1/21ページ

ダウンロード(465.3Kb)

このカタログについて

| ドキュメント名 | ADA4571 Integrated AMR Angle Sensor and Signal Conditioner |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 465.3Kb |

| 取り扱い企業 | マウザー・エレクトロニクス (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

Integrated AMR Angle Sensor and Signal

Conditioner

Data Sheet ADA4571

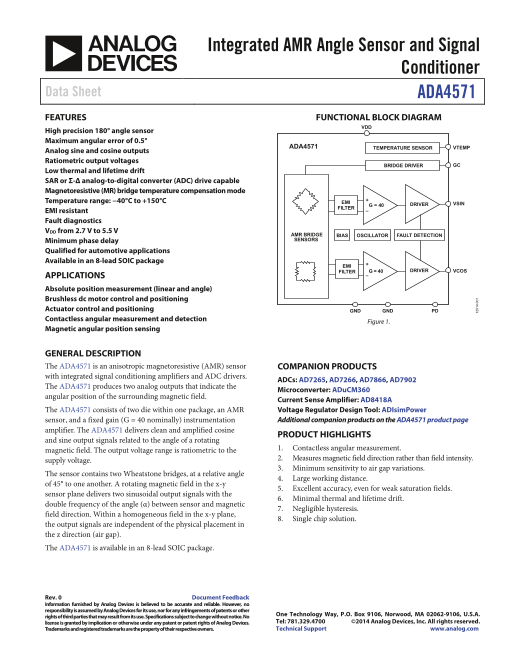

FEATURES FUNCTIONAL BLOCK DIAGRAM

VDD

High precision 180° angle sensor

Maximum angular error of 0.5°

ADA4571

Analog sine and cosine outputs TEMPERATURE SENSOR VTEMP

Ratiometric output voltages

BRIDGE DRIVER GC

Low thermal and lifetime drift

SAR or Σ-∆ analog-to-digital converter (ADC) drive capable

Magnetoresistive (MR) bridge temperature compensation mode

Temperature range: −40°C to +150°C EMI +

G = 40 DRIVER VSIN

EMI resistant FILTER

–

Fault diagnostics

VDD from 2.7 V to 5.5 V

AMR BRIDGE BIAS OSCILLATOR FAULT DETECTION

Minimum phase delay SENSORS

Qualified for automotive applications

Available in an 8-lead SOIC package

EMI +

FILTER G = 40 DRIVER VCOS

APPLICATIONS –

Absolute position measurement (linear and angle)

Brushless dc motor control and positioning

Actuator control and positioning GND GND PD

Contactless angular measurement and detection Figure 1.

Magnetic angular position sensing

GENERAL DESCRIPTION

The ADA4571 is an anisotropic magnetoresistive (AMR) sensor COMPANION PRODUCTS

with integrated signal conditioning amplifiers and ADC drivers.

ADCs: AD7265, AD7266, AD7866, AD7902

The ADA4571 produces two analog outputs that indicate the Microconverter: ADuCM360

angular position of the surrounding magnetic field. Current Sense Amplifier: AD8418A

The ADA4571 consists of two die within one package, an AMR Voltage Regulator Design Tool: ADIsimPower

sensor, and a fixed gain (G = 40 nominally) instrumentation Additional companion products on the ADA4571 product page

amplifier. The ADA4571 delivers clean and amplified cosine

PRODUCT HIGHLIGHTS

and sine output signals related to the angle of a rotating

magnetic field. The output voltage range is ratiometric to the 1. Contactless angular measurement.

supply voltage. 2. Measures magnetic field direction rather than field intensity.

3. Minimum sensitivity to air gap variations.

The sensor contains two Wheatstone bridges, at a relative angle 4. Large working distance.

of 45° to one another. A rotating magnetic field in the x-y 5. Excellent accuracy, even for weak saturation fields.

sensor plane delivers two sinusoidal output signals with the 6. Minimal thermal and lifetime drift.

double frequency of the angle (α) between sensor and magnetic 7. Negligible hysteresis.

field direction. Within a homogeneous field in the x-y plane, 8. Single chip solution.

the output signals are independent of the physical placement in

the z direction (air gap).

The ADA4571 is available in an 8-lead SOIC package.

Rev. 0 Document Feedback

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

license is granted by implication or otherwise under any patent or patent rights of Analog Devices. Tel: 781.329.4700 ©2014 Analog Devices, Inc. All rights reserved.

Trademarks and registered trademarks are the property of their respective owners. Technical Support www.analog.com

12514-001

Page2

ADA4571 Data Sheet

TABLE OF CONTENTS

Features .............................................................................................. 1 Pin Configuration and Descriptions ...............................................8

Applications ....................................................................................... 1 Typical Performance Characteristics ..............................................9

Functional Block Diagram .............................................................. 1 Terminology .................................................................................... 13

General Description ......................................................................... 1 Theory of Operation ...................................................................... 14

Companion Products ....................................................................... 1 Application Information ................................................................ 16

Product Highlights ........................................................................... 1 Angle Calculation ....................................................................... 16

Revision History ............................................................................... 2 Connection to ECU ................................................................... 16

Specifications ..................................................................................... 3 Mechanical Tolerances Diagrams ............................................ 18

Magnetic Characteristics ............................................................. 3 Diagnostics .................................................................................. 19

Electrical Characteristics ............................................................. 3 Outline Dimensions ....................................................................... 21

Absolute Maximum Ratings ............................................................ 7 Ordering Guide .......................................................................... 21

Thermal Resistance ...................................................................... 7 Automotive Products ................................................................. 21

ESD Caution .................................................................................. 7

