1/28ページ

ダウンロード(2.9Mb)

クールマッスルは、省スペース、省配線、コスト削減に貢献します。ひとつ先のモーションコントロールを体感してください。

◆一体型ACサーボシステム

クールマッスルはドライバ・コントローラ・エンコーダ一体型ACサーボシステムです。モータの後ろには磁気ポジションセンサと32ビットのRISCCPUを搭載したインテリジェントドライバ基板が内蔵されており驚異的なコンパクト化に成功しました。

◆オールインワンソリューション

インテリジェントドライバ

コントローラ

高分解能磁気エンコーダ

◆詳細は、カタログをダウンロードしてご覧ください。

◆不明点があればお電話にてお気軽にご質問ください。

関連メディア

このカタログについて

| ドキュメント名 | 一体型ACサーボシステム クールマッスル1 モータ・エンコーダ・ドライバ・コントローラ内蔵 |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 2.9Mb |

| 登録カテゴリ | |

| 取り扱い企業 | マッスル株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page2

Do you need help?

ス

ス

ス ース

....

Maintenance

Man-hour

Cost

Space

Bad environment

Noise

Complex programming

Design

Development cost ....

There are various problems in the site.

1

Page3

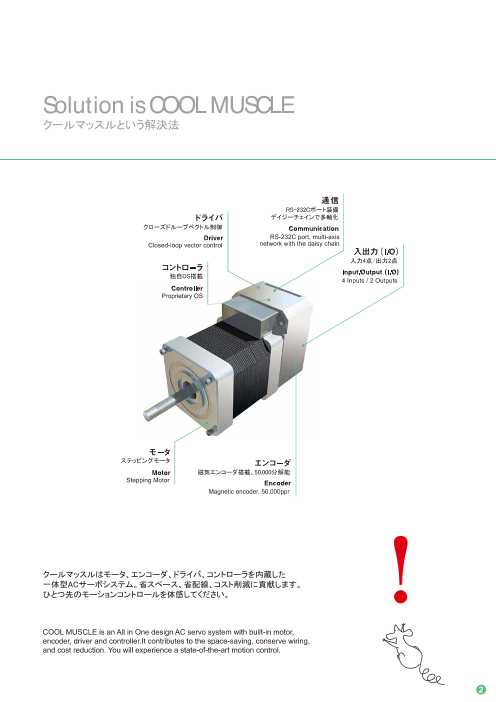

Solution is COOL MUSCLE

クールマッスルという解決法

ー

ー

ク ー ルー ク ル

RS-232C port, multi-axis

Closed-loop vector control network with the daisy chain

4 / 2

4 Inputs / 2 Outputs

Proprietary OS

ス ッ ー

ー 解

Stepping Mot o1r

Magnetic encoder, 50,000ppr

クールマッスル ー ー ー

AC ー ス ス ース ス

と ー ール い

COOL MUSCLE is an All in One design AC servo system with built-in motor,

encoder, driver and controller.It contributes to the space-saving, conserve wiring,

and cost reduction. You will experience a state-of-the-art motion control.

2

Page4

Concept クールマッスル コンセプト

一体型ACサーボシステム Integrated AC Servo System

クールマッスル ー ー AC ー COOL MUSCLE is the integrated AC servo system

ス ー と32 ッ RISC combining a drive,controller and encoder.

COOL MUSCLE realized its compactification by

CPU

embedded magnetic encoder and intelligent

ク driver with 32-bit RISC CPU on the back of motor.

ー ーシ All in One Solution

*Driver

ー

*Controller

ー

*Encoder

COOL MUSCLE is an all in one solution

for your motion control needs.

Integrated Driver

An intelligent driver mounted on the back of motor

テ eliminates an external driver box.

Also the intelligent driver allows only necessary

current drawn to produce its torque by its power

management functionality.That restricts motor’s

temperature raise and power consumption.

Integrated Controller

Based upon a 32-bit RISC CPU, the integrated

ー controller offers a wide range of hardware and

software features. Motion programs can be stored

32 CPU within the motor, eliminating the need for driver and

controller boxes. An added feature of networking

capabilities allows communication between motors

increasing efficiencies and capabilities whiles

decreasing the need for additional hardware.

