750 V One feedback (input) photodiode is used to generate

rms

a control signal that provides a servomechanism

to the LED drive current, thus compensating

Features for the LED's nonlinear time and temperature

• 0.01% Servo Linearity characteristics. The other (output) photodiode

• THD -87dB Typical provides an output signal that is linear with respect

• Wide Bandwidth (>200kHz) to the servo LED current. The product features

• Couples Analog and Digital Signals wide bandwidth, high input to output isolation, and

• High Gain Stability excellent servo linearity.

• Low Input/Output Capacitance Approvals

• Low Power Consumption

• 8-Pin Flatpack or DIP Package • UL Recognized Component: File # E76270

• Surface Mount and Tape & Reel Versions Available • CSA Certified Component: Certificate # 1175739

• EN/IEC 60950-1 Certified Component:

TUV Certificate # B 13 12 82667 003

Applications

Ordering Information

• Modem Transformer Replacement With No

Insertion Loss Part Number Description

• Digital Telephone Isolation LOC110 8-Pin DIP (50/Tube)

• Power Supply Feedback Voltage/Current LOC110P 8-Pin Flatpack (50/Tube)

• Medical Sensor Isolation LOC110PTR 8-Pin Flatpack (1000/Reel)

• Audio Signal Interfacing LOC110S 8-Pin Surface Mount (50/tube)

• Isolation of Process Control Transducers LOC110STR 8-Pin Surface Mount (1000/Reel)

Each tube or reel will contain only devices of one K3-sorted value.

Devices will be individually marked with the letter of their K3 bin.

K3 Sorted Bins

Bin C = 0.668 - 0.732

Bin D = 0.733 - 0.805

Bin E = 0.806 - 0.886

Bin F = 0.887 - 0.974

Bin G = 0.975 - 1.072

Bin H = 1.073 - 1.179

Devices of any available bin will be shipped.

Pin Configuration

1 8

- LED N/C

2 7

+ LED N/C

3 6

C1 C2

4 5

A1 A2

DS-LOC110-R11 www.ixysic.com 1

Page2

INTEGRATED CIRCUITS DIVISION LOC110

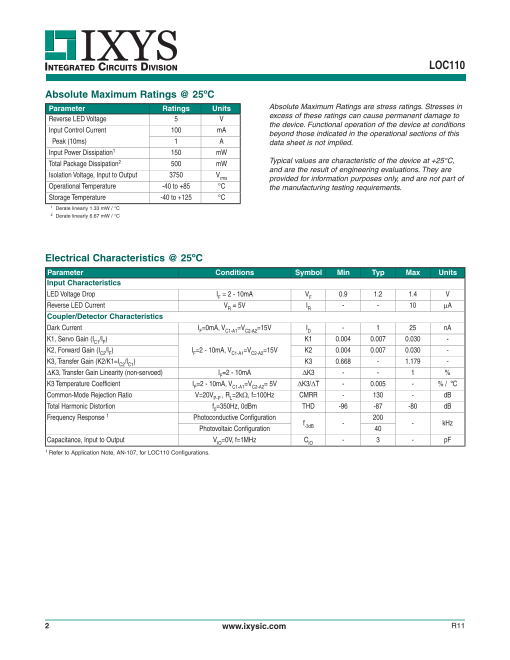

Absolute Maximum Ratings @ 25ºC

Parameter Ratings Units Absolute Maximum Ratings are stress ratings. Stresses in

Reverse LED Voltage 5 V excess of these ratings can cause permanent damage to

the device. Functional operation of the device at conditions

Input Control Current 100 mA beyond those indicated in the operational sections of this

Peak (10ms) 1 A data sheet is not implied.

Input Power Dissipation1 150 mW

Total Package Dissipation2 500 mW Typical values are characteristic of the device at +25°C,

and are the result of engineering evaluations. They are

Isolation Voltage, Input to Output 3750 Vrms provided for information purposes only, and are not part of

Operational Temperature -40 to +85 °C the manufacturing testing requirements.

