1/8ページ

ダウンロード(1.5Mb)

このカタログについて

| ドキュメント名 | Firstohm Company Profile |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 1.5Mb |

| 取り扱い企業 | 日本ミック株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

liability

ity • Re

Innovation

ual wn via

Q

Cost-Do

Page2

eliability

ty • R Innovation

uali n via

w

Company Profile Q

Cost-Do

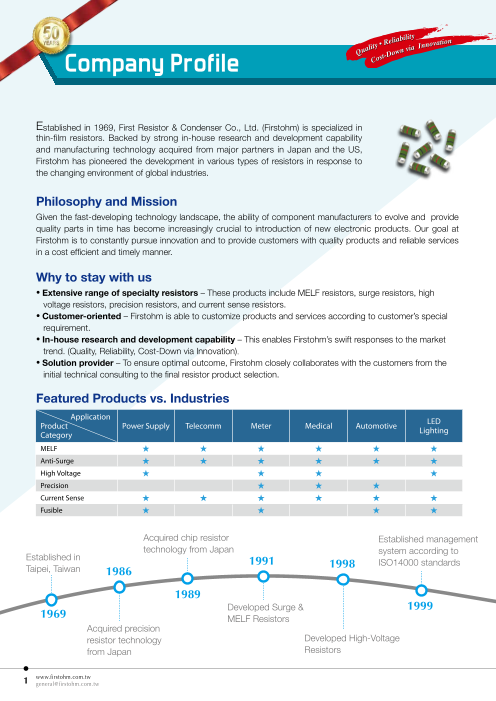

Established in 1969, First Resistor & Condenser Co., Ltd. (Firstohm) is specialized in

thin-film resistors. Backed by strong in-house research and development capability

and manufacturing technology acquired from major partners in Japan and the US,

Firstohm has pioneered the development in various types of resistors in response to

the changing environment of global industries.

Philosophy and Mission

Given the fast-developing technology landscape, the ability of component manufacturers to evolve and provide

quality parts in time has become increasingly crucial to introduction of new electronic products. Our goal at

Firstohm is to constantly pursue innovation and to provide customers with quality products and reliable services

in a cost efficient and timely manner.

Why to stay with us

Extensive range of specialty resistors – These products include MELF resistors, surge resistors, high

voltage resistors, precision resistors, and current sense resistors.

Customer-oriented – Firstohm is able to customize products and services according to customer’s special

requirement.

In-house research and development capability – This enables Firstohm’s swift responses to the market

trend. (Quality, Reliability, Cost-Down via Innovation).

Solution provider – To ensure optimal outcome, Firstohm closely collaborates with the customers from the

initial technical consulting to the final resistor product selection.