ー High Resolution Magnetic Encoder

50,000 COOL MUSCLE’s high resolution magnetic encoder

AC realizes the 50,000 resolution perrotation.It allows a

very smooth motion at low speed by its own drive

method,the same as AC Servo Drive and also the

3 closed-loop control eliminates mis-steps.

Page5

All in One Solution

い ル ス COOL MUSCLE allows you to save space, to

と ス ース ス reduce wiring and cost, also to shorten

development time.

ス Conventional system

A typical conventional slider system requires a

driver, controller, origin sensor, limit sensor

and so on, making the entire system bulky and

complicated.

Very hard to differentiate your product

Bulk wiring

Bulky and complicated system

High cost

Need development and maintenance time

クールマッスル ス COOL MUSCLE system

COOL MUSCLE eliminates the need for an

external driver box, controller and sensors

making your system compact and simple.

Leave your competition behind

with COOL MUSCLE!

Wiring reduction

Compact and simple system

Cost reduction

ク ル Shorten development and maintenance time

4

Page6

Types クールマッスル プ

COOL MUSCLE supports three different

interfaces; C type for Computer, P type for

Pulse control and V type for Analog control.

Choose a system that best fits for your needs.

C 3 < C type >

C type is the most functionable COOL MUSCLE

PLC among three choices. A repetitive motion can be

executed from PC or PLC by pre-programming it.

An arbitrary motion can be executed by sending

commands from PC or PLC anytime required.

Programs and arbitrary motions can be combined

and also an affordable multiple motor control can

be realized by a daisy chain network.

1. 1. Pre-program

An external controller can be eliminated by

PLC pre-programming repetitive motions and store

them in the motor. The stored programs can be

executed by switches,PC or PLC.

Pre-programmed slider system using a C type

COOL MUSCLE system

2. ク マ 2. Direct Command

If your application requires complex or arbitrary

motion, you can send commands directly to the

COOL MUSCLE via PC or embedded computer.

A slider system with COOL MUSCLE controlled

by direct command via PC

3. ッ ーク 3. Network

C The development of more simple and affordable

multiple motor application by using multiple C type

COOL MUSCLE in a daisy chain network.

X-Y system using C type COOL MUSCLE in a

daisy chain network system

XY

5

Page7

P < P type >

Replacing your current pulse driven system with

P type COOL MUSCLE system will save space

and remove problems associated with an open

loop stepper. P type COOL MUSCLE system

supports both CW/CCW and Pulse/Direction.

P P type COOL MUSCLE usage example

V (0 +5V) < V type >

V type COOL MUSCLE can vary speeds or

positions in proportion to voltage input level.

Set maximum speed or travel distance with

ease by selecting the parameters making it an

ideal solution for constant feed systems, and

valve applications.

Slider system with V type COOL MUSCLE

V controlled by a joy stick

Cool Muscle Type selection?

for a repetitive motion system

to perfom complicated motion from

PC or dedicated controller

to run a multi-axis machine

to replace in pulse driver system

to improve machine performance

to remove problems associated with

an open loop stepper

to save space and reduce cost

to control speed or position with

an analog input

to save space and reduce cost

a simple solution

6

Page8

Features クールマッスル

COOL MUSCLE is packed with features that

help you to reduce the size and cost, and

also shortening development time of your

machines.

01 シ

32 RISC CPU 01. Simple and Compact

An intelligent driver with a 32 bit RISC CPU,

Magnetic encoder, and motor are all built in right

on the motor.

No more driver boxes

Space saving

ALL IN ONE Reduce wiring

Shorten development time

Motor Encoder

Driver Controller

02. Full Closed Loop System

COOL MUSCLE is a full closed loop system.

The high resolution magnetic encoder and the

02 ー システム intelligent driver board mounted on the back constantly monitors its position and eliminates

any miss-step.

COOL MUSCLE's power management allows

only the optimum current based on load drawn

and keeps the motor cool.

In addition, COOL MUSCLE generates high

torque at low speed by a stepping motor feature.

Higher repeatability, stability, and accuracy.

Longer motor life

Increased power efficiency

Reduced need for gear boxes

ー ー Closed Loop

ー ー

コント ー

セット ント Controller

Input Error

ー ック

By receiving position input from Open Loop SystemFeedback

the sensor COOL MUSCLE Not knowing its position, often

know its position and can Target Position resulting in problems such as

correct itself. miss-steps and targets.