Storage Temperature -40 to +125 °C

1 Derate linearly 1.33 mW / °C

2 Derate linearly 6.67 mW / °C

Electrical Characteristics @ 25ºC

Parameter Conditions Symbol Min Typ Max Units

Input Characteristics

LED Voltage Drop IF = 2 - 10mA VF 0.9 1.2 1.4 V

Reverse LED Current VR = 5V IR - - 10 A

Coupler/Detector Characteristics

Dark Current IF=0mA, VC1-A1=VC2-A2=15V ID - 1 25 nA

K1, Servo Gain (IC1/IF) K1 0.004 0.007 0.030 -

K2, Forward Gain (IC2/IF) IF=2 - 10mA, VC1-A1=VC2-A2=15V K2 0.004 0.007 0.030 -

K3, Transfer Gain (K2/K1=IC2/IC1) K3 0.668 - 1.179 -

K3, Transfer Gain Linearity (non-servoed) IF=2 - 10mA K3 - - 1 %

K3 Temperature Coefficient IF=2 - 10mA, VC1-A1=VC2-A2= 5V K3/T - 0.005 - % / ºC

Common-Mode Rejection Ratio V=20VP-P , RL=2k, f=100Hz CMRR - 130 - dB

Total Harmonic Distortion f0=350Hz, 0dBm THD -96 -87 -80 dB

Frequency Response 1 Photoconductive Configuration 200

f - - kHz

Photovoltaic Configuration -3dB 40

Capacitance, Input to Output VIO=0V, f=1MHz CIO - 3 - pF

1 Refer to Application Note, AN-107, for LOC110 Configurations.

2 www.ixysic.com R11

Page3

INTEGRATED CIRCUITS DIVISION LOC110

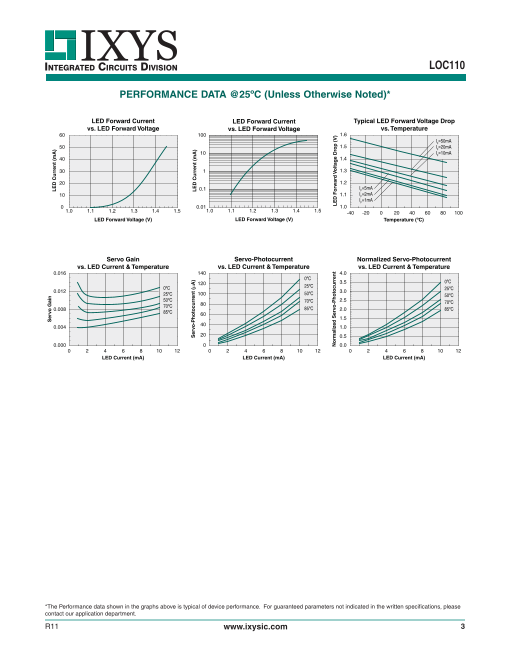

PERFORMANCE DATA @25ºC (Unless Otherwise Noted)*

LED Forward Current LED Forward Current Typical LED Forward Voltage Drop

vs. LED Forward Voltage vs. LED Forward Voltage vs. Temperature

60 100 1.6

IF=50mA

50 1.5 IF=20mA

10 IF=10mA

40 1.4

30 1 1.3

20 1.2

0.1 IF=5mA

10 1.1 IF=2mA

IF=1mA

0 0.01 1.0

1.0 1.1 1.2 1.3 1.4 1.5 1.0 1.1 1.2 1.3 1.4 1.5 -40 -20 0 20 40 60 80 100

LED Forward Voltage (V) LED Forward Voltage (V) Temperature (ºC)

Servo Gain Servo-Photocurrent Normalized Servo-Photocurrent

vs. LED Current & Temperature vs. LED Current & Temperature vs. LED Current & Temperature

0.016 140 4.0

0ºC

120 3.5 0ºC

0ºC 25ºC

0.012 3.0 25ºC

25ºC 100 50ºC 50ºC

50ºC 70ºC 2.5 70ºC

70ºC 80

0.008 85ºC 85ºC

85ºC 2.0

60

1.5

0.004 40 1.0

20 0.5

0.000 0 0.0

0 2 4 6 8 10 12 0 2 4 6 8 10 12 0 2 4 6 8 10 12

LED Current (mA) LED Current (mA) LED Current (mA)

*The Performance data shown in the graphs above is typical of device performance. For guaranteed parameters not indicated in the written specifi cations, please

contact our application department.