REVISION HISTORY

10/14—Revision 0: Initial Version

Rev. 0 | Page 2 of 21

Page3

Data Sheet ADA4571

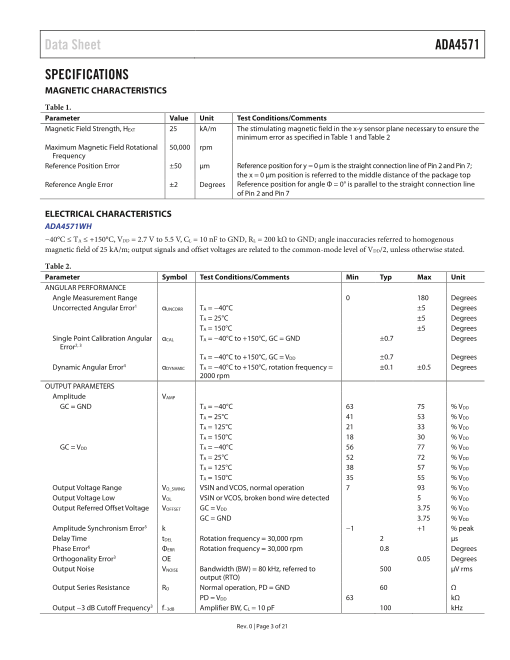

SPECIFICATIONS

MAGNETIC CHARACTERISTICS

Table 1.

Parameter Value Unit Test Conditions/Comments

Magnetic Field Strength, HEXT 25 kA/m The stimulating magnetic field in the x-y sensor plane necessary to ensure the

minimum error as specified in Table 1 and Table 2

Maximum Magnetic Field Rotational 50,000 rpm

Frequency

Reference Position Error ±50 µm Reference position for y = 0 µm is the straight connection line of Pin 2 and Pin 7;

the x = 0 µm position is referred to the middle distance of the package top

Reference Angle Error ±2 Degrees Reference position for angle Φ = 0° is parallel to the straight connection line

of Pin 2 and Pin 7

ELECTRICAL CHARACTERISTICS

ADA4571WH

−40°C ≤ TA ≤ +150°C, VDD = 2.7 V to 5.5 V, CL = 10 nF to GND, RL = 200 kΩ to GND; angle inaccuracies referred to homogenous

magnetic field of 25 kA/m; output signals and offset voltages are related to the common-mode level of VDD/2, unless otherwise stated.

Table 2.

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

ANGULAR PERFORMANCE

Angle Measurement Range 0 180 Degrees

Uncorrected Angular Error1 αUNCORR TA = −40°C ±5 Degrees

TA = 25°C ±5 Degrees

TA = 150°C ±5 Degrees

Single Point Calibration Angular αCAL TA = −40°C to +150°C, GC = GND ±0.7 Degrees

Error2, 3

TA = −40°C to +150°C, GC = VDD ±0.7 Degrees

Dynamic Angular Error4 αDYNAMIC TA = −40°C to +150°C, rotation frequency = ±0.1 ±0.5 Degrees

2000 rpm

OUTPUT PARAMETERS

Amplitude VAMP

GC = GND TA = −40°C 63 75 % VDD

TA = 25°C 41 53 % VDD

TA = 125°C 21 33 % VDD

TA = 150°C 18 30 % VDD

GC = VDD TA = −40°C 56 77 % VDD

TA = 25°C 52 72 % VDD

TA = 125°C 38 57 % VDD

TA = 150°C 35 55 % VDD

Output Voltage Range VO_SWING VSIN and VCOS, normal operation 7 93 % VDD

Output Voltage Low VOL VSIN or VCOS, broken bond wire detected 5 % VDD

Output Referred Offset Voltage VOFFSET GC = VDD 3.75 % VDD

GC = GND 3.75 % VDD

Amplitude Synchronism Error5 k −1 +1 % peak

Delay Time tDEL Rotation frequency = 30,000 rpm 2 µs

Phase Error6 ΦERR Rotation frequency = 30,000 rpm 0.8 Degrees

Orthogonality Error3 OE 0.05 Degrees

Output Noise VNOISE Bandwidth (BW) = 80 kHz, referred to 500 µV rms

output (RTO)

Output Series Resistance RO Normal operation, PD = GND 60 Ω

PD = VDD 63 kΩ

Output −3 dB Cutoff Frequency3 f−3dB Amplifier BW, CL = 10 pF 100 kHz

Rev. 0 | Page 3 of 21

Page4

ADA4571 Data Sheet

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

Power Supply Rejection3 PSRR Measured as output variation from VDD/2, 80 dB

VDD = 2.7 V to 5.5 V, RL = 200 kΩ to GND,

GC = GND or VDD

Output Short-Circuit Current ISC Short to GND per pin (VSIN, VCOS) 15 20 mA

Short to VDD per pin (VSIN, VCOS) −15 −18 mA

Sensitivity SEN α1 = 0°, α2 = 135°, TA = 25°C 52 mV/°

POWER SUPPLY

Supply Voltage VDD 2.7 5.5 V

Quiescent Supply Current ISY PD = GND, GC = GND, no load 3.5 4.5 6.5 mA

PD = GND, GC = VDD, no load 7 mA

PD = VDD, no load 15 µA

Power-Up Time tPWRUP To 98% of desired output level after VDD was 150 µs

reached

To 98% of desired output level after PD cycling 100 µs

DIGITAL INPUTS

Input Bias Current (GC) IB_GC For GC mode control pin, GC = GND 30 µA

For GC mode control pin, GC = VDD 3 µA

Input Bias Current (PD) IB_PD For PD pin, PD = GND 3 µA

For PD pin, PD = VDD 30 µA

Input Voltage (GC and PD)

