1/11ページ

ダウンロード(917.3Kb)

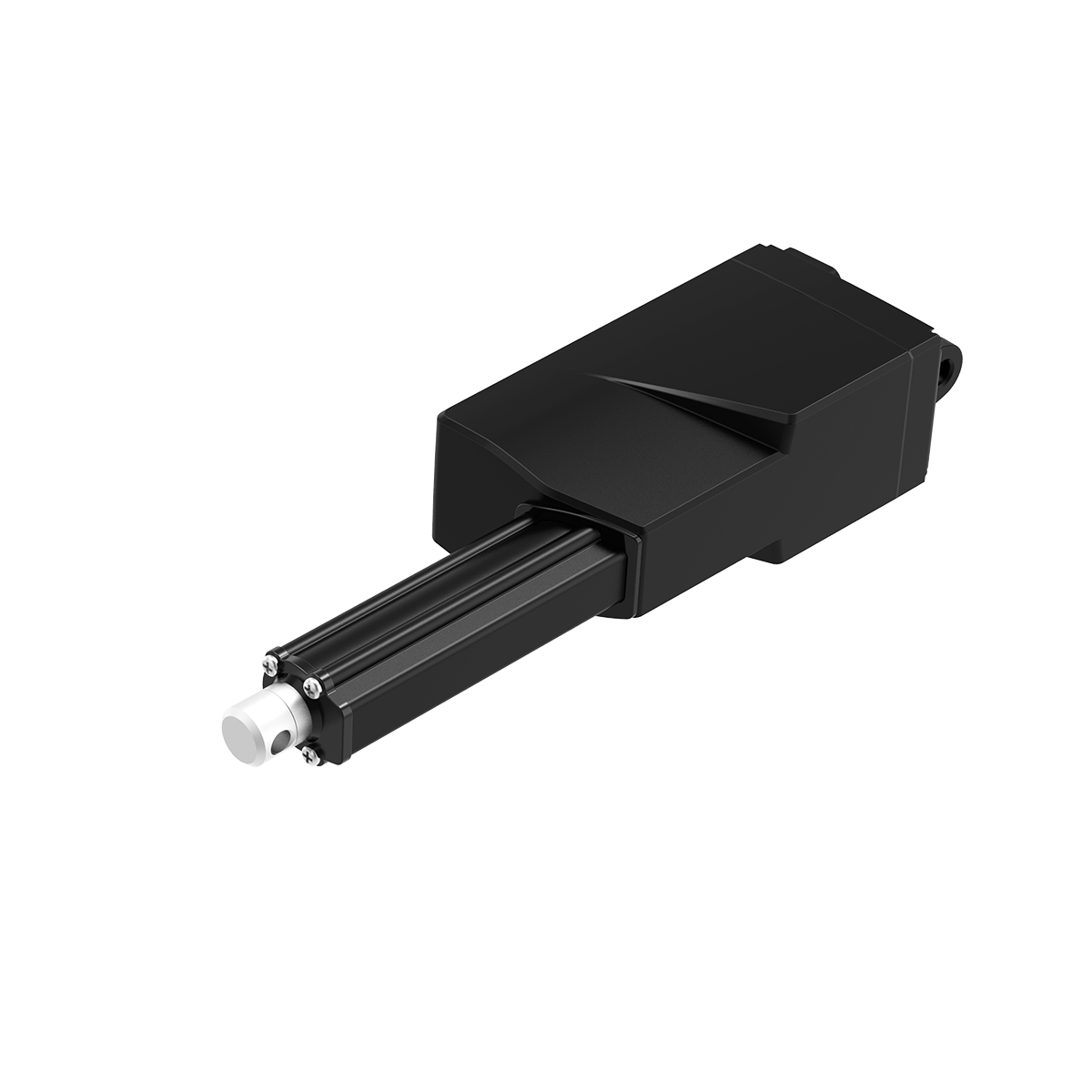

TiMOTIONのMA5リニアアクチュエータは過酷な作業環境向けに特別に設計され、IP69Kの保護は高圧ウォータージェット、および塵埃、その他の固体汚染物の侵入に耐えることができます。

MA5は、アプリケーションの要件に応じてさまざまなフィードバックオプションでカスタマイズすることもできます。 さらに、グリースニットを装備し、保護度合い寿命を向上させることができます。 MA5の適切なアプリケーションには、スプレッダー、ハーベスター、穀物ハンドラーなどの農業機器が含まれます。

【主な特長】

最大負荷:3,500N(Push)、2,000N(Pull)

速度(定格負荷時):45mm/sec(1,000N仕様)

ストローク:≥20〜1000mm

取付寸法:≥200mm

IP等級:最高IP69K

使用温度範囲:-25˚C〜+65˚C

フルパフォーマンスでの使用温度範囲:+ 5°C〜+ 45°C

オプション:ホールセンサー、POT、グリースチャンバー

このカタログについて

| ドキュメント名 | 電動リニアアクチュエータ【MA5】 |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 917.3Kb |

| 登録カテゴリ | |

| 取り扱い企業 | TiMotion Japan株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

MA5

series

Product Segments TiMOTION’s MA5 linear actuator is specifically designed for applications which

face harsh working environments and require ruggedness and durability. Its

• Industrial Motion IP69K protection can withstand high pressure water jets, and the ingress of

dust and other solid contaminants.