7

Page9

03 03. Smooth and Accurate Movements

The COOL MUSCLE’s high resolution encoder

realizes 50,000 resolution per rotation.The vector

loop control enables a smooth motion at low speed

and it helps reducing the noise in your machinery.

AC Provide the same level of performance as

AC Servo motor at an affordable pricing

Not affected across the ages

クトル

Speed and Direction Vector

Position 1 Vector Drive Control

Vector Drive is a servo motor control technique that is

different from micro-stepping control and produces

smooth movements.

Position 2

04 ー 04. User Definable Parameters

Set the parameters of your COOL MUSCLE to

PID 40 suit your needs. COOL MUSCLE gives you over

CML 40 parameters. The parameters can easily be set

by using CML.

Flexibly change your motor characteristic

Easy Parameter Setting Example

K46.1=1

Baseline position is automatically set upon motor

initialization using the mechanical stopper.

K28.1=7000 4

Set Origin Search to Input4

K34.1=21 2 1

Set Alarm to Output2, Inposition to Output1

K60.1=50 50

Set the torque to 50% in Push Mode

ットセン セン コスト No more the Origin / Limit Sensor, saved the cost

Software Origin Search

COOL MUSCLE can complete an origin search by

pushing a mechanical stopper until it reaches specified

current level.Then an origin sensor can be eliminated.

CW / CCW Software Limit

Software Limits can be set at the both CW/CCW

sides by parameters. It eliminates the need for limit

sensors.

8

Page10

Features クールマッスル

05 CML 05. Easy Programming Language

CML COOL MUSCLE Language クールマッスル CML( COOL MUSCLE Language) is a programming

CML ス ー マ と language designed for COOL MUSCLE. Programs

クール ークス ー ー ル can be easily created by ASC commands on the

と free software COOLWORKS LITE or any standard

terminal program.

Easy programming

Shorten development time

ー Available the free open software

06

06. Easy to Use

[ クト ー ]

RS-232C いCML マ ー と <Direct Mode>

COOL MUSCLE can be directly operated by

just entering the CML commands via RS-232C

communication.

ク ー Direct mode example

ク

S.1 = 250 速度設定 Direct operation

Set speed by PC <Program Mode> (C type only)

A.1 = 100 加速度設定 Programs can be downloaded to COOL MUSCLE

Set acceleration so that various motions can be executed by PC

P.1 = 10000 目標位置設定 or simple switches. Programmable Max.500

Set target position steps.

^ .1 実行

Execute

Great solution for repetitive motion

Possible to design more simple and

プ ー compact machines

クールマッスル ー ー と

ス ッ

ス ッ

1. Define motion

P1.1 = 1000

S A

P2.1 = 3000

P マ- T

P3.1 = -1000

S1.1 = 100

S2.1 = 300 Speed(S), acceleration(A),

A1.1 = 50 position(P) and timer(T)are the motion definition.

T1.1 = 100

2. Program ス ッ

B1.1 Execute programs

A1.1 , S1.1 , P1.1 by switches

A1.1 , S2.1 , P2.1 マ-

T1.1

S1.1 , P3.1 Define motion programs using

the motion profiles defined above.

9

Page11

07 07. Assignment I/O

Configure and assign multiple functions to I/Os

on COOL MUSCLE. COOL MUSCLE comes

/ / / ( ) standard with 4 Inputs and 2 outputs that can be

used either digital, analog I/O, serial or pulse

counters (input only). COOL MUSCLE allows you

to assign a function to each signal point.

Multiple functions can be assigned to each I/O

ports.

User flexible applications of these powerfully

built in features

Input Function Example

Origin search

Origin sensor

Manual jog

Execute Bank1

Motor free

Enable motor

Execute next step

Execute previous step

Output Function Example

Alarm

In-position

Analog output for monitoring

08 ー 08. Virtual Input Signal

I/O ports can be used more efficiently by using

2 a unique virtual signal technique. COOL MUSCLE

creates the 2nd signal after the set time interval

1 from an original signal. Multiple functions can be

assigned to an input by the virtual signal

technique that can be set by parameters.