Featured Products vs. Industries

Application

Product Power Supply Telecomm Meter Medical Automotive LED

Category Lighting

MELF ★ ★ ★ ★ ★ ★

Anti-Surge ★ ★ ★ ★ ★ ★

High Voltage ★ ★ ★ ★

Precision ★ ★ ★

Current Sense ★ ★ ★ ★ ★ ★

Fusible ★ ★ ★ ★

Acquired chip resistor Established management

technology from Japan system according to

Established in 1991 1998 ISO14000 standards

Taipei, Taiwan 1986

1989

Developed Surge & 1999

1969 MELF Resistors

Acquired precision

resistor technology Developed High-Voltage

from Japan Resistors

1 www.firstohm.com.tw

general@firstohm.com.tw

Page3

ility ility

lity • Reliab ion ab

a via Innovat

ality • Reli ovation

Qu own Qu own via Inn

ost-DC Product Classification by Application Cost-D

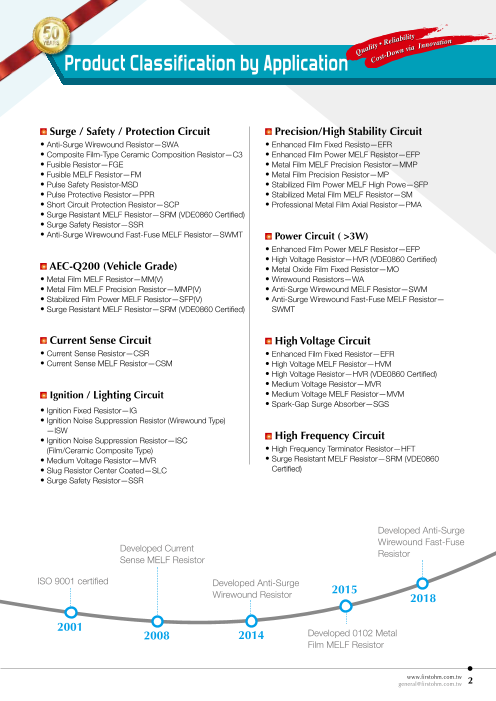

Surge / Safety / Protection Circuit Precision/High Stability Circuit

Anti-Surge Wirewound Resistor—SWA Enhanced Film Fixed Resisto—EFR

Composite Film-Type Ceramic Composition Resistor—C3 Enhanced Film Power MELF Resistor—EFP

Fusible Resistor—FGE Metal Film MELF Precision Resistor—MMP

Fusible MELF Resistor—FM Metal Film Precision Resistor—MP

Pulse Safety Resistor-MSD Stabilized Film Power MELF High Powe—SFP

Pulse Protective Resistor—PPR Stabilized Metal Film MELF Resistor—SM

Short Circuit Protection Resistor—SCP Professional Metal Film Axial Resistor—PMA

Surge Resistant MELF Resistor—SRM (VDE0860 Certified)

Surge Safety Resistor—SSR

Anti-Surge Wirewound Fast-Fuse MELF Resistor—SWMT Power Circuit ( >3W)

Enhanced Film Power MELF Resistor—EFP

High Voltage Resistor—HVR (VDE0860 Certified)

AEC-Q200 (Vehicle Grade) Metal Oxide Film Fixed Resistor—MO

Metal Film MELF Resistor—MM(V) Wirewound Resistors—WA

Metal Film MELF Precision Resistor—MMP(V) Anti-Surge Wirewound MELF Resistor—SWM

Stabilized Film Power MELF Resistor—SFP(V) Anti-Surge Wirewound Fast-Fuse MELF Resistor—

Surge Resistant MELF Resistor—SRM (VDE0860 Certified) SWMT

Current Sense Circuit High Voltage Circuit

Current Sense Resistor—CSR Enhanced Film Fixed Resistor—EFR

Current Sense MELF Resistor—CSM High Voltage MELF Resistor—HVM

High Voltage Resistor—HVR (VDE0860 Certified)

Medium Voltage Resistor—MVR

Ignition / Lighting Circuit Medium Voltage MELF Resistor—MVM

Spark-Gap Surge Absorber—SGS

Ignition Fixed Resistor—IG

Ignition Noise Suppression Resistor (Wirewound Type)

—ISW

Ignition Noise Suppression Resistor—ISC High Frequency Circuit

(Film/Ceramic Composite Type) High Frequency Terminator Resistor—HFT

Medium Voltage Resistor—MVR Surge Resistant MELF Resistor—SRM (VDE0860

Slug Resistor Center Coated—SLC Certified)

Surge Safety Resistor—SSR

Developed Anti-Surge

Wirewound Fast-Fuse

Developed Current Resistor

Sense MELF Resistor

ISO 9001 certified Developed Anti-Surge

Wirewound Resistor 2015

2018

2001

2008 2014 Developed 0102 Metal

Film MELF Resistor

www.firstohm.com.tw

general@firstohm.com.tw 2

Page4

Reliability

ality •

via Innovation

u wn

Specialist MELF Resistors Q

ost-Do

C

Over 30 years' experience in Advantages

MELF resistors with high quality. of MELF Resistor:

• Stronger mechanical structure, resistant

to seismic vibration and thermal shock.

• Excellent in heat dissipation.

(Especially suitable for air cooling).

• Superior surge protection than chip

resistors (Surge Proof).

• Highly stable, suitable for long period

usage. (Excellent Stability).

• Low temperature drift, high precision.