High VIH 1.4 V

Low VIL 0.35 V

TEMPERATURE SENSOR

Error Over Temperature TERR 5 °C

Temperature Voltage Range TRANGE TA = −40°C to +150°C 0 82 % VDD

Temperature Coefficient TCO 3.173 mV/V/°C

VTEMP Output Voltage TA = 25°C 18 40 % VDD

VTEMP Output Impedance Buffered output 50 Ω

VTEMP Load Capacitance Optional load capacitance 0 22 nF

VTEMP Short-Circuit Current ISC_VTEMP Short-circuit to VDD or GND 2 mA

LOAD CAPACITOR

External Load Capacitance CL Between VSIN to GND and VCOS to GND; 10 nF

solder close to package

1 αUNCORR is the total mechanical angular error after arctan computation. This parameter is 100% production tested at 25°C and 150°C. This error includes all sources of

error over temperature before calibration. Error components such as offset, amplitude synchronism, amplitude synchronism drift, thermal offset drift, phase error,

hysteresis, orthogonality error, and noise are included.

2 αCAL is the total mechanical angular error after arctan computation. This error includes all sources of error over temperature after an initial offset (nulling) is performed

at TA = 25°C. Error components such as amplitude synchronism drift, amplifier gain matching, thermal offset drift, phase error, hysteresis, orthogonality error, and

noise are included.

3 Guaranteed through characterization.

4 αDYNAMIC is the total mechanical angular error after arctan computation. This parameter is 100% production tested. This error includes all sources of error over

temperature after a continuous background calibration is performed to correct offset and amplitude synchronism errors. Error components such as phase error,

hysteresis, orthogonality error, noise, and lifetime drift are included.

5 Peak-to-peak amplitude mismatch. k = 100 × VSIN/VCOS.

6 Rotation frequency dependent phase error, after offset correction, amplitude calibration, and arctan calculation.

Rev. 0 | Page 4 of 21

Page5

Data Sheet ADA4571

ADA4571B

−40°C ≤ TA ≤ +125°C, VDD = 2.7 V to 5.5 V, CL = 10 nF to GND, RL = 200 kΩ to GND; angle inaccuracies referred to homogenous

magnetic field of 25 kA/m; output signals and offset voltages are related to the common-mode level of VDD/2, unless otherwise stated.

Table 3.

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

ANGULAR PERFORMANCE

Angle Measurement Range 0 180 Degrees

Uncorrected Angular Error1 αUNCORR TA = −40°C ±3 Degrees

TA = 25°C ±3 Degrees

TA = 125°C ±4 Degrees

Single Point Calibration Angular αCAL TA = −40°C to +125°C, GC = GND ±0.5 Degrees

Error2, 3

TA = −40°C to +125°C, GC = VDD ±0.5 Degrees

Dynamic Angular Error4 αDYNAMIC TA = −40°C to +125°C, rotation frequency = 0.1 ±0.4 Degrees

2000 rpm

Angular Inaccuracy3, 5 ∆α After end of line (EOL) calibration for offset 0.05 Degrees

voltage error and amplitude synchronism at

TA = −40°C to +125°C (only 180° range)

OUTPUT PARAMETERS

Amplitude VAMP

GC = GND TA = −40°C 63 75 % VDD

TA = 25°C 41 53 % VDD

TA = 125°C 21 33 % VDD

GC = VDD TA = −40°C 56 77 % VDD

TA = 25°C 52 72 % VDD

TA = 125°C 38 57 % VDD

Output Voltage Range VO_SWING VSIN and VCOS, normal operation 7 93 % VDD

Output Voltage Low VOL VSIN or VCOS, broken bond wire detected 3.75 % VDD

Output Referred Offset Voltage VOFFSET GC = VDD 3.75 % VDD

GC = GND 3.75 % VDD

Amplitude Synchronism Error6 k −0.75 +0.75 % peak

Delay Time tDEL Rotation frequency = 30,000 rpm 2 µs

Phase Error7 ΦERR Rotation frequency = 30,000 rpm 0.8 Degrees

Orthogonality Error3 OE 0.05 Degrees

Output Noise VNOISE BW = 80 kHz, RTO 500 µV rms

Output Series Resistance RO Normal operation, PD = GND 50 Ω

PD = VDD 63 kΩ

Output −3 dB Cutoff Frequency3 f−3dB Amplifier BW, CL = 10 pF 100 kHz

Power Supply Rejection3 PSRR Measured as output variation from VDD/2, 80 dB

VDD = 2.7 V to 5.5 V, RL = 200 kΩ to GND,

GC = GND or VDD

Output Short-Circuit Current ISC Short to GND per pin (VSIN, VCOS) 15 20 mA

Short to VDD per pin (VSIN, VCOS) −15 −18 mA

Sensitivity SEN α = 0° and 135°, TA = 25°C 52 mV/°

POWER SUPPLY

Supply Voltage VDD 2.7 5.5 V

Quiescent Supply Current ISY PD = GND, GC = GND, no load 3.5 4.5 6 mA

PD = GND, GC = VDD 6.5 mA

PD = VDD, no load 12.5 µA

Power-Up Time tPWRUP To 98% of desired output level after VDD was 150 µs

reached

To 98% of desired output level after PD cycling 100 µs

Rev. 0 | Page 5 of 21

Page6

ADA4571 Data Sheet

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

DIGITAL INPUTS

Input Bias Current (GC) IB_GC For GC mode control pin, GC = GND 30 µA

For GC mode control pin, GC = VDD 3 µA

Input Bias Current (PD) IB_PD For PD pin, PD = GND 3 µA

For PD pin, PD = VDD 30 µA

Input Voltage (GC and PD)

