1/12ページ

ダウンロード(1.7Mb)

ワイヤーハーネス生産とハウジング挿入が可能な完全自動ブロックローディングマシン

【生産の短時間化 – 在庫の少量化へ】

短納期 – 生産時間を大幅に削減

仕掛り品の在庫数を最小化

生産プロセスの最適化

【自動化による最終製品の品質向上】

高品質を維持し、作業者への依存を削減

小型コンポーネントへ信頼性の高いローディング

ローディングプロセス全体に対するフォースモニタリング

オプションのACD(自動導体検知)機能による芯線接触の監視

【高い柔軟性】

標準化された装置 – 素早くかつ個々に段取り替えが可能

無限に広がる適応範囲

このカタログについて

| ドキュメント名 | 全自動ブロックローディングマシン Omega 740/750 |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 1.7Mb |

| 取り扱い企業 | Komax Japan株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

harness manufacturing

EN

Page2

OMEGA

740

750

Komax has developed the fully automatic block

loader machines, the Omega 740 and Omega

750, for wire harness production with insertion of

housings. The highly flexible system enables

operator-independent production with double -

sided block loading in the highest quality and

different complexity without the need for inter-

im storage of individual wires. It is the economi-

cal answer to ongoing miniaturization and

increasingly smaller batches. The Omega series

makes it possible to manufacture a range of dif-

ferent wire harnesses while simultaneously re-

ducing production time significantly. The tried

and tested EtherCAT platform improves overall

system performance and significantly increases

Shorter run – less storage

requirement

– Shortest lead times – significantly reduced pro-

duction time

– Minimized stock level of semi-finished

products

– O ptimized production process

Automated quality for the end product

– Continuous quality, independent of the opera-

tor

– R eliable loading of miniaturized components

– Force monitoring of the entire loading process

– Optional ACD incision monitoring

High flexibility

– S tandard machine – quick and individual

changeover

– U nlimited number of applications

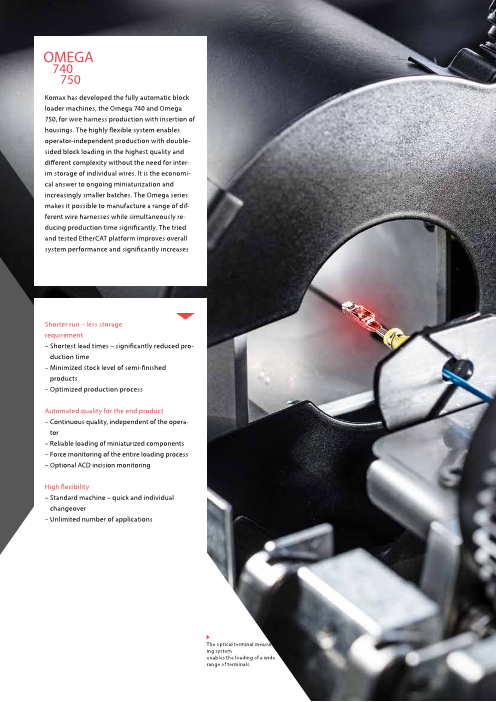

The optical terminal measur-

ing system

enables the loading of a wide

range of terminals.

Page3

QUANTUM LEAP

IN FULLY AUTOMATIC WIRE HARNESS PRODUCTION

Page4

PRECISION AND FLEXIBILITY

FOR AUTOMATIC BLOCK LOADING

Highly flexible block loading

The new Omegas feature a 40 percent larger

pallet to accommodate many different hous-

ings. This makes it possible to mount more

types of housings on a single pallet and man-

ufacture different wire harness configura-

tions simultaneously, thus significantly in-

creasing flexibility. The pallets are loaded

and unloaded as the machine is running,

while another wire harness is produced on

the second pallet with the newly developed,

rapid hybrid gripper.

Shorter lead times – less storage

requirement – optimized process

Decisive savings in time and logistics and a

corresponding growth in productivity can

be achieved thanks to the absence of manu-

al steps, interim storage and transport. Cut- High flexibility and simple operation

ting, crimping and loading of the terminals The new fully automatic blockloaders with

all take place on the same machine and the enlarged mounting pallets ensure even

time-consuming storage of individual wires greater flexibility for specific manufacturing

is eliminated. Stock levels of semi-finished across a wide range of applications. They

products can also be reduced, resulting in process wire harnesses in a single process

faster responses to design changes and re- step from A to Z and open up new possibili-

ducing the amount of material to be liqui- ties for the required wire sets. Already creat-

dated. ed wire harnesses can be loaded again in

seconds and re-produced. Thanks to individ-

ual configurations – the Omega 740 with five

process modules and the Omega 750 with

eight – changeovers and interruptions are

reduced to a minimum.

Page6

Wide variety with up to 36 wire types

The different wire types for versatile wire har-

ness production are available on the Omegas

without the need for changeovers. The auto-

matic wire changer provides up to 36 differ-

ent wires from the entire cross-section range.

Two automated inkjet printers mark the wires

in black and one additional color within the

same sequence.

New possibilities thanks to the

optional OBMS

The optional OBMS optical measuring system

makes the application even more flexible. It

measures the individual block chambers pre-

cisely using a camera system and enables the

automatic loading of components that could

only be processed manually until now.

Guaranteed quality of the end

01

Up to 36 different cables from the entire

cross section range are

available in the wire selector.