Superior surge protection than chip resistors

Firstohm SRM204T and anti-surge 1206 CHIP resistor of Company V1 connected in series

AC 12.25W applied individually:

Firstohm SRM204T V1 company Anti-Surge 1206 CHIP resistor

(100Ω, 5%) (100Ω, 5%)

Average change in resistance value: < 0.1% Open in approximately 0.1s ~ 0.2s

Comparison of the internal heat resistance (Rthi):

Advantage Firstohm: (Better heat dissipation) ; ΔT = Tb – Ta : 17°C~20°C

• FIRSTOHM SFP101V (MELF RESISTOR) • Competitor V1 (Chip resistor)

3 www.firstohm.com.tw

general@firstohm.com.tw

Page5

eliability n liability

y • R n

ualit n via Innovatio

lity • Re

ua n via Innovatio

Q t-Dow w

Cos What’s New Q -Do

Cost

What's New

Anti-Surge Wire wound

Fast-Fuse Resistor (SWAT/SWMT)

• Patented enhancement to the wire welded spot

• Multi-Purpose Resistors (include Fast Fusing & Anti-Surge functions) to reduce total BOM cost

• Applications now include lighting circuits, motor energizing, ignition system, rush current protection

for power capacitors, mobile phone charger, etc.

International Certifications

No. FM 577844 No. EMS 594693

Certificate No: FM 577844 Certificate No: EMS 594693 Certificate No: 40011593 & 40043961

Firstohm commits to processes Minimizing environmental impact High Voltage Resistor HVR series & Surge

that engage Various teams in while growing the business is of Resistant MELF Resistor SRM series tested

providing better customer service utmost importance to us. and certified according to DIN EN 60065

effectively and efficiently. (VDE 0860): 2011-10 clause 14.1 a)

www.firstohm.com.tw

general@firstohm.com.tw 4

Page6

ility

lity • Reliab

a ia Innovation

u wn v

Resistors-SMD Q st-Do

Co

Series Description Power Range Tolerance TCR/PPM Feature

C3M100 • SMD-enabled structure

Composite Film - Type • Suitable replacement for ceramic composition resistors,

Ceramic Composition MELF 1W 33R~22K ±5%~20% -3000 which are requiements in most applications.

Resistor • Maximum permissible surge voltage: 15KV

• Typical 10μs maximum pulse load: 40000W

CM ±300

-500

Carbon Film MELF Resistor 1/4W~1/2W 0, 0.51R~10M ± 5% -700 • SMD enabled structure

-1000 • Excellent solderability termination

-1500

CSM ±50 • High power handling with superior reliability and stability

Current Sense MELF ±100 • Conformal multi-layer coating against humidity

1/4W~3W 10mR~510mR ± 1%~5% ±200 • SMD enabled structure with excellent solderability

Resistor ±300 • HeatSinkerTM technology for better heat dissipation

±600 • Typical temperature coefficient: 50ppm ~ 600ppm

EFP

±200 • High power handling

Enhanced Film Power

1/2W~5W 0, 0.51R~10M ± 0.5% ~ 5% ±400 • Superior reliability and stability

MELF Resistor ±600 • SMD enabled structure with excellent solderability

±800 • Typical temperature coefficient: 200ppm ~ 800ppm

ESM 80A @2/10μs 1300V • Protects the circuit by sparking over the porous layer when

60A @8/20μs DC surge exceeds the spark-over voltage

ESD Surge Absorber MELF Surge Spark-Over ± 30% -- • Patented construction with reduced costs

Current • High insulation resistance, low capacitance, and fast

Capacity Voltage response time

FM

• SMD enabled structure

Fusible MELF Resistor 1/3W~1/2W 2R2~10K ± 5% ±200 • Excellent solderability termination

• Fuses within 10 sec. at 9.8W ~ 10.5W

HFT

High Frequency Terminator ±50 • SMD enabled structure

1/4W~2W 24R9~75R ± 0.1%~1% ±100 • Superior frequency response

Resistor • Excellent solderability termination

HVM • Handles much higher working voltage than general purpose

±200 resistors

High Voltage MELF Resistor 1/6W~3W 56K~68M ± 1%~5% ±400 • Pure tin-plated termination for excellent solderability

±800 • SMD enabled structure

±1200 • Anti-surge feature available

• Maximum working voltage: 600V DC ~ 8400V DC

ISC • Dedicatedly designed for high-voltage spark ignition systems

Ignition Noise Suppression • Proprietary ceramic composite withstands high-voltage

Resistor (Ceramic Film 1/2W~3W 1K~10K ±5%~20% ±3300 surge impacts with long-term stability.