High VIH 1.4 V

Low VIL 0.35 V

TEMPERATURE SENSOR

Error Over Temperature TERR 5 °C

Temperature Voltage Range TRANGE TA = −40°C to +125°C 0 69 % VDD

Temperature Coefficient TCO 3.173 mV/V/°C

VTEMP Output Voltage TA = 25°C 18 40 % VDD

VTEMP Output Impedance Buffered output 50 Ω

VTEMP Load Capacitance Optional load capacitance 0 22 nF

VTEMP Short-Circuit Current ISC_VTEMP Short-circuit to VDD or GND 2 mA

LOAD CAPACITOR

External Load Capacitance CL Between VSIN to GND and VCOS to GND; 10 nF

solder close to package

1 αUNCORR is the total mechanical angular error after arctan computation. This parameter is 100% production tested at 25°C and 150°C. This error includes all sources of

error over temperature before calibration. Error components such as offset, amplitude synchronism, amplitude synchronism drift, thermal offset drift, phase error,

hysteresis, orthogonality error, and noise are included.

2 αCAL is the total mechanical angular error after arctan computation. This error includes all sources of error over temperature after an initial offset (nulling) is performed

at TA = 25°C. Error components such as amplitude synchronism drift, amplifier gain matching, thermal offset drift, phase error, hysteresis, orthogonality error, and

noise are included.

3 Guaranteed through characterization.

4 αDYNAMIC is the total mechanical angular error after arctan computation. This parameter is 100% production tested. This error includes all sources of error over

temperature after a continuous background calibration is performed to correct offset and amplitude synchronism errors. Error components such as phase error,

hysteresis, orthogonality error, noise, and lifetime drift are included.

5 Angular speed <300 rpm. Limited to 180° rotation. The value is calculated only with the third and fifth harmonics of the spectrum of output signal amplitude by the

ideal homogeneous field.

6 Peak-to-peak amplitude mismatch. k = 100 × VSIN/VCOS.

7 Rotation frequency dependent phase error, after offset correction, amplitude calibration, and arctan calculation.

Rev. 0 | Page 6 of 21

Page7

Data Sheet ADA4571

ABSOLUTE MAXIMUM RATINGS

Table 4. THERMAL RESISTANCE

Parameter Rating θJA is specified for the worst case conditions, that is, a device

Operating Temperature −40°C to +150°C soldered in a circuit board for surface-mount packages.

Storage Temperature −65°C to +150°C

Table 5. Thermal Resistance

Supply Voltage (VDD)1 −0.3 V to +6 V

Output Short-Circuit Duration to GND or VDD Indefinite Package Type θJA Unit

VTEMP Short-Circuit to GND or VDD Indefinite 8-Lead SOIC 120 °C/W

ESD

Human Body Model (HBM)2 4000 V

ESD CAUTION

Machine Model (MM)3 300 V

Charge Device Model (CDM)4 1250 V

1 GC or PD at VDD + 0.3 V.

2 Applicable standard: JESD22-C101.

3 Applicable standard: JESD22-A115.

4 Applicable standard: ESDA/JEDEC JS-001-2011.

Stresses at or above those listed under Absolute Maximum

Ratings may cause permanent damage to the product. This is a

stress rating only; functional operation of the product at these

or any other conditions above those indicated in the operational

section of this specification is not implied. Operation beyond

the maximum operating conditions for extended periods may

affect product reliability.

Rev. 0 | Page 7 of 21

Page8

ADA4571 Data Sheet

PIN CONFIGURATION AND DESCRIPTIONS

GC 1 8 PD

VCOS 2 ADA4571 7 VDD

TOP VIEW

GND 3 (Not to Scale) 6 GND

VSIN 4 5 VTEMP

Figure 2. Pin Configuration

Table 6. Pin Function Descriptions

Pin No. Mnemonic Description

1 GC Gain Control Mode Enable

2 VCOS Analog Cosine Output

3 GND Ground

4 VSIN Analog Sine Output

5 VTEMP Temperature Output

6 GND Ground

7 VDD Supply Pin

8 PD Power-Down Pin, Active High

Rev. 0 | Page 8 of 21

12514-002

Page9

Data Sheet ADA4571

TYPICAL PERFORMANCE CHARACTERISTICS

5 40

–40°C

+25°C

35 +125°C

+150°C

4

30

25

3

20

2

15

10

1

5

0 0

0 90 180 270 360 0 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50

RELATIVE MECHANICAL ANGLE (Degrees) DYNAMIC ANGULAR ERROR (Degrees)

Figure 3. Raw Output Waveforms, VDD = 5 V, GC = On, T = 25°C Figure 6. Dynamic Angular Error, VDD = 5.5 V, GC = Off

0.2 35

–40°C

+25°C

30 +125°C

+150°C

0.1

25

20

0

15

–0.1 10

5

–0.2

0 90 180 270 360 0

0 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50

MECHANICAL ANGLE (Degrees) DYNAMIC ANGULAR ERROR (Degrees)

Figure 4. Error Waveform After Offset Correction, VDD = 5 V, GC = On Figure 7. Dynamic Angular Error, VDD = 2.7 V, GC = On

40 35

–40°C –40°C

+25°C +25°C

35 +125°C +125°C

+150°C 30

+150°C

30

25

25

20

20

15

15

10 10

5 5

0

0 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0

0 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50

DYNAMIC ANGULAR ERROR (Degrees)

DYNAMIC ANGULAR ERROR (Degrees)