I/O Eliminates the external I/O board

Cost reduction

Real Signal

Target Voltage Level

Rising Edge

Quick Response Signal Falling Edge

Stop

Target Voltage Level

Falling Edge

Slow Response Signal Rising Edge Motor free

Motor enable

Time delay

10

Page12

Features クールマッスル

09 (C 09. Push Motion (C type only)

Push Motion can be activated for a given time at a

given current level which realizes to push a rod to

a work just as a typical pneumatic cylinder.

Speed

S3

A1 A1

S1

P1 P2

0

Time

Torque

Torque limit set by Parameter

ルク ー

Pushing

0

Time

Time duration set by Parameter

ー

Push Motion

10. Advanced Motion

10 COOL MUSCLE supports standard PTP motion サ ー control, as well as wide variety of custom

programmed movement. Speed or acceleration

PTP can be changed real-time during the motion.

COOL MUSCLE supports advanced functions

such as continuous PTP motion (Merge Motion)

PTP with different acceleration and deceleration.

PTP Standard PTP

Speed

S2

A1 A1

S1 A1 A1 A1 A1 P3

P1 P2

T1 T1 Time

マー Merge Motion

Speed

S3

A2 A2

S2

A1

P3

S1

A1 P2

P1

Time

PTP PTP with different acceleration and deceleration

Speed

S1

A1 A2

P1 P2

Time

11

Page13

11 ー 11. Network

COOL MUSCLE system provides a low cost

networking solution. Multiple COOL MUSCLEs

D- can easily be daisy chained by adding network cards. Standard D-sub 9 pin cable can be used

SUB for network cables that provides a cost reduction.

CML

Visual Basic C++

Simple and low cost network solutions

15 Available the Multi-axis control up to 15 axes

ー ッ ーク Daisy Chain Network

PC or PLC

マス ー ー ス ー ー ス ー ー

Master Motor Slave Motor Slave Motor

12 ー 12. Gain Tuning

PID COOL MUSCLE systems can be tuned with three

simple parameters.

PID Simple tuning solution

Shorten mechanical development time

Positioning

P

+ Torque

Positioning PComImand 1DVelocity PositionCommand I x Integral Integral Output- InertiaD Position Loop

Position Feed Back

Simple

12

Page14

Software ト

ー ー ス COOLWORKS LITE

COOLWORKS LITE クール ークス と クールマッスル

ー クールマッスル い

ス う

ー とい

クールマッスル い

マッスル ー ー ー いい

www.musclecorp.com

COOLWORKS LITE is our free open software for COOL MUSCLE

motors for ease of use and to shorten development time. ー ー

COOLWORKS LITE includes all the basic function that are required

for parameter setting, program creation, jogging and status MotorData / Information

monitoring. Confirmation of the speed data

COOLWORKS LITE is available for free at the MUSCLE's web site. and parameters

www.musclecorp.com

ム

クール ークス ProgramExecution

FunctionalDescr Execution / Pause of program, etc.iption

ー

クールマッスル

Sent Data

Display data sent to Cool Muscle

ー

クールマッスル

Motor Response

Display the data received from Cool Muscle

CML

ー マ ー

CMLEditor

Edit and send

マ Parameters and commands

Command Line

Enter commands in a single line and send

ー

Set the parameter

Draw the graph

ーシ

Calculate the motion

13

Page15

Accessories クセ /

C A B L E

ー ー ル Motor Cable RS232C ー ル RS232C Cable スト ート ー ル Straight Cable

CM1C1-400S (400mm) CM1C2-2000A (2000mm) CM1DC1-SSC-1800 (1800mm)

ー ル ル ー ー ル D-SUB9 ル ー ル ー

Standard Motor Cable. ー ッ ーク ー

RS232C Cable is required to connect Cool Muscle Straight Cable is required for daisy chain

to a serial port of PC. You would need it for various networking using an interface card.

of setting.

NETWORK CARD POWER SUPPLY EtherCAT

CM1DC1-MBSC CM1DC1-SBSC CM1DC1-CASE CMPS-XMUS-150 CMPS-XMUS-240 EtherCATクールマッスル ッ

ス ー EtherCAT COOL MUSCLE Bridgeス ー ース 150W/6A 240W/10A

Master Card Set Slave Card Set Network Card Case EB01(CM1) EB12(CM1-CM2)

ー ッ ーク ー ク クールマッスル ッ ーク

1 マス ー ッ 2 ス ー ッ い クールマッスル ッ

い い ー ル ー ル ー ル

ス ー ー ル

Designed specifically for Cool Muscle, EtherCAT COOL MUSCLE Bridge that adapts /

Daisy chain Cool Muscle systems using Network cards. our power supply is built to withstand connects COOL MUSCLE to EtherCAT network.