Composite Type) • One of few sources in the world capable of manufacturing

such type of resistor

ISW

Ignition Noise Suppression • Dedicatedly designed for high-voltage spark ignition systems

2W~3W 1K~5K ±5%~20% ±300 • Enhanced weld spot is reliable against surge with long-term

Resistor (Wirewound Type) stability

MM • SMD enabled structure

± 1%, ± 2%, ±25

Metal Film MELF Resistor 1/6W~1/2W 0, 0R51~10M ±50 • Excellent solderability termination

± 5% ±100 • Typical 10μs maximum pulse load: 32W ~ 70W

• Typical temperature coefficient: 25ppm ~ 100ppm

MM(V) • AEC-Q200 compliant

Metal Film MELF Resistor, ± 1%, ± 2%, ±25

1/4W~1/2W 0R47~10M ±50 • Excellent solderability termination

Vehicle Grade ± 5% ±100 • Typical 10μs maximum pulse load: 35W ~ 80W

• Typical temperature coefficient: 25ppm ~ 100ppm

MM102

±25 • SMD-enabled structure

Metal Film MELF Resistor 0.2W 0, 0.22R~2.2M ±0.5%~5% ±50 • Excellent solderability termination

±100 • Typical temperature coefficient: 25ppm ~ 100ppm

MM(P) • SMD enabled structure

Metal Film MELF Resistor ± 1%, ± 2%,

1/6W~1/2W 0R1~330K ±50 • Excellent solderability termination

±100 • Enhanced pulse withstanding capability

(Pulse Withstanding) ± 5% • Typical temperature coefficient: 50ppm, 100ppm

• Typical 1.2/50μs maximum pulse voltage: 4000V

5 www.firstohm.com.tw

general@firstohm.com.tw

Page7

Reliability ty

ity • Innovation • Reliabili

l a lity a Innovation

Qua own vi a vi

-D u wn

Cost Resistors-SMD Q o

Cost-D

Series Description Power Range Tolerance TCR/PPM Feature

MMP ±5

± 0.1%, • SMD enabled structure

Metal Film MELF Precision ±10

1/6W~1W 10R~1M ± 0.25%, ±15 • Excellent solderability termination

Resistor • Typical 10μs maximum pulse load: 32W ~ 70W

± 0.5% ±25

±50 • Typical temperature coefficient: 5ppm ~ 50ppm

MMP(V)

• AEC-Q200 Compliant

Metal Film MELF Precision ±15

1/4W~1/2W 10R~1M ±0.1%~0.5% ±25 • Excellent solderability termination

Resistor, Vehicle Grade ±50 • Typical 10μs maximum pulse load: 35W ~ 80W

• Typical temperature coefficient: 15ppm ~ 50ppm

MVM • SMD enabled structure

±200 • Anti-surge feature available

Medium Voltage MELF

0.4W~1W 332K~40M ±5% ±400 • Pure tin-plated termination for excellent solderability

Resistor ±800 • Handles much higher working voltage than general purpose

±1200 resistors

• Maximum working voltage: 750V DC - 1,000V DC

SFP

±50 • Low temperature coefficient and tolerances

Stabilized Film Power

1/2W~3W 0R5~10M ± 0.5%~5% ±100 • Excellent stability

MELF Resistor ±200 • Superior power handling

• Typical temperature coefficient: 50ppm ~ 200ppm

SFP(V)

• AEC-Q200 Complicant

Stabilized Film Power MELF

1/2W~3W 0R22~1M ±1%~5% ±25 • Low temperature coefficient and terance

Resistor, Vehicle Grade ±50 • Superior power handing

• Typical temperature coefficient: 25ppm - 50ppm

SL • Specially treated metal caps withstand abrasions, impacts,

and corrosions, so as to reduce contact resistance during

operation. conductive film is enhanced to withstand

Slug Resistor 1/6W~1/2W 1R~9M1 ± 5%~10% ±200 ~ -800 abrasions, impacts, and corrosions as well. Suitable for

clip-in (embedded) application like switches with neon

indicators, neon/LED modules, LED display array, etc.