Figure 5. Dynamic Angular Error, VDD = 5.5 V, GC = On Figure 8. Dynamic Angular Error, VDD = 2.7 V, GC = Off

Rev. 0 | Page 9 of 21

COUNT (%) ERROR (Degrees) OUTPUT AMPLITUDE (V)

12514-012

12514-011 12514-010

COUNT (%) COUNT (%) COUNT (%)

12514-015 12514-014 12514-013

Page10

ADA4571 Data Sheet

40 35

–40°C –40°C

+25°C +25°C

35 +125°C 30 +125°C

+150°C +150°C

30

25

25

20

20

15

15

10

10

5 5

0 0

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

UNCORRECTED ANGULAR ERROR (Degrees) UNCORRECTED ANGULAR ERROR (Degrees)

Figure 9. Uncorrected Angular Error, VDD = 5.5 V, GC = On Figure 12. Uncorrected Angular Error, VDD = 2.7 V, GC = Off

40 1.2

–40°C

+25°C

35 +125°C

+150°C 1.0

30

0.8

25

20 0.6

15

0.4

10

0.2

5

0 0

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 –40 0 40 80 120

UNCORRECTED ANGULAR ERROR (Degrees) TEMPERATURE (°C)

Figure 10. Uncorrected Angular Error, VDD = 5.5 V, GC = Off Figure 13. Single Point Calibration Angular Error, VDD = 5.5 V, GC = On

35 1.2

–40°C

+25°C

30 +125°C

+150°C 1.0

25

0.8

20

0.6

15

0.4

10

5 0.2

0 0

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 –40 0 40 80 120

UNCORRECTED ANGULAR ERROR (Degrees) TEMPERATURE (°C)

Figure 11. Uncorrected Angular Error, VDD = 2.7 V, GC = On Figure 14. Single Point Calibration Angular Error, VDD = 5.5 V, GC = Off

Rev. 0 | Page 10 of 21

COUNT (%) COUNT (%) COUNT (%)

12514-018 12514-017 12514-016

ERROR (Degrees) ERROR (Degrees) COUNT (%)

12514-019

12514-021 12514-020

Page11

Data Sheet ADA4571

1.2 5.8

GC OFF (mA)

GC ON (mA)

1.0 5.6

0.8 5.4

0.6 5.2

0.4 5.0

0.2 4.8

0 4.6

–40 0 40 80 120 –40 0 40 80 120

TEMPERATURE (°C) TEMPERATURE (°C)

Figure 15. Single Point Calibration Angular Error, VDD = 2.7 V, GC = On Figure 18. Supply Current (ISY) vs. Temperature, VDD = 5 V

1.2 4.6

GC OFF (mA)

GC ON (mA)

1.0

4.4

0.8

4.2

0.6

4.0

0.4

3.8

0.2

0 3.6

–40 0 40 80 120 –40 0 40 80 120

TEMPERATURE (°C) TEMPERATURE (°C)

Figure 16. Single Point Calibration Angular Error, VDD = 2.7 V, GC = Off Figure 19. Supply Current (ISY) vs. Temperature, VDD = 3 V

7 10

5V

3V

8

6

6

5

4

4

2

3 0

2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5 –40 0 40 80 120

VDD (V) TEMPERATURE (°C)

Figure 17. Supply Current (I ) vs. Voltage (V ), T = 25°C Figure 20. Power-Down Current (IPD) vs. Temperature

SY DD

Rev. 0 | Page 11 of 21

ISY (mA) ERROR (Degrees) ERROR (Degrees)

12514-023 12514-022

12514-024

IPD (µA) ISY (mA) ISY (mA)

12514-027 12514-026 12514-025

Page12

ADA4571 Data Sheet

100 100

VOUT p-p GC OFF

90 VOUT p-p GC ON

90

80 80

70 70

60 60

50 50

40 40

30 30

20 20

10 10

0 0

–40 0 40 80 120 –40 0 40 80 120

TEMPERATURE (°C)

TEMPERATURE (°C)

Figure 21. VTEMP Output Voltage vs. Temperature Figure 23. Output Voltage (VSIN and VCOS) Peak-to-Peak vs.

Temperature (% VDD)

20 0

18 –0.1

16 –0.2

14 –0.3

12 –0.4

10 –0.5

8 –0.6

6 –0.7

4 –0.8

2 –0.9 ERROR –40°C

ERROR +25°C

ERROR +150°C

0 –1.0

–1.00 –0.75 –0.50 –0.25 0 0.25 0.50 0.75 1.00 300 3000 30000

AMPLITUDE MISMATCH (%)

RPM (Mechanical)

Figure 22. Amplitude Synchronism (% k) Figure 24. Angular Error Delay vs. RPM (Mechanical)

Rev. 0 | Page 12 of 21

COUNT (%) VTEMP (%VDD)

12514-028

12514-029

ANGULAR ERROR DELAY (Degrees) VOUT (V p-p %VDD)

12514-030

12514-031

Page13

Data Sheet ADA4571

TERMINOLOGY

Reference Position Error Uncorrected Angular Error

The reference position error is the absolute mounting position The uncorrected angular error is defined as the maximum

deviation of the sensor from its nominal placement. The deviation from an ideal angle reading, when calculating the

reference position for Y = 0 µm is the straight connection line of angle from VSIN and VCOS without offset calibration.

Pin 2 and Pin 7. The X = 0 µm position is referred to the middle Single Point Calibration Angular Error

distance of the package top. The position accuracies are within The single point calibration angular error is defined as the

a precision of ±0.05 mm (±50 µm) in both the X and Y maximum deviation from an ideal angle reading, when

direction. calculating the angle from VSIN and VCOS after an initial

Reference Angle Error calibration for offset voltage at TA = 25°C.