*Separately Straight Cable for Network required. current draw spikes that hard stops or * Separately CM* communication cable, power cable

starts often require. and LAN cable required.

マス ー ー ス ー ー

Master Card Slave Card

Conformance tested

A C T U A T O R G E A R

サーボ ー Servo Actuator Gearbox

クールマッスル Integrated actuator with COOL と A wide range of high quality

ー ー ク MUSCLE embedded with a driver, ー い gearboxes are available to suit your

ー ー controller and encoder. It allows you application needs.

ー ス ッ ーク ス to build a low cost and very precise ック ッ ス Combine a high precision, low

と network system with Max.15-axis ー クールマッスル backlash, zero maintenance,

ー ク ー over daisy chain. Many different と durable gearbox with a Cool Muscle

い kinds of servo actuators can be ー と い to maximize performance.

easily combined to form ideal servo

systems.

14

Page16

Specifications

型 Model Name

CM1 - C - 17L 30C

ール ー

Control Type Motor Size Length Max. Speed

C… ー Computer Type 11…28 L… Long 30…3000 rpm

P… ルス Pulse Type 17…42 S… ー Short 20…2000 rpm EMC RoHS

V… Analog Type 23…56 *COOL MUSCLE is the products that meet the EMC & RoHS.

CM1- -11L / S

MODEL CM1- -11L30A CM1- -11S30A

[ ]

Motor Output [W] 18 9

Max. Speed [rpm] 3000 3000

[Kgfcm](Nm)

Rated Continuous Torque [Kgfcm] (Nm) 0.56 (0.055) 0.28 (0.027)

[Kgfcm](Nm)

Peak Torque [Kgfcm] (Nm) 0.8 (0.078) 0.4 (0.039)

[g cm 2]

Load Inertia [g cm 2 ] 180 80

18 8

[g cm 2]

Motor Inertia [g cm 2 ]

Depending on the load inertia, servo gain needs to be adjusted within the above range : adjustable by parameters

Encoder Incremental Magnetic Encoder (50,000 pulses / Rotation)

Control Method Closed Loop Vector Control

Input Supply Voltage DC24V± 10%

1.2 / 1.5 A 0.8 / 1.0 A

Input Supply Current Rated / /

( Continuous Torque / Rated Peak Torque ) ( Continuous Torque / Rated Peak Torque )

/

Resolution ( Pulse / Rotation ) From 200 to 50,000 Set by parameter

[g]

Mass [g] 300 240

/ 0 40 / -20 60

Operating/Storage Temperature 0 +40 / -20 +60 No Condensation condition)

90 RH

Environment Operating Humidity Less Than 90% RH

/ 10G / 1G

Impact / Vibration Less than 10G / Less than 1G

ー Torque Curve

CM1- -11L30A CM1- -11S30A

0.9 0.45

0.8 0.40

0.7 0.35

0.6 0.30

0.5 0.25

0.4 0.20

0.3 0.15

0.2 0.10

0.1 0.05

15 0 0500 1000 1500 2000 2500 3000 RPM 500 1000 1500 2000 2500 3000 RPM

Torque (Kgfcm)

Torque (Kgfcm)

Page17

CM1- -17L / S

MODEL CM1- -17L30C CM1- -17S30C

[ ]

Motor Output [W] 18 18

Max. Speed [rpm] 3000 3000

[Kgfcm](Nm)

Rated Continuous Torque [Kgfcm] (Nm) 3.7 (0.36) 0.84 (0.082)

[Kgfcm](Nm)

Peak Torque [Kgfcm] (Nm) 5.3 (0.518) 1.2 (0.117)

[g cm 2]

Load Inertia [g cm 2 ] 760 380

74 36

[g cm 2]

Motor Inertia [g cm 2 ]

Depending on the load inertia, servo gain needs to be adjusted within the above range : adjustable by parameters

Encoder Incremental Magnetic Encoder (50,000 pulses / Rotation)

Control Method Closed Loop Vector Control

Input Supply Voltage DC24V± 10%

1.5 / 1.8 A 0.8 / 1.0 A

Input Supply Current Rated / /

( Continuous Torque / Rated Peak Torque ) ( Continuous Torque / Rated Peak Torque )