The MA5 can also be customized with various feedback options depending

on the application requirements; moreover, it can be equipped with a grease

nipple to increase the protection degree and life cycle. Suitable applications for

MA5 include agricultural equipment, such as spreaders, harvesters, and grain

handlers.

General Features

Maximum load 3,500N in push

Maximum load 2,000N in pull

Maximum speed at full load 45mm/s

(with 250N in a push or pull condition)

Stroke ≥20~1000mm

Minimum installation dimension ≥200mm (upon the front attachment)

IP rating Up to IP69K

Operational temperature range -25˚C ~ +65˚C

Operational temperature range +5°C~+45°C

at full performance

Options Hall sensors, POT, grease chamber

1

Page2

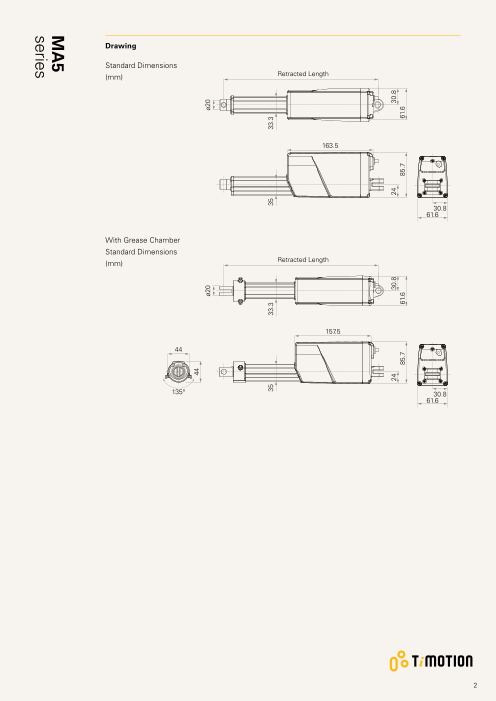

Drawing

Standard Dimensions

(mm) Retracted Length

163.5

30.8

61.6

With Grease Chamber

Standard Dimensions

(mm) Retracted Length

157.5

44

135° 30.8

61.6

2

44

ø20 ø20

35 33.3 35 33.3

24 30.8 24 30.8

85.7 61.6 85.7 61.6

MA5

series

Page3

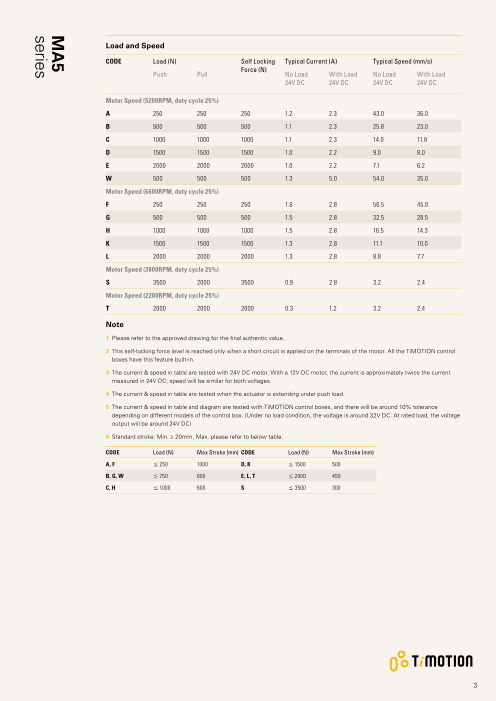

Load and Speed

CODE Load (N) Self Locking Typical Current (A) Typical Speed (mm/s)

Force (N)

Push Pull No Load With Load No Load With Load

24V DC 24V DC 24V DC 24V DC

Motor Speed (5200RPM, duty cycle 25%)

A 250 250 250 1.2 2.3 43.0 36.0

B 500 500 500 1.1 2.3 25.8 23.0

C 1000 1000 1000 1.1 2.3 14.0 11.8

D 1500 1500 1500 1.0 2.2 9.0 8.0

E 2000 2000 2000 1.0 2.2 7.1 6.2

W 500 500 500 1.3 5.0 54.0 35.0

Motor Speed (6600RPM, duty cycle 25%)