The reference angle error is the absolute mounting rotation Dynamic Angular Error

deviation of the sensor from its nominal placement. Marking The dynamic angular error is defined as the maximum

the position for angle Φ= 0° position is referred parallel to the deviation from an ideal angle reading, when calculating the

straight connection line of Pin 2 and Pin 7. angle from VSIN and VCOS while a continuous offset calibration is

taken into account.

GC 1 8 PD

VCOS 2 7 VDD Phase Error

GND 3 6 GND The phase error (ΦERR) is defined as the rotation frequency

VSIN 4 5 VTEMP dependent error due to bandwidth limitation of the instrumen-

tation amplifiers. VSIN and VCOS are impacted by the amplifier

Figure 25. Bonding Arrangement and Sensor Alignment in Package

propagation delay, referred to the actual angle direction of the

Output Amplitude Synchronism Error rotating magnetic field. The typical characteristics value can be

The output amplitude matching error (k) is defined as the used for a first-order compensation of this error on very high

relationship between both output channel amplitudes at rotations per minute. For low rotational speed systems, this error

continuously rotating magnetic excitation of the MR sensor component is negligible and no compensation is necessary.

mathematically expressed as

k = 100% × VSIN_P-P/VCOS_P-P

Rev. 0 | Page 13 of 21

12514-006

Page14

ADA4571 Data Sheet

THEORY OF OPERATION

The ADA4571 is an AMR sensor with integrated signal Electromagnetic interference (EMI) filters at the sensor outputs

conditioning amplifiers and ADC drivers. The ADA4571 and between the first and second stages reject unwanted noise

produces two analog outputs, sine and cosine, which indicate and interference from appearing in the signal band.

the angular position of the surrounding magnetic field. The architecture of the instrumentation amplifier consists of

The AMR sensing element is designed and manufactured by precision, low noise, zero drift amplifiers that feature a proprietary

Sensitec GmbH. chopping technique. This chopping technique offers a low input

offset voltage of 0.3 µV typical and an input offset voltage drift

of 0.02 µV/°C typical. The zero drift design also features

Figure 27 shows the sine channel, consisting of an AMR sensor chopping ripple suppression circuitry, which removes glitches

element and the supporting functions for control, filtering, and other artifacts caused by chopping.

buffering, and signal amplification. A reference voltage that is Offset voltage errors caused by common-mode voltage swings

proportional to the supply voltage is generated and it controls and power supply variations are also corrected by the chopping

the supply voltage of the sensor bridges. For noise and technique, resulting in a dc common-mode rejection ratio that

electromagnetic compatibility (EMC) suppression purposes, the is greater than 150 dB. The amplifiers feature low broadband

bridge supply is low-pass filtered. The bridge output voltages noise of 22 nV/√Hz and no 1/f noise component. These features

are amplified by a constant factor (G = 40, GC mode disabled) are ideal for amplification of the low level AMR bridge signals

and buffered. The single-ended outputs are biased around a for high precision sensing applications.

common-mode voltage of VDD/2 and are capable of driving the In addition, extensive diagnostics are integrated on-chip to self

inputs of an external ADC referenced to the supply voltage. check sensor and IC conditions.

For optimum use of the ADC input range, the cosine and sine

1 8

output voltages track the supply voltage ensuring a ratiometric

2 ADA4571 7

configuration. To achieve high signal performance both output TOP VIEW

3 (Not to Scale) 6

signals are carefully matched in both amplitude and phase. The 4 5

amplifier bandwidth is sufficient to ensure low phase delay at

maximum specified rotation speed.

Figure 26. Direction of Homogeneous Magnetic Field for α = 0°

VDD VDD

VDD

+

–

62.7pF

+

VTEMP

–

–

AMR

BRIDGE 20pF VSIN

+

ADA4571 –

+

62.7pF VDD/2

Figure 27. Detailed Internal Diagram of the ADA4571 Sine Channel

Rev. 0 | Page 14 of 21

12514-004

12514-005

Page15

Data Sheet ADA4571

DIAGNOSTIC

93% V BAND

DD

VCOS

VOFFSET

V p-p

LINEAR

50% VDD REGION

VSIN

7% VDD DIAGNOSTIC

BAND

0 90 180 270 360

MAGNETIC

Figure 28. Typical Output Waveforms; Sine and Cosine vs. Magnetic Angle

Rev. 0 | Page 15 of 21

12514-003

Page16

ADA4571 Data Sheet

APPLICATIONS INFORMATION

The integrated AMR sensor is designed for applications with a To achieve maximum accuracy from the VTEMP output

separate processing IC or electronic control unit (ECU) containing voltage, perform an initial calibration at a known, controlled

an ADC with references connected to the supply voltage. With temperature. Then, use the following equation to extract

the ADC input resolution related to VDD in the same way as the temperature information:

AMR sensor output, the system is inherently ratiometric and the

V V

signal dependency on supply voltage changes are minimized. TEMP – CAL – T T

V V CAL CO

DD DD

T

VTEMP

ANGLE CALCULATION TC

VTEMP

To calculate angle from the output of the AMR device, use the where:

trigonometric function arctangent2. The arctangent2 function TVTEMP is the calculated temperature (°C) from the VTEMP

is a standard arctangent function with additional quadrant output voltage.

information to extend the output from the magnetic angle range VTEMP is the VTEMP output voltage during operation.

of −90° to +90° to the magnetic angle range of −180° to +180°. VDD is the supply voltage.