• Protective coating is optional

SLC • Specially treated metal caps withstand abrasions, impacts,

and corrosions, so as to reduce contact resistance during

Slug Resistor Center

1/6W~1/2W 1R~9M1 ± 5%~10% ±200 ~ -800 operation. conductive film is enhanced to withstand

Coated abrasions, impacts, and corrosions as well. Suitable for

clip-in (embedded) application like switches with neon

indicators, neon/LED modules, LED display array, etc.

SM

• Conformal coating against humidity

Stabilized Metal Film MELF ±25

1/6W~1/2W 0R51~10M ± 1%~5% ±50 • Excellent solderability termination

Resistor ±100 • Typical 10μs maximum pulse load: 32W ~ 70W

• Typical temperature coefficient: 25ppm ~ 100ppm

SRM • IEC60065 & UL1676 Compliant

• Miniaturized MELF design handles high power

• Special conductive film enhances anti-surge capability

Surge Resistant MELF ±100 • Absorbs harmful surge which damages precious devices or

Resistor 1/4W~3W 0R1~2M2 ± 1%~5% ±200 components

±400 • SMD-enabled alternative to carbon composition resistors

• Maximum permissible surge voltage: 2KV ~ 10KV

• Typical 10μs maximum pulse load: 70W ~ 8000W

• Approved to the safety requirement of VDE0860 under

license number 40043961

SWM • SMD enabled structure

• Flameproof multi-layer coating equivalent to UL 94 V-0

• Flameproof feature equivalent to overload test UL 1412

• SWM series can be adopted for high surge applications

Anti-Surge Wirewound

1W~4W 0R1~1K2 ± 5% ±100 such as high rush current protection for power capacitor,

MELF Resistor ±300 motor start-up protection, car & motorcycle engine ignition,

etc. to absorb harmful surge energy and prevent hazard of

circuit damage caused by surge impact.

• Enhanced weld spot is reliable against surge impact

• Maximum permissible surge voltage: 11KV

SWMT • Fast-acting fuse device for high-power applications

Anti-Surge Wire Wound • Advanced combined anti- surge & fast-fuse structure

1W~4W 1R~1KR ±5% ±200 • Thermal fuse to protect against over-heating in electronic

Fast-Fuse MELF Resistors products

• Flameproof multi-layer coating equivalent to UL 94 V-0

ZMM

2A ~ 4A • SMD enable structure

Zero Ohm Metal Film Maximum < 20mR N/A -- • Excellent solderability termination

MELF Resistor Current • Stable metal film construction

www.firstohm.com.tw

general@firstohm.com.tw 6

Page8

liabilitye

lity • R ia Innovation

Qua own v

Global Reach Cost-D

Poland Global Reach

Belarus

Germany (The biggest market: Germany)

UK China France

EUROPE

France Hong Kong Germany

JAPAN NORTH AMERICA

Spain ASIA

China India Italy

AFRICA Korea Spain

Thailand

Switzerland Taiwan USA

(Headquarter)

Italy Russia Sweden

India SOUTH

AMERICA

Malaysia

Singapore AUSTRALIA Singapore Switzerland

Slovenija Poland

Turkey

Australia United States United Kingdom

With operating culture built on its belief in sustaining growth, pursuit of excellence, and most importantly,

customer satisfaction, Firstohm will continue to be a prestigious player and a valuable partner in the

electronic component industry.

At a Glance

Services Available: Registered Total Capital: USD16.70million

► Resistor Manufacuring Factory Locations: Hualien, Taiwan

► Resistor Research and Development Main customer locations: Europe, China, Taiwan, Southeast Asia, America

► Technical Consulting Proprietary Manufacturing Equipments and In-house R&D Capability

Specialty Item: MELF Resistors

FIRST RESISTOR & CONDENSER CO., LTD.

9F., NO.233, Sec. 4, Xinyi RD., Da-an District, Taipei 106, Taiwan.

TEL: +886 2 2705 1878 FAX: +886 2 2703 6701

E-mail: general@firstohm.com.tw

Firstohm group commits to make the earth a better place