/

Resolution ( Pulse / Rotation ) From 200 to 50,000 Set by parameter

[g]

Mass [g] 480 330

/ 0 40 / -20 60

Operating/Storage Temperature 0 +40 / -20 +60 No Condensation condition)

90 RH

Environment Operating Humidity Less Than 90% RH

/ 10G / 1G

Impact / Vibration Less than 10G / Less than 1G

ー Torque Curve

CM1- -17L30C CM1- -17S30C

6.00 1.4

5.00 1.2

4.00 1.0

3.00 0.8

2.00 0.6

1.00 0.4

0.00 0.00

0 500 1000 1500 2000 2500 3000RPM 0 500 1000 1500 2000 2500 3000RPM

16

Torque (Kgfcm)

Torque (Kgfcm)

Page18

Specifications

CM1- -23L / S

MODEL CM1- -23L20C CM1- -23S30C

[ ]

Motor Output [W] 30 45

Max. Speed [rpm] 2000 3000

[Kgfcm](Nm)

Rated Continuous Torque [Kgfcm] (Nm) 8.9 (0.87) 3.0 (0.294)

[Kgfcm](Nm)

Peak Torque [Kgfcm] (Nm) 12.7 (1.24) 4.3 (0.42)

[g cm 2]

Load Inertia [g cm 2 ] 4600 1400

360 100

[g cm 2]

Motor Inertia [g cm 2 ]

Depending on the load inertia, servo gain needs to be adjusted within the above range : adjustable by parameters

Encoder Incremental Magnetic Encoder (50,000 pulses / Rotation)

Control Method Closed Loop Vector Control

Input Supply Voltage DC24V± 10%

2.6 / 3.4 A 3.9 / 5.1 A

Input Supply Current Rated / /

( Continuous Torque / Rated Peak Torque ) ( Continuous Torque / Rated Peak Torque )

/

Resolution ( Pulse / Rotation ) From 200 to 50,000 Set by parameter

[g]

Mass [g] 1100 550

/ 0 40 / -20 60

Operating/Storage Temperature 0 +40 / -20 +60 No Condensation condition)

90 RH

Environment Operating Humidity Less Than 90% RH

/ 10G / 1G

Impact / Vibration Less than 10G / Less than 1G

ー Torque Curve

CM1- -23L20C CM1- -23S30C

14.0 4.5

12.0 4.0

10.0 3.5

8.0 3.0

6.0 2.5

4.0 2.0

2.0 1.5

0.00 1.00

0 500 1000 1500 2000 RPM 0 500 1000 1500 2000 2500 3000RPM

17

Torque (Kgfcm)

Torque (Kgfcm)

Page19

CM1- -11L/S

Dimension (UNIT : mm)

38.6

4-M2.6

Dep 3MIN

D-cut

10±0.5

±0.2

23 ±0.2 1.5

28 ±0.3

15±0.5 18.6 19

L

Model Name L

CM1- -11L30A 85

CM1- -11S30A 71

CM1- -17L/S

Dimension (UNIT : mm)

Model Name L1 L

CM1- -17L30C 51.5 75.5

CM1- -17S30C 36.5 60.5

18

28 ±0.3

23 ±0.2

53

0

22 -0.025

5 0-0.012

4.5±0.2

53

Page20

Specifications

CM1- -23L/S

Dimension (UNIT : mm)

Model Name L1 L

CM1- -23L20C 76 100

CM1- -23S30C 42 66

Connection Example

COOL MUSCLE

Controller Connector

DC+24V IN) DC+24V1

External Power GND1 2

Supply Source

DC+24V 10mA

INPUT1+ Current Limiter10

1k

INPUT1- 8

10mA

INPUT2+ Current Limiter

9

1k

INPUT2- 3

DC+5V

INPUT3 4.7k 4707

DC+5V 470pF

DC+24V INPUT4 6 4.7k 470

470pF

*R OUTPUT1 5

6mA MAX)

*R OUTPUT2 4

6mA MAX)

DC+5V(OUT) DC+5V12

10mA MAX)

GND2 11

*R=4.7k

(DC24V

(An example of using with the power DC24V)

1-12

*Number of 1-12 is PIN No.

19