Because of the sensing range of AMR technology, this VCAL is the VTEMP output voltage during calibration at a

calculated magnetic angle repeats over each pole of the magnet. controlled temperature.

For a simple dipole magnet, the following equation reports TCAL is the controlled temperature during calibration.

absolute angle over 180° mechanical: TCO is the temperature coefficient of the internal circuit; see the

Specifications section for the exact value.

V

arctan( SIN )

V Gain Control Mode

COS

2 Gain control (GC) enable mode can be activated by switching

CONNECTION TO ECU the GC pin to the VDD pin. In this mode, the AMR bridge

Because of the limited driving capability of the ADA4571 sensor amplitude outputs are compensated to reduce

output, minimize the length of printed circuit board (PCB) temperature variation. This results in higher and controlled

traces between the ADA4571 and other IC. Shielding of the output voltage levels, boosting system dynamic range and

signal lines is recommended. Match the load capacitors and easing the system design task. If the GC pin is left floating, a

resistors for best angular accuracy. Add bandwidth limitation weak pull-up resistor ensures that the GC mode is enabled as a

filters related to the sampling frequency of the system in front default condition. The GC mode can also be used as a sensor

of the ADC inputs to reduce noise bandwidth. self diagnostic by comparing the sine and cosine amplitude

outputs when enabled and disabled, such as radius check. In the

In Figure 29, the load resistors on VCOS and VSIN are event that the radius does not change, it indicates a gross failure

representing the input load of the filter and the ADC. The in the IC.

processor may be used for arctan and offset calculations, offset

storage, and additional calibration. Power-Down Mode

Power-down mode can be activated by switching the PD pin to

VTEMP Output Pin

the VDD pin. Within this mode, the device shuts down and its

A proportional to absolute temperature circuit provides a output pins are set to high impedance to avoid current

voltage output at the VTEMP pin for temperature monitoring consumption across the load resistors. The VTEMP output is

or temperature calibration purposes. The output voltage is connected to ground through a pull-down resistor. Power-down

ratiometric to the supply voltage enabling the interface with an mode can be entered with GC = VDD or GC = GND. An internal

ADC that uses the supply voltage to generate the reference pull-down resistor ensures that the device remains active if the

voltage. This pin must be left open when not in use. PD pin is left floating.

Rev. 0 | Page 16 of 21

Page17

Data Sheet ADA4571

VDD

RLO4 CLO4

VDD

VTEMP

ADA4571 TEMPERATURE SENSOR

GC VDD

BRIDGE DRIVER

EMI + VSIN

G = 40 DRIVER

FILTER ADC

– RLO1 CLO1

AMR BRIDGE BIAS OSCILLATOR FAULT DETECTION MICROPROCESSOR

SENSORS

EMI +

VCOS

FILTER G = 40 DRIVER

– ADC

RLO2 CLO2

GND GND PD

RLO3 CLO3

Figure 29. Typical Application Diagram with Separate Processor and Data Conversion

Power Consumption Offset of Signal Outputs

Worst case quiescent power occurs when the supply current The single-ended output signals are referenced to VDD/2

runs at its specified maximum of 7 mA and the ADA4571 is run generated internally on-chip. Offsets originate from matching

at the maximum V of 5.5 V, giving a worst case quiescent inaccuracies and other imperfections during the production

DD

power of 38.5 mW. process. For tight tolerances, it is required to match the external

loads for VSIN and VCOS to each other. For ESD and EMC

The power consumption is dependent on VDD, temperature, protection, the outputs contain a series resistance of 50 Ω. The

load resistance (RL), load capacitance (CL), and frequency of the influence of this series resistance is minimized with a large

rotating magnetic field. It is recommended to refer RL and CL to output load resistance.

ground. The output voltages are protected against short circuit

to the VDD pin or ground by current limitation within the Signal Dependence on Air Gap Distance

given time duration. Placing the device 180° rotated into the The IC measures the direction of the external magnetic field

socket may lead to damages if the supply current is not limited within its x-y plane. The result is widely independent of the

to 100 mA. field strength as long as it is above the specified minimum value

of 25 kA/m. Within a homogeneous field in x-y direction, the

result is independent of its placement in z direction (air gap).

The nominal z distance of the internal x-y plane to the top

surface of the plastic package is 0.400 mm.

Rev. 0 | Page 17 of 21

12514-007

Page18

ADA4571 Data Sheet

MECHANICAL TOLERANCES DIAGRAMS

5.00

4.90 A

4.80 2.50

2.45

SENSING ELEMENT B LEAD TIPS

CENTER 2.40

3.10

8 5 2.00 3.00

NOTE 4 1.95 2.90

4.00 1.90 6.20

0.50 C B

3.90 6.00

3.80 2° MAX 1 5.80

4

NOTE 2

0.854

0.25 C A

NOTES 3, 6, 7

0.10 C

0.487

0.437 1.27

C SEATING PLANE

0.387

NOTES 5, 6

0.25 M C A B

ALL LEADS

NOTES

1. DIMENSIONS ARE IN MILLIMETERS.

2. MAXIMUM SENSOR ROTATION.

3. THIS DIMENSION AND TRUE POSITION SPECIFY THE LOCATION OF THE CENTER

OF THE SENSING ELEMENT WITH RESPECT TO THE CENTER OF THE PACKAGE.

THE CENTER OF THE SENSING ELEMENT IS ALIGNED WITH THE EDGES OF

LEAD 2 AND LEAD 7.

4. THE CENTER OF THE SENSING ELEMENT IS ALIGNED WITH THE CENTER LINE

OF THE PACKAGE (DATUM B).