R11 www.ixysic.com 3

Servo Gain

LED Current (mA)

Servo-Photocurrent ( A) LED Current (mA)

Normalized Servo-Photocurrent LED Forward Voltage Drop (V)

Page4

INTEGRATED CIRCUITS DIVISION LOC110

Manufacturing Information

Moisture Sensitivity

All plastic encapsulated semiconductor packages are susceptible to moisture ingression. IXYS Integrated

Circuits Division classified all of its plastic encapsulated devices for moisture sensitivity according to

the latest version of the joint industry standard, IPC/JEDEC J-STD-020, in force at the time of product

evaluation. We test all of our products to the maximum conditions set forth in the standard, and guarantee proper

operation of our devices when handled according to the limitations and information in that standard as well as to any

limitations set forth in the information or standards referenced below.

Failure to adhere to the warnings or limitations as established by the listed specifications could result in reduced

product performance, reduction of operable life, and/or reduction of overall reliability. This product carries a Moisture

Sensitivity Level (MSL) classification as shown below, and should be handled according to the requirements of the

latest version of the joint industry standard IPC/JEDEC J-STD-033.

Device Moisture Sensitivity Level (MSL) Classifi cation

LOC110 / LOC110S MSL 1

LOC110P MSL 3

ESD Sensitivity

This product is ESD Sensitive, and should be handled according to the industry standard JESD-625.

Soldering Profile

Provided in the table below is the Classification Temperature (TC) of this product and the maximum dwell time the

body temperature of this device may be above (TC - 5)ºC. The classification temperature sets the Maximum Body

Temperature allowed for this device during lead-free reflow processes. For through hole devices, and any other

processes, the guidelines of J-STD-020 must be observed.

Device Classifi cation Temperature (TC) Dwell Time (tp) Max Refl ow Cycles

LOC110 250ºC N/A

LOC110S 250ºC 30 seconds 3

LOC110P 240ºC 3

Board Wash

IXYS Integrated Circuits Division recommends the use of no-clean flux formulations. Board washing to reduce

or remove flux residue following the solder reflow process is acceptable provided proper precautions are taken

to prevent damage to the device. These precautions include, but are not limited to: using a low pressure wash

and providing a follow up bake cycle sufficient to remove any moisture trapped within the device due to the

washing process. Due to the variability of the wash parameters used to clean the board, determination of the bake

temperature and duration necessary to remove the moisture trapped within the package is the responsibility of the

user (assembler). Cleaning or drying methods that employ ultrasonic energy may damage the device and should not

be used. Additionally, the device must not be exposed to flux or solvents that are Chlorine- or Fluorine-based.

4 www.ixysic.com R11

Page5

INTEGRATED CIRCUITS DIVISION LOC110

Mechanical Dimensions

LOC110

9.652 ± 0.381 7.620 ± 0.254 PCB Hole Pattern

2.540 ± 0.127 (0.380 ± 0.015) (0.300 ± 0.010)

(0.100 ± 0.005) 8-0.800 DIA. 2.540 ± 0.127

(8-0.031 DIA.) (0.100 ± 0.005)

6.350 ± 0.127 9.144 ± 0.508

(0.250 ± 0.005) (0.360 ± 0.020)

6.350 ± 0.127

(0.250 ± 0.005)

Pin 1 3.302 ± 0.051

0.457 ± 0.076 (0.130 ± 0.002)

(0.018 ± 0.003) 7.239 TYP. 7.620 ± 0.127

(0.285) (0.300 ± 0.005)

7.620 ± 0.127

4.064 TYP (0.300 ± 0.005)

(0.160) 0.254 ± 0.0127

(0.010 ± 0.0005)

Dimensions

0.813 ± 0.102 mm

(0.032 ± 0.004) (inches)

LOC110P

2.286 MAX. PCB Land Pattern

(0.090 MAX.)