02

Individual block chambers can be mea-

sured precisely with the OBMS optical

measuring system.

01

02

Page7

products

The quality of the end product is continually 03The loading gripper monitors loading

guaranteed, independent of the machine op- force throughout production and checks

for correct terminal latching.

erator. A high-precision force sensor moni-

tors the entire insertion process and correct

latching of the terminal parts in the

housing. The individual default values are

synchronized. As a result, the insertion of

small components, which can almost no lon-

ger be inserted by hand, is carried out in an

absolutely reliable manner – supported by a

precise and fast spindle drive. Thanks to the

direct production of wire harnesses and the

removal of interim storage, the danger of ter-

minals being damaged through the storage

process or from mistakes and incorrect load-

ing is also eliminated.

The optional automatic conductor detector

03

(ACD) reduces operator influence and en-

sures quality monitoring even for the finest

wires. The ACD detects the slightest contact

between the blades and conductor strands

during stripping.

Continuous data flow and traceability

Production data can be sent directly to the

machine via a network. The quality data from

the production process is saved for each wire

harness and traceability is guaranteed at all

times.

Comprehensive advice for functional imple-

mentation

Komax brings the corresponding expert

knowledge for the automation of wire har-

ness production with Omega. Specialists

evaluate the design of the wire harnesses

and components with regard to automated

processing. They present design proposals

and assist companies in the optimal integra-

tion into their production process.

Page8

01

02

01

Three pairs of blades with optional auto-

matic conductor detector (ACD) cover the

entire cross-section range.

02

With the help of the wire storage system,

double-sided wire harnesses with a high

degree of complexity can easily be pro-

duced.

Page9

Technical data Omega 740/750

Piece output, one-ended and two-en- 1.8s per loading

ded loading*

Shortest wire length one-sided loading:

240 mm (9.45 in.)

jumper connections at both ends:

300 – 560 mm** (11.81 – 22.05 in.**)

complex loading:

Stripping lengths Up to 25 mm (0.98 in.) with full stripping

Up to 42 mm (1.65 in.) with half stripping (side 2 up to 27.5 mm (1.08 in.))

Process monitoring (integrated) Collision monitoring (block cavities)

Monitoring of loading force

Monitoring of terminal interlocking

Block feed Carousel with pallets

(customer-specific solution on request)

* The output rate depends on the wire length and housing/terminal combinations.

** Depends on wire harness structure.

*** Certain extremely hard, tough wires may not be able to be processed even if they are within the indicated cross section range.

In case of doubt, we are happy to produce samples of your wires.

Omega 740 4785 mm (188.4 in.)

Omega 750 5745 mm (226.1 in.)

Machine height with safety cover closed 2060 mm (81.1 in.)

Machine height with safety cover open 2870 mm (113 in.)

03 03

The automatic marking sys-

tem for two different inkjets

marks the cables in an opti-

mum manner.

2050 mm (80.7 in.)

Page10

Processing examples

Cutting to length Wire feed

Cutting pulled strands Wire deposit system/binding

Full stripping Seal monitoring

Half stripping Crimp force analyzer CFA+

Double sheath cable Integrated crimp height measurement

Crimping Integrated pull-out force measurement

Double crimping Wire length correction

Seal insertion Splice detection

Twisting / tinning Good/bad separation / Bad part cutting

Sleeve insertion Sequence processing

Split cycle for closed barrels Batch separation

Ferrule crimping Networking (Manufacturing execution system, WPCS, MIKO)

MIL crimping Material change detection / Material verification

Wire end solidifying, splicing, welding Wire changer

Inkjet marking Programmable crimp height

Block loading

Page11

Options and accessories

Marking systems Komax IMS inkjet marking systems • Automatic inkjet head

changer

Process modules C1370 crimping module (with programmable crimp height) •

S1440 seal module • MIL crimp • Ferrule module •

Quality control Integrated crimp height measurement • Integrated pull-out

force measurement • CFA/CFA+ crimp force analysis •

Splice detection • ACD automatic conductor detector •

Material change detection • Material verification

Software WPCS networking interface • TopConvert data conversion • Komax

MES

The untwisting module is

used to neutralize twists in

the wire.

Page12

Komax – leading the fi eld now and in the future

As a pioneer and market leader in the fi eld of automated wire

processing, Komax provides its customers with innovative

and sustainable solutions for any situation that calls for precise

contact connections. Komax manufactures series and customer-

specific machinery for various industries, catering for every

degree of automation and customization. Its range of quality tools,

test systems, and intelligent networking solutions complete the

portfolio, and ensure safe and effi cient production.

Komax is a globally active Swiss company with development and

production facilities on several continents. It supports customers

locally in more than 60 countries with its extensive distribution

and service network, ensuring the availability and value of their

investments after equipment commissioning through standardized

service processes. Komax includes more than 30 companies

worldwide and employs around 1700 members of staff .

Market segments

Komax off ers outstanding

competence and solutions for

various areas of application and

draws on them to generate the

desired value-added for the entire

process and optimize economic

effi ciency in line with customer

requirements. The main markets

of Komax are as follows:

automotive, aerospace, industrial

and telecom & datacom. With this

breadth of experience, customers

obtain expert knowledge for

process optimization and access

to the latest technologies.

Komax AG

Industriestrasse 6

CH-6036 Dierikon

Phone +41 41 455 04 55

Fax +41 41 450 15 79

komaxgroup.com

0374548 V0 Omega 740/750

Subject to change