5. THE LEAD WIDTH DIMENSION IS TOLERANCED MORE TIGHTLY THAN ON

THE R8 PACKAGE OUTLINE DRAWING. THIS DIMENSION IS MEASURED AT

THE FOOT OF THE LEAD (NO FLASH, BURRS).

6. DOES NOT INCLUDE MOLD FLASH, DAMBAR PROTRUSIONS, OR BURRS.

7. MOLD BODY WIDTH AND LENGTH DIMENSIONS DO NOT INCLUDE MOLD FLASH,

OFFSETS, OR MOLD GATE PROTRUSIONS.

8. REFER TO THE R8 PACKAGE OUTLINE DRAWING FOR DIMENSIONS NOT SHOWN HERE.

Figure 30. Mechanical Drawing of the ADA4571

0.475

0.400 AMR SENSING ELEMENT

0.325

1.400

1.250

0.10 C

1.100

C SEATING PLANE

Figure 31. Cross Sectional View of the ADA4571

Rev. 0 | Page 18 of 21

12514-035

12514-034

Page19

Data Sheet ADA4571

DIAGNOSTICS VSIN

100 +150°C

95 +125°C

Radius Calculation

90 +25°C

–40°C

The VSIN and VCOS outputs can be used to calculate a radius 85

80

value. These outputs have a fixed 90° phase relationship and 75

therefore the calculated radius value remains in a predictable, 70

predetermined range that varies with the temperature of the 65

V

60 RAD

device independent of the current magnetic field direction. This 55

radius, VRAD, can be used to validate the VSIN and VCOS readings 50 VCOS

VCOS

in the ECU. When the calculated radius is no longer within the 45

40

acceptable bounds, a fault may occur in the system. To calculate 35

radius, use the following formula: 30

25

V V 20

( DD

V V ) 2 ( DD

V ) 2

15

RAD SIN COS

2 2 10

It is important to perform offset calibration before calculating 5

0

the radius.

Figure 32 shows the allowable radius values when GC mode is VCOS MAGNITUDE (%VDD)

enabled and Figure 33 shows the allowable radius values when GC OFF

GC mode is disabled. The maximum and minimum VRAD values Figure 33. GC Off Radius Values

are calculated based on the allowable amplitude range for VSIN Monitoring of the VTEMP pin can allow an even tighter range

and VCOS, over the entire operating temperature of the device as for radius length at the known temperature. See the

specified in the Specifications section. This range is represented Specifications section and the Typical Performance

by the shaded region in Figure 32 and Figure 33. Characteristics section for exact values and output amplitude

Typical VRAD values for −40°C, +25°C, +125°C, and +150°C are specifications at each temperature.

indicated as well. Broken Bond Wire Detection

VSIN

100 +150°C The ADA4571 includes circuitry to detect broken bond wire

95 +125°C conditions between the AMR sensor and the instrumentation

90 +25°C

–40°C

85 amplifier. The detection circuitry consists of current sources

80 and window comparators placed on the signal connections

75 between the AMR sensor and the ASIC. The purpose of the

70

65 current sources is to pull the signal node outside of the normal

60 VRAD operating region in the event of an open bond wire between the

55 AMR sensor and the ASIC. The purpose of the window

50 V

V COS

COS

45 comparators is to detect when the signal from the AMR sensor

40 is outside of the normal operating region. When the comparators

35

30 detect that the signal nodes are outside the normal operating

25 region, the circuit pulls the VSIN and/or VCOS node to ground

20 to indicate the fault to the host controller.

15

10 In addition to the active circuitry, there are applications

5 recommendations, such as the utilization of pull-up and pull-

0

down resistors, which detect broken bond wires by pulling

VCOS MAGNITUDE (%VDD) nodes outside of the defined operating regions. A broken bond

GC ON wire at VTEMP, VCOS, and VSIN interrupts the corresponding

Figure 32. GC On Radius Values outputs. To ensure that the output enters into a known state if

there is a broken bond wire on these pins, connect a 200 kΩ

pull-down resistor at these pins. Pulling these nodes outside of

the normal operating region signals a fault to the host

controller.

Rev. 0 | Page 19 of 21

VSIN MAGNITUDE (%VDD)

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

V

80 SIN

85

90

95

100

12514-101

VSIN MAGNITUDE (%VDD)

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80 VSIN

85

90

95

100

12514-100

Page20

ADA4571 Data Sheet

Short-Circuit Condition to GND or VDD Short-Circuit Between Sine and Cosine Sensor Outputs

In the event of a short-circuit condition, the output voltages are In the event of a short-circuit between sensor outputs, the IC

pulled to the GND or VDD pin. output voltages are tied to the output common-mode voltage. A

gross angular error is detected in the microcontroller.

100%

SHORT-CIRCUIT DIAGNOSTIC BAND (HIGH)

93%

LINEAR REGION

7%

SHORT-CIRCUIT DIAGNOSTIC BAND (LOW)

0%

Figure 34. Output Span Classification During Short-Circuit Diagnostic Condition

Table 7. Diagnostic Cases

Fault Description Output Conditions Alert

Broken Bond Wire Between the Broken bond wire detection is activated; the Diagnostic region violation

Internal MR Sensor and the ASIC broken channel(s), VSIN or VCOS, are pulled to

ground

Broken Bond Wire at the PD Pin Device remains functional No alert

Broken Bond Wire at the GC Pin Gain control is activated Possible change in output amplitude

Output Short-Circuit to GND Shorted channel is pulled to ground Diagnostic region violation

Output Short-Circuit to VDD Shorted channel is pulled to VDD Diagnostic region violation

Rev. 0 | Page 20 of 21

OUTPUT LEVEL

12514-009