2.540 ± 0.127 0 MIN / 0.102 MAX

(0.100 ± 0.005) (0 MIN / 0.004 MAX) 2.54

(0.10)

6.350 ± 0.127 7.620 ± 0.254 0.635 ± 0.127

9.398 ± 0.127

(0.250 ± 0.005) (0.025 ± 0.005)

(0.370 ± 0.005) (0.300 ± 0.010)

8.70

1.55 (0.3425)

Pin 1

0.203 ± 0.013 (0.0610)

9.652 ± 0.381 (0.008 ± 0.0005)

(0.380 ± 0.015)

0.65

2.159 ± 0.025 (0.0255)

(0.085 ± 0.001)

0.457 ± 0.076

(0.018 ± 0.003) Dimensions

0.864 ± 0.120 mm

(0.034 ± 0.004) (inches)

LOC110S

9.652 ± 0.381 PCB Land Pattern

(0.380 ± 0.015) 0.635 ± 0.127

2.540 ± 0.127 3.302 ± 0.051 (0.025 ± 0.005) 2.54

(0.100 ± 0.005) (0.130 ± 0.002) (0.10)

6.350 ± 0.127 9.525 ± 0.254

(0.250 ± 0.005) (0.375 ± 0.010)

1.65 8.90

(0.0649) (0.3503)

7.620 ± 0.254

Pin 1 (0.300 ± 0.010)

0.457 ± 0.076 0.254 ± 0.0127

(0.018 ± 0.003) (0.010 ± 0.0005) 0.65

(0.0255)

4.445 ± 0.127

(0.175 ± 0.005)

Dimensions

0.813 ± 0.102 mm

(0.032 ± 0.004) (inches)

R11 www.ixysic.com 5

Page6

INTEGRATED CIRCUITS DIVISION LOC110

LOC110PTR Tape & Reel

2.00 4.00

330.2 DIA. (0.079) (0.157)

(13.00 DIA.)

7.50 W = 16.00

Top Cover (0.295) (0.63)

Tape Thickness

0.102 MAX. Bo = 10.30

(0.004 MAX.) (0.406)

K = 2.70 P = 12.00 Ao = 10.30

0 (0.472) (0.406)

(0.106)

Dimensions

K1 = 2.00

Embossed Carrier (0.079) User Direction of Feed mm

(inches)

NOTES:

1. All dimensions carry tolerances of EIA Standard 481-2

Embossment 2. The tape complies with all “Notes” for constant dimensions listed on page 5 of EIA-481-2

LOC110STR Tape & Reel

330.2 DIA.

(13.00 DIA.)

Top Cover W=16.00

Tape Thickness Bo=10.30 (0.63)

0.102 MAX. (0.406)

(0.004 MAX.)

Ao=10.30 P=12.00

K =4.90 (0.406) (0.472)

0

(0.193)

K1 =4.20

User Direction of Feed

(0.165)

Embossed Carrier Dimensions

mm

(inches)

NOTES:

1. Dimensions carry tolerances of EIA Standard 481-2

Embossment 2. Tape complies with all “Notes” for constant dimensions listed on page 5 of EIA-481-2

For additional information please visit our website at: www.ixysic.com

IXYS Integrated Circuits Division makes no representations or warranties with respect to the accuracy or completeness of the contents of this publication and reserves the right to make

changes to specifications and product descriptions at any time without notice. Neither circuit patent licenses nor indemnity are expressed or implied. Except as set forth in IXYS Integrated

Circuits Division’s Standard Terms and Conditions of Sale, IXYS Integrated Circuits Division assumes no liability whatsoever, and disclaims any express or implied warranty, relating to

its products including, but not limited to, the implied warranty of merchantability, fitness for a particular purpose, or infringement of any intellectual property right.

The products described in this document are not designed, intended, authorized or warranted for use as components in systems intended for surgical implant into the body, or in other

applications intended to support or sustain life, or where malfunction of IXYS Integrated Circuits Division’s product may result in direct physical harm, injury, or death to a person or severe

property or environmental damage. IXYS Integrated Circuits Division reserves the right to discontinue or make changes to its products at any time without notice.

Specification: DS-LOC110-R11

©Copyright 2016, IXYS Integrated Circuits Division

All rights reserved. Printed in USA.

6 2/1/2016