F 250 250 250 1.6 2.8 56.5 45.0

G 500 500 500 1.5 2.8 32.5 28.5

H 1000 1000 1000 1.5 2.8 16.5 14.3

K 1500 1500 1500 1.3 2.8 11.1 10.0

L 2000 2000 2000 1.3 2.8 8.8 7.7

Motor Speed (3800RPM, duty cycle 25%)

S 3500 2000 3500 0.9 2.8 3.2 2.4

Motor Speed (2200RPM, duty cycle 25%)

T 2000 2000 2000 0.3 1.2 3.2 2.4

Note

1 Please refer to the approved drawing for the final authentic value.

2 This self-locking force level is reached only when a short circuit is applied on the terminals of the motor. All the TiMOTION control

boxes have this feature built-in.

3 T he current & speed in table are tested with 24V DC motor. With a 12V DC motor, the current is approximately twice the current

measured in 24V DC; speed will be similar for both voltages.

4 The current & speed in table are tested when the actuator is extending under push load.

5 The current & speed in table and diagram are tested with TiMOTION control boxes, and there will be around 10% tolerance

depending on different models of the control box. (Under no load condition, the voltage is around 32V DC. At rated load, the voltage

output will be around 24V DC)

6 Standard stroke: Min. ≥ 20mm, Max. please refer to below table.

CODE Load (N) Max Stroke (mm) CODE Load (N) Max Stroke (mm)

A, F ≦ 250 1000 D, K ≦ 1500 500

B, G, W ≦ 750 800 E, L, T ≦ 2000 450

C, H ≦ 1000 600 S ≦ 3500 300

3

MA5

series

Page4

Performance Data (24V DC Motor)

Motor Speed (5200RPM)

Speed vs. Load

50.0

40.0

A W

30.0

B

20.0

C

10.0 D

E

0.0

0 1000 2000 3000 4000 5000

Load (N)

Current vs. Load

W

5.0

4.0

3.0

A B C D E

2.0

1.0

0.0

0 1000 2000 3000 4000 5000

Load (N)

Note

1 The performance data in the curve charts shows theoretical value.

4

Current (A) Speed (mm/s)

MA5

series

Page5

Performance Data (24V DC Motor)

Motor Speed (6600RPM)

Speed vs. Load

50.0

F

40.0

30.0 G

20.0

H

K

10.0 L

0.0

0 1000 2000 3000 4000 5000

Load (N)

Current vs. Load

5.0

4.0

3.0 F G H K L

2.0

1.0

0.0

0 1000 2000 3000 4000 5000

Load (N)

Note

1 The performance data in the curve charts shows theoretical value.

5

Current (A) Speed (mm/s)

MA5

series

Page6

Performance Data (24V DC Motor)

Motor Speed (3800RPM)

Speed vs. Load

5.0

4.0

3.0

S

2.0

1.0

0.0

0 1000 2000 3000 4000 5000

Load (N)

Current vs. Load

5.0

4.0

3.0 S

2.0

1.0

0.0

0 1000 2000 3000 4000 5000

Load (N)

Note

1 The performance data in the curve charts shows theoretical value.

6

Current (A) Speed (mm/s)

MA5

series

Page7

Performance Data (24V DC Motor)

Motor Speed (2200RPM)

Speed vs. Load

5.0

4.0

3.0

T

2.0

1.0

0.0

0 1000 2000 3000 4000 5000

Load (N)

Current vs. Load

5.0

4.0

3.0

2.0

T

1.0

0.0

0 1000 2000 3000 4000 5000

Load (N)

Note

1 The performance data in the curve charts shows theoretical value.

7

Current (A) Speed (mm/s)

MA5

series

Page8

MA5 Ordering Key

MA5

Version: 20190327-E

Voltage 1 = 12V DC 2 = 24V DC 5 = 24V DC, PTC 6 = 12V DC, PTC

Load and Speed See page 3

Stroke (mm)

Retracted Length See page 9

(mm)

Rear Attachment 4 = A luminum casting, U clevis, slot 6.0, width 10.5, hole 6 = Aluminum casting, U clevis, slot 6.0, width 10.5, hole

(mm) 6.4, one piece casting with gear box 10.1, one piece casting with gear box

See page 10 5 = Aluminum casting, U clevis, slot 6.0, width 10.5, hole

8.0, one piece casting with gear box

Front Attachment 1 = Aluminum casting, hole 6.4 4 = Aluminum CNC, U clevis, slot 6.0, depth 16.0, hole

(mm) 2 = Aluminum casting, hole 8.0 6.4

See page 10 3 = A luminum CNC, U clevis, slot 6.0, depth 16.0, hole 5 = Aluminum CNC, U clevis, slot 6.0, depth 16.0, hole

10.0 8.0

Direction of 1 = 90° 2 = 0°

Rear Attachment

(Counterclockwise)

See page 10

Functions for 1 = Two switches at full retracted / extended positions to cut current

Limit Switches 2 = Two switches at full retracted / extended positions to cut current + third one in between to send signal

See page 11 3 = Two switches at full retracted / extended positions to send signal

4 = Two switches at full retracted / extended positions to send signal + third one in between to send signal

Output Signals 0 = Without 1 = POT 5 = Hall sensor*2

Connector 1 = DIN 6P, 90° plug 2 = Tinned leads

See page 11

Cable Length (mm) 1 = Straight, 300 2 = Straight, 600 3 = Straight, 1000

IP Rating 6 = IP66D 9 = IP69K

Wiper Set & 0 = Normal wiper, without grease chamber

Grease Nipple 1 = Enhanced wiper set, with grease chamber, grease nipple*1

2 = Enhanced wiper set, with grease chamber, grease nipple*2

3 = Enhanced wiper set, with grease chamber, without grease nipple

8

Page9

MA5 Ordering Key Appendix

Retracted Length (mm)

1. Calculate A+B+C = Y

2. Retracted length needs to ≥ Stroke + Y

3. The total Retacted length calculated must be equal or longer than below minimum value

(1) When choosing the wiper set #0: And the front attachment is #1, #2, min retracted length ≥ 200mm, And the front attachment

is #3, #4, #5, min retracted length ≥ 212mm

(2) When choosing the wiper set #1, #2, #3: And the front attachment is #1, #2min retracted length ≥ 238mm, And the

front attachment is #3, #4, #5min retracted length ≥ 250mm

A. Front Attachment C. Ouput Signals

1, 2 +112 0, 5 -

3, 4, 5 +124 1 +30

B. Load V.S. Stroke D. Wiper Set & Grease Nipple

Stroke (mm) Load (N) 0 -

< 3500 = 3500 1, 2, 3 +10

20 ~150 - +5

151~200 +2 +7

201~250 +2 +7

251~300 +2 +7

301~350 +12 +17

351~400 +22 +27

401~450 +32 +37

451~500 +42 +47

501~550 +52 +57

551~600 +62 +67

601~650 +72 +77

651~700 +82 +87

701~750 +92 +97

751~800 +102 +107

801~850 +112 +117

851~900 +122 +127

901~950 +132 +137

951~1000 +142 +147

9

Page10

MA5 Ordering Key Appendix

Rear Attachment (mm)

4 = A luminum casting, U clevis, slot 5 = Aluminum casting, U clevis, slot 6 = Aluminum casting, U clevis, slot

6.0, width 10.5, hole 6.4, one 6.0, width 10.5, hole 8.0, one 6.0, width 10.5, hole 10.1, one

piece casting with gear box piece casting with gear box piece casting with gear box

15 15 15

R11 R11 R11

ø6.4 ø8 ø10.1

10.5 10.5 10.5

Front Attachment (mm)

1 = Aluminum casting, hole 6.4 2 = Aluminum casting, hole 8.0 3 = Aluminum CNC, U clevis, slot 6.0, 4 = Aluminum CNC, U clevis, slot 6.0,

depth 16.0, hole 10.0 depth 16.0, hole 6.4

ø6.4 ø8 ø10 ø6.4

9 9

16 16

5 = A luminum CNC, U clevis, slot 6.0,

depth 16.0, hole 8.0

ø8

16

Direction of Rear Attachment (Counterclockwise)

1 = 90° 2 = 0°

10

ø20

6

ø20

6

22

ø20

6

22

ø20

6

6

22

ø20

6

Page11

MA5 Ordering Key Appendix

Functions for Limit Switches

Wire Definitions

CODE Pin

1 (Green) 2 (Red) 3 (White) 4 (Black) 5 (Yellow) 6 (Blue)

1 extend (VDC+) N/A N/A N/A retract (VDC+) N/A

2 extend (VDC+) N/A middle switch pin B middle switch pin A retract (VDC+) N/A

3 extend (VDC+) common upper limit switch N/A retract (VDC+) lower limit switch

4 extend (VDC+) common upper limit switch medium limit switch retract (VDC+) lower limit switch

Connector

1 = DIN 6P, 90° plug 2 = Tinned leads

4

50

Terms of Use

The user is responsible for determining the suitability of TiMOTION products for a specific application.

TiMOTION products are subject to change without prior